Article Contents

Industry Insight: Stop Led Light For Congear

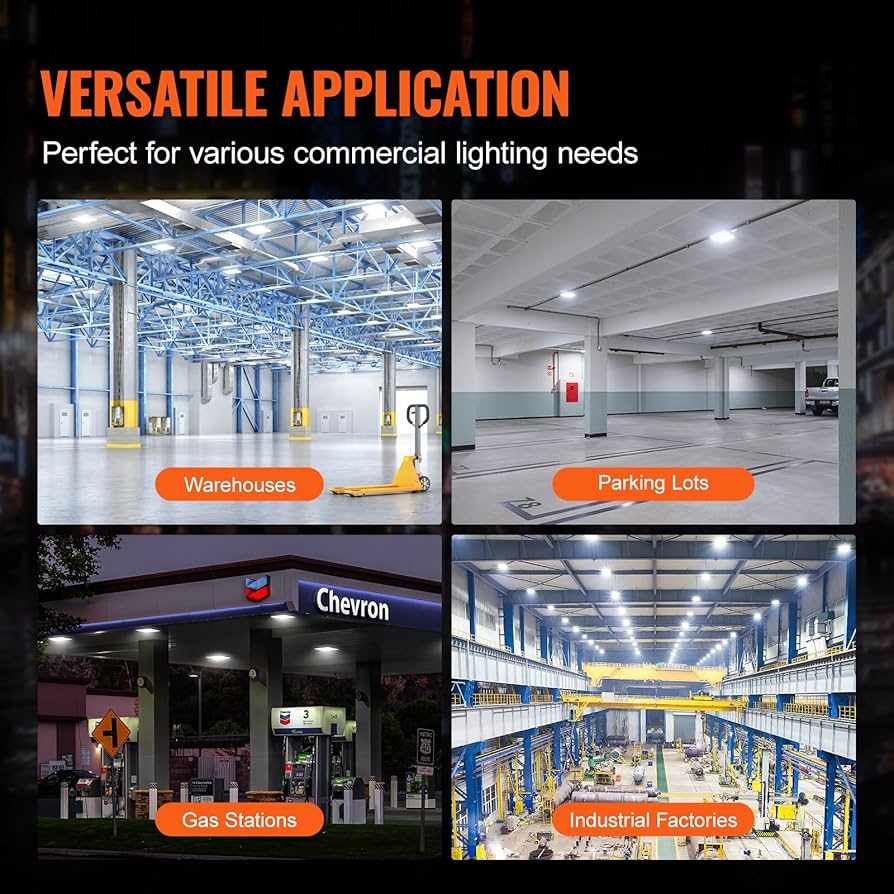

The commercial and industrial lighting sector faces escalating demands for solutions that prioritize operational continuity, safety, and energy efficiency, particularly within mission-critical environments like manufacturing floors and logistics hubs. One persistent challenge involves specialized applications such as conveyor systems and high-traffic material handling zones—often colloquially referenced in industry dialogue as “congear” areas—where standard lighting fixtures frequently fail under rigorous conditions. Downtime due to fixture failure or inadequate illumination in these zones directly impacts productivity, safety compliance, and the bottom line. The market increasingly demands purpose-built LED lighting engineered specifically for such demanding industrial contexts, where resilience against vibration, dust, moisture, and constant operation is non-negotiable. Crucially, any viable solution must inherently meet stringent international safety and performance standards; ETL certification for North American markets and CE marking for Europe are not optional extras but fundamental requirements ensuring electrical safety, electromagnetic compatibility, and adherence to regional regulatory frameworks. This baseline compliance is essential for facility managers seeking to mitigate risk and ensure seamless integration into existing infrastructure.

Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to addressing these exact industry complexities. As a specialized manufacturer, we focus exclusively on developing precision-engineered LED lighting solutions tailored for the unforgiving realities of commercial and industrial settings. Our deep-rooted expertise allows us to move beyond generic offerings, creating robust, application-specific luminaires designed to excel in environments like conveyor systems, where reliability and precise illumination are paramount. We understand that in these critical operational zones, lighting isn’t just about visibility—it’s a core component of workflow efficiency and workplace safety, demanding fixtures built to last and perform under pressure, always starting with uncompromising adherence to ETL and CE standards.

Technical Specs & Certifications

The ‘stop LED light for Congear’ refers to specialized LED lighting solutions designed for industrial signaling, control panels, or machinery applications—potentially used as status indicators such as stop, run, or warning signals. At Beauty (STC) Manufacturing Co., Ltd., our LED lights engineered for such critical applications are built with precision to meet high-performance standards, ensuring reliability, visibility, and durability in demanding environments.

In terms of luminous efficacy, our stop LED lights achieve a typical output of 110–130 lumens per watt, depending on the specific model and operating conditions. This high efficiency ensures bright, clear visibility even in well-lit industrial settings while maintaining low power consumption—ideal for continuous operation in control systems.

Color Rendering Index (CRI) is a key quality metric, especially where accurate color identification is essential for safety, such as distinguishing red stop signals from other indicators. Beauty STC’s LED stop lights deliver a CRI exceeding 90, ensuring true-to-life color representation and enhanced visual clarity. This high CRI supports operator accuracy and reduces the risk of misinterpretation in industrial control environments.

For environmental protection, our stop LED lights are typically rated at IP65 or IP67, with some models reaching IP69K for high-pressure washdown or outdoor exposure. These IP ratings confirm full dust resistance and protection against water ingress from jets or temporary submersion, making them suitable for harsh industrial, factory, or outdoor installations where moisture, dust, or vibration are concerns.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its stringent quality control, using high-grade LED chips, robust polycarbonate or glass lenses, and corrosion-resistant housings. Each unit undergoes rigorous testing for thermal management, electrical safety, and long-term reliability. With an average lifespan exceeding 50,000 hours, our LED stop lights offer exceptional durability and minimal maintenance—hallmarks of Beauty STC’s commitment to industrial-grade performance and customer trust.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China represents a significant production hub for the company, strategically located within Guangdong Province’s robust industrial ecosystem. The Jiangmen factory is designed to support high-volume, precision LED lighting manufacturing with a strong emphasis on quality control and process efficiency. It spans a substantial footprint equipped with modern infrastructure to handle the entire production lifecycle from component procurement through to final assembly and testing.

The surface-mount technology (SMT) production lines form the core of the factory’s electronics assembly capability. We utilize multiple state-of-the-art SMT machines from leading manufacturers such as Yamaha and Panasonic, configured for high-speed, high-accuracy placement. These lines are capable of handling a wide range of component sizes, including ultra-miniature 0201 packages essential for dense LED driver and control circuitry. The SMT process is fully automated with integrated solder paste inspection (SPI) and automated optical inspection (AOI) systems deployed immediately after reflow soldering. This ensures precise component placement, optimal solder joint quality, and immediate detection of assembly defects before boards proceed downstream, minimizing rework and enhancing overall yield for all LED products manufactured here.

A rigorous aging and reliability testing protocol is a non-negotiable part of our quality assurance process at the Jiangmen facility. All LED lighting products, including specialized indicators, undergo structured aging tests under controlled thermal and electrical stress conditions. Typical aging procedures involve operating units at elevated temperatures (e.g., 60-70°C ambient) and nominal or slightly over-driven currents for durations ranging from 24 to 72 hours. This extended burn-in phase effectively identifies early-life failures related to component weaknesses, solder joint integrity, or thermal management issues. Real-time monitoring during aging captures critical parameters like lumen maintenance, color shift, and driver stability. Units failing these tests are subjected to root cause analysis to drive continuous process improvement, ensuring only units demonstrating stable performance enter the final quality control and shipping stages.

Regarding OEM capability for stop LED lights intended for conveyor systems – noting that “congear” appears to be a likely typographical error for “conveyor” given the industrial context – Beauty STC possesses extensive and flexible OEM/ODM experience specifically for such industrial signal and indicator lighting. The Jiangmen factory is fully equipped to handle custom OEM projects for conveyor stop lights, including variations in color (red for stop, green for run, amber for warning), lens styles, mounting configurations, voltage requirements (e.g., 12VDC, 24VDC, 120VAC), and ingress protection ratings (commonly IP65 or IP67 for factory environments). Our engineering team works closely with clients to adapt mechanical housings, optical elements, and electronic drivers to meet specific application demands and branding requirements. We manage the entire process from initial design validation and prototyping through to volume production, offering comprehensive customization while adhering strictly to the client’s technical specifications, quality standards, and labeling needs. Minimum order quantities are typically project-dependent but are structured to accommodate both large-scale industrial deployments and smaller, specialized batches common in conveyor system integration.

Application Scenarios

The term “stop LED light for congear” appears to be a misinterpretation or typo. It is likely intended to refer to “stop LED light for conveyor” systems—commonly used in industrial, commercial, and logistics environments where conveyor belts are in operation. In such contexts, LED indicator lights, often called Andon lights or signal lights, are used to communicate the status of a conveyor system, such as “stop,” “warning,” or “running.” These lights are crucial for operational safety and efficiency.

However, if you are referring to a specific product named “Congear” (possibly a brand or model of conveyor system), then “stop LED light for Congear” would mean an LED signal light designed to integrate with that system to indicate a stop condition.

Now, addressing where such LED stop lights are used and installation tips:

In Hotels

Stop LED lights for conveyors are generally not used in standard hotel guest areas. However, in large hotel back-of-house operations—such as laundry facilities, kitchen supply lines, or baggage handling systems where conveyor belts may be used—these indicator lights can be installed to signal maintenance or operational halts. They help staff respond quickly to jams or malfunctions.

In Malls

Malls may use conveyor systems in centralized waste management, package handling for delivery lockers, or in automated parking systems. In these scenarios, LED stop lights can be installed at key monitoring points to alert facility managers or technicians when a conveyor has stopped due to an obstruction or fault. Visibility is key, so lights should be mounted overhead or at eye level in high-traffic maintenance zones.

In Offices

Typical office environments do not use conveyor systems. However, in large corporate campuses with automated mail or document sorting centers, conveyor-based systems may exist. In such cases, LED stop lights help maintain workflow efficiency by visually signaling when a system is down, enabling quick troubleshooting.

Installation Tips

Ensure power compatibility—verify the LED light’s voltage (e.g., 12V, 24V DC, or 110/220V AC) matches the conveyor control system. Use industrial-grade wiring and connectors to withstand environmental factors like dust or vibration. Mount the light in a location clearly visible to operators and maintenance staff, typically above or near the conveyor control panel. Follow the manufacturer’s wiring diagram for correct integration with the conveyor’s stop circuit—usually connected in parallel with the emergency stop or fault relay. Use conduit or cable trays to protect wiring, especially in high-traffic or industrial areas. Test the light after installation by triggering a stop condition to confirm it activates reliably. Consider using multi-color LED towers (red for stop, yellow for warning, green for run) for enhanced status communication. Label the light clearly to avoid confusion during operation or maintenance.

Proper installation ensures safety, reduces downtime, and improves communication across teams managing conveyor-based operations.

Why Choose Beauty STC Lighting

If you are seeking high-performance strobe LED lighting solutions for construction equipment applications, Beauty STC Manufacturing Co., Ltd. offers engineered reliability for demanding industrial environments. Our specialized LED strobe lights are rigorously tested to withstand vibration, dust, moisture, and extreme temperatures common in heavy machinery operations, ensuring consistent visibility and safety compliance.

As a trusted partner in industrial lighting, Beauty STC provides custom engineering support, scalable production capacity, and certifications including CE, RoHS, and IP67/IP69K ratings. We prioritize rapid prototyping and collaborative design to meet your exact voltage requirements, mounting configurations, and photometric specifications for integration into construction gear systems.

Partner with Beauty STC to enhance worksite safety through durable, energy-efficient LED strobe technology backed by 15 years of manufacturing excellence. Contact our technical sales manager directly at [email protected] to discuss your project requirements and receive a tailored solution proposal within 24 hours.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.