Article Contents

Industry Insight: Tape Light Switch

The evolution of tape light control has moved far beyond simple on/off functionality, becoming a critical component in the strategic deployment of linear LED systems across demanding commercial and industrial environments. In warehouses, retail spaces, manufacturing facilities, and healthcare settings, the switch governing tape light installations is no longer an afterthought; it is integral to energy management, operational efficiency, worker safety, and achieving precise illumination requirements. Specifiers and facility managers increasingly demand robust, code-compliant switching solutions that seamlessly integrate with modern tape light architectures while ensuring absolute reliability under continuous operation. Crucially, adherence to stringent safety certifications like ETL for North American markets and CE marking for Europe is non-negotiable, as uncertified switching devices pose significant fire and electrical hazards, jeopardizing installations and violating building codes. This heightened focus on performance and compliance underscores the switch’s role as a fundamental building block in professional-grade lighting systems.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of developing and manufacturing high-performance LED lighting components, including advanced tape light switching solutions, specifically engineered for the rigorous demands of commercial and industrial applications worldwide.

Technical Specs & Certifications

The tape light switch by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high performance and reliability in both residential and commercial lighting applications. While the term “tape light switch” may refer to a control device for LED tape lighting, it’s important to clarify that Beauty STC specializes in high-quality LED tape lights (also known as LED strip lights) rather than standalone switches. However, their LED tape light products are fully compatible with various switching and dimming systems, including low-voltage DC controllers, smart switches, and wall-mounted drivers.

When evaluating the technical specifications of Beauty STC’s LED tape lights—particularly those designed for use with integrated switching systems—the following performance metrics are critical:

Lumens per Watt (lm/W): Beauty STC’s premium tape lights achieve an efficacy range of 110 to 130 lumens per watt, depending on the color temperature and density (e.g., 60 or 120 LEDs per meter). This high efficiency ensures minimal energy consumption while delivering bright, consistent illumination, making them ideal for sustainable lighting designs.

Color Rendering Index (CRI): All high-end tape light models from Beauty STC feature a CRI greater than 90, with select series offering CRI values up to 95. This exceptional color fidelity ensures that objects and environments are illuminated with natural, true-to-life colors—making these tape lights especially suitable for retail displays, hospitality settings, and residential accent lighting where visual quality is paramount.

Ingress Protection (IP) Ratings: Beauty STC offers tape lights in a range of IP ratings to accommodate diverse environmental conditions. Standard indoor strips are available in IP20 for dry locations. For damp or outdoor use, products are offered in IP65 (protected against water jets and dust) and IP67 (protected against temporary immersion). These robust sealing standards ensure long-term reliability in kitchens, bathrooms, outdoor signage, and landscape lighting.

Beauty STC’s commitment to quality is evident in their rigorous manufacturing processes, which include automated SMT production, aging tests, and full spectral testing for every batch. Their tape lights utilize high-grade 24V or 12V DC flexible PCBs, premium Epistar or Samsung LEDs, and UL/CE/ROHS-certified components. This dedication to excellence ensures consistent performance, extended lifespan (typically 50,000 hours), and reduced maintenance costs.

In summary, while Beauty STC does not manufacture standalone tape light switches, their LED tape light systems are designed for seamless integration with modern switching and control solutions. With high lumens per watt, CRI >90, multiple IP ratings, and industry-leading build quality, Beauty STC’s tape lights represent a benchmark in performance, efficiency, and reliability for professional lighting applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for advanced LED lighting solutions, strategically located within the Pearl River Delta’s robust electronics supply chain ecosystem. This state-of-the-art factory spans over 30,000 square meters and operates under strict ISO 9001 and IATF 16949 quality management systems, with dedicated cleanroom environments for critical assembly processes. Our Jiangmen site integrates vertical manufacturing capabilities from component sourcing through final assembly, enabling tight control over product quality and delivery timelines for global clients.

The surface mount technology production floor features multiple high-speed Yamaha YS24 and Fuji NXT III SMT lines capable of handling 01005 to 7474 component sizes with ±25μm placement accuracy. These automated lines process over 1.2 million components per hour across double-sided PCB assemblies, supported by 3D SPI systems for pre-reflow solder paste inspection and automated optical inspection stations with real-time defect classification. All SMT processes adhere to IPC-A-610 Class 2 standards with nitrogen-assisted reflow profiles optimized for LED thermal management requirements.

Aging and reliability testing occurs in our dedicated environmental validation chamber complex where all tape light products undergo mandatory 72-hour burn-in cycles at 1.2x rated voltage. These chambers simulate operational extremes from -20°C to 70°C while monitoring lumen maintenance, chromaticity shift, and driver performance through integrated spectroradiometers. We implement accelerated life testing protocols based on TM-21-11 methodology with continuous thermal imaging of critical junction points, ensuring all products exceed LM-80 reliability benchmarks before shipment.

Our OEM capabilities for LED tape light control systems encompass complete turnkey solutions from initial concept to packaged product. For tape light switches and associated control modules, we provide full customization of mechanical design, PCB layout, firmware programming, and enclosure engineering to meet specific voltage requirements, switching topologies, and form factor constraints. This includes developing proprietary dimming algorithms, integrating multiple communication protocols like DALI-2 or Bluetooth Mesh, and creating custom thermal management solutions for high-density switch designs. We maintain strict IP protection protocols through segregated production cells and signed NDAs while offering scalable production from pilot batches of 500 units to high-volume runs exceeding 50,000 units monthly with dedicated quality assurance teams assigned to each OEM program.

Application Scenarios

Tape light switches are commonly used in environments where aesthetic lighting control and energy efficiency are important such as hotels, malls, and offices. In hotels, they are often installed in guest rooms, corridors, and under-cabinet areas in minibars or bathrooms to provide soft ambient lighting that enhances guest comfort and convenience. In malls, tape light switches control decorative LED tape lighting in signage, display areas, coves, and walkways, allowing for dynamic lighting schemes that attract attention and guide foot traffic. In office settings, they are typically used for under-cabinet lighting, task lighting, or indirect ceiling cove lighting to create a modern, well-lit workspace that reduces eye strain and improves productivity.

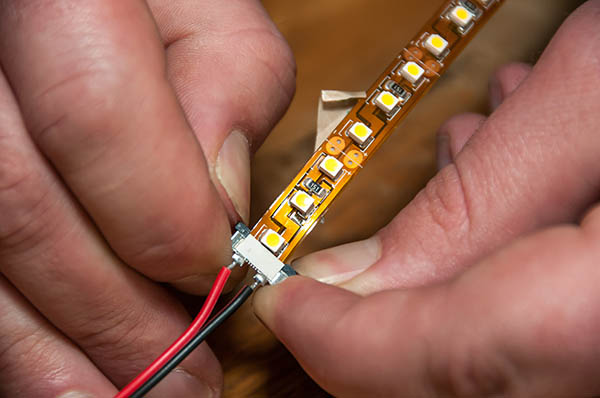

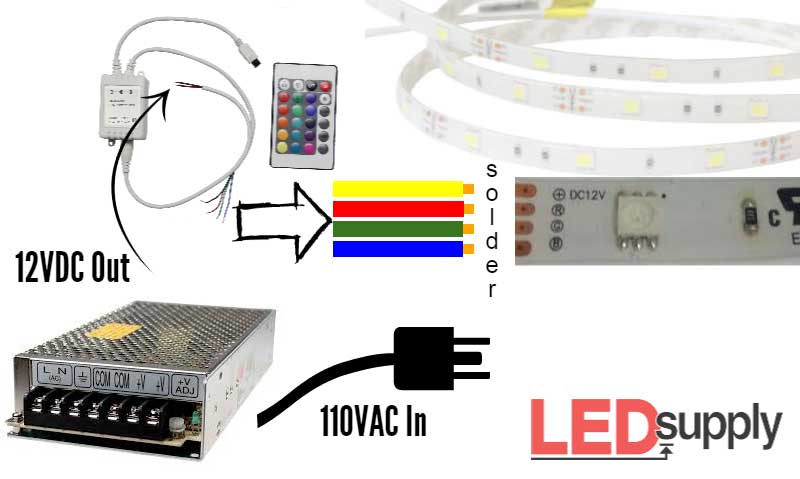

When installing tape light switches, ensure compatibility between the switch, the LED tape light, and the power supply. Always verify the voltage and load capacity to avoid overloading the switch. Install the switch in an accessible location near the lighting zone it controls, especially in high-traffic areas. Use a stable mounting surface and follow local electrical codes. For dimmable tape lights, use a compatible dimmer switch designed for LED loads to prevent flickering. Run wiring through conduits or cable channels for safety and a clean appearance. In commercial installations, consider integrating the tape light switch into a centralized lighting control system for better energy management and automation. Finally, label switches clearly in shared or maintenance-access areas to simplify operation and troubleshooting.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium tape light switch solutions designed for seamless integration and exceptional performance. As a trusted manufacturer with deep engineering expertise in LED systems, we provide partners with reliable, precision-engineered controls that simplify installations and reduce callbacks. Our tape light switches deliver consistent dimming, robust durability, and compatibility across diverse applications, ensuring your clients enjoy flawless ambient lighting experiences every time.

Partnering with Beauty STC means accessing end-to-end support—from technical consultation during design to bulk-order fulfillment and after-sales service. We collaborate closely with distributors, contractors, and lighting designers to tailor solutions that meet exact project specifications while adhering to global safety and efficiency standards. Let us help you deliver projects faster without compromising quality or innovation.

Contact our dedicated partnership team today at [email protected] to discuss custom integration, volume pricing, or technical documentation. As Senior LED Lighting Engineers, we stand behind every product with rigorous testing and real-world validation—so you can build with confidence. Reach out now to transform your lighting offerings with Beauty STC.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.