Article Contents

Industry Insight: T12 Ballast Bypass Led

The transition from traditional fluorescent lighting to energy-efficient LED solutions has become a cornerstone of modern commercial and industrial facility upgrades. Among the most impactful innovations in this shift is the T12 ballast bypass LED tube, a retrofit solution designed to eliminate outdated magnetic ballasts and deliver superior performance, longevity, and energy savings. Engineered for seamless integration into existing T12 fixtures, ballast bypass LED tubes operate directly on line voltage, reducing points of failure and improving overall system efficiency. These lamps are increasingly specified in warehouses, manufacturing plants, parking garages, and retail spaces where reliability and low maintenance are critical.

Compliance with international safety and performance standards is essential in demanding industrial environments. Reputable T12 ballast bypass LED products are ETL and CE certified, ensuring they meet rigorous North American and European electrical and safety requirements. These certifications not only validate product quality but also provide peace of mind to facility managers and electrical contractors responsible for long-term operational performance.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in commercial and industrial lighting solutions, Beauty STC combines advanced engineering with stringent quality control to deliver high-performance LED products trusted by clients worldwide. With a deep commitment to sustainability, reliability, and technical excellence, Beauty STC continues to lead the evolution of intelligent, energy-saving lighting systems across global markets.

Technical Specs & Certifications

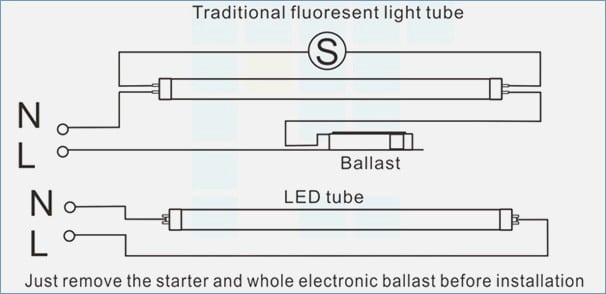

T12 ballast bypass LED tubes are designed as direct replacements for obsolete T12 fluorescent lamps in existing fixtures, requiring the removal of the fluorescent ballast and direct line-voltage wiring to the tube’s tombstone sockets. This retrofit solution significantly improves energy efficiency and eliminates ballast-related failures. At Beauty STC Manufacturing Co., Ltd., our engineered T12 ballast bypass LED tubes prioritize high performance and reliability for commercial and industrial applications.

Lumens per Watt (lm/W) efficiency is a critical metric for these retrofit products. Beauty STC’s T12 ballast bypass LED tubes consistently achieve 140-180 lumens per watt, depending on tube length and lumen output configuration. For standard 4-foot (1200mm) tubes, typical efficacy ranges from 150-170 lm/W at 2200-2400 lumens, while high-output variants may reach 140-150 lm/W at 2800-3200 lumens. This high efficacy is achieved through optimized driver circuitry, high-efficiency SMD LEDs, and advanced thermal management in the aluminum PCB design, ensuring sustained performance over the product lifespan without lumen depreciation from excessive heat.

Color Rendering Index (CRI) exceeding 90 is a standard specification across Beauty STC’s premium T12 retrofit portfolio. Our tubes utilize carefully selected high-CRI phosphor blends, ensuring R9 (saturated red) values above 50 and full TM-30-15 fidelity and gamut metrics for accurate color representation. This is essential for retail, healthcare, and manufacturing environments where true color discrimination impacts operations. All units undergo rigorous spectrophotometric testing during production to guarantee CRI >90 (Ra) with tight binning tolerances, avoiding the common pitfall of marginal CRI compliance in lower-cost alternatives.

Regarding IP Ratings, standard T12 ballast bypass LED tubes are typically rated IP20 as they are designed for installation within existing enclosed or gasketed fluorescent fixtures that provide environmental protection. Beauty STC emphasizes that the overall IP rating of the retrofitted luminaire depends on the fixture housing, not solely the tube. For applications requiring damp or wet location operation such as car washes, refrigerated display cases, or outdoor canopies, we offer specialized T12-form-factor LED tubes rated IP65. These feature dual silicone end caps and conformal-coated internal components to withstand humidity, condensation, and direct water spray when installed in compatible open or semi-open fixtures.

Beauty STC’s quality leadership in T12 ballast bypass LED technology is demonstrated through multiple engineering safeguards. Our tubes incorporate multi-layer surge protection (10kV+) to withstand electrical transients common in industrial settings, rigorous 100% hi-pot testing during manufacturing, and a minimum L70 lifetime of 50,000 hours at 25°C ambient. We enforce strict component sourcing from tier-1 suppliers, with LEDs binned to MacAdam 3-step color consistency and drivers featuring active power factor correction (PFC >0.95). Every production batch undergoes accelerated life testing and photometric validation, backed by a comprehensive 5-year warranty. This commitment to quality ensures our T12 ballast bypass solutions deliver not only superior efficiency and color quality but also exceptional longevity and reliability in demanding real-world installations, reducing total cost of ownership through minimized maintenance and energy savings. All products carry UL/cUL certification with full compliance to IEC/EN 62776 safety standards for double-insulated LED tubes.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped factory located in Jiangmen, Guangdong Province, a region known for its strong manufacturing infrastructure and supply chain efficiency. The facility is designed to support high-volume production of LED lighting products with a strong emphasis on quality control, automation, and compliance with international standards.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines that ensure precise and efficient mounting of electronic components onto LED light circuit boards. These SMT machines are fully automated, offering high-speed placement accuracy and consistent soldering quality, which are critical for producing reliable and long-lasting LED lighting products. The integration of automated optical inspection (AOI) systems within the SMT process enables real-time defect detection, minimizing errors and ensuring product consistency.

To guarantee durability and performance, Beauty STC conducts comprehensive aging tests on its LED products. Completed units undergo extended operational testing under elevated temperature and voltage conditions to simulate long-term use. This aging process typically lasts for 4 to 12 hours, depending on product specifications, and helps identify early failures or performance inconsistencies before shipment. The factory also performs photometric testing, electrical safety checks, and thermal performance evaluations as part of its quality assurance protocol.

Beauty STC has strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, allowing it to customize LED lighting solutions according to client requirements. For the ‘T12 ballast bypass LED’ tube—a direct-wire LED replacement for traditional fluorescent T12 lamps with magnetic or electronic ballasts—the company offers full OEM support. This includes custom labeling, packaging, lumen output, color temperature (ranging from 2700K to 6500K), and beam angle configurations. The ballast bypass design eliminates reliance on external ballasts, improving energy efficiency and reducing maintenance issues. Beauty STC ensures that all T12 ballast bypass LED tubes comply with safety standards such as UL, CE, and RoHS, and are compatible with standard G13 bases.

Overall, the Jiangmen factory combines advanced automation, rigorous testing, and flexible manufacturing to deliver high-quality, customized LED lighting solutions for global markets.

Application Scenarios

T12 ballast bypass LED tubes are specifically designed for retrofitting existing fluorescent lighting fixtures that originally housed T12 fluorescent lamps and utilized magnetic or older electronic ballasts. Their primary application is in commercial and institutional buildings where legacy T12 fluorescent systems remain in service, as these fixtures are increasingly obsolete but still present in older structures. Within the contexts of hotels, malls, and offices, these LEDs are most appropriate for areas utilizing T12 fixtures, which are now uncommon in new construction but may persist in older sections or less upgraded zones. In hotels, focus on back-of-house areas such as service corridors, laundry rooms, storage closets, boiler rooms, and older employee break rooms where initial construction might have used T12 systems. For malls, target maintenance corridors, stockrooms, janitorial closets, electrical/mechanical rooms, and potentially older sections of the building not recently renovated, avoiding high-visibility retail spaces where T12 is unlikely to exist. Offices should consider basements, utility rooms, older conference rooms in legacy wings, archive storage areas, and server rooms within buildings constructed or last renovated prior to the mid-2000s when T12 was phased out.

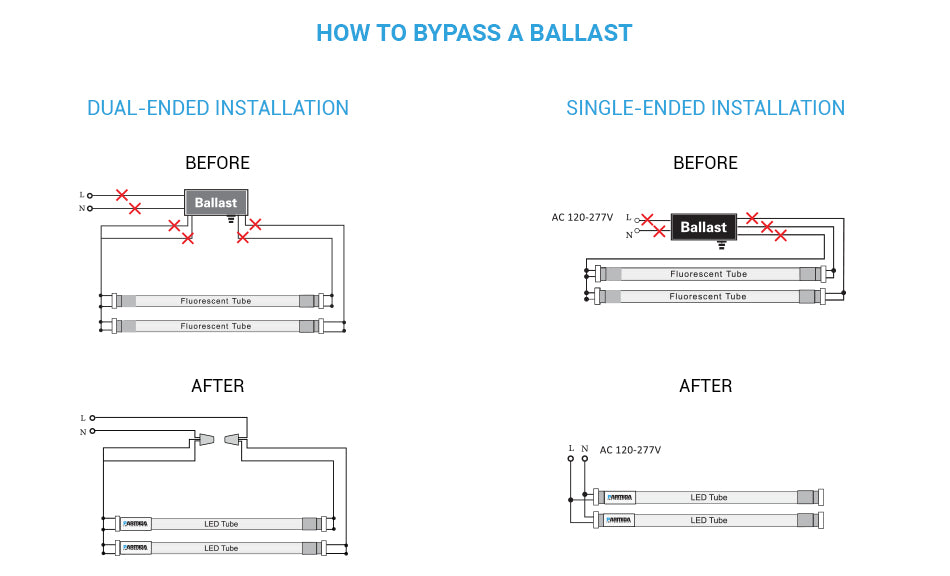

Installation of T12 ballast bypass LED tubes requires strict adherence to electrical safety protocols and fixture modification. The most critical step is the complete removal of the existing fluorescent ballast; leaving it in place will cause premature LED failure, potential safety hazards, and negates the energy savings. Always begin by de-energizing the circuit at the breaker panel and verifying the absence of voltage with a multimeter before any work commences. Once the ballast is removed, the fixture wiring must be reconfigured to send line voltage directly to the lamp holders (tombstones). This typically involves connecting the line (hot) wire to one end of the fixture and the neutral wire to the opposite end, effectively bypassing the original ballast wiring points. Pay close attention to the type of tombstones present; non-shunted tombstones are required for bypass installations as shunted types will short the circuit when wired for direct line voltage. If the fixture contains shunted tombstones, they must be replaced with non-shunted versions. Wiring must follow the specific diagram provided by the LED tube manufacturer, as configurations vary between single-ended power (wiring both pins on one end) and double-ended power (wiring one pin per end). Ensure all wire nuts are securely tightened and wires are neatly secured away from sharp edges. After installation, test the fixture thoroughly before restoring full power to the area. Given the direct line voltage exposure and permanent modification of the fixture, this work should only be performed by a qualified electrician familiar with local electrical codes; improper installation creates significant shock and fire risks. Crucially, confirm the fixture originally used T12 lamps before proceeding, as installing T12-specific bypass tubes into T8 or T5 fixtures will result in malfunction. This retrofit solution delivers substantial energy savings and reduced maintenance compared to aging T12 systems but demands meticulous execution for safe and reliable operation.

Why Choose Beauty STC Lighting

Upgrade your lighting system efficiently and cost-effectively by switching to T12 ballast bypass LED tubes. These energy-saving solutions eliminate the need for outdated ballasts, reducing maintenance costs and improving overall performance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting innovation, to ensure high-quality, reliable products tailored to your project needs. For inquiries and wholesale opportunities, contact us at [email protected] and let Beauty STC power your transition to smarter lighting.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.