Article Contents

Industry Insight: Strip Glue

The commercial and industrial LED lighting sector constantly evolves, driven by demands for energy efficiency, design flexibility, and long-term reliability. Within this high-stakes environment, a critical yet often overlooked component significantly impacts project success: the adhesive system securing LED strips. Standard double-sided tapes frequently fail under real-world conditions—exposure to temperature extremes, humidity, chemical cleaners, or vibration in warehouses, retail spaces, and manufacturing facilities leads to costly strip detachment, safety hazards, and expensive callbacks. This underscores the non-negotiable requirement for rigorously tested, high-performance strip glue engineered specifically for demanding professional applications. Compliance with safety and performance standards like ETL and CE is not merely a checkbox; it is fundamental validation that the adhesive system meets stringent electrical safety, environmental resistance, and longevity requirements essential for commercial viability and liability protection. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over two decades to mastering this precise challenge. We bring deep expertise in developing and manufacturing advanced adhesive solutions that deliver the consistent, fail-safe bonding commercial and industrial projects demand, ensuring installations remain secure, safe, and visually impeccable for their intended lifespan. Our focus is on solving the adhesive challenges that directly impact your project’s bottom line and reputation.

Technical Specs & Certifications

Strip glue refers to the adhesive silicone or epoxy material used in the manufacturing of LED strip lights to encapsulate and protect the LEDs and circuitry. At Beauty (STC) Manufacturing Co., Ltd., the strip glue used in our high-performance LED strips is engineered to support both optical efficiency and environmental durability. While the glue itself does not generate lumens or consume watts, its optical clarity and thermal stability directly influence the overall performance metrics of the LED strip, including lumens per watt (lm/W), color rendering index (CRI), and ingress protection (IP) ratings.

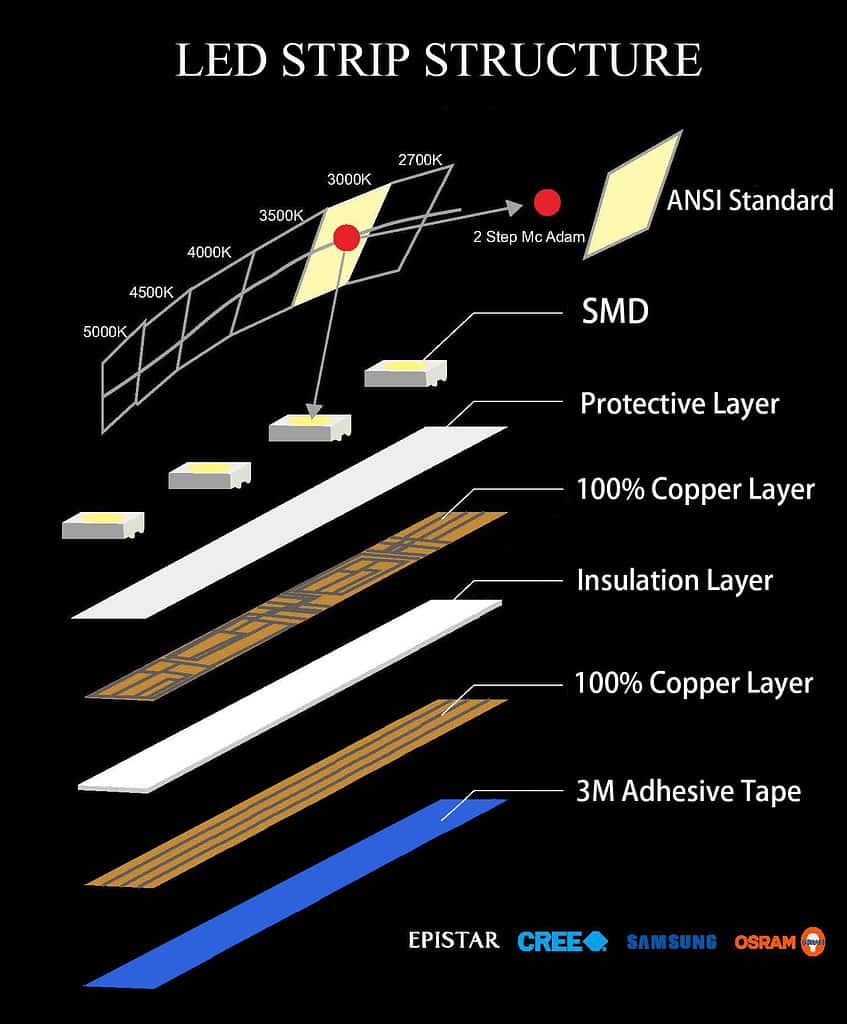

Our LED strips achieve luminous efficacies ranging from 110 to 150 lumens per watt, depending on the LED density, binning, and driver configuration. This high efficiency is supported by the use of premium-grade phosphor-coated SMD LEDs—typically 2835, 3528, or 5050 types—combined with optically clear, thermally stable silicone glue that minimizes light absorption and yellowing over time. The clarity and refractive properties of our strip glue ensure maximum light output retention, contributing directly to sustained lm/W performance throughout the product’s lifespan.

All Beauty STC LED strips designed for high color fidelity utilize strip glue formulations that are compatible with CRI >90 LED packages. The silicone encapsulant is UV-resistant and non-yellowing, preserving the spectral integrity of the emitted light. This ensures accurate color representation, which is critical in retail, hospitality, and architectural lighting applications. Our manufacturing process includes rigorous binning and testing to guarantee consistent CRI performance across production batches.

In terms of environmental protection, the strip glue plays a central role in achieving high IP ratings. For IP65-rated strips, a conformal coating of silicone glue is applied over the components, providing resistance to dust and low-pressure water jets. For IP67 and IP68 ratings, the entire strip is potted or double-coated with thick, flexible silicone glue, enabling submersion in water up to 1 meter for extended durations. The adhesive properties of the glue ensure a seamless seal around each LED and solder joint, preventing moisture ingress and corrosion.

Beauty (STC) Manufacturing Co., Ltd. maintains strict quality control standards in the formulation and application of strip glue. We use only RoHS-compliant, halogen-free silicone materials sourced from trusted suppliers. Our production lines are equipped with precision dispensing systems to ensure uniform glue thickness and coverage, which enhances both optical performance and long-term reliability. Every batch undergoes thermal cycling, humidity resistance, and photometric testing to verify performance consistency.

In summary, while strip glue is a supporting material, its quality is integral to achieving high lm/W output, CRI >90 color accuracy, and robust IP-rated protection. Beauty STC’s commitment to superior materials and precision manufacturing ensures that our LED strips deliver exceptional performance and longevity in demanding lighting environments.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, represents a core component of our production capacity, specifically dedicated to high-volume LED lighting solutions. This modern factory is strategically located within the Pearl River Delta region, leveraging excellent logistics infrastructure for raw material sourcing and global distribution. The Jiangmen site operates under strict ISO 9001 and ISO 14001 management systems, ensuring consistent quality and environmental compliance across all processes.

Surface Mount Technology (SMT) assembly forms the backbone of PCB production at this facility. We operate multiple high-speed, fully automated SMT lines featuring advanced machines from leading manufacturers such as Yamaha and Siemens. These lines are capable of handling a wide range of component sizes, from ultra-fine pitch 0201 LEDs and ICs to larger power components, with placement accuracy consistently achieving ±25µm. The process includes automated solder paste application via precision stenciling, multi-zone reflow soldering profiles tailored to specific board assemblies, and comprehensive Automated Optical Inspection (AOI) systems deployed post-reflow to verify component placement, solder joint quality, and potential defects. This high-precision SMT capability ensures the reliable foundation for all our LED modules and strip products.

Rigorous aging and burn-in testing is a non-negotiable step integrated into our production flow at the Jiangmen factory. Completed LED strip assemblies undergo structured aging procedures where units are operated continuously at elevated temperatures, typically 50-60°C, and at their rated voltage for periods ranging from 24 to 72 hours. This process is conducted on dedicated aging racks with individual channel monitoring to identify early-life failures, validate thermal management performance, and ensure component stability under sustained operational stress. Statistical sampling plans are applied to every production batch, with data meticulously recorded and analyzed to drive continuous improvement in product reliability and longevity. This commitment to thorough aging directly translates to the extended lifespan and consistent performance our customers expect.

The Jiangmen facility possesses significant OEM capability specifically tailored for LED strip light products, commonly referred to internally and by customers using terms like ‘strip glue’ – indicating flexible strips with pre-applied adhesive backing. We offer extensive customization options under OEM agreements, including precise cutting to customer-specified lengths, varying LED densities (e.g., 30, 60, 120 LEDs per meter), multiple color temperatures and CRI options, diverse silicone encapsulation levels (IP20, IP65, IP67), and selection of high-performance adhesive tapes such as 3M VHB. Our engineering team collaborates closely with clients to adapt electrical specifications, connector types, and reel packaging to meet unique project requirements. Furthermore, we provide full branding services, applying customer logos and specifications to both the product reels and retail packaging, ensuring a seamless private label experience from manufacturing through to end-user delivery. This flexibility, combined with our SMT precision and aging rigor, makes the Jiangmen factory a robust partner for global brands seeking customized LED strip solutions.

Application Scenarios

Strip glue is commonly used in commercial and hospitality environments such as hotels, malls, and offices to securely install LED strip lights in coves, under cabinets, along signage, and within architectural features. It provides a strong, clean, and discreet mounting solution without the need for mechanical clips or brackets, especially where visible hardware is undesirable.

In hotels, strip glue is ideal for installing LED strips in guest room cove lighting, behind headboards, under vanity cabinets, and in走廊 accent lighting. It ensures a sleek, seamless appearance that enhances the premium aesthetic expected in hospitality settings. In malls, it is frequently used for illuminating signage, display niches, and feature walls where long, continuous runs of lighting are required and visual cleanliness is important. In office environments, strip glue supports the installation of LED strips in under-cabinet task lighting, within suspended ceiling coves, and along stair treads or partition accents, contributing to both ambient and functional lighting designs.

When applying strip glue, ensure the surface is clean, dry, and free of dust, oil, or debris. Wipe the surface with isopropyl alcohol before application for optimal adhesion. Press the LED strip firmly into place along the glued surface and hold for 10–15 seconds to ensure initial bonding. Allow the adhesive to fully cure—typically within 24 hours—before powering the lights or exposing the installation to vibration or temperature fluctuations. Avoid applying strip glue in extremely cold or humid conditions, as this can reduce bonding effectiveness. For heavy or long LED strip runs, consider combining strip glue with additional mechanical support every 12–16 inches to prevent sagging over time. Always follow the manufacturer’s guidelines for application temperature and compatible substrates.

Why Choose Beauty STC Lighting

For professional LED installations requiring reliable adhesion, Beauty STC delivers precision-engineered strip glue solutions trusted across the lighting industry. Our advanced formulations ensure consistent bonding strength, thermal stability, and clean removal on diverse surfaces, directly supporting seamless project execution and long-term fixture performance. Partner with Beauty STC to integrate our industry-proven strip glue technology into your supply chain and elevate your project outcomes with confidence.

Contact our dedicated partnership team today at [email protected] to discuss customized strip glue solutions, volume pricing, and technical support tailored to your specific requirements. Let Beauty STC become your strategic adhesive partner for superior LED integration.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.