Article Contents

Industry Insight: Strip Lighting Plug In

Introduction & Market Demand for Plug-in Strip Lighting

Market Demand in Commercial and Industrial Applications

Plug-in strip lighting has become a critical solution for modern commercial and industrial applications, driven by demands for energy efficiency, design flexibility, and compliance with evolving building codes. These products are increasingly specified for retail displays, office under-cabinet lighting, warehouse task areas, and architectural accents due to their low heat output, longevity, and adaptability. As projects prioritize precise lighting control and regulatory adherence, the need for certified, reliable products has intensified—particularly in markets with stringent safety and performance requirements.

The Critical Role of Certifications for Global Importers

For distributors and contractors sourcing globally, certifications are non-negotiable gatekeepers to market access. ETL certification in North America and TUV CE certification in Europe validate compliance with electrical safety, electromagnetic compatibility, and performance standards. Products lacking these certifications face significant risks: customs delays, port rejections, costly recalls, and liability exposure. Beauty STC Lighting’s consistent adherence to these standards ensures seamless integration into Western markets, eliminating compliance headaches for importers while reducing project delays and warranty claims.

Beauty STC Lighting: 25+ Years of Certified Manufacturing Excellence

Established in 1998, Beauty STC Lighting has delivered factory-direct LED solutions to over 50 countries across Europe, North America, Asia, and Australia. Based in Jiangmen, Guangdong, China, our facilities maintain rigorous quality control processes aligned with international standards. Our ETL (USA/Canada) and TUV CE (Europe) certifications are regularly audited to ensure ongoing compliance, while our OEM/ODM capabilities enable customization of voltage configurations, color temperatures, dimming protocols, and IP ratings to meet exact project specifications. This depth of experience ensures distributors receive products engineered for real-world industrial applications—not just theoretical compliance.

Key Specifications for Plug-in Strip Lighting Solutions

| Parameter | Specification |

|---|---|

| Input Voltage | 120V AC (Plug-in), 12V/24V DC (with driver options) |

| CRI (Ra) | Standard >90, High CRI >95 available |

| IP Rating | IP20 (Indoor), IP65 (Damp/Wet Locations), IP67 (Submersible) |

| Color Temperature | 2700K – 6500K, Adjustable White Options |

| Dimming Compatibility | TRIAC, 0-10V, PWM, DALI (OEM customizable) |

| Length Options | Standard 5m/10m reels; Custom lengths up to 50m |

| Certifications | ETL (US/Canada), CE (TUV), RoHS, FCC |

All products undergo 100% burn-in testing and third-party validation to ensure reliability in high-demand environments. Custom engineering support available for project-specific requirements.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – “Strip Lighting Plug-In”

1. Key Metrics That Matter in Industrial / Commercial Projects

| Parameter | Why It Counts | Beauty STC Standard |

|---|---|---|

| System Efficacy | Determines energy rebate eligibility & ROI | 120–140 lm/W @ 24 VDC (Tj 65 °C) |

| CRI | 90+ required in retail, inspection & colour-critical areas | Ra ≥ 90 (R9 > 50) |

| SDCM | Guarantees visual uniformity on long runs | ≤ 3-step MacAdam ellipse |

| Flicker Index | IEEE 1789-2015 < 0.1 for camera & human comfort | < 0.05 (no visible stroboscopic effect) |

| IP Rating | Outdoor façade, cold-room & high-pressure wash | IP65 (sleeved) / IP67 (tube) / IP68 (encapsulated) |

| PCB Copper Mass | Thermal spreading & current density | 2 oz (70 µm) ED copper, 10 mm width, 5 mm pitch |

| Life-time Prediction | L70B10 @ Ta 45 °C | > 54 000 h (TM-21, 6 000 h data set) |

2. Factory-Direct Consistency Controls (Beauty STC, est. 1998)

- Bin-on-reel: every 0.5 m section is spectrally binned with SDCM 3; reel ID recorded for full traceability.

- 48-hour burn-in: 100 % production loaded on 45 °C heat-plate, 24 VDC, 1.05× rated current.

- Hi-Pot & Ground Bond: 1 500 Vac / 1 s on finished plug-in cord set; leakage < 0.5 mA.

- Automatic solder-paste inspection (SPI): 3-D paste height ±15 µm; AOI for component placement.

- ETL & TÜV CE file maintenance: yearly factory audit, critical component database locked—no substitution without re-submission.

3. Generic Market vs. Beauty STC Certified Quality

| Attribute | “Generic” Strip (common web listing) | Beauty STC Certified Strip |

|---|---|---|

| LED Source | Unbranded 2835, 20–22 lm, 3 V | Epistar 2835, 24–26 lm, 3.1 V, 6 000 h LM-80 |

| Copper Weight | 1 oz (35 µm), 8 mm width | 2 oz (70 µm), 10 mm width |

| Efficacy @ 24 V | 75–85 lm/W (advertised) | 120–140 lm/W (verified in 25 °C integrating sphere) |

| CRI / R9 | Ra 80, R9 –10 | Ra 90, R9 > 50 |

| SDCM | 5–7 | ≤ 3 |

| IP Option | IP20 only or misleading “IP65” sleeve | IP65/67/68 with co-extruded UV-9 PU, salt-spray 720 h |

| Certifications | Supplier self-declaration | ETL/cETL (UL 2108 & CSA C22.2#9), TÜV CE (EN 60598-2-20), RoHS/REACH, ERP 1194/2012 |

| Plug-in Cord Set | 2-pin without strain relief | 2 × 0.75 mm² 105 °C VDE rubber cable, integrated ferrite, 30 / 60 / 120 W TRIAC dimmable driver optional |

| Warranty | 1 year limited | 5 year factory warranty, backed by 25-year OEM track record |

4. PCB Construction Detail (Industrial Grade)

Base Material: FR-4 140 °C Tg, CTI ≥ 175, halogen-free.

Thermal Via Array: 0.3 mm Ø under each LED pad, 1.6 mm pitch, filled & capped for < 3 K/W junction-to-board.

Surface Finish: ENIG (Au 0.05 µm, Ni 3–5 µm) for wire bonding shelf-life > 12 months.

Conformal Coating: UV-resistant polyurethane, 25 µm, optional nano-acrylic for IP68 variant.

5. Compliance Snapshot for Distributors & Specifiers

North America: ETL listed to UL 2108 & CSA C22.2 #9, Class 2 output, suitable for dry, damp & wet locations.

Europe: TÜV Bauart-mark, EN 60598-2-20, EN 62493 (EMF), ERP 1194/2012 dimming compatibility.

RoHS / REACH: full material disclosure on request—no exemptions 7(a)-7(c).

ISO 9001:2015 & ISO 14001:2015 production site audited annually by TÜV since 2005.

For OEM colour temperature tuning, custom reel lengths, or project-specific lumen packages, contact the factory engineering cell at [email protected] or +86-13902885704.

Factory Tour: Manufacturing Excellence

Precision Manufacturing: Behind Our Industrial-Grade Strip Lighting

With 26 years of manufacturing expertise since 1998, Beauty STC Lighting operates a dedicated facility in Jiangmen’s High-tech Industrial Zone. Our production processes comply with ETL (USA/Canada) and TUV CE (Europe) standards, ensuring reliable performance for global commercial and industrial applications. All manufacturing adheres to strict environmental controls and traceability protocols to maintain consistency across high-volume production runs.

Advanced SMT Production Line

Our facility employs industrial-grade Surface Mount Technology (SMT) lines with automated optical inspection (AOI) systems for precision component assembly. Key operational features include:

0.1mm placement accuracy for consistent solder joint integrity

RoHS-compliant lead-free soldering processes with real-time flux monitoring

Automated reel feeding systems for continuous high-volume output

IPC-A-610 Class 2 compliance for all soldering quality standards

This automation minimizes human error while maintaining thermal stability during high-density LED array mounting, critical for long-term lumen maintenance in commercial applications.

Rigorous Quality Assurance Protocol

Every production batch undergoes multi-stage verification aligned with international safety standards. Our protocol includes:

| Stage | Inspection Criteria | Standards Applied |

|---|---|---|

| Component Incoming | Material specs, RoHS compliance, batch traceability | IEC 62612, RoHS 2.0 |

| SMT Assembly | Solder joint integrity, component placement | IPC-A-610 Class 2 |

| Aging Test | Thermal stability, voltage tolerance (±10%) | 24h continuous operation at rated load |

| Final QC | Lumen output consistency, color accuracy, dielectric strength | ETL/CE certification requirements |

All products undergo accelerated thermal cycling and electrical safety testing before shipment. Batch records are digitally archived for full traceability per ISO 9001-aligned procedures.

OEM/ODM Customization Capabilities

Beauty STC Lighting offers end-to-end engineering support for project-specific lighting solutions. Our customization framework supports:

| Parameter | Standard Options | Customization Range |

|---|---|---|

| Length | 1m, 5m reels | 0.5m increments up to 50m |

| CCT | 3000K, 4000K, 5000K | 2700K–6500K adjustable |

| CRI | Ra80, Ra90 | Ra80+ to Ra95+ |

| Packaging | Standard retail boxes | Custom branding, bulk pallets, anti-static packaging |

Additional engineering capabilities:

Driver compatibility engineering (0-10V, DALI, TRIAC)

Custom waterproofing (IP65, IP67) for outdoor applications

Thermal management optimization for high-power density designs

Project-specific lumen output and beam angle configurations

All custom solutions undergo pre-production validation with thermal imaging and spectral analysis to ensure compliance with client specifications and regional certification requirements.

For project-specific technical requirements or OEM collaboration, contact our engineering team at [email protected] or +86 13902885704.

Installation & Application Scenarios

Application Scenarios for Plug-In LED Strip Systems

(Factory-direct, ETL/TUV-CE certified, 1998~)

1. Hospitality & Retail – 24 h Operation, Zero Downtime

Typical spaces

Lobby coffers, reception desks, bar shelves

Corridor bulkheads & hand-rail undercuts

Window displays, shelf edge, mannequin niches

Contractor notes

Use 120 V constant-current reels (5 m / 16.4 ft) to eliminate remote drivers—one plug, one circuit.

TCB ≥ 85 °C rated 3 oz copper FPC keeps CCT shift < 200 K after 15 000 h (L₇₀B₁₀).

Feed from GFCI-protected receptacles every 10 m; voltage drop < 5 % at reel end.

Mount on aluminium profile ≥ 12 mm width for passively keeping Tj ≤ 75 °C in 25 °C ambient.

Quick spec reference (Beauty STC PS-120V series)

| Parameter | Hotel / Retail Grade | Unit |

|---|---|---|

| Input | 120-277 | Vac |

| Power | 9.6 | W/m |

| CCT / CRI | 3000 / 90 | K / Ra |

| Cert. | ETL cETL, TUV CE | — |

| IP rating | IP65 (PU glue) | — |

| Reel length | 5 / 10 / 25 | m |

2. Commercial Offices – Unified Glare & Flicker Compliance

Locations

Task light coves above work desks

Perimeter ceiling slot to boost vertical illuminance

AV credenza / video-conference back-lighting

Installation tips

Choose <1 % flicker driver (IEEE 1789-2015) to meet WELL & CE-EN 12464-1.

Parallel wiring with push-in WAGO 221 keeps maintenance swap time < 2 min.

4000 K, 80 Ra minimum; 200 lm/ft delivers 150 lx on desk when mounted 0.8 m from wall.

Integrate with occupancy sensor (120 V relay) to reach LPD ≤ 5 W/m² (ASHRAE 90.1-2022).

3. Architectural Facade & Landscape – Tool-less Field Length

Use cases

Soffit perimeter, parapet outlines, cantilever beams

Handrail lighting in pedestrian bridges

Step & retaining-wall markers

Field practice

IP67 encapsulated strip with 180 ° side-entry cable gland—no onsite potting.

UV-stable silicone lens, -40 °C to +60 °C, ΔE < 3 after 1 000 h Q-SUN.

120 V plug-in means local photo-cell/timer receptacle—no secondary driver boxes on wall.

Bond to extrusion with 3 M VHB 5952; mechanical fixing every 30 cm for 90 km/h wind load.

4. Pop-Up & Retail Refit – Tool-Less OEM Custom Length

Why plug-in matters

Landlord prohibits hard-wiring; UL-listed cord-set keeps code compliance.

OEM 0.5 m to 5 m cut-points in factory; shipped in individual blister with printed SKU for franchise rollout.

Contractor gain

30 % labour reduction versus 24 V system with remote driver.

Uniform brightness binning ≤ 3 SDCM guarantees store-to-store colour consistency.

5. Industrial “Shadow-Corridor” Retrofit – Former Fluorescent Strip

Target

Replace 8 ft T8 surface strip above conveyors, mezzanine racks.

120 V LED strip kit snaps into existing junction box; uses ½ inch EMT strap.

Energy proof

18 W LED vs 64 W T8 = 1.3 yr payback at 0.12 US$/kWh, 24/7.

ETL-listed -20 °C cold-start for freezer aisles.

Universal Installation Checklist (Factory-Supplied)

- Verify plug receptacle is on dedicated 15 A breaker (max 12 A continuous).

- Measure line voltage under load; >125 V requires 277 V SKU to protect SMD resistors.

- Allow 5 cm loop every 1 m for thermal movement; never tension the FPC.

- For lengths >10 m, centre-feed to keep luminous flux variance <7 %.

- After install, run 2 h burn-in; IR scan Tj ≤80 °C; record for 5-year warranty file.

Need project-specific IES files, BIM object or LM-79 data?

Email: [email protected] | WhatsApp: +86-13902885704

Beauty STC Lighting – OEM since 1998, ETL & TUV-CE listed, exporting to 50+ countries.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Industrial-Grade LED Strip Solutions for Global Projects

Beauty STC Lighting delivers certified, factory-direct LED strip lighting solutions engineered for reliability and compliance in demanding industrial, commercial, and architectural applications. With over 25 years of manufacturing expertise and a global export network spanning 50+ countries, we provide scalable, specification-grade products tailored to your project’s technical and regulatory requirements.

Certified Compliance for International Markets

Our products meet rigorous regional standards, ensuring seamless integration into projects across North America, Europe, and other key markets.

| Certification | Scope | Compliance Standards |

|---|---|---|

| ETL | USA & Canada | UL 1598, UL 2108 |

| TUV CE | European Union | EN 60598-1, EN 62368-1 |

| Global Reach | 50+ Countries | Direct compliance with regional safety and performance requirements |

Manufacturing Excellence Since 1998

As a vertically integrated manufacturer, we control every stage of production—from R&D to final testing—to ensure consistency, quality, and on-time delivery for projects of any scale.

| Capability | Detail |

|---|---|

| Industry Experience | 25+ years (established 1998) |

| OEM/ODM Services | Full customization: electrical specs, IP ratings, color temperatures, and housing designs |

| Supply Chain Rigor | ISO 9001-aligned processes with traceable quality control at every stage |

| Logistics Network | Dedicated export teams supporting FOB, CIF, and DDP shipping terms |

Why Partner with Us?

Regulatory Confidence: All products undergo third-party testing for ETL and CE compliance—no guesswork for your project approvals.

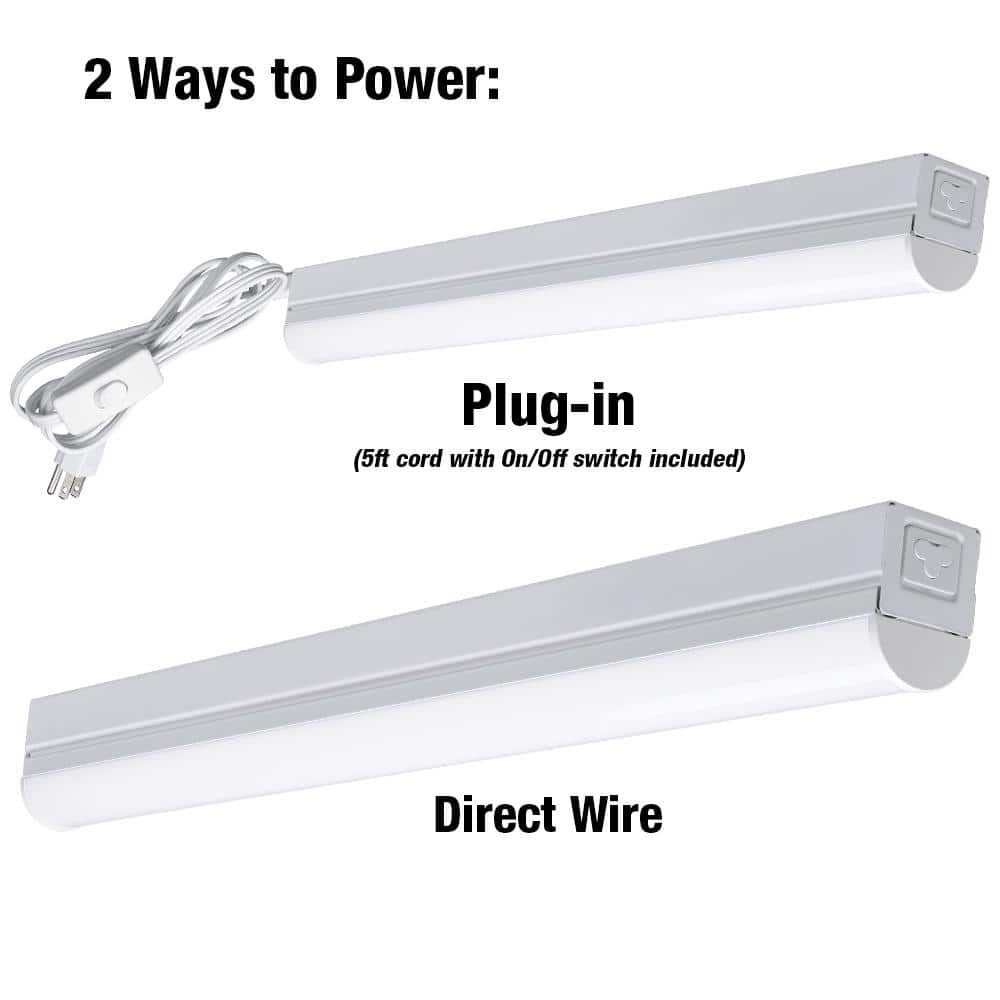

Technical Precision: Engineered for plug-and-play integration with existing infrastructure (e.g., 120V AC direct-wire options, TRIAC/0-10V dimming compatibility).

Global Scalability: Consistent quality across all markets, backed by localized technical support for North American, European, and Asian projects.

“Be a responsible enterprise, Be a caring person” is not just a principle—it’s embedded in our manufacturing ethos. From energy-efficient designs to end-of-life recycling protocols, we prioritize sustainability without compromising performance.

Ready to specify certified LED strip lighting for your next project?

Contact our engineering team for technical documentation, compliance files, and custom solutions:

[email protected] | +86 13902885704

Beauty (STC) Manufacturing Co., Ltd

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).