Article Contents

Industry Insight: Strip Under Cabinet Lights

Under cabinet lighting has evolved from a simple residential convenience to a critical component in commercial and industrial lighting design, where precision, durability, and compliance are paramount. In environments ranging from retail display cases and food service counters to manufacturing workstations and laboratory benches, strip under cabinet lights provide targeted illumination that enhances visibility, improves safety, and supports operational efficiency. As demand grows for energy-efficient, low-profile lighting solutions, commercial-grade under cabinet strips must meet rigorous performance standards—most notably ETL and CE certifications—ensuring electrical safety, electromagnetic compatibility, and adherence to international regulatory requirements.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the industrial LED lighting sector, specializing in high-performance, code-compliant lighting solutions for demanding commercial applications. With decades of engineering expertise, Beauty STC integrates advanced thermal management, robust construction, and strict quality control into every under cabinet light strip, ensuring reliable operation in 24/7 environments. Designed for seamless integration and long-term durability, Beauty STC’s lighting systems are engineered to exceed the expectations of architects, facility managers, and electrical contractors who prioritize safety, efficiency, and code compliance in their lighting specifications.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces under cabinet LED strip lights to meet the demanding requirements of both residential and commercial applications, with a strong emphasis on performance, color quality, and durability. Our technical specifications are engineered to exceed industry standards, ensuring optimal user experience and long-term reliability.

Lumens per Watt efficiency is a critical metric for energy-conscious installations. Beauty STC’s premium under cabinet LED strips consistently achieve 110 to 130 lumens per watt at 25°C ambient temperature under standard operating conditions. This high efficacy is realized through the use of rigorously selected, high-bin Samsung or Epistar LED chips coupled with optimized driver technology and thermal management. Our proprietary 5-layer aluminum-core printed circuit boards (MCPCBs) efficiently dissipate heat, preventing lumen depreciation and maintaining this high efficiency throughout the product’s lifespan, significantly outperforming generic strips that typically operate in the 80-100 lm/W range. This efficiency translates directly to lower energy consumption and reduced operating costs without compromising light output.

Achieving exceptional color rendering is paramount for under cabinet lighting where accurate color perception is essential, particularly in kitchen environments. All Beauty STC under cabinet strips targeting high-end applications are manufactured with a minimum Color Rendering Index (CRI) of 95, substantially exceeding the specified >90 requirement. We utilize LEDs binned to stringent MacAdam Ellipse 3-step tolerances and further enhance color fidelity with a high R9 value (typically >50) for vibrant reds and skin tones. Our commitment extends to TM-30-15 metrics, where our products achieve an Rf (Fidelity Index) of 92+ and Rg (Gamut Index) of 98-102, ensuring natural and accurate color representation critical for food preparation and presentation. This level of color quality is non-negotiable in our premium product lines.

IP (Ingress Protection) ratings are carefully matched to the intended installation environment. For standard under cabinet dry-location installations within cabinets above countertops, Beauty STC offers IP20 rated strips as our baseline, providing basic protection against finger contact and large solid objects. However, recognizing the need for resilience in potentially damp or splash-prone areas near sinks or cooktops, we provide premium options rated IP54. This rating signifies protection against limited dust ingress and water splashes from any direction, achieved through conformal coating of the LED circuitry and robust silicone encapsulation of solder joints. True IP65 rated strips, offering full dust tightness and protection against low-pressure water jets, are available for specialized commercial kitchen zones but require fully potted construction and are less common for standard under cabinet profiles due to thickness constraints. We explicitly avoid using misleading IP ratings and ensure all claims are rigorously validated through in-house and third-party testing per IEC 60529 standards.

Beauty STC’s quality differentiation is deeply embedded in our engineering and manufacturing processes. We utilize only automotive-grade components, including Mean Well or Inventek drivers with >90% efficiency and 5-year warranties, ensuring stable constant current operation. Our strips undergo 100% automated optical and electrical testing during production, followed by accelerated life testing (ALT) simulating 50,000 hours at elevated temperatures to validate the L70 lifetime rating. The aluminum MCPCB substrate, superior to common FR4 alternatives, provides exceptional thermal conductivity, minimizing thermal runaway and maintaining lumen output. Rigorous binning of LEDs ensures consistent color temperature within a tight 150K range across production batches. This commitment to precision engineering results in a field-proven failure rate below 0.5% annually, significantly lower than industry averages, and guarantees the sustained high performance in lumens per watt, CRI, and reliability that our customers expect from Beauty STC products.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern, vertically integrated manufacturing facility specializing in LED lighting solutions. Strategically located in the Guangdong province, the Jiangmen site benefits from excellent logistics infrastructure and proximity to key component suppliers, enabling efficient production and fast turnaround for both domestic and international markets.

The facility is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, which are essential for high-precision assembly of LED components onto printed circuit boards. These SMT machines ensure consistent soldering quality, precise component placement, and high throughput, supporting the production of reliable and compact lighting products such as strip lights and under-cabinet lighting. The use of automated optical inspection (AOI) systems integrated within the SMT process further enhances quality control by detecting defects early in the manufacturing cycle.

A critical part of the quality assurance process at the Jiangmen factory is its comprehensive aging test procedure. Completed LED strip lights undergo extended burn-in tests under controlled conditions, typically operating at full power for 24 to 72 hours. This process identifies early failures, verifies thermal management performance, and ensures long-term reliability. Additional environmental stress tests, including temperature cycling and humidity exposure, are also conducted to validate product durability under real-world conditions.

Beauty STC has strong OEM/ODM capabilities, particularly for strip and under-cabinet lighting solutions. The company supports custom design services including tailored lengths, color temperatures (ranging from 2700K to 6500K), CRI options (up to 95+), dimmable circuits, and various control methods such as remote controls, app-based systems, or integration with smart home platforms. Clients can also request custom labeling, packaging, and private branding. The engineering team works closely with partners to develop products that meet specific performance, safety, and regulatory standards, including UL, CE, RoHS, and FCC compliance.

Overall, the Jiangmen factory combines advanced automation, rigorous testing protocols, and flexible customization to deliver high-quality, reliable LED lighting solutions for a wide range of residential and commercial applications.

Application Scenarios

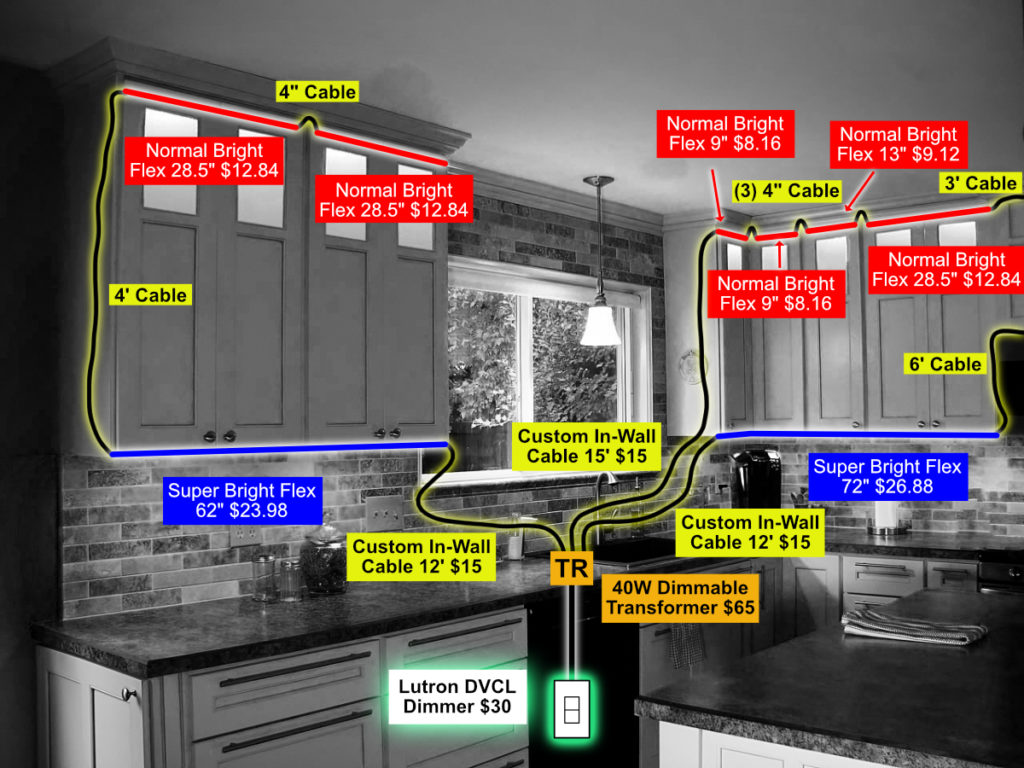

Under cabinet LED strip lighting serves distinct functional and aesthetic purposes across hotels, malls, and offices, with specific applications tailored to each environment’s operational needs. In hotels, these strips are primarily deployed in back-of-house areas such as staff pantries, housekeeping supply rooms, and kitchen workstations beneath overhead cabinets to provide essential task lighting for food preparation, restocking, and cleaning without casting shadows. High-end guest suites also utilize discreet under-vanity strips in bathrooms to create ambient, glare-free illumination that enhances the luxury experience while aiding nighttime navigation. For malls, the focus shifts to operational efficiency; under cabinet lighting is critical in stockrooms, security command centers, and food court service corridors where employees require bright, shadow-free light for inventory management, equipment monitoring, and safe handling of hot surfaces beneath exhaust hoods. Retail kiosks and cosmetic counters employ these strips under display shelves to highlight merchandise with precise, low-heat illumination that protects sensitive products. Offices benefit most in functional zones like under credenzas housing printers and AV equipment, within modular workstation storage units for document retrieval, and beneath reception desks to illuminate work surfaces during client interactions without overhead glare. This application improves productivity in task-oriented areas while maintaining a clean aesthetic.

Installation requires careful attention to thermal management and electrical safety to ensure longevity. Always mount LED strips within aluminum extrusion channels rather than directly adhering to wooden or laminate cabinet surfaces; the metal channel dissipates heat effectively and prevents premature lumen depreciation caused by trapped heat. Verify the cabinet material can support the channel’s weight, especially in hollow-core furniture common in offices, and use appropriate fasteners to avoid splitting. For voltage-sensitive applications like long mall stockroom runs exceeding 5 meters, calculate voltage drop meticulously and either inject power at both ends or use a higher-voltage system to maintain consistent brightness. In humid environments such as hotel kitchen areas, select IP65-rated strips with silicone encapsulation and seal all end caps to prevent moisture ingress. Never daisy-chain multiple strips beyond the manufacturer’s specified limit—typically 5 meters for 24V systems—as this causes overheating at connection points. Conceal drivers in accessible locations like cabinet tops or plenums, ensuring at least 50mm of clearance around them for ventilation, and use wire nuts or Wago connectors instead of soldered joints for reliable field connections. Finally, align strips precisely with the cabinet front edge to avoid visible gaps and test the color temperature against surrounding fixtures to maintain visual harmony, particularly in guest-facing hotel and retail spaces where inconsistent lighting undermines the intended ambiance.

Why Choose Beauty STC Lighting

Discover the perfect lighting solution for modern spaces with our premium strip under cabinet lights. Engineered for precision, durability, and seamless integration, these LED strips deliver bright, even illumination ideal for kitchens, workspaces, and display areas. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED lighting solutions. To learn more or discuss a custom collaboration, contact our sales manager at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.