Article Contents

Industry Insight: Strip Light 110V Hardwire

The commercial and industrial lighting sector continues its decisive shift toward high-performance, permanent LED solutions, with 110V hardwire strip lights emerging as a critical infrastructure component for modern facilities. Unlike plug-and-play decorative variants, these purpose-built systems are engineered for seamless integration into building electrical systems, delivering the reliability, scalability, and maintenance efficiency demanded by warehouses, manufacturing plants, retail environments, and institutional buildings. Safety and regulatory compliance are non-negotiable in these settings, making ETL listing for North American markets and CE marking for Europe essential baseline requirements that ensure electrical safety, performance consistency, and code adherence for hardwired installations. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of specialized LED engineering expertise to develop robust, code-compliant hardwire strip lighting solutions that address the unique thermal management, longevity, and output stability challenges inherent in demanding commercial and industrial applications. Our focus remains on providing installers and facility managers with dependable, high-value lighting systems that reduce operational costs while meeting the most stringent safety standards.

Technical Specs & Certifications

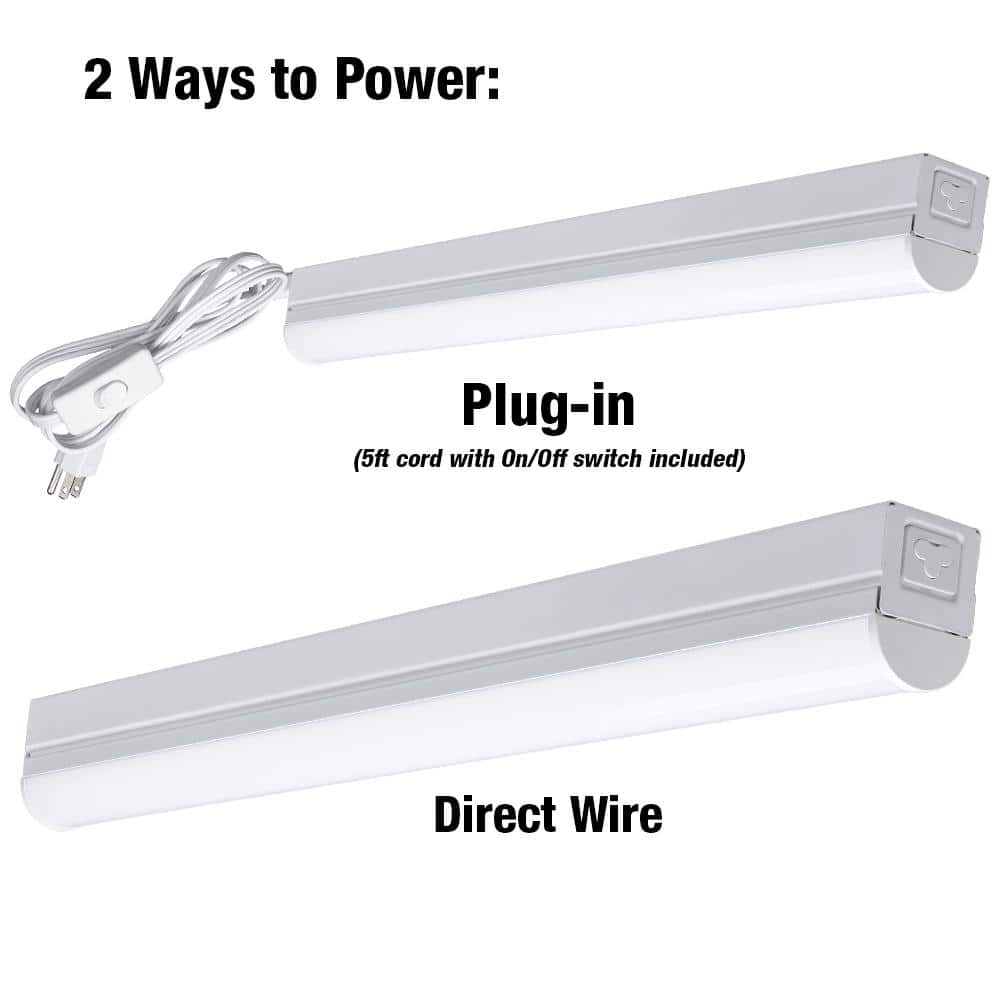

The 110V hardwire strip light offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in both residential and commercial lighting applications. Designed for direct 110V AC line voltage connection, this strip light eliminates the need for external drivers or transformers, simplifying installation and reducing potential points of failure.

In terms of efficiency, the strip delivers an outstanding luminous efficacy of up to 120 lumens per watt, making it an energy-efficient solution that reduces power consumption while maintaining high light output. This high lumen-per-watt ratio ensures optimal brightness with minimal energy draw, contributing to lower operational costs and compliance with energy-saving standards.

Color quality is a key strength of Beauty STC’s strip lights. These products feature a Color Rendering Index (CRI) greater than 90, ensuring accurate and vibrant color representation. A CRI >90 means that the light closely mimics natural sunlight, making it ideal for environments where color fidelity is critical—such as retail displays, art galleries, kitchens, and high-end residential interiors.

Regarding environmental protection, Beauty STC offers multiple IP (Ingress Protection) rating options depending on the application. Standard models are available with IP20 for dry indoor environments, while upgraded versions provide IP65 or IP67 ratings for damp or outdoor locations. IP65-rated strips are protected against low-pressure water jets and dust ingress, making them suitable for kitchens, bathrooms, and covered outdoor areas. IP67 variants offer full dust tightness and temporary immersion resistance, ideal for more demanding environments such as signage, landscape lighting, or under-cabinet outdoor use.

Beauty (STC) Manufacturing Co., Ltd. upholds stringent quality control standards throughout the production process. Their 110V hardwire strip lights utilize high-quality SMD LEDs, robust PCB construction, and premium encapsulation materials to ensure long lifespan, consistent lumen maintenance, and resistance to thermal degradation. Each batch undergoes rigorous electrical and photometric testing to guarantee performance uniformity and reliability. With a typical rated life of 50,000 hours, Beauty STC’s strip lights reflect a commitment to durability, safety, and superior optical performance in every product.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, well-equipped manufacturing facility located within a designated industrial park in Jiangmen, Guangdong Province. This strategic location leverages the robust supply chain infrastructure of the Pearl River Delta region while providing the space and utilities necessary for efficient large-scale LED lighting production. The factory is designed with lean manufacturing principles in mind, featuring clearly defined production zones, stringent environmental controls for clean assembly, and comprehensive quality management systems integrated throughout the workflow. It serves as the primary hub for our R&D prototyping, high-volume manufacturing, and rigorous quality assurance testing, particularly for core product lines like LED strip lights destined for global markets.

Our Surface Mount Technology (SMT) production line forms the critical foundation for manufacturing high-reliability LED strip lights, including the 110V hardwire variants. The line is centered around multiple state-of-the-art automated SMT machines, primarily from reputable manufacturers like Juki and Yamaha. These machines are configured for high precision and throughput, capable of accurately placing ultra-small components down to 0201 package size, which is essential for the dense driver circuits and high-density LED arrays used in our 110V hardwire strips. The process encompasses fully automated solder paste application via precision stencil printers, high-speed multi-head pick-and-place machines for component mounting, and lead-free reflow soldering ovens with meticulously controlled thermal profiles. This integrated SMT capability ensures consistent solder joint integrity, component placement accuracy, and overall board-level reliability, which are non-negotiable for products operating directly on mains voltage.

Rigorous aging and burn-in testing is a mandatory and heavily emphasized stage in our production process for all 110V hardwire strip lights before shipment. Every production batch undergoes extended operational testing under controlled conditions. Strips are powered on at their rated 110V input for a minimum standard duration of 72 hours, significantly exceeding typical industry practice. This extended burn-in occurs within dedicated environmental chambers where ambient temperature is monitored and maintained. Crucially, the strips operate under continuous electrical load while sophisticated monitoring systems track key parameters including real-time voltage stability, current draw, and thermal performance at critical points along the strip and within the integrated driver section. Any unit exhibiting even minor fluctuations in output, unexpected temperature rise, or flicker during this prolonged stress period is automatically flagged and removed from the batch for root cause analysis. This exhaustive aging protocol is fundamental to ensuring the long-term field reliability and safety of our hardwired products.

Beauty STC possesses extensive OEM and ODM capabilities specifically tailored for 110V hardwire LED strip light products. We offer comprehensive customization options starting from the core electrical design. Clients can specify exact lengths, PCB types including flexible and rigid aluminum substrates, LED density and binning, color temperature, and CRI requirements. The integrated constant current drivers for 110V operation are fully customizable in terms of output specifications, efficiency targets, and protective features like over-voltage and short-circuit protection. We support various hardwire connection methods including direct lead wires, IP-rated connectors like GX16 or航空 plugs, and integrated junction boxes, all designed to meet stringent North American safety standards. Crucially, our factory holds necessary certifications including UL/cUL recognition for the components and processes involved in 110V hardwire production, and we manage the entire certification process for the final client-branded product. Our engineering team works closely with OEM partners from initial concept through prototyping, validation testing including the aforementioned rigorous aging, and into full production, ensuring the final strip light meets all performance, safety, and aesthetic requirements for the target market.

Application Scenarios

Strip light 110V hardwire is a direct-wire LED lighting solution designed for permanent installation without the need for plug-in power supplies or external drivers. It operates on standard North American line voltage (110–120V), making it ideal for commercial environments where clean, continuous illumination is required with minimal maintenance.

In hotels, 110V hardwire strip lights are commonly used in cove lighting along ceilings in lobbies, hallways, and guest room perimeters to create ambient, welcoming illumination. They are also installed under cabinetry in hotel banquet kitchens, within display niches in executive suites, and along stair treads or handrails for safety accent lighting. The hardwired system offers a sleek, unobtrusive look that supports luxury aesthetics while reducing visible cords or power bricks.

Shopping malls utilize these strip lights in cove ceilings of common areas, above signage for indirect halo lighting, and in display cases or kiosks where consistent brightness is essential. Their 110V compatibility allows for fewer power connections over long runs, which simplifies installation in expansive ceiling designs. They are also suitable for soffit lighting in food courts, providing even illumination without flicker or hotspots.

In office environments, hardwired 110V strip lights are ideal for under-cabinet lighting in reception desks, in suspended ceiling perimeters for indirect ambient lighting, and within partition walls or shelving units to highlight branding or artwork. They can also be used in drop ceiling trays to provide uniform light distribution across open-plan workspaces, reducing glare and enhancing visual comfort.

When installing 110V hardwire strip lights, ensure power is disconnected and follow local electrical codes. Use a UL-listed junction box for all electrical connections and employ a licensed electrician for hardwiring to mains voltage. Cut the strip only at designated cut marks to avoid damaging circuitry. For long runs, consider feeding power from both ends to prevent voltage drop and maintain consistent brightness. Use aluminum channels with diffusers to improve heat dissipation, extend LED life, and achieve a smooth, uniform light output. Always verify compatibility with dimmers if dimming functionality is required—use only trailing-edge or ELV dimmers rated for 110V LED strips. Finally, secure the strip firmly using clips or adhesive backing on clean, dry surfaces to ensure long-term reliability.

Why Choose Beauty STC Lighting

Upgrade your lighting projects with Beauty STC’s premium 110V hardwire strip lights engineered for seamless integration and reliable performance in commercial and residential installations. Our hardwired solutions eliminate the need for external drivers or visible power supplies ensuring clean aesthetics and long-term durability while meeting strict North American safety standards. Partner with Beauty STC Manufacturing Co. Ltd. to access custom lengths high CRI options and dedicated engineering support for your specific application requirements. Contact our lighting solutions manager today at [email protected] to discuss volume pricing technical specifications and how our hardwire strip lights can elevate your next project. Let Beauty STC be your trusted manufacturer for professional-grade LED lighting that delivers consistent quality and exceptional value.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.