Article Contents

Industry Insight: Strip Led Waterproof

Waterproof strip LED technology has evolved from a niche solution to an indispensable component in demanding commercial and industrial lighting environments, where reliability under harsh conditions is non-negotiable. Beyond basic illumination, modern applications—from expansive warehouse ceilings exposed to condensation and temperature swings to outdoor architectural facades enduring relentless rain and UV exposure, and critical food processing or washdown areas requiring stringent sanitation—demand lighting that performs flawlessly despite moisture, dust, and physical stress. In this high-stakes arena, compliance with rigorous safety and performance standards like ETL certification for the North American market and CE marking for Europe transcends mere regulatory checkboxes; it serves as the fundamental assurance that a product will operate safely, consistently, and with a long service life, preventing costly failures, maintenance disruptions, and potential safety hazards. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of specialized engineering expertise to develop waterproof strip LED solutions engineered specifically for the uncompromising realities of commercial and industrial settings. Our deep understanding of the interplay between robust sealing technology, thermal management, and certified electrical safety allows us to deliver products where performance integrity in wet or challenging environments is not an afterthought, but the core design principle.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. produces high-performance waterproof LED strip lights engineered for reliability, efficiency, and superior light quality. Our waterproof LED strips are designed for both indoor and outdoor applications, meeting stringent environmental and performance standards.

Each waterproof LED strip is built with high-efficiency SMD LEDs—commonly using SMD2835 or SMD5050 chips—delivering a luminous efficacy ranging from 110 to 130 lumens per watt, depending on color temperature and density. This high lumens-per-watt ratio ensures energy-efficient operation while maintaining excellent brightness output, making our strips ideal for commercial, residential, and industrial lighting projects.

A key feature of Beauty STC’s premium waterproof LED strips is a Color Rendering Index (CRI) exceeding 90 (CRI >90). This high CRI ensures accurate and vibrant color representation, which is critical in environments where true color perception is essential—such as retail displays, hospitality spaces, and architectural accent lighting. The use of high-quality phosphor coatings and binning processes ensures consistent color quality across production batches.

In terms of environmental protection, Beauty STC offers multiple IP-rated variants to suit different installation conditions. Our standard waterproof LED strips are available with IP65 rating, featuring a silicone coating that protects against dust and low-pressure water jets—ideal for damp indoor locations or sheltered outdoor areas. For more demanding environments, we provide IP67-rated strips, which are fully protected against dust and can withstand temporary immersion in water up to 1 meter for 30 minutes. Additionally, IP68-rated versions are available for continuous submersion applications, with robust silicone encapsulation ensuring long-term durability even in underwater or harsh outdoor settings.

All waterproof LED strips from Beauty STC are manufactured using rigorous quality control processes, including 100% aging tests, electrical consistency checks, and environmental stress screening. Our production adheres to ISO9001 standards, and our products are RoHS compliant and CE/UL certified where applicable. The combination of high lumens per watt, exceptional color fidelity, and reliable IP protection underscores Beauty STC’s commitment to engineering excellence and long-lasting LED lighting solutions.

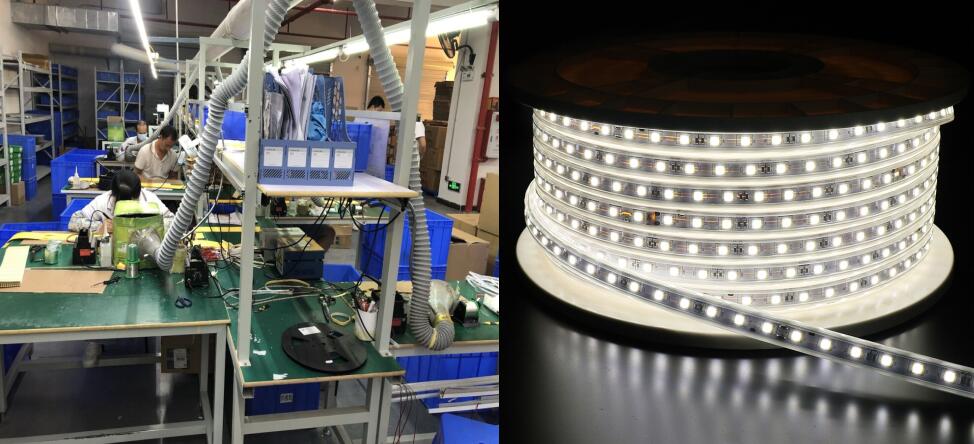

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, serves as our primary production hub for flexible LED lighting products, including specialized waterproof LED strips. The factory is a modern, ISO 9001-certified operation designed for high-volume precision manufacturing with stringent quality control protocols integrated throughout the production flow. Our Jiangmen site houses multiple dedicated SMT production lines specifically configured for LED strip assembly. These lines utilize advanced Yamaha YS24 and Fuji NXT III placement machines capable of handling ultra-fine pitch components down to 0201 metric package sizes. The SMT process includes nitrogen-reflow soldering for superior joint reliability and is optimized for both standard FR-4 and flexible FPC substrates used in strip production. For waterproof LED strips, the SMT stage is followed by critical secondary processes including automated conformal coating application or precision silicone extrusion depending on the IP rating required, ensuring robust environmental protection at the component level before final encapsulation.

Aging and reliability testing represent a cornerstone of our quality assurance at the Jiangmen facility. All waterproof LED strip products undergo mandatory 72-hour continuous aging tests under controlled thermal and electrical conditions. Strips operate at 1.2 times their rated voltage within climate-controlled chambers maintained at 50°C ambient temperature to accelerate stress screening. We employ automated optical inspection during aging to detect early failures, coupled with thermal imaging to identify thermal anomalies across the strip length. Post-aging, strips undergo rigorous IP67/IP68 verification through submersion testing in calibrated tanks, alongside dielectric strength testing at 1500V AC for 1 minute to validate insulation integrity. This comprehensive aging protocol ensures field failure rates remain below 0.1% for our premium waterproof strip lines.

Our OEM capabilities for waterproof LED strips are highly developed and flexible at the Jiangmen factory. We support full customization from electrical specifications to mechanical form factors, including tailored lumen output, color temperature, CRI values, and beam angles. For waterproof variants, we offer multiple protection methodologies: silicone-coated IP65 strips for splash resistance, fully potted IP67 strips for temporary submersion, and double-jacketed IP68 strips rated for continuous underwater operation. Production supports reel-to-reel processing with custom cut lengths, specialized connectors, and branding options including laser marking or printed labels. The facility handles low-volume prototyping starting at 300 meters and scales to full container loads, with engineering support for thermal management validation and electrical safety certification including UL/CUL, CE, and TÜV. All OEM projects benefit from our in-house tooling department for custom extrusion dies and fixture fabrication, ensuring rapid iteration and consistent quality for client-specific waterproof strip requirements.

Application Scenarios

Strip LED waterproof lighting is ideal for environments where moisture, humidity, or outdoor exposure is a concern. While hotels, malls, and offices are primarily indoor spaces, there are specific areas within these buildings where waterproof strip LEDs are highly beneficial.

In hotels, waterproof strip LEDs are commonly used in bathrooms, both under vanities and around mirrors, to provide soft ambient lighting that resists steam and splashes. They are also effective in pool areas, spas, and outdoor patios or balconies where exposure to water is frequent. Coving and soffit lighting near exterior entrances or covered walkways can also benefit from waterproofing due to potential weather exposure.

In malls, waterproof strip LEDs are suitable for outdoor signage, fountain lighting, and architectural features exposed to the elements. They can also be used in restrooms, especially in coves or under benches in family or gender-neutral facilities, and in decorative elements near indoor water features or food courts with high humidity.

In offices, while general workspaces don’t require waterproof lighting, these strips are useful in restrooms, pantry areas, or near drinking fountains where moisture may accumulate. They are also appropriate for outdoor lobbies, canopies, or stairwells exposed to rain or cleaning processes.

For installation, always ensure the power supply is disconnected before beginning work. Use a compatible low-voltage driver and confirm the IP65 or higher rating for true waterproof performance. Mount the strip on a clean, dry, and grease-free surface—aluminum channels with diffusers are recommended to enhance heat dissipation and light distribution while protecting the strip. Avoid sharp bends; maintain the minimum bending radius specified by the manufacturer. When connecting multiple strips, use waterproof connectors or solder joints sealed with heat shrink tubing. Finally, test the installation before final sealing and ensure all connections are properly insulated and protected from direct water contact.

Why Choose Beauty STC Lighting

For professionals seeking reliable waterproof LED strip solutions, Beauty STC Manufacturing Co., Ltd. delivers engineered excellence backed by 15 years of specialized expertise. Our IP65, IP67, and IP68-rated LED strips undergo rigorous environmental testing to ensure consistent performance in demanding applications including outdoor architectural lighting, marine environments, and high-moisture commercial spaces. We prioritize material integrity with silicone encapsulation and robust copper PCBs to prevent corrosion and lumen depreciation under extreme conditions.

Partnering with Beauty STC means accessing custom engineering support for voltage configurations, color temperature stability, and thermal management specific to your project requirements. Our manufacturing adheres to stringent IEC and RoHS standards, with traceable quality control from component sourcing to final assembly. Elevate your lighting projects with solutions designed for longevity and safety in wet locations.

Reach out to our engineering team directly to discuss technical specifications, volume production capabilities, or custom design collaboration. Contact Manager at [email protected] to initiate a technical consultation and receive detailed performance data sheets for our waterproof LED strip portfolio. Let us provide the illumination reliability your clients demand.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.