Article Contents

Industry Insight: Strip Lights Under Cupboards

Under-cabinet strip lighting has evolved far beyond its residential kitchen origins to become a critical component in demanding commercial and industrial environments. In settings like commercial kitchens, laboratories, retail display cases, manufacturing workbenches, and healthcare facility task areas, precise, shadow-free illumination is not merely convenient but essential for safety, productivity, and quality control. The shift from outdated fluorescent solutions to high-performance LED strip lighting addresses key industrial challenges: delivering intense, uniform task lighting without excessive heat generation, ensuring long operational life to minimize disruptive maintenance in critical zones, and providing the flexibility to integrate seamlessly into diverse fixture designs and architectural constraints. Crucially, compliance with rigorous safety and performance standards is non-negotiable in these professional settings. Reputable manufacturers prioritize certifications such as ETL for the North American market and CE marking for Europe, guaranteeing that products meet stringent electrical safety, electromagnetic compatibility, and environmental requirements, thereby mitigating liability risks and ensuring reliable operation under continuous duty cycles.

Beauty STC Manufacturing Co., Ltd., established in 1998, stands at the forefront of this specialized lighting segment. With over two decades of dedicated engineering and manufacturing expertise, we have consistently developed and refined high-quality LED strip lighting solutions specifically engineered for the exacting demands of commercial and industrial applications. Our deep understanding of the thermal management, optical control, and durability requirements inherent in professional under-cabinet installations allows us to deliver products that combine superior performance with the critical safety certifications demanded by specifiers and facility managers worldwide.

Technical Specs & Certifications

Strip lights designed for under-cabinet installation are essential for task lighting in kitchens, workbenches, and display areas. At Beauty (STC) Manufacturing Co., Ltd., our under-cabinet LED strip lights are engineered to deliver high performance, reliability, and aesthetic appeal, meeting the rigorous demands of both residential and commercial environments.

Our LED strip lights achieve an efficiency of 100 to 120 lumens per watt, ensuring bright illumination while maintaining low energy consumption. This high lumens-per-watt ratio translates into significant energy savings over time without compromising on light output, making our strips ideal for continuous or frequent use in kitchen and workspace settings.

Color Rendering Index (CRI) is a critical factor in environments where accurate color representation is important, such as food preparation and detailed tasks. All our under-cabinet LED strips feature a CRI greater than 90, with select models reaching up to CRI 95. This ensures that colors appear natural and vibrant, enhancing visual clarity and user comfort. The high CRI is achieved through the use of premium-grade LEDs and phosphor coatings, carefully selected and tested during our manufacturing process.

Regarding environmental protection, our strip lights are available in multiple IP (Ingress Protection) ratings to suit various installation conditions. For standard under-cabinet use in dry indoor areas, we offer IP20-rated strips, which provide basic protection against touch and dust. For installations in more demanding environments—such as near sinks or in high-humidity kitchens—we provide IP65-rated versions. These are fully dust-tight and resistant to low-pressure water jets, making them suitable for damp locations while maintaining long-term reliability.

Beauty (STC) Manufacturing Co., Ltd. upholds stringent quality control throughout production. Our strip lights undergo rigorous testing for thermal management, electrical safety, color consistency, and lifespan performance. We use high-quality flexible PCBs, durable silicone encapsulation (for IP65 models), and constant-current drivers to ensure stable output and extended service life—typically rated at L70 >50,000 hours. Our commitment to excellence ensures that every product meets international standards including CE, RoHS, and UL certification where applicable.

In summary, Beauty STC’s under-cabinet LED strip lights combine high efficiency (100–120 lm/W), exceptional color fidelity (CRI >90), and versatile IP protection (IP20 to IP65), all backed by robust build quality and consistent performance. These features make our lighting solutions a trusted choice for professionals and homeowners seeking reliable, high-quality task lighting.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility is a purpose-built 10,000 square meter LED lighting production plant strategically located within the Pearl River Delta industrial corridor. This location provides efficient access to key component suppliers and major logistics hubs while maintaining cost-effective operations. The factory operates under strict ISO 9001 quality management protocols with a dedicated cleanroom environment specifically designed for high-precision LED assembly.

Our SMT production lines feature eight fully automated Yamaha YS24 modular placement systems capable of handling components down to 0201 metric package sizes. These machines achieve placement accuracy of ±25μm at speeds up to 100,000 components per hour per line. Each line includes automated optical inspection stations with 3D solder paste inspection and post-reflow AOI verification, ensuring precise mounting of LED chips, drivers, and control ICs onto flexible PCBs used in strip light production. The SMT area maintains controlled temperature and humidity levels between 22-25°C and 45-55% RH to prevent electrostatic discharge and ensure solder paste stability.

All strip light products undergo rigorous aging testing protocols before shipment. Finished reels enter climate-controlled aging chambers maintained at 50°C ambient temperature with continuous operation at 110% rated voltage for 24 hours. We utilize automated monitoring systems that log voltage, current, and lumen output every 30 minutes throughout the test cycle. Any unit exhibiting >3% lumen depreciation or thermal anomalies detected via infrared thermal imaging is automatically flagged for failure analysis. This process occurs at a capacity of 50,000 meters daily across our dedicated aging bays.

For OEM production of under-cabinet strip lights, we offer comprehensive turnkey solutions from initial design validation through to finished goods. Our engineering team supports customizations including specific color temperatures (1800K-6500K), CRI>90 options, dimming protocols (0-10V, DALI, PWM), and custom PCB lengths up to 5 meters per segment. We accommodate reel lengths of 30m or 50m with optional pre-attached connectors and 3M adhesive backing configurations. The factory maintains UL/cUL certification for all standard strip light constructions and can develop custom solutions meeting IEC, PSE, or KC requirements. Minimum order quantities for custom OEM programs start at 5,000 meters with standard lead times of 15-18 days from final artwork approval. All OEM projects include full documentation packages with photometric reports, thermal profiles, and safety certification support.

Application Scenarios

Strip lights under cupboards are commonly used in environments where task lighting and ambient illumination are important for functionality and aesthetics. While they are most frequently associated with residential kitchens, their application extends to commercial and hospitality spaces such as hotels, malls, and offices—particularly in areas that mimic kitchen or preparation zones, service counters, or reception desks.

In hotels, under-cupboard strip lights are often installed beneath overhead cabinets in staff kitchens, housekeeping preparation areas, and behind reception or concierge desks. These locations benefit from focused lighting that enhances visibility for detailed tasks while maintaining a clean and modern appearance. In some boutique or luxury hotels, under-cabinet lighting may also be used in minibars or vanity units within guest rooms to add a subtle ambient glow.

In malls, strip lighting under cupboards or counters is typically used in food court preparation areas, kiosks, and retail service desks. For example, in coffee shops or quick-service restaurants located within malls, under-cabinet lights illuminate countertops where orders are assembled. The lighting improves operational efficiency and contributes to a more inviting display of products.

In office environments, under-cupboard strip lights are most useful in pantry areas, kitchenettes, or modular workstations with overhead storage. They provide practical lighting for food preparation and cleanup while reducing shadows cast by upper cabinets. Additionally, in modern office designs that incorporate open-plan kitchens or collaborative spaces with integrated cabinetry, these lights contribute to both usability and visual appeal.

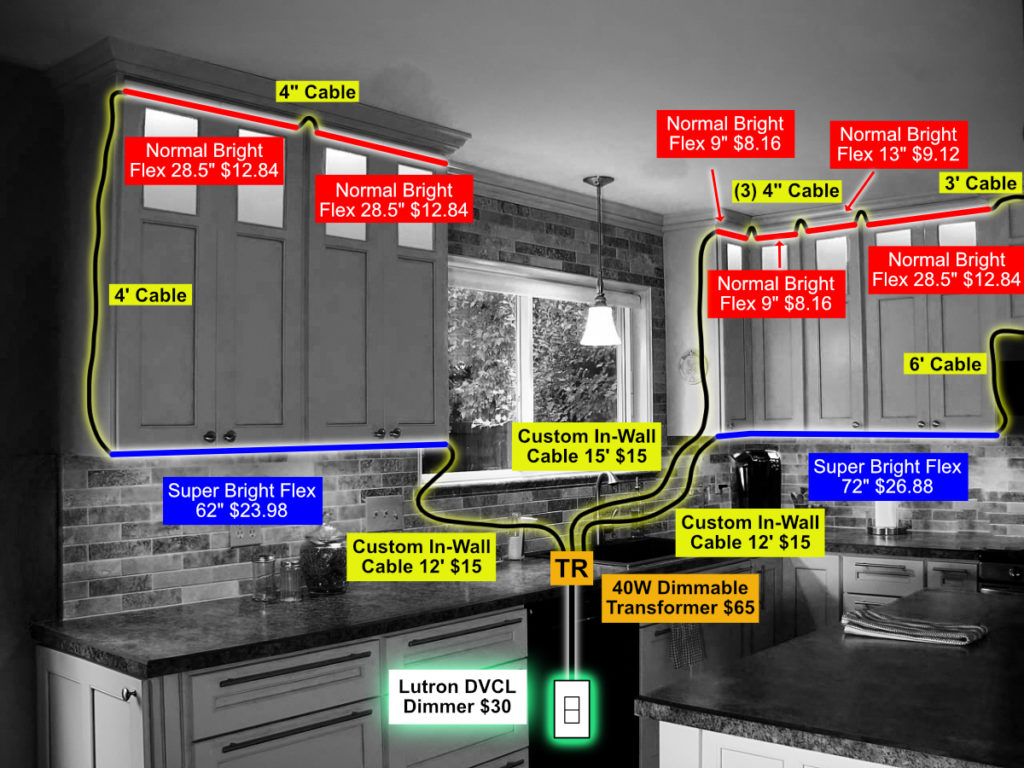

When installing strip lights under cupboards, several best practices should be followed to ensure optimal performance and longevity. First, select LED strip lights with a suitable color temperature—typically 3000K to 4000K—for balanced, comfortable illumination. Ensure the strips are rated for the environment; for instance, use IP65-rated waterproof strips in areas prone to moisture or cleaning splashes.

Mounting should be done on a clean, dry surface. Use the adhesive backing provided or opt for mounting clips for a more secure and adjustable fit. Avoid placing the strip too close to the front edge of the cabinet to prevent glare; positioning it slightly back allows light to reflect off the countertop, creating even illumination without harsh shadows.

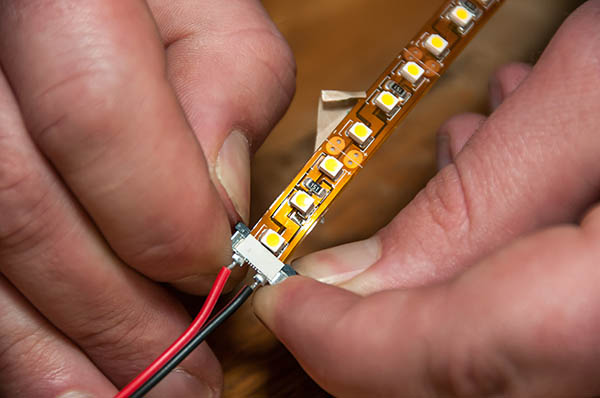

Connect the strip light to a reliable power source using appropriate drivers and connectors. For longer runs, consider splitting the power feed to avoid voltage drop, which can cause dimming at the far end of the strip. In commercial settings, integrate the lighting with occupancy sensors or dimmers to enhance energy efficiency and user convenience.

Lastly, ensure all electrical installations comply with local building codes and safety standards, especially in commercial environments where inspections and certifications are required. Proper installation not only improves functionality but also ensures safety and reduces maintenance needs over time.

Why Choose Beauty STC Lighting

Transform your kitchen lighting projects with precision-engineered under-cabinet strip lights designed for professional installations. Beauty STC delivers superior LED solutions that combine seamless integration, flicker-free performance, and exceptional color rendering to elevate task lighting in residential and commercial spaces. Our strips feature robust thermal management, easy mounting systems, and customizable lengths to ensure flawless execution in any cabinetry configuration.

As your dedicated manufacturing partner, Beauty STC provides end-to-end support including technical consultation, rapid prototyping, and scalable production to meet your project timelines without compromising quality. We prioritize reliability and energy efficiency in every product, ensuring your clients experience consistent illumination that enhances both functionality and ambiance.

Partner with Beauty STC to integrate lighting that sets industry standards. Contact our engineering and partnership team directly at [email protected] to discuss custom solutions, technical specifications, or volume collaboration opportunities. Let us help you deliver exceptional results for every under-cabinet application.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.