Article Contents

Industry Insight: Strip Light Diffuser

In the rapidly evolving landscape of commercial and industrial lighting, strip light diffusers have emerged as a critical component in achieving optimal light distribution, visual comfort, and energy efficiency. As LED technology continues to dominate modern lighting design, the demand for high-performance diffusers that minimize glare, eliminate hotspots, and ensure uniform illumination has never been greater. In demanding environments such as warehouses, manufacturing facilities, retail spaces, and office buildings, the quality of a diffuser directly impacts both operational safety and aesthetic appeal. Regulatory compliance is equally essential, with ETL and CE certifications serving as hallmarks of electrical safety, reliability, and adherence to international standards—key considerations for facility managers and lighting specifiers.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of developing innovative optical solutions for the lighting industry. With over two decades of expertise, Beauty STC specializes in precision-engineered strip light diffusers designed to meet the rigorous demands of commercial and industrial applications. Combining advanced materials science with strict quality control, the company delivers diffusers that enhance optical performance while ensuring compliance with ETL and CE requirements. As a trusted partner to lighting manufacturers worldwide, Beauty STC continues to drive advancements in light diffusion technology, supporting the evolution of smarter, safer, and more sustainable built environments.

Technical Specs & Certifications

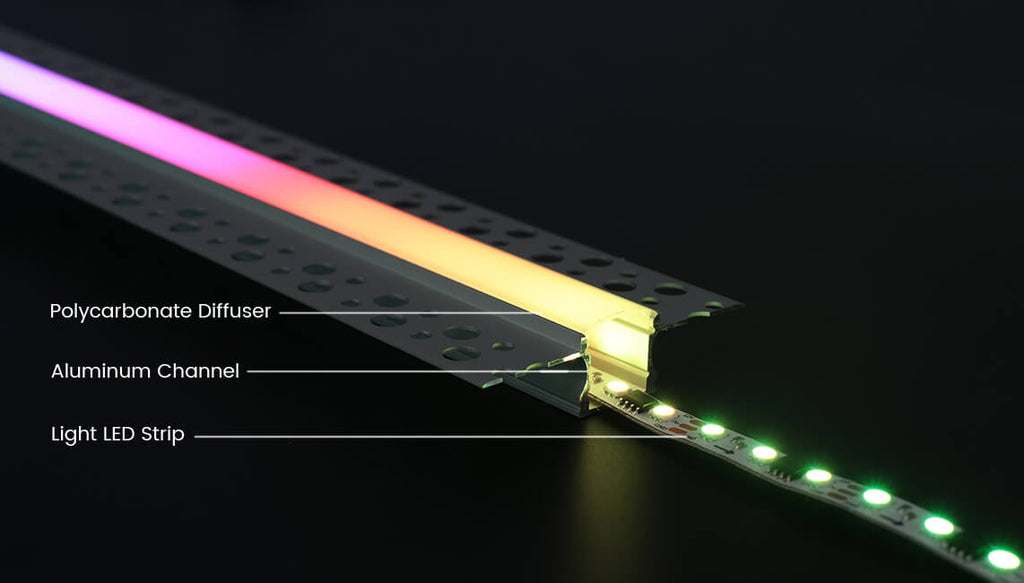

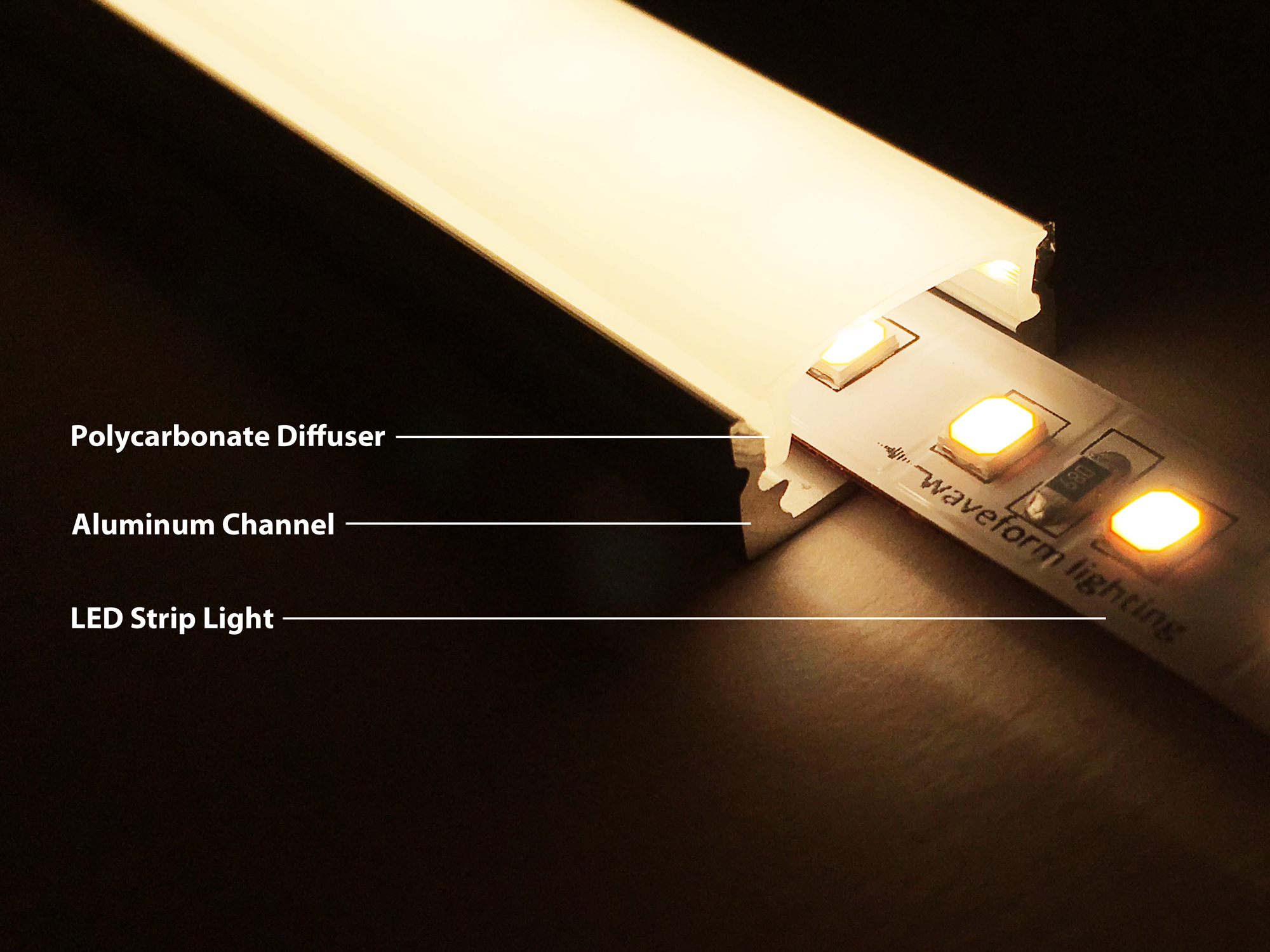

Strip light diffusers themselves do not generate lumens or consume watts; they are optical components that modify the light output from the underlying LED strip assembly. Therefore, Lumens per Watt (Lm/W) is a system-level specification determined by the LED chips, driver efficiency, and thermal management of the complete strip light product, not the diffuser alone. However, the diffuser material and profile significantly influence optical performance. High-quality diffusers like those engineered by Beauty STC minimize luminous flux attenuation, typically maintaining 85-95% of the bare strip’s output depending on profile design and material clarity. Our proprietary co-extruded polycarbonate diffusers utilize optimized prismatic or frosted internal geometries to ensure even light distribution with minimal loss, directly supporting higher effective system efficacy when paired with efficient LED engines.

Color Rendering Index (CRI) values exceeding 90 are achieved through the selection of high-CRI LED chips (typically 90-97 Ra) and phosphor formulations within the LED package itself, not the diffuser material. Beauty STC rigorously sources LED components meeting stringent CRI >90 and R9 >50 specifications for critical red rendering. While the diffuser does not alter the fundamental CRI of the light source, our diffuser materials are formulated with ultra-high clarity polycarbonate and UV stabilizers to prevent yellowing or spectral shift over time. This ensures the high-CRI light output from the LEDs is transmitted consistently throughout the product’s lifespan without degradation in color fidelity, maintaining the specified Ra and Rf values as certified in our photometric reports.

IP (Ingress Protection) Ratings apply to the complete sealed strip light assembly, where the diffuser is a critical component forming the primary environmental barrier. Beauty STC diffusers are integral to achieving robust IP ratings. For standard indoor applications, our diffusers paired with aluminum profiles and end caps achieve IP20. For demanding environments, our diffusers feature precision-engineered silicone gasket channels and seamless end cap integration. This design, combined with rigorous sealing protocols during manufacturing, enables consistent achievement of IP65 (dust-tight and protected against low-pressure water jets) and IP67 (dust-tight and protected against temporary immersion up to 1 meter) ratings across our product lines. All IP-rated assemblies undergo 100% automated water ingress testing per IEC 60529 standards.

Beauty STC’s diffuser quality is distinguished by material science and precision manufacturing. We utilize medical-grade, UV-resistant polycarbonate with rigorous optical clarity tolerances (haze <3%) and thermal stability up to 130°C. Our diffusers undergo accelerated lifetime testing exceeding 5,000 hours under 85°C/85% RH conditions with minimal yellowing (ΔYI <2.0). Precision extrusion ensures consistent wall thickness and optical geometry, eliminating dark spots or striations. Every diffuser batch is spectrophotometrically verified for transmission and diffusion properties. This commitment to material integrity and dimensional accuracy ensures uniform light distribution, long-term color stability, and reliable environmental protection, directly supporting the high lumen maintenance (L70/B50 >50,000 hours) and performance consistency demanded in professional architectural and commercial lighting applications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility located in Jiangmen, Guangdong Province, a region known for its robust electronics and lighting industry infrastructure. The factory is equipped with advanced Surface Mount Technology (SMT) production lines that ensure high precision and efficiency in assembling LED strip light components. These SMT machines are automated and capable of handling fine-pitch components, enabling consistent soldering quality and high-density board mounting, which is critical for the performance and reliability of LED lighting products.

All products undergo rigorous aging tests within the Jiangmen facility to ensure long-term durability and performance under real-world conditions. The aging process typically involves operating the LED strip lights at elevated temperatures and full power for extended durations—commonly 24 to 72 hours. This helps identify early failures, verify thermal management, and confirm consistent light output and color stability before products are shipped to customers.

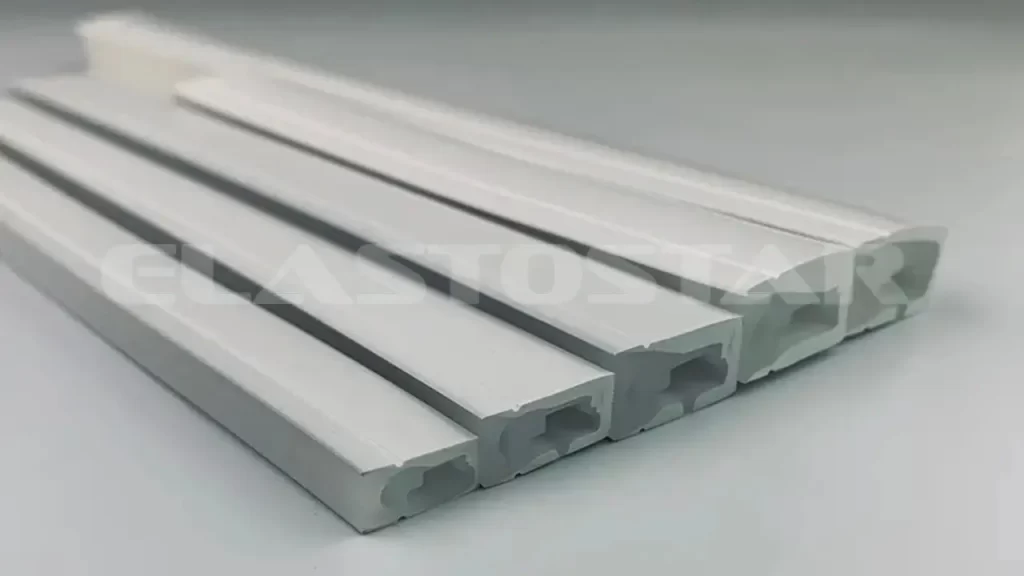

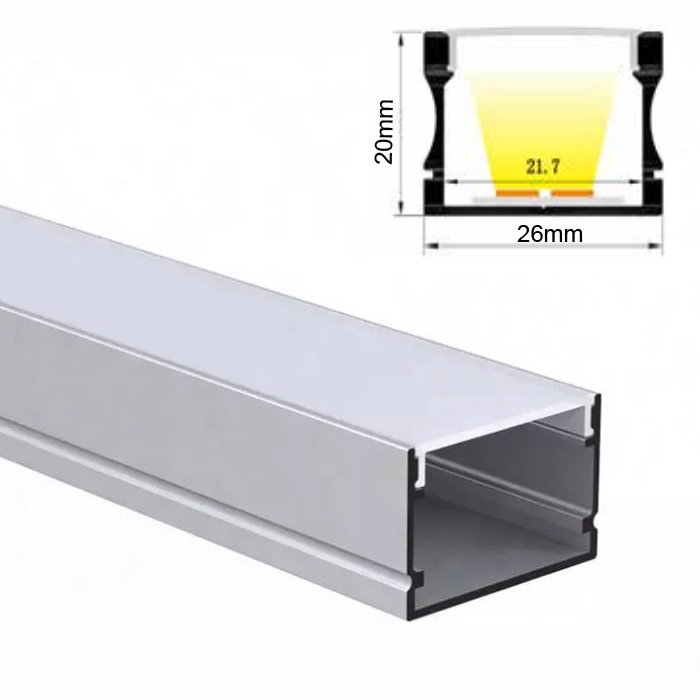

The factory has strong OEM capabilities, particularly for strip light diffuser products. Beauty STC can customize diffuser profiles in various lengths, optical transmittance levels, colors, and materials including PC (polycarbonate) and PMMA (acrylic), depending on customer requirements. The company supports full turnkey solutions—from diffuser design and mold development to integration with LED modules and packaging—allowing clients to brand and launch products under their own labels. With in-house engineering, tooling, and quality control, Beauty STC provides flexible, scalable OEM services tailored to both domestic and international market standards.

Application Scenarios

Strip light diffusers are essential for achieving uniform, glare-free illumination in commercial environments by softening the point-source nature of individual LEDs. In hotels, they are most effectively deployed in guest room headboards for ambient backlighting, under reception desk counters to create a floating effect, within bathroom mirror perimeters for shadow-free grooming lighting, and along hallway cove ceilings to provide gentle wayfinding illumination. High-end properties also utilize them in pool cabana soffits and bar under-counter installations where moisture resistance (IP67-rated diffusers) is critical. For malls, diffusers excel in upper-level retail display windows to evenly illuminate product backdrops without hotspots, beneath escalator handrails for safety accent lighting, within food court counter soffits, and in fitting room ceilings where consistent color rendering is necessary for customer satisfaction. Office applications prioritize diffusers under desk worksurfaces to eliminate screen glare, within conference room perimeter coves for video conference-friendly ambient light, along open-plan workstation dividers for task-appropriate illumination, and in executive suite reception areas where seamless light lines convey premium aesthetics.

Installation requires careful attention to material selection and technique. Always choose polycarbonate diffusers for high-traffic zones like mall corridors due to superior impact resistance, while offices may utilize cost-effective acrylic variants where durability demands are lower. Precisely match diffuser width to the LED strip’s dimensions—typically 10mm or 12mm—to prevent light leakage at the edges. Mount diffusers using integrated aluminum channels with spring clips rather than adhesive alone, ensuring channels are secured to substrates every 300mm to prevent sagging in linear runs exceeding 2 meters. Critical for visual quality is eliminating gaps between diffuser segments; employ silicone end caps at termination points and use thermal expansion joints in runs over 5 meters. In humid environments like hotel bathrooms, specify diffusers with sealed end caps and verify IP65+ ratings during installation. Never compress diffusers into channels—maintain a 1-2mm air gap between the LED strip and diffuser surface to manage heat buildup and prevent yellowing. Always conduct a mock-up test in the actual installation environment before full deployment, adjusting strip density or diffuser opacity based on observed light distribution. For curved applications in mall feature walls, use flexible silicone diffusers with a minimum 150mm bending radius to avoid stress fractures.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality strip light diffusers designed for optimal light distribution and seamless aesthetics. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in precision lighting components. For inquiries and collaboration opportunities, contact our sales manager at [email protected]. Let Beauty STC be your reliable partner in innovative lighting solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.