Article Contents

Industry Insight: Tape Light Diffuser

Tape light diffusers have become an essential component in modern commercial and industrial lighting systems, offering both functional performance and aesthetic refinement. As LED technology continues to dominate the lighting landscape, the demand for high-quality light diffusion has grown significantly—particularly in environments where uniform illumination, glare control, and durability are critical. From warehouses and manufacturing facilities to retail spaces and office buildings, tape light diffusers ensure that LED strip lighting delivers a seamless, professional-grade glow while protecting the internal components from dust, moisture, and physical damage.

Compliance with international safety and performance standards is non-negotiable in these applications. Reputable solutions in the market today are engineered to meet rigorous certifications such as ETL and CE, ensuring they adhere to North American and European safety requirements. These certifications not only validate electrical safety and electromagnetic compatibility but also provide assurance to contractors, facility managers, and building owners that the products will perform reliably in demanding environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the design and production of high-performance lighting components for commercial and industrial applications. With over two decades of engineering expertise, Beauty STC specializes in precision extruded diffusers tailored for tape lighting systems, combining optical efficiency with robust material science. The company’s commitment to quality, innovation, and regulatory compliance has made it a preferred partner for lighting manufacturers and system integrators worldwide.

Technical Specs & Certifications

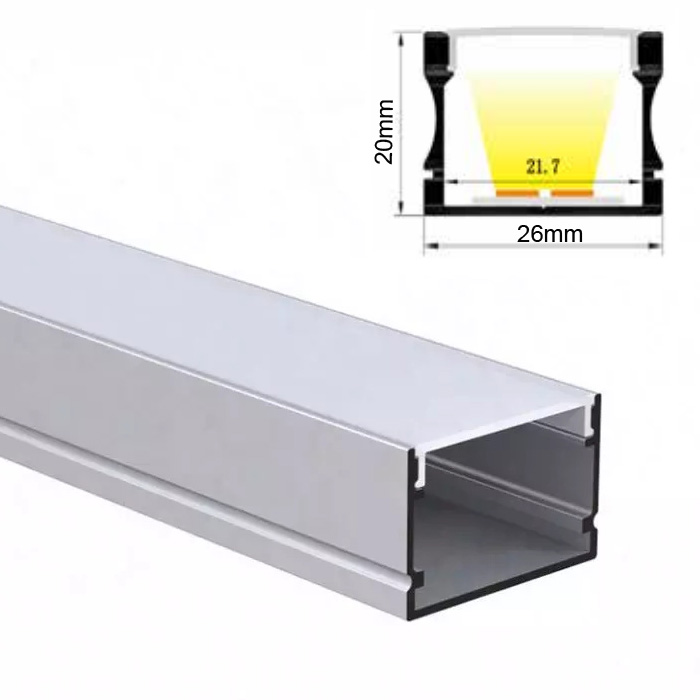

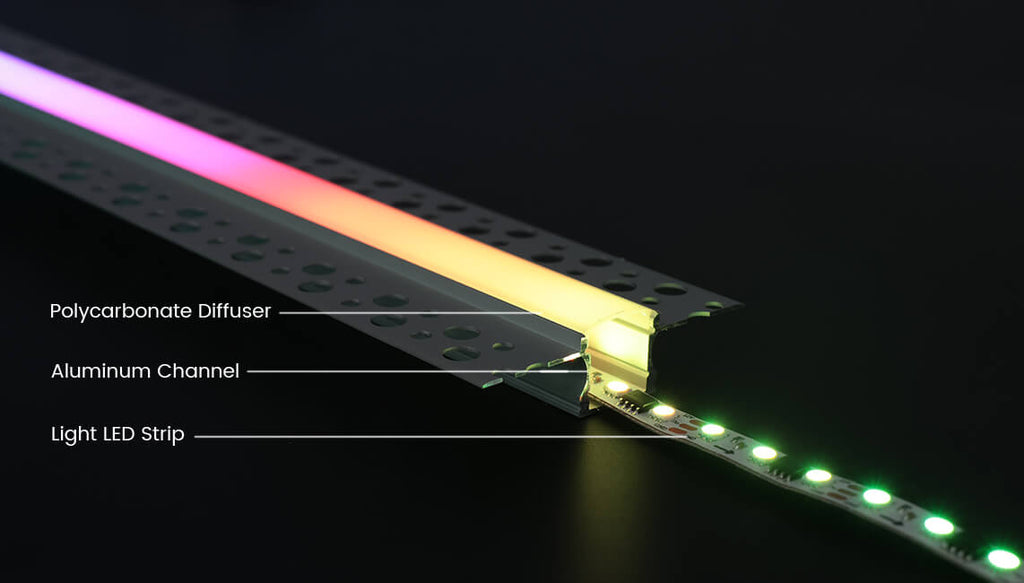

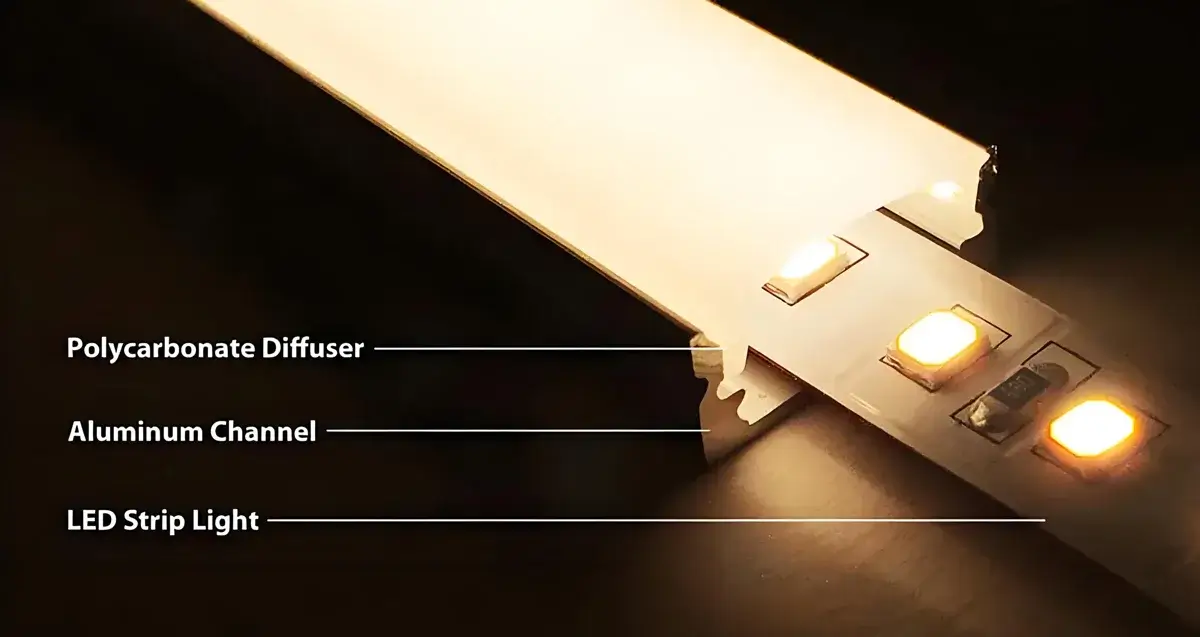

Tape light diffusers themselves do not possess lumens per watt ratings or CRI values, as these specifications are inherent properties of the LED light source embedded within the tape light assembly. The diffuser’s critical role is to modify and distribute the light output generated by the LEDs, directly influencing perceived brightness uniformity, glare control, and color consistency, while protecting the internal components. Beauty STC manufactures high-performance diffusers designed to maximize the efficiency and quality of the underlying LED system without introducing significant losses or distortion.

Lumens per watt (efficacy) is determined by the LED chips, driver efficiency, and thermal management of the tape light. A high-quality diffuser like those produced by Beauty STC minimizes light absorption and scattering losses. Our proprietary co-extruded polycarbonate (PC) and polymethyl methacrylate (PMMA) diffusers typically maintain over 95% of the tape’s original lumen output. This ensures the system efficacy remains close to the bare tape specification, often achieving 120-140 lumens per watt for standard high-efficacy tapes and up to 160+ lumens per watt for premium COB or high-density tape configurations when paired with our optimized diffusers. Poor diffuser materials can reduce system efficacy by 10-20% due to excessive absorption or internal reflection.

Regarding Color Rendering Index (CRI), values exceeding 90 are exclusively a characteristic of the LED emitter and phosphor formulation. Beauty STC sources only LEDs with CRI Ra >90 (and often R9 >50 for strong red rendering) from Tier-1 suppliers. Our diffusers are engineered with optical-grade materials and precise internal structures to prevent spectral shift or color separation. The diffuser ensures the high CRI light is distributed evenly without introducing yellowing or color fringing, maintaining the specified color fidelity across the entire illuminated length. Rigorous in-line spectrophotometer testing during diffuser production guarantees optical clarity and neutrality.

IP ratings are where the diffuser plays a direct and critical role. Beauty STC diffusers are integral components in achieving robust ingress protection. For IP20 applications (indoor dry locations), our standard diffusers provide basic dust protection and optimal light diffusion. For demanding environments, we offer diffuser profiles specifically designed for higher ratings. Our IP65-rated diffusers utilize seamless silicone gaskets and precision-molded end caps that create a watertight seal when correctly installed over the tape light within an aluminum channel. For fully encapsulated IP67/IP68 solutions, we employ specialized overmolding processes where the diffuser is fused directly onto the tape PCB with no separate seals, submergible to 1 meter. All IP-rated diffusers undergo stringent 30-minute water immersion testing at 1 meter depth per IEC 60529 standards.

Beauty STC’s diffuser quality is defined by material integrity, dimensional precision, and optical consistency. We utilize only virgin PC/PMMA co-extruded compounds with UV stabilizers, ensuring no yellowing for over 50,000 hours under typical operating conditions. Wall thickness tolerances are held to ±0.05mm, critical for uniform diffusion and structural rigidity. Every production batch undergoes transmittance, haze, and color shift validation. Our diffusers maintain consistent performance across temperatures from -40°C to +85°C, resisting warping or clouding that plagues inferior PVC or polystyrene alternatives. This commitment to material science and manufacturing control ensures the final tape light system delivers the specified lumen output, color quality, and environmental resilience demanded by architectural and commercial lighting professionals.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen Hi-Tech Industrial Park, the facility benefits from streamlined logistics and access to a skilled manufacturing workforce. The factory is designed to support both large-scale production and specialized OEM/ODM projects, with a strong emphasis on quality control, efficiency, and technical innovation.

The manufacturing process is anchored by advanced Surface Mount Technology (SMT) lines, which include high-speed pick-and-place machines, precision stencil printers, reflow ovens, and automated optical inspection (AOI) systems. These SMT machines ensure accurate and consistent placement of LED components and other surface-mount devices on flexible and rigid PCBs used in tape light assemblies. The integration of automation enhances throughput, minimizes human error, and supports the production of compact, high-density LED strips with excellent thermal and electrical performance.

To ensure product reliability and longevity, the Jiangmen factory conducts comprehensive aging tests on all tape light products. Finished LED strips undergo extended burn-in cycles—typically 24 to 72 hours—at elevated temperatures and full operating power. This process identifies early-life failures and verifies stable performance under continuous use. Additional environmental testing, including thermal cycling and humidity exposure, is performed as needed for specific customer requirements or international certifications.

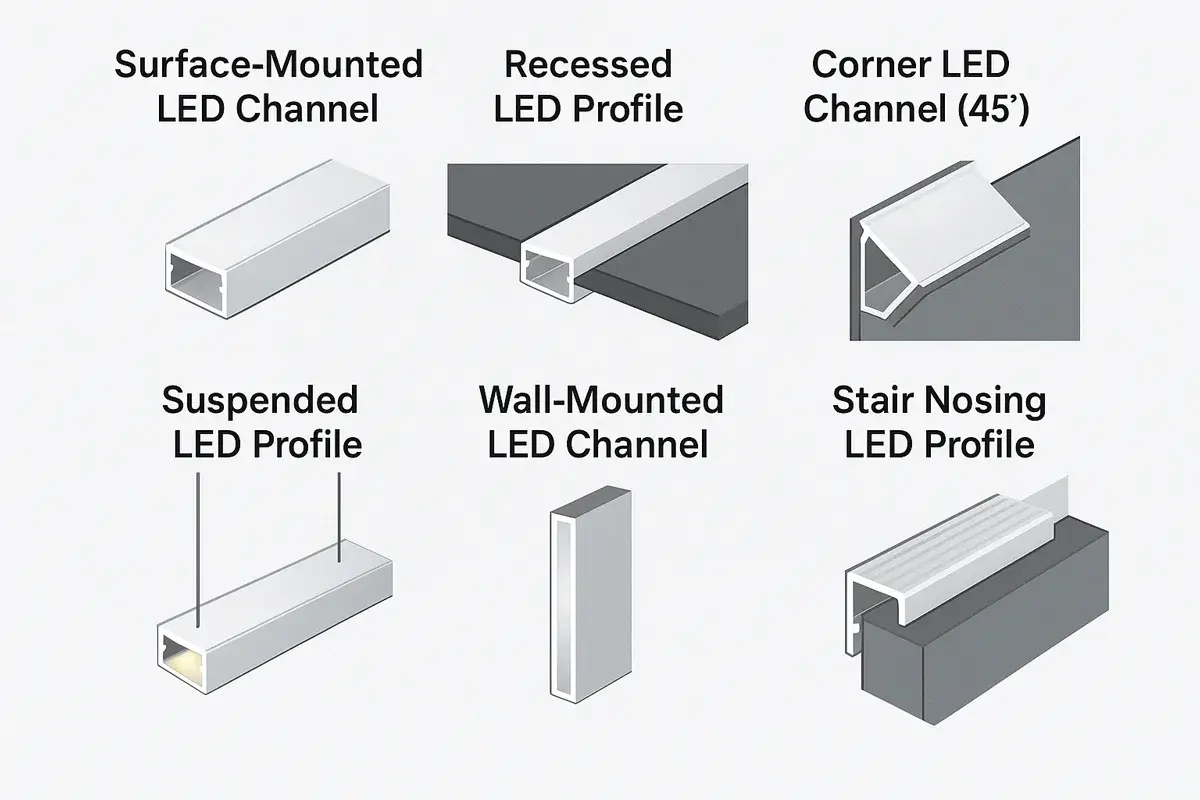

Beauty STC has robust OEM capabilities for tape light diffuser solutions. The company can customize diffuser profiles in various shapes—round, square, or side-glow—using PC or PMMA materials to achieve desired light distribution, clarity, and diffusion levels. The factory supports full turnkey OEM services, including optical design, diffuser extrusion, profile cutting, packaging, and integration with LED PCBs. Clients can specify color temperature, lumen output, CRI, IP rating, and mechanical dimensions, with STC managing tooling, prototyping, and volume production under strict quality standards such as ISO 9001 and compliance with CE, RoHS, and UL regulations.

Overall, the Jiangmen facility reflects Beauty STC’s commitment to engineering excellence, scalable manufacturing, and flexible customer support in the competitive LED lighting market.

Application Scenarios

Tape light diffusers serve a critical function in commercial lighting applications by eliminating visible LED dots and hotspots, creating a smooth, uniform glow essential for high-end aesthetics and visual comfort. In hotels, they are indispensable for cove lighting in lobbies and guest room ceilings, under-bar counter illumination, within headboard niches for ambient backlighting, and along stair treads or handrails for safety and luxury appeal. The diffuser ensures the light appears as a continuous band rather than discrete points, elevating the perceived quality of the space without glare.

For malls and retail environments, diffusers are non-negotiable in display case lighting where merchandise must be showcased without distracting shadows or bright spots, along escalator undersides for architectural definition, within column wraps for dramatic effect, and above feature walls in food courts. Here, the diffuser transforms functional lighting into a seamless visual element that directs attention to products or design features while maintaining a clean, modern appearance expected in premium shopping destinations.

In office settings, diffusers are equally vital beneath workstation cabinets for task lighting without eye strain, integrated into partition tops for indirect ambient illumination, within reception desk perimeters, and along corridor soffits. This application minimizes visual fatigue during extended work hours by distributing light evenly, supporting both productivity and WELL Building or LEED compliance through glare reduction and enhanced spatial quality.

Installation requires meticulous surface preparation; substrates must be clean, dry, and free of dust or grease to ensure optimal adhesion of both the tape light and diffuser channel. Always mount the LED tape first using its integrated adhesive or mechanical clips, verifying secure attachment before adding the diffuser. Avoid overhanging the diffuser beyond the tape ends to prevent dark zones, and maintain a minimum 2mm gap between the tape and diffuser interior to allow heat dissipation and prevent yellowing. For curved installations, select flexible polycarbonate diffusers and secure them at frequent intervals to avoid warping. Crucially, test the entire system for 15 minutes before final diffuser attachment to identify any hotspots or electrical issues, as correcting problems post-installation is significantly more labor-intensive. Always match the diffuser width precisely to the tape light width to eliminate light leakage at the edges, which compromises the uniform appearance these venues demand.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality tape light diffusers designed for seamless, uniform illumination. At Beauty (STC) Manufacturing Co., Ltd., we specialize in precision-engineered diffusers that enhance the performance and aesthetics of LED tape lighting. Partner with Beauty STC to access reliable, custom-ready solutions built to meet the demands of architectural, commercial, and residential applications. Our team is committed to quality, innovation, and timely delivery.

To learn more or discuss your specific requirements, contact us today at [email protected]. Let Beauty STC be your trusted manufacturing partner for superior tape light diffuser solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.