Article Contents

Industry Insight: Strip Light Adapter

The commercial and industrial lighting landscape increasingly demands adaptable, efficient, and reliable solutions, where LED strip lighting has become a cornerstone for task lighting, architectural highlighting, and functional illumination in settings ranging from warehouses and retail backrooms to manufacturing facilities and office under-cabinet applications. Beyond the LED strip itself, the critical yet often overlooked component enabling seamless integration and system longevity is the strip light adapter. These essential connectors and power interfaces are fundamental for ensuring safe, stable electrical connections between drivers, strips, and control systems, directly impacting performance, maintenance frequency, and overall system safety in demanding environments. For facility managers and electrical contractors, specifying adapters meeting rigorous safety certifications like ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements) is non-negotiable, as they mitigate fire hazards, ensure code compliance during inspections, and provide assurance against costly downtime or liability issues stemming from substandard components. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of dedicated expertise in designing and manufacturing high-performance LED lighting components precisely for these professional applications. We understand the uncompromising demands of commercial and industrial projects, which is why our strip light adapters are engineered from the outset to exceed ETL and CE safety benchmarks, deliver consistent power delivery under continuous operation, and provide the robust, vibration-resistant connections essential for reliable performance in real-world installations. Partnering with Beauty STC means integrating components built on decades of engineering rigor, ensuring your lighting systems operate safely, efficiently, and with minimal disruption from day one.

Technical Specs & Certifications

The strip light adapter from Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high performance and reliability in LED lighting systems, particularly for flexible and rigid strip light applications. While the adapter itself is not a light-emitting component, its role in powering LED strips directly influences the efficiency, stability, and overall output of the lighting system. When paired with compatible high-efficiency LED strips, the system achieves optimal lumens per watt (lm/W) performance. Typical strip configurations powered by Beauty STC’s adapters deliver luminous efficacies ranging from 110 to 130 lumens per watt, depending on the LED density and chip technology used—such as high-grade SMD2835 or SMD5050 diodes.

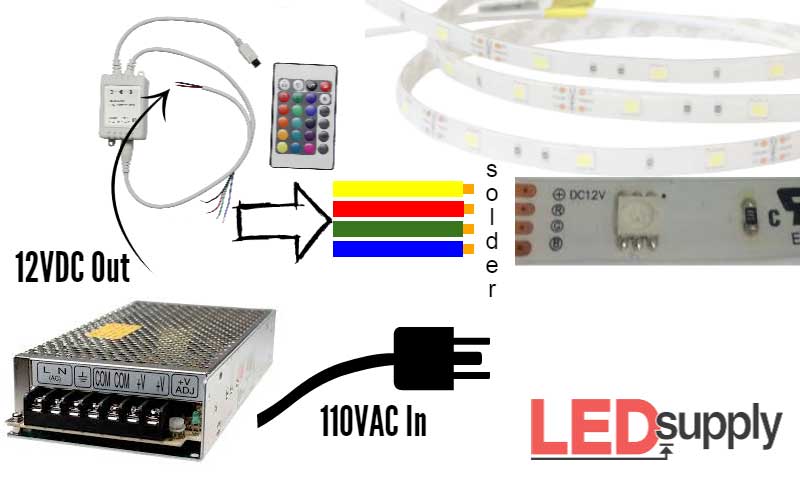

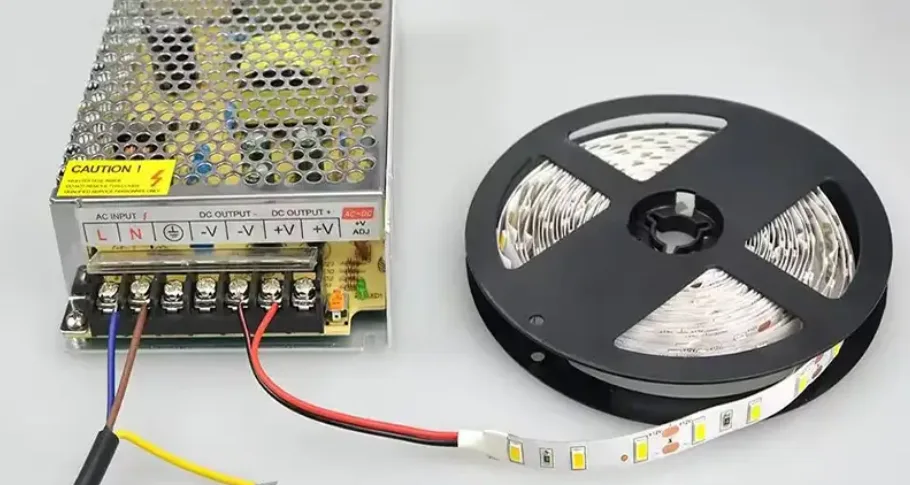

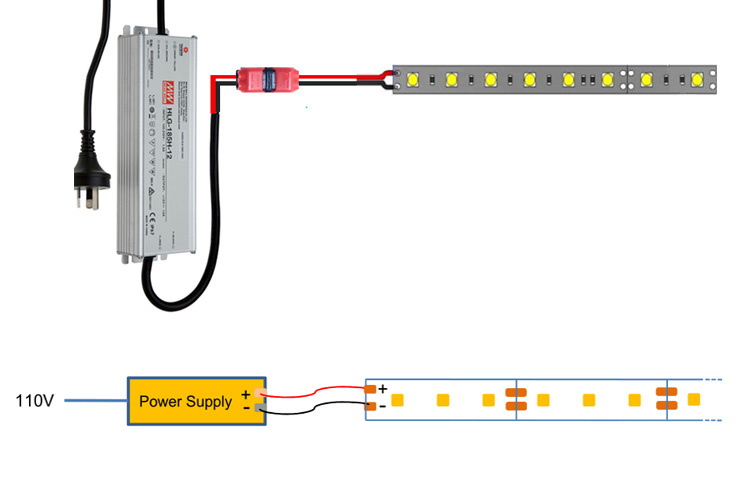

A critical feature of Beauty STC’s ecosystem is compatibility with LED strips that maintain a Color Rendering Index (CRI) greater than 90. This ensures exceptional color fidelity, making the lighting ideal for retail, residential, and professional environments where accurate color representation is essential. The adapters support constant voltage outputs—commonly 12V DC or 24V DC—providing stable current to maintain consistent brightness and color temperature across the strip, preventing flicker and lumen degradation over time.

Regarding environmental protection, Beauty STC designs its strip light systems with durability in mind. The adapters are typically rated IP67 or IP68 when housed in appropriate enclosures, offering full dust protection and resistance to temporary or prolonged water immersion. This makes them suitable for both indoor and outdoor installations, including damp or high-moisture areas such as kitchens, bathrooms, or landscape lighting. The LED strips themselves, when properly selected and paired with these adapters, can achieve IP65 to IP68 ratings depending on the silicone jacketing and sealing methods employed.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its stringent quality control, adherence to international standards (including CE, RoHS, and UL certifications), and use of premium electronic components such as high-reliability capacitors and efficient SMPS (Switch Mode Power Supply) circuitry. This commitment ensures long operational life, minimal energy loss, and safe performance under continuous load. The combination of high lm/W efficiency, CRI >90 compatibility, and robust IP-rated protection reflects Beauty STC’s dedication to engineering excellence and customer satisfaction in the LED lighting industry.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as our primary production hub for LED lighting solutions, including specialized components like strip light adapters. The factory is a modern, vertically integrated operation designed for high efficiency, stringent quality control, and robust OEM/ODM support. Our Jiangmen campus features extensive cleanroom environments dedicated to surface mount technology assembly, ensuring the precision required for sensitive LED driver and adapter electronics.

The SMT production lines form the backbone of our electronics manufacturing capability. We operate multiple high-speed Yamaha YS series SMT lines, each equipped with advanced 3D solder paste inspection (SPI) systems and automated optical inspection (AOI) stations. These lines are capable of placing ultra-miniature components down to 0201 package size with placement accuracy exceeding 0.025mm, critical for the compact circuitry found in modern strip light adapters. The lines run continuously with integrated conveyor systems, supporting a combined monthly capacity exceeding 15 million components. This infrastructure allows us to handle complex double-sided PCB assemblies and fine-pitch ICs common in efficient, low-profile adapter designs, maintaining a first-pass yield rate consistently above 99.95%.

Rigorous aging and reliability testing is deeply embedded in our quality assurance process, particularly for power conversion products like strip light adapters. Every production batch undergoes mandatory burn-in testing in our dedicated environmental chambers. Adapters are subjected to continuous operation at full rated load for a minimum of 72 hours under controlled elevated ambient temperatures ranging from 45°C to 55°C. During this period, critical parameters such as output voltage stability, ripple current, and thermal performance at key component locations are continuously monitored using automated data logging systems. Units exhibiting any deviation beyond our tight specifications are automatically flagged for root cause analysis. We also conduct accelerated life testing on statistical samples, simulating years of operational stress to validate long-term reliability before product release.

Our OEM capability for strip light adapters is a core strength, built on over a decade of specialized experience. We offer comprehensive turnkey solutions where clients can provide specifications for voltage output (commonly 12VDC or 24VDC), current rating, waterproof rating (IP20 to IP67), form factor, connector types, and safety certifications. Our engineering team collaborates closely from the initial design phase, providing DFM feedback and prototyping support, typically delivering functional samples within 15-20 working days. We manage the entire supply chain for critical components like ICs, transformers, and capacitors, ensuring consistent quality. Production scales seamlessly from initial pilot runs to high-volume orders with flexible MOQs, supported by our in-house tooling and plastic injection molding capabilities for custom housings. All OEM adapters undergo our full suite of safety and performance validations, including pre-shipment testing to UL, CE, RoHS, and relevant regional standards, with full documentation and traceability provided. This integrated approach ensures clients receive adapters that are not only precisely tailored to their strip light systems but also meet the highest benchmarks for safety and longevity.

Application Scenarios

Strip light adapters are commonly used in hotels, malls, and offices to simplify the installation, maintenance, and replacement of LED strip lighting systems. These adapters serve as connectors between the power source and the LED strip, enabling quick plug-and-play functionality without the need for soldering or complex wiring.

In hotels, strip light adapters are frequently used in guest rooms, under-bed lighting, cove lighting in hallways, and accent lighting in lobbies. They allow maintenance staff to easily replace or extend lighting runs without disrupting the aesthetics or requiring electricians for minor repairs. For example, in high-end hotel rooms, adapters make it simple to service under-cabinet or headboard lighting discreetly.

In malls, strip light adapters are ideal for display lighting, signage backlighting, and architectural cove lighting in common areas. The high foot traffic and need for consistent lighting make quick maintenance essential. Using adapters ensures that lighting in promotional displays or feature walls can be serviced swiftly during business hours without shutting down large sections of power.

In offices, these adapters are used in suspended ceiling coves, under-cabinet task lighting, and along stairwells or corridors. They support modular lighting designs that can be reconfigured as office layouts change. This flexibility is especially useful in open-plan offices where lighting zones may need repositioning during renovations.

For successful installation, ensure the polarity of the adapter matches the LED strip—most use a standard 24V or 12V DC configuration. Always verify the voltage and current rating of both the power supply and the strip to prevent overheating. Install adapters in accessible locations for future maintenance, avoiding tight or concealed spaces. Use weatherproof adapters and enclosures if installing in humid or outdoor-adjacent areas. Finally, secure connections with cable clamps or strain relief to prevent accidental disconnection due to vibration or movement.

Why Choose Beauty STC Lighting

Integrate our precision-engineered strip light adapter into your product lineup and eliminate compatibility headaches for your customers. Beauty STC delivers robust, universal adapters engineered for seamless installation across major LED strip systems, reducing returns and enhancing end-user satisfaction through rigorous quality control and thermal management design.

Partner with Beauty STC to leverage our 20+ years of LED innovation and scalable manufacturing for custom adapter solutions tailored to your specifications. Our engineering team provides full technical support from prototyping to mass production, ensuring your products meet global safety standards while maintaining aesthetic integrity.

Contact our partnership manager directly at [email protected] to discuss volume pricing, exclusive configurations, or engineering collaboration. Let us help you strengthen your market position with reliable, future-proof lighting components backed by Beauty STC’s industry reputation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.