Article Contents

Industry Insight: Switch For Led Light Strip

The commercial and industrial LED lighting sector demands components engineered for unwavering reliability, stringent safety compliance, and seamless integration within sophisticated control ecosystems. While LED light strips themselves offer transformative flexibility for architectural accents, task lighting, and signage, their performance and longevity are critically dependent on the often-overlooked switching interface. Unlike residential applications, commercial and industrial environments subject switches to higher usage cycles, demanding electrical loads, potential exposure to harsh conditions, and an absolute requirement for certified safety to mitigate fire and operational hazards. This makes the selection of switches bearing recognized certifications like ETL (confirming compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental protection legislation) non-negotiable for facility managers, electrical contractors, and lighting designers. These certifications are fundamental assurances that the switch can safely handle the specific demands of professional installations, from warehouses and retail spaces to healthcare facilities and manufacturing plants, where failure is not an option. Beauty STC, a dedicated LED lighting solutions manufacturer established in 1998, brings over 25 years of focused engineering expertise to this critical component space. We understand that robust, certified switching is not merely an accessory but an essential element ensuring the operational integrity, safety compliance, and sustained performance of professional LED strip lighting systems across diverse industrial and commercial settings.

Technical Specs & Certifications

When selecting a switch for an LED light strip, it’s essential to understand that the switch itself does not determine the lumen output, efficacy (lumens per watt), CRI (Color Rendering Index), or IP (Ingress Protection) rating—these are characteristics of the LED strip and driver system. However, the switch plays a critical role in controlling and enabling the performance of the LED system. Below are the technical specifications and considerations relevant to the overall LED lighting system when using a switch designed for LED light strips, with emphasis on high performance and reliability as delivered by Beauty (STC) Manufacturing Co., Ltd.

Lumens per Watt (Efficacy):

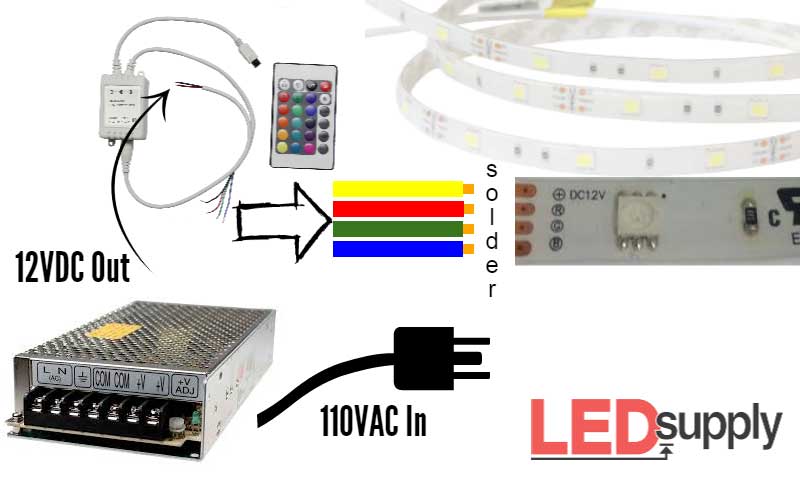

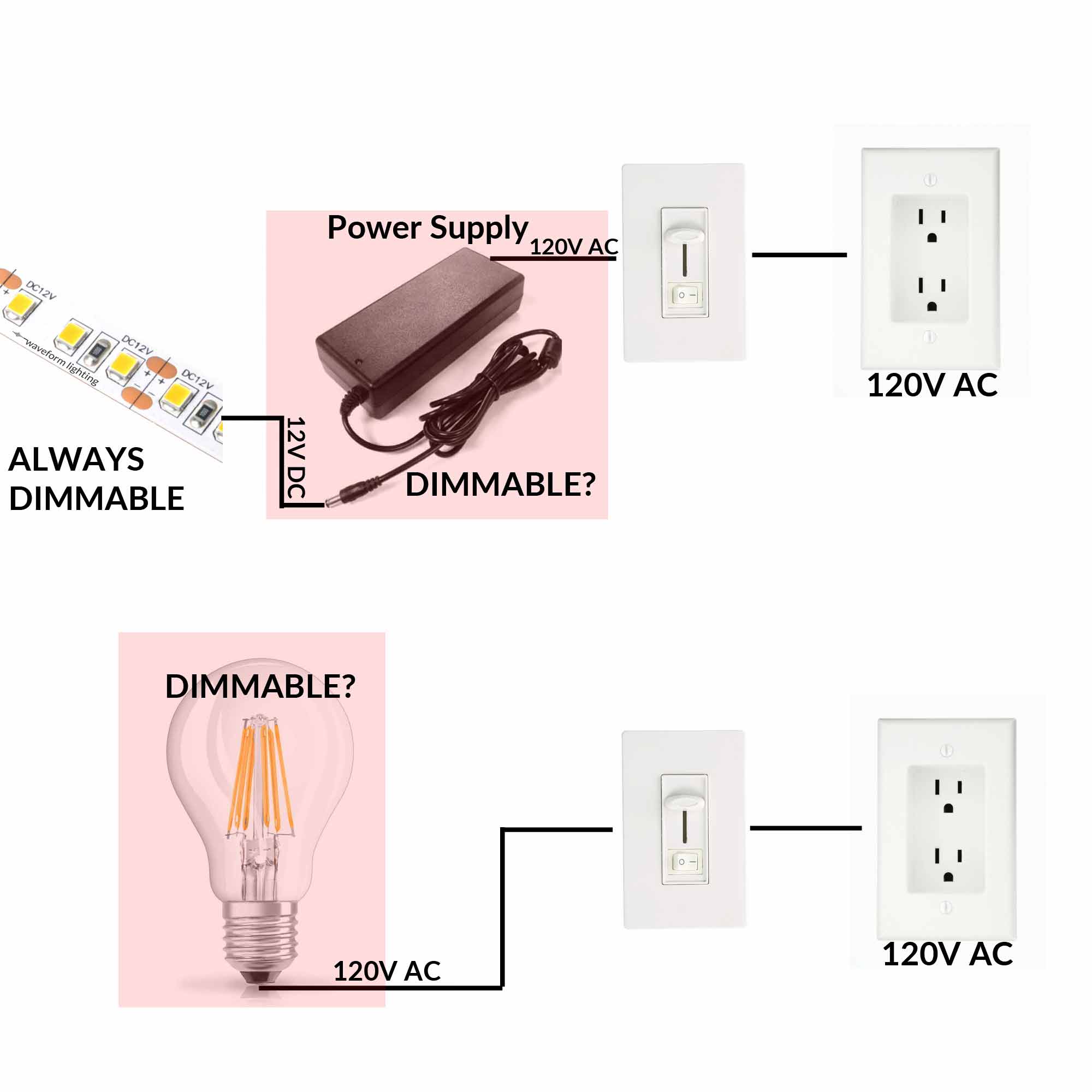

High-efficiency LED light strips typically deliver between 90 to 130 lumens per watt, depending on the LED chip technology and driver efficiency. Beauty STC utilizes premium SMD LEDs (such as 2835 or 5050 types) and optimized circuit design to ensure maximum light output with minimal power consumption. When paired with a compatible constant-voltage driver and an appropriate switch—such as a high-quality dimmer or electronic low-voltage switch—the system maintains stable current flow, preserving luminous efficacy over time. The switch must be rated to handle the total wattage of the connected LED strip to prevent voltage drop or overheating, which could otherwise degrade performance.

CRI >90:

Color Rendering Index (CRI) measures how accurately a light source reveals the true colors of objects compared to natural light. Beauty STC manufactures LED strips with CRI values exceeding 90 (CRI >90), achieved through the use of high-quality phosphor coatings and tightly binned LEDs. This ensures vibrant, natural color representation ideal for retail, residential, and commercial environments. While the switch does not directly influence CRI, it must support smooth dimming (if applicable) without flicker or color shift. Beauty STC recommends pairing high-CRI LED strips with trailing-edge dimmer switches or PWM (pulse-width modulation) controllers to maintain consistent color quality across all brightness levels.

IP Ratings:

Ingress Protection ratings indicate the level of protection against dust and moisture. Beauty STC offers LED light strips in various IP ratings to suit different environments. Common configurations include IP20 for indoor, dry locations; IP65 for damp or outdoor areas with water resistance via silicone coating; and IP67 or IP68 for full waterproofing, suitable for submerged or high-humidity applications. The switch used in conjunction with these systems must also match the environmental requirements. For example, an IP65-rated remote control switch or wall-mounted dimmer is recommended when the LED strip is installed in bathrooms, kitchens, or outdoor settings. Beauty STC provides fully sealed, UV-resistant switch housings for outdoor use, ensuring long-term reliability and safety.

Beauty STC Quality Assurance:

As a trusted manufacturer in the LED lighting industry, Beauty (STC) Manufacturing Co., Ltd. adheres to strict quality control standards. All LED strips and compatible control systems undergo rigorous testing for electrical safety, thermal performance, and longevity. Components are RoHS-compliant and certified to international standards including CE, UL, and TUV. Beauty STC’s switches and controllers are designed for seamless integration with their LED strips, offering stable performance, minimal electromagnetic interference, and extended lifespan—often exceeding 50,000 hours of operation. The company’s commitment to innovation and quality ensures that every lighting solution delivers consistent brightness, high efficiency, excellent color rendering, and environmental durability.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern manufacturing facility in Jiangmen, Guangdong Province, designed specifically for high-volume, precision LED lighting production. The factory spans over 20,000 square meters and is equipped with fully automated production lines meeting international quality and safety standards. Central to our operations are three state-of-the-art SMT (Surface Mount Technology) lines featuring Yamaha YS24 and YSM20 placement machines. These systems handle components down to 0201 package size with placement accuracy of ±25μm and throughput exceeding 98,000 components per hour. The lines include fully automated solder paste printers, nitrogen-reflow ovens with 10-zone thermal profiling, and 3D AOI (Automated Optical Inspection) systems that verify 100% of solder joints and component placement before proceeding to assembly. This infrastructure ensures consistent, defect-free PCB assembly for all LED strip products, including complex multi-layer boards for high-density applications.

Aging and reliability testing form a critical part of our quality control process at the Jiangmen facility. We maintain dedicated environmental chambers where finished LED strips undergo rigorous 72-hour continuous aging tests at 85°C and 85% relative humidity, simulating accelerated long-term operation per IEC 60068-2-66 standards. Each batch is monitored in real-time for lumen maintenance, chromaticity shift, and electrical stability using calibrated integrating spheres and spectroradiometers. Beyond standard aging, we conduct 10,000-hour accelerated life testing on sample batches and perform thermal imaging analysis to identify potential hotspots. All test data is logged to our centralized quality management system, enabling traceability from raw materials to final shipment and ensuring compliance with LM-80 and TM-21 reliability requirements.

Regarding OEM capability for switches integrated with LED light strips, Beauty STC provides comprehensive turnkey solutions. While we do not manufacture the physical switch components ourselves, we maintain certified partnerships with UL/CE-approved switch suppliers to source toggle, rocker, and remote-control switches meeting IP65-IP68 ratings. Our engineering team collaborates with clients to integrate these switches directly into custom LED strip assemblies, handling PCB design modifications, connector selection, and wiring harness integration. We support full customization of switch placement, wiring length, and connector types (JST, IP68 waterproof, etc.) and can incorporate dimming protocols like 0-10V or PWM. The entire process—from switch procurement through final assembly and functional testing—is managed in-house under our ISO 9001-certified quality system. Clients receive fully tested, ready-to-install switch-integrated LED strip solutions with packaging and labeling tailored to their specifications, backed by our standard 3-5 year product warranty.

Application Scenarios

Switches for LED light strips are commonly used in hotels, malls, and offices to provide flexible and energy-efficient lighting solutions. Each environment has unique requirements that influence where and how these switches should be installed.

In hotels, LED light strip switches are often installed in guest rooms, corridors, lobbies, and under-cabinet areas in service kitchens or staff zones. In guest rooms, LED strips with switches are typically used for ambient lighting behind headboards, along cove ceilings, or under furniture. A switch allows guests or staff to control mood lighting easily. In corridors and lobbies, switches can control decorative LED strips that highlight architectural features. It’s important to use dimmable switches in guest areas to offer adjustable brightness for comfort.

In malls, LED light strip switches are ideal for accent lighting in display windows, signage, escalator handrails, and ceiling coves. These switches help manage lighting during non-operational hours to save energy. For safety and convenience, switches should be placed in easily accessible locations for maintenance staff, such as electrical closets or control rooms. Consider using motion-sensor or timer-based switches in low-traffic areas to automate lighting and reduce power consumption.

In offices, LED light strips are commonly used under cabinets, in conference rooms, reception areas, and workstations for task or ambient lighting. Switches should be installed near room entrances or integrated into existing lighting control panels. For modern office environments, consider using smart switches that allow remote or app-based control, especially when combined with motion sensors or daylight harvesting systems to optimize energy use.

When installing switches for LED light strips, always ensure compatibility between the switch and the LED driver or power supply. Use trailing-edge dimmer switches for dimmable LED strips to avoid flickering. Make sure the total load of the LED strip does not exceed the switch’s rated capacity. Install in dry, accessible locations and follow local electrical codes. For longer runs, consider using multiple switches or relays to control different zones independently. Always disconnect power before installation and use proper insulation and connectors to ensure safety and longevity.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I can confirm our precision-engineered switches for LED light strips deliver unmatched reliability and seamless integration for professional lighting installations. Our components undergo rigorous testing to ensure compatibility with diverse voltage requirements and extended operational lifespans, directly addressing common industry pain points like flickering or premature failure.

Partner with Beauty STC to access OEM/ODM solutions tailored to your specifications, backed by our decade of manufacturing expertise in energy-efficient lighting controls. Elevate your product line with switches designed for high-volume production without compromising on safety certifications or thermal management.

Contact our dedicated partnership manager directly at [email protected] to discuss technical specifications, MOQ flexibility, and how our engineering support can accelerate your time-to-market. Let us handle the complexity while you focus on growth.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.