Article Contents

Industry Insight: Strip Rgb

RGB LED strip lighting has evolved far beyond its decorative origins to become a strategic element in commercial and industrial facility design, driving both functional performance and experiential value. Today’s sophisticated projects demand dynamic, controllable illumination for applications ranging from retail accent lighting and hospitality ambiance to critical industrial task lighting, safety zone delineation, and architectural feature highlighting. However, deploying RGB strips in these demanding environments requires far more than basic color-changing capability. Rigorous adherence to safety and performance standards like ETL and CE certification is non-negotiable, ensuring electrical safety, electromagnetic compatibility, and long-term reliability under continuous operation – factors that directly impact project compliance, insurance requirements, and facility uptime. Unverified products risk fire hazards, signal interference, and premature failure, leading to costly callbacks and liability exposure.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over two and a half decades of specialized expertise in engineering high-performance LED lighting solutions precisely for these complex commercial and industrial settings. We understand that success hinges on delivering not just vibrant color, but consistent output, robust thermal management, precise color calibration, and seamless integration with building management systems – all backed by the rigorous testing and documentation that ETL and CE certifications represent. Our focus is on providing reliable, code-compliant RGB strip systems that empower facility managers and designers to achieve their vision without compromising on safety or operational integrity.

Technical Specs & Certifications

The RGB LED strip lights manufactured by Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver high performance, vibrant color output, and long-term reliability for both residential and commercial applications. When focusing on technical specifications such as lumens per watt, color rendering index (CRI), and ingress protection (IP) ratings, Beauty STC’s RGB strip lights stand out due to their precision engineering and rigorous quality control standards.

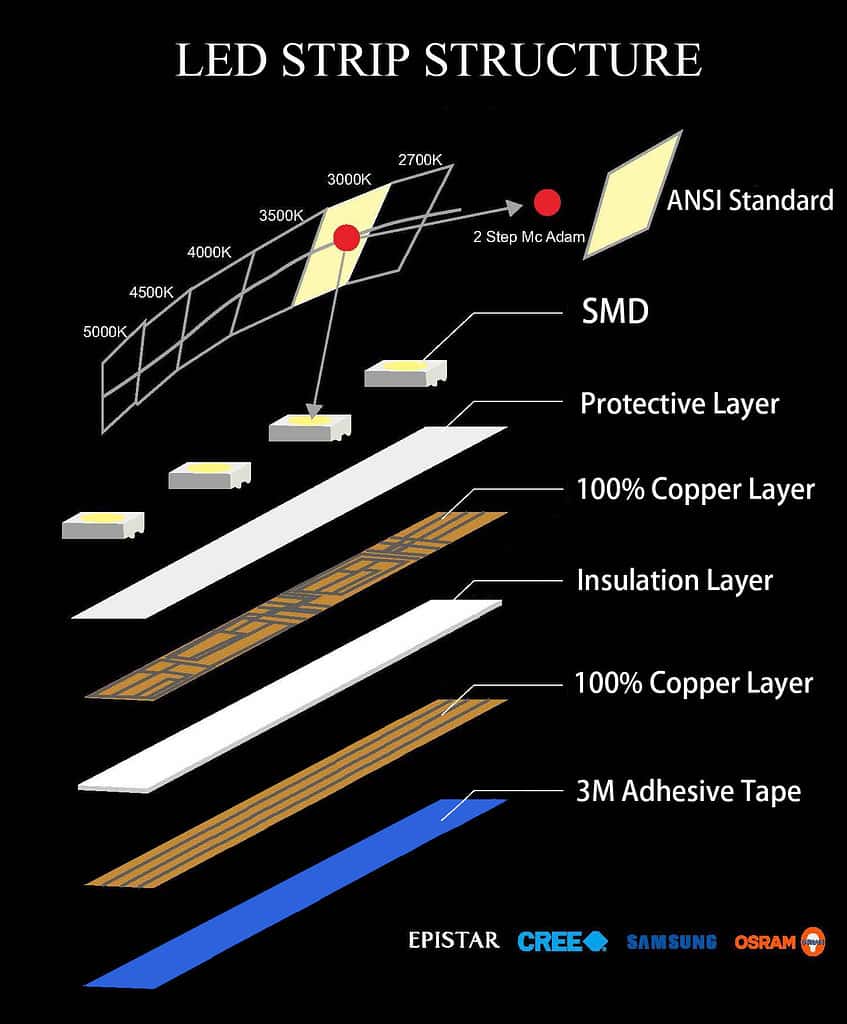

In terms of efficiency, Beauty STC’s RGB LED strips typically achieve a luminous efficacy in the range of 18 to 22 lumens per watt per color channel. When all three primary colors (red, green, blue) are driven simultaneously to produce white or mixed hues, the combined output efficiency remains optimized due to high-quality phosphor coatings and efficient SMD LED chips, commonly using 5050 or 3535 package types. While RGB strips are inherently less efficient than dedicated white LEDs due to color blending dynamics, Beauty STC ensures maximum light output through tightly binned LEDs and efficient constant-current drivers.

A key differentiator is Beauty STC’s ability to offer RGB strips with a Color Rendering Index (CRI) exceeding 90 when operating in white-light mixed modes. This is achieved through advanced LED binning processes and the use of high-CRI LED components combined with precise current regulation. A CRI >90 ensures that colors appear natural and vibrant under the illuminated environment, making these strips ideal for retail lighting, hospitality, and architectural accent applications where visual quality is critical.

Regarding environmental protection, Beauty STC provides RGB strip lights in multiple IP rating configurations to suit diverse installation conditions. The standard non-protected flexible strips are rated IP20, suitable for indoor dry locations. For damp or outdoor use, strips are available in IP65-rated versions, featuring a silicone encapsulation that protects against dust and low-pressure water jets. For fully submersible or harsh environment applications, IP67 and IP68 rated versions are offered, with robust silicone overmolding allowing operation under water up to 1 meter for extended periods. These ratings are verified through in-house testing to ensure compliance with international standards.

Beauty STC’s commitment to quality is evident in every stage of production. The company utilizes automated SMT lines for consistent component placement, performs 100% electrical and optical testing, and subjects finished strips to thermal cycling and humidity resistance tests. All materials, including flexible PCBs and encapsulants, are sourced from qualified suppliers to ensure longevity and color stability over time. With over two decades of experience in LED manufacturing, Beauty STC maintains ISO9001 and ISO14001 certifications, underscoring its dedication to product excellence and environmental responsibility.

In summary, Beauty STC’s RGB strip lights combine efficient light output, high color fidelity with CRI >90, and versatile IP protection levels, all backed by stringent quality assurance protocols. These features make them a trusted choice for demanding lighting applications worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. operates a modern LED lighting production facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta manufacturing hub to leverage regional supply chain efficiencies and skilled labor resources. This factory serves as a dedicated center for high-volume LED product assembly, with particular specialization in flexible LED strip lighting, including RGB variants, supporting both proprietary brand production and extensive OEM/ODM services for global clients.

The facility integrates advanced SMT (Surface Mount Technology) production lines as the core of its manufacturing capability. We utilize multiple high-speed Fuji NXT III modular placement platforms, configured for optimal throughput and precision in LED strip assembly. These systems handle components down to 0201 package sizes with micron-level accuracy, essential for densely populated RGB LED strips requiring tight pitch control. Each SMT line includes automatic solder paste printers, nitrogen-reflow ovens for void-minimized solder joints, and automated optical inspection (AOI) stations performing real-time defect detection. Typical throughput exceeds 120,000 components per hour per line, enabling efficient production of complex RGB strips incorporating integrated drivers, microcontrollers, and densely packed SMD LEDs such as 5050 or 3535 packages. The SMT area operates under strict ESD controls and humidity management to ensure first-pass yield rates above 99.5% for demanding RGB circuitry.

Rigorous aging and reliability testing forms a non-negotiable phase in our quality assurance protocol, especially critical for RGB LED strips where thermal management and component longevity directly impact color stability and lifespan. Every production batch undergoes mandatory 72-hour continuous aging tests under elevated temperature conditions (typically 50°C ±2°C) at full operational voltage. Strips are monitored via automated data logging systems tracking key parameters including forward voltage drift, luminous flux depreciation, and color point shift (Δu’v’) across all RGB channels. Visual inspection during and post-aging identifies early failures such as LED dropout, solder joint fractures, or phosphor degradation. For premium OEM orders or harsh-environment applications, we implement extended 168-hour aging cycles with thermal cycling profiles. This systematic approach ensures field failure rates remain below 0.1% for standard RGB strip products, directly supporting our 3-5 year warranty commitments.

Our OEM capability for RGB LED strips is highly developed and flexible, catering to diverse client specifications across architectural, entertainment, and decorative lighting sectors. We support full customization of electrical and mechanical parameters including PCB width (8mm to 20mm standard), LED density (30 to 144 LEDs/meter), voltage platforms (5V, 12V, or 24V DC), and control protocols (analog PWM, digital ICs like WS2812B, SK6812, or DMX512). The factory manages end-to-end OEM production from bare PCB sourcing through component kitting, SMT assembly, conformal coating (where specified), cut-to-length processing, and custom reel packaging. Clients provide either complete design files or collaborate with our engineering team on tailored solutions for specialized requirements such as high-CRI options, waterproofing levels (IP20 to IP68), or proprietary connector interfaces. All OEM productions comply with mandatory certifications including UL, CE, RoHS, and ERP, with documentation fully transferable to the client’s brand. This vertical integration—from component procurement to final aging validation—ensures consistent quality and scalability for OEM partners requiring volumes from 5,000 to over 1 million meters annually.

Application Scenarios

Strip RGB lighting is a versatile and energy-efficient solution that can be effectively used across various commercial environments including hotels, malls, and offices. Each application benefits from the customizable color options, design flexibility, and ambient lighting capabilities that RGB strips offer.

In hotels, strip RGB lighting is ideal for creating dynamic and inviting atmospheres. It can be installed behind headboards, under furniture, along stair edges, in cove lighting for lobbies, and within bathrooms for accent lighting. The ability to change colors allows hotel designers to match lighting with themes, events, or guest preferences, enhancing the overall guest experience. RGB strips can also be used in pool areas and spas to create relaxing or vibrant environments depending on the desired mood.

In malls and retail spaces, RGB strip lighting helps highlight architectural features, accent product displays, and guide customer flow. It is commonly used in ceiling coves, signage backlighting, display windows, and around column wraps. The vibrant color options attract attention and can be synchronized with seasonal promotions or events. Proper zoning and control systems allow different areas to display unique lighting scenes, contributing to an engaging shopping environment.

In office environments, strip RGB lighting is typically used more subtly to accent architectural elements, reception desks, or break areas. While functional white lighting remains primary for workspaces, RGB strips can add visual interest in collaborative zones, conference rooms, or branded areas. For example, company colors can be illuminated during events or used to indicate room availability through color coding. Care should be taken to avoid overly bright or distracting colors in focused work areas.

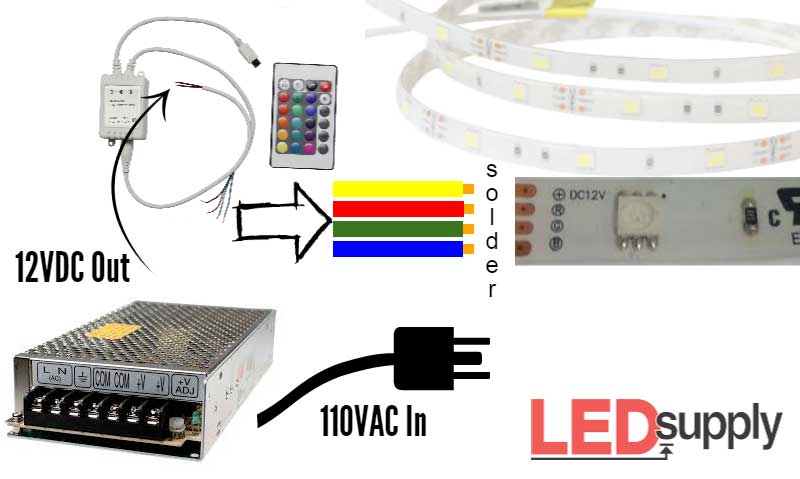

When installing RGB strip lighting, several best practices should be followed. First, ensure the surface is clean, dry, and smooth before applying the strip to maximize adhesive performance. For longer runs or high-traffic areas, mechanical fasteners or aluminum channels provide better support and heat dissipation. Always use a compatible RGB controller and power supply, and consider using a power injection method for runs exceeding 5 meters to prevent color fading at the end of the strip. Install controllers and drivers in accessible locations for maintenance. Use waterproof strips in humid areas like bathrooms or outdoor-facing zones. Finally, test the lighting and control system before finalizing the installation to ensure smooth operation and desired color output.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium RGB LED strip solutions engineered for exceptional color accuracy, durability, and seamless integration. As a trusted manufacturing partner, we provide fully customizable strips alongside comprehensive engineering support and reliable global supply chain management to meet your exact specifications and volume requirements. Partner with Beauty STC to leverage our advanced thermal management systems and rigorous quality control processes that ensure superior performance in demanding applications. Contact our dedicated partnership team today to discuss your RGB strip needs and receive tailored technical guidance. Reach out to Manager at [email protected] to initiate a collaboration that delivers innovation and value to your customers. As Senior LED Lighting Engineers at Beauty STC Manufacturing Co. Ltd. we stand ready to support your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.