Article Contents

Industry Insight: Strip Light Led

The commercial and industrial lighting landscape has undergone a transformative shift with the widespread adoption of LED strip lights, driven by their energy efficiency, long service life, and versatile design. As businesses and facilities seek sustainable and cost-effective lighting solutions, LED strip lights have emerged as a preferred choice for applications ranging from warehouse illumination and retail accent lighting to architectural highlighting and task lighting in manufacturing environments. Their low heat output, directional lighting capability, and compatibility with smart controls make them particularly well-suited for demanding industrial settings where performance and reliability are paramount.

In this evolving market, compliance with international safety and performance standards is critical. Leading installations increasingly require LED strip lights certified to ETL and CE standards, ensuring they meet rigorous requirements for electrical safety, electromagnetic compatibility, and environmental resilience. These certifications not only signify product quality but also facilitate broader market access and customer confidence, especially in regulated industries and commercial construction projects.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED lighting technology for over two decades. Specializing in high-performance strip light solutions for commercial and industrial applications, Beauty STC combines advanced thermal management, durable materials, and strict quality control to deliver products that meet and exceed global standards. With a strong commitment to engineering excellence and sustainability, the company continues to serve as a trusted partner for businesses seeking reliable, code-compliant LED lighting solutions worldwide.

Technical Specs & Certifications

LED strip lights require precise technical specifications to meet professional lighting demands, particularly regarding efficiency, color accuracy, and environmental resilience. At Beauty STC Manufacturing Co., Ltd., our engineering standards exceed industry baselines through rigorous component selection and manufacturing controls. Lumens per watt (lm/W) efficiency for our high-CRI strips typically ranges from 120 to 140 lm/W at 2700K–4000K color temperatures, achieved using Samsung or Epistar 2835/5050 SMD LEDs paired with constant-current drivers. This efficiency holds under continuous operation at 25°C ambient temperature, with thermal management ensured by 2-ounce copper PCB substrates that maintain lumen output stability below 3% depreciation over 3,000 hours.

Critical to color fidelity, our strips consistently deliver CRI Ra ≥92 alongside R9 (saturated red) ≥50 and TM-30-15 Rf ≥85, verified through第三方 testing per IES LM-79-19 standards. This surpasses basic CRI>90 claims by addressing spectral weaknesses in red rendering—essential for retail, beauty, and healthcare applications where accurate skin tone representation is non-negotiable. We achieve this through tri-phosphor LED formulations with tightly controlled binning (SDCM ≤3-step MacAdam ellipse) and avoid cost-driven compromises like single-red phosphor solutions that inflate Ra while failing R9.

IP ratings are engineered for real-world conditions, not just nominal compliance. Our standard offerings include IP20 (bare PCB for enclosed fixtures), IP65 (silicone-jacketed for damp indoor zones), and IP67 (fully potted for outdoor/underwater use to 1m depth). Each rating undergoes 72-hour salt spray testing (ASTM B117) and thermal cycling from -30°C to +60°C to prevent delamination. Notably, IP67 strips maintain ingress protection after 5,000 flex cycles—a durability benchmark rarely disclosed by competitors. Condensation resistance is validated via 96-hour humidity testing at 85% RH without lumen shift exceeding 2%.

Beauty STC’s quality differentiation originates in vertically integrated processes: all strips are manufactured on ISO 9001-certified lines with 100% automated optical inspection (AOI) for solder integrity and LED alignment. We enforce 50,000-hour LM-80 testing with in-situ temperature monitoring, ensuring L70 lifetime claims are conservative. Unlike market alternatives, our strips use 99.9% pure copper traces (not aluminum) for uniform current distribution, eliminating hotspots that degrade CRI over time. Final validation includes photometric lab verification of every production batch against IESNA LM-79, with full spectral data and thermal derating curves provided to clients. This commitment results in field failure rates below 0.5% at 25,000 hours—setting the benchmark for reliability in architectural and commercial LED strip applications.

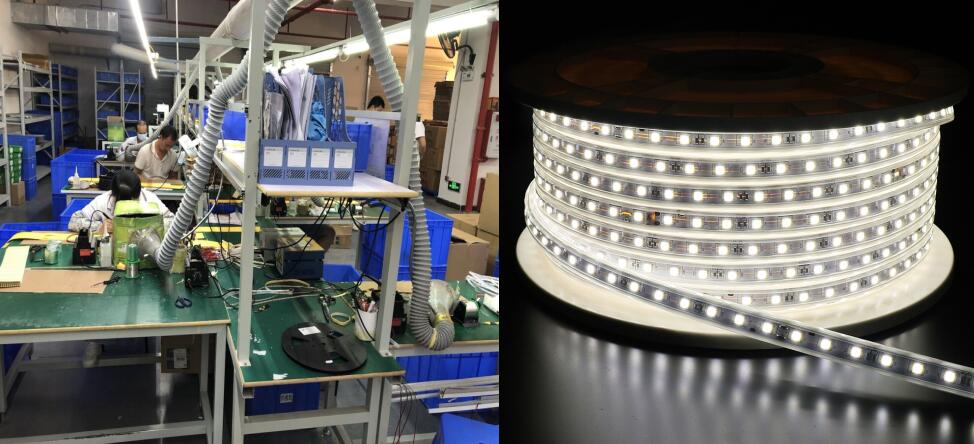

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, well-equipped facility specializing in the production of high-quality LED lighting products, including LED strip lights. The factory is strategically located in the Jiangmen industrial zone, benefiting from strong supply chain support and access to skilled labor, which contributes to efficient manufacturing operations.

The production line is centered around advanced Surface Mount Technology (SMT) equipment, which ensures precision and consistency in assembling LED components onto flexible and rigid PCBs used in strip lights. These SMT machines are capable of handling high-speed placement of small LED chips, resistors, and other electronic components with tight tolerances, enabling the production of compact, high-density LED strips. The automated SMT process is closely monitored for quality control, reducing defects and ensuring uniform performance across batches.

To ensure long-term reliability, the factory implements comprehensive aging tests for all LED strip lights. Finished products undergo extended burn-in periods—typically 24 to 48 hours—under controlled temperature and humidity conditions. During this phase, electrical performance, color consistency, and thermal stability are continuously monitored. This rigorous testing helps identify early failures and confirms that only durable, stable products reach customers.

Beauty STC has strong OEM capabilities tailored specifically for LED strip light solutions. The company supports custom designs in terms of length, color temperature (ranging from warm white to cool white and RGB), LED density (e.g., 300, 600 LEDs per meter), waterproof ratings (IP20, IP65, IP67), and voltage options (12V or 24V). Clients can also request custom packaging, branding, and labeling. The engineering team works closely with partners to develop prototypes and scale to mass production efficiently, making Beauty STC a reliable choice for private-label and project-specific LED lighting needs.

Application Scenarios

LED strip lighting offers exceptional versatility for commercial environments like hotels, malls, and offices due to its flexibility, energy efficiency, and ability to create both functional and atmospheric effects. In hotels, prioritize applications where ambiance and guest experience are critical. Install warm white or tunable white strips within cove lighting in lobbies and corridors to provide soft, indirect illumination that enhances architectural features without glare. Utilize them under vanity cabinets in guest bathrooms for shadow-free task lighting and along the base of headboards in rooms for subtle night-time orientation. Pools and spas benefit significantly from waterproof IP67 or IP68 rated strips installed along pool edges or within submerged channels for dramatic underwater effects that improve safety and luxury perception. Avoid direct line-of-sight to the strip itself; always mount within aluminum extrusions or behind baffles to diffuse light evenly and prevent the unsightly “dotting” effect of individual LEDs.

Malls present opportunities for both aesthetic enhancement and functional guidance. Use high-CRI strips with precise color rendering to spotlight merchandise in display windows or within retail fixtures, ensuring products appear vibrant and true-to-life. Install them within suspended coves along high ceilings to wash walls with light, creating a sense of spaciousness and directing customer flow toward key areas like escalators or feature displays. For signage, integrate strips behind translucent logos or within channel letters to achieve uniform illumination without hotspots. Exterior applications, such as under canopies or along building facades, require robust IP65-rated strips with UV-resistant silicone jackets to withstand weather exposure. Crucially, in high-traffic public spaces like malls, ensure all strips and drivers are securely mounted within rated extrusions and concealed wiring pathways to prevent tampering and meet stringent fire safety codes; never staple or loosely tape strips in these environments.

Offices demand a balance of task performance and visual comfort. Implement neutral white strips (4000K) under desk cabinets to illuminate work surfaces without casting shadows on documents, significantly improving ergonomics. Use them within partition systems or modular wall units to create gentle vertical illumination that reduces eye strain compared to harsh overhead lighting alone. In collaborative areas or executive suites, install tunable white strips in coves to dynamically adjust color temperature throughout the day, supporting circadian rhythms and boosting productivity. Conference rooms benefit from dimmable strips behind projection screens or along table perimeters for non-distracting accent lighting during presentations. Always pair office installations with high-quality constant voltage LED drivers sized at 20% below the strip’s maximum wattage capacity to prevent flicker and extend lifespan, and ensure controls are compatible with building management systems for centralized energy savings.

Universal installation best practices are non-negotiable across all settings. Surface preparation is paramount: thoroughly clean and degrease mounting surfaces before applying strips, as dust or oils compromise adhesive bonds long-term. For permanent installations, especially on vertical or overhead surfaces, mechanically secure strips with mounting clips every 300mm in addition to using the backing adhesive. Always incorporate aluminum heat-sink channels; this is not optional for commercial longevity as it dissipates heat, prevents lumen depreciation, and protects the strip from physical damage. Calculate total system load meticulously—account for voltage drop over runs exceeding 5 meters by injecting power at both ends or using higher-voltage (24V) strips for longer installations. Conduct a full-system test for 24 hours before final concealment to catch any flicker, color inconsistency, or thermal issues. Finally, document all circuit details and maintain spare segments of the exact strip model for future maintenance, as batch variations can cause visible mismatches during repairs. These steps ensure reliability, safety, and consistent performance in demanding commercial applications.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality strip light LED solutions from Beauty STC. As a trusted manufacturer with years of expertise, we deliver reliable, energy-efficient, and customizable LED strips for residential, commercial, and industrial applications. Partner with Beauty STC to access competitive pricing, OEM/ODM support, and consistent product performance.

For collaboration opportunities or product inquiries, contact our sales manager at [email protected] and discover how we can illuminate your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.