Article Contents

Industry Insight: Strip Cabinet Lighting

The commercial and industrial lighting sector continuously demands solutions that balance operational efficiency, stringent safety compliance, and precise task-specific illumination. Within this demanding environment, strip cabinet lighting has evolved far beyond basic visibility, becoming a critical component for enhancing productivity, ensuring safety in workspaces, and optimizing energy consumption across warehouses, manufacturing floors, retail backrooms, and service facilities. Modern applications require robust, reliable, and easily installable linear lighting that withstands challenging conditions while delivering consistent, shadow-free light exactly where needed. Crucially, adoption in professional settings hinges on adherence to globally recognized safety and performance standards; ETL certification for the North American market and CE marking for Europe are not merely optional credentials but fundamental requirements for specifiers and facility managers, ensuring electrical safety, electromagnetic compatibility, and regulatory compliance. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over two decades to engineering and manufacturing high-performance LED lighting solutions specifically for these demanding commercial and industrial applications. Our expertise lies in developing strip cabinet lighting systems that seamlessly integrate rigorous safety certifications like ETL and CE with the durability, optical precision, and energy efficiency demanded by today’s professional environments, providing facility operators with dependable, code-compliant illumination they can trust.

Technical Specs & Certifications

Strip cabinet lighting from Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and precision illumination in cabinetry, display cases, under-cabinet installations, and other interior lighting applications where clarity, color fidelity, and energy efficiency are critical. Our LED strip lighting solutions are designed with advanced optical technology and premium components to ensure superior light quality and long-term reliability.

In terms of efficiency, Beauty STC’s cabinet lighting strips deliver an industry-leading luminous efficacy ranging from 100 to 120 lumens per watt, depending on the specific model and color temperature. This high lumens-per-watt ratio ensures optimal brightness while minimizing energy consumption, making the strips ideal for both residential and commercial environments where lighting runs for extended periods.

Color Rendering Index (CRI) is a key focus for our cabinet lighting products. All premium strip lights offered by Beauty STC feature a CRI greater than 90, with select high-CRI variants reaching up to 95 or higher. This exceptional color accuracy ensures that illuminated objects—particularly food, artwork, or retail merchandise—appear vibrant, natural, and true to life. High CRI performance is achieved through the use of carefully selected LED chips and phosphor coatings, combined with stringent binning processes during manufacturing.

Regarding environmental protection, Beauty STC offers cabinet lighting strips in multiple IP (Ingress Protection) ratings to suit various installation conditions. For standard dry indoor environments such as kitchen cabinets or display units, IP20-rated strips provide basic protection against touch and dust. For applications where moisture or cleaning is a concern—such as in retail display cases or humid kitchens—we offer IP54 and IP65-rated versions. These models feature conformal coating or silicone encapsulation to protect against dust, splashing water, and condensation, ensuring long-term durability and safe operation.

Beauty STC is committed to uncompromising quality. Our strip cabinet lighting undergoes rigorous testing for thermal management, lumen maintenance (L70/L90), chromatic consistency, and electrical safety. We utilize high-quality flexible printed circuit boards (FPCBs), reliable 2835 or 3014 SMD LEDs, and efficient constant-current drivers to ensure stable performance across varying temperatures and operating hours. All products are RoHS compliant and meet international safety standards, including UL, CE, and SAA certifications where applicable.

With precision optics, exceptional color rendering, high efficiency, and robust build quality, Beauty STC’s strip cabinet lighting sets a benchmark for performance and reliability in the LED lighting industry.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED production infrastructure, strategically located within the Pearl River Delta’s robust electronics supply chain. This factory is purpose-built for high-volume, precision LED lighting manufacturing, featuring a cleanroom environment specifically designed for SMT assembly and rigorous quality control processes essential for reliable products like strip cabinet lighting.

The SMT production line forms the core of our capability, equipped with state-of-the-art automated placement machines from leading manufacturers such as Juki and Panasonic. These systems handle components ranging from ultra-small 0201 LEDs and resistors to larger ICs with exceptional precision, typically achieving placement accuracy within ±25 microns. High-speed placement heads operate efficiently for standard components, while flexible heads manage complex board geometries common in custom strip lighting designs. The lines are fully integrated with automated solder paste inspection (SPI) and 3D automated optical inspection (AOI) systems immediately post-reflow, ensuring solder joint integrity and component placement accuracy are verified in real-time before products move to subsequent stages. This setup supports high-mix production, crucial for fulfilling diverse OEM strip lighting requirements.

A critical phase for strip cabinet lighting reliability is the comprehensive aging test process. All assembled LED strips undergo a minimum 72-hour continuous operational burn-in at elevated temperatures, typically maintained at 45°C, significantly exceeding standard ambient conditions. This extended stress test occurs on dedicated aging racks where strips operate at full rated current. Voltage and current are continuously monitored, and any early-life failures or significant lumen depreciation are immediately flagged for root cause analysis and corrective action. This meticulous protocol ensures only strips demonstrating stable thermal performance and consistent light output progress to final packaging, directly addressing the longevity demands of cabinet lighting applications where heat buildup can be a concern.

Our OEM capability for strip cabinet lighting is a core strength, supported by the full suite of engineering and production resources within the Jiangmen facility. We offer end-to-end service from initial concept through to finished goods. This includes custom optical design (lens selection, diffuser integration), precise PCB layout for thermal management and flexibility requirements, tailored driver integration (constant current/voltage, dimming protocols), and bespoke mechanical configurations (adhesive types, connectors, cut points). The factory handles all aspects of production control, including strict material sourcing against client specifications, in-process quality checks at multiple stages, and final functional and visual inspection. We readily accommodate specific branding, labeling, packaging configurations, and documentation needs. Compliance with major international safety and performance standards (UL, CE, RoHS) is integral to the process, and our ERP system provides full traceability from raw material reels to finished strip reels, ensuring consistency and accountability for every OEM order. The combination of advanced SMT, rigorous aging protocols, and deep OEM experience makes the Jiangmen factory particularly well-suited for producing high-reliability, custom strip lighting solutions for demanding cabinet applications.

Application Scenarios

Strip cabinet lighting is a versatile and energy-efficient lighting solution that enhances visibility, aesthetics, and functionality in various commercial environments. It is commonly used in hotels, malls, and offices, particularly in areas where focused, low-profile illumination is needed.

In hotels, strip cabinet lighting is ideal for illuminating front desks, reception cabinets, display niches, and vanity units in guest rooms. It adds a modern, elegant touch while ensuring that important areas are well-lit for both staff and guests. Under-cabinet strips in hotel lobbies or concierge desks provide subtle ambient lighting that improves visibility without creating glare.

In malls, strip lighting is frequently installed in retail display cabinets, kiosks, and fitting rooms. It highlights merchandise effectively, drawing customers’ attention to products while maintaining a clean and unobtrusive design. Backlit shelving and glass display cases benefit greatly from LED strip lighting, offering uniform illumination that enhances color rendering and product appeal.

In offices, strip cabinet lighting is commonly used under overhead cabinets, in filing units, or within built-in shelves. It improves task lighting at workstations, especially in areas where documents or supplies are frequently accessed. It also contributes to a sleek, contemporary office aesthetic, particularly in modern reception areas or executive offices.

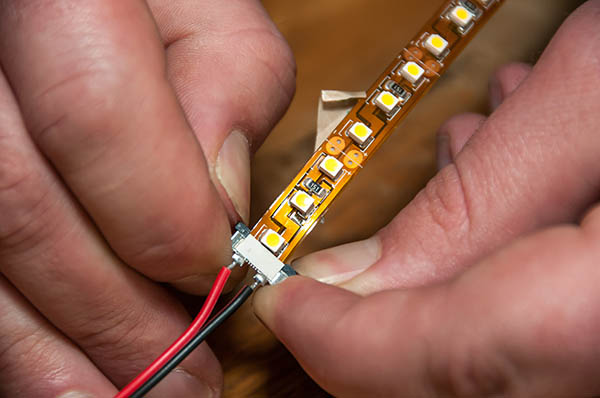

When installing strip cabinet lighting, start by measuring the interior or underside of the cabinet to determine the required length of the strip. Ensure the surface is clean, dry, and free of dust to promote strong adhesion of the backing tape. For better longevity and heat dissipation, consider using aluminum channels, especially in enclosed spaces. Always position the strip facing toward the interior wall or downward to minimize direct visibility of the LEDs, creating a more diffused and pleasant light effect. Use connectors or soldering for seamless joints when multiple strips are needed, and ensure the power supply matches the voltage and current requirements of the LED strips. Finally, test the lighting before finalizing the installation and consider using dimmable drivers to allow adjustable brightness based on ambient conditions and user preference.

Why Choose Beauty STC Lighting

Elevate your cabinet lighting projects with precision-engineered strip solutions from Beauty STC. As your dedicated manufacturing partner, we deliver high-performance LED strips featuring exceptional color rendering CRI 90+ seamless dimming capabilities and robust thermal management specifically optimized for cabinet applications. Our engineering expertise ensures reliable, flicker-free illumination that enhances product visibility and creates premium ambiance in retail displays kitchen installations and commercial environments. Partner with Beauty STC for custom configurations rigorous quality control and responsive technical support tailored to your unique specifications. Contact our lighting solutions manager today at [email protected] to discuss how our strip cabinet lighting can transform your next project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.