Article Contents

Industry Insight: Sticking Led Strip Lights

The commercial and industrial lighting sector increasingly demands flexible, efficient, and rapidly deployable solutions, where adhesive-backed LED strip lights have become indispensable. Far beyond simple convenience, reliable “sticking” performance is critical in demanding environments – from warehouse ceilings vibrating with forklift traffic to retail displays requiring precise, shadow-free illumination, or factory floors needing resilient task lighting. Failure due to adhesive degradation under temperature extremes, humidity, or substrate incompatibility leads to costly rework, safety hazards, and operational downtime. This underscores why robust adhesion science and rigorous third-party safety certifications like ETL (verifying compliance with North American safety standards) and CE (indicating conformity with essential health and safety requirements for the European market) are non-negotiable for professional installations. At Beauty STC, we have engineered solutions for these exact challenges since our founding in 1998. Our deep expertise in LED technology and material science, forged over 25 years serving global commercial and industrial clients, ensures our strip lights deliver not just brilliant, energy-efficient light, but also the unwavering, certified adhesion professionals rely on for lasting, safe, and code-compliant installations.

Technical Specs & Certifications

Sticking LED strip lights from Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and reliability, combining efficient lighting with robust construction. These adhesive-backed LED strips are designed for easy installation on a variety of surfaces, making them ideal for architectural accent lighting, under-cabinet lighting, cove lighting, and commercial display applications.

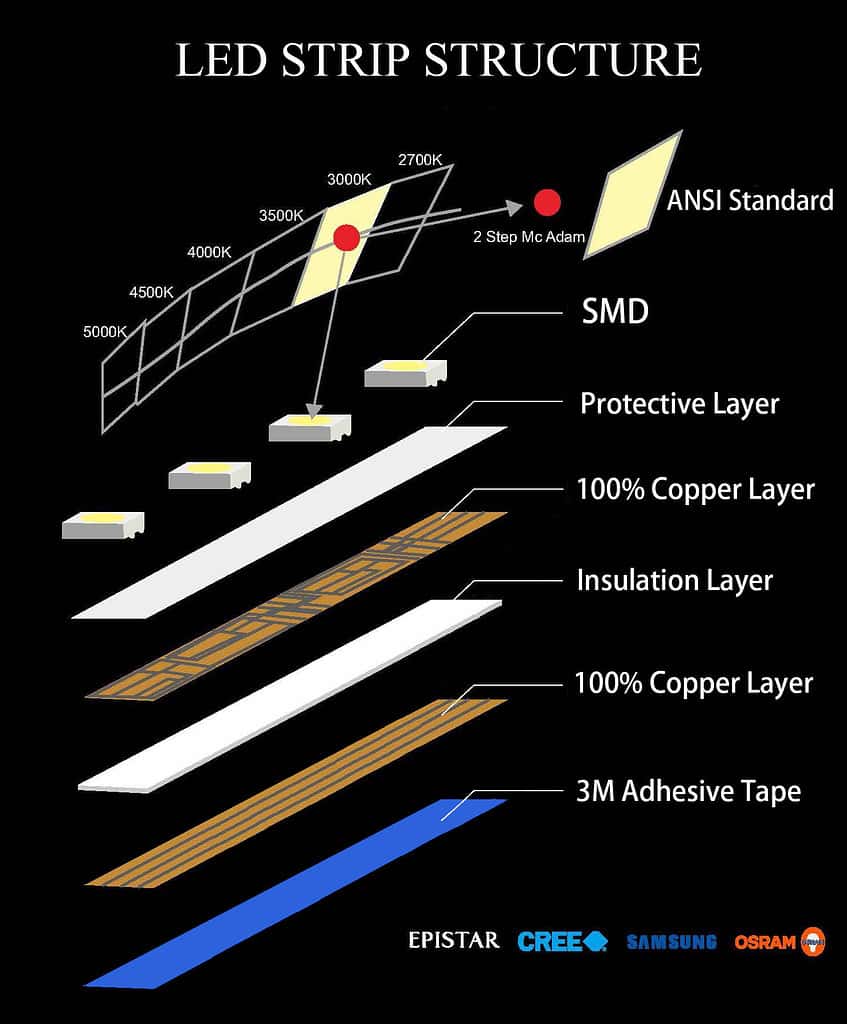

In terms of efficiency, Beauty STC’s LED strip lights typically deliver between 100 to 130 lumens per watt, depending on the specific model and LED density. This high lumens-per-watt ratio ensures energy-efficient operation, reducing power consumption while maintaining bright, consistent illumination. The use of high-quality SMD LEDs—commonly SMD2835 or SMD5050—contributes to this efficiency, enabling longer run times and lower operating costs over the product’s lifespan.

Color rendering is a key strength of Beauty STC’s LED strips. All premium models are designed with a Color Rendering Index (CRI) greater than 90, ensuring accurate and vibrant color representation. This high CRI is especially beneficial in retail, hospitality, and residential environments where true-to-life color appearance is critical. The LEDs are available in multiple color temperatures ranging from warm white (2700K–3000K) to cool white (6000K–6500K), allowing for flexibility in design and ambiance.

Regarding environmental protection, Beauty STC offers sticking LED strip lights in various IP (Ingress Protection) ratings to suit different application needs. IP20-rated strips are suitable for dry, indoor environments where dust and moisture are not concerns. For damp or outdoor locations, IP65-rated strips provide protection against water jets and dust ingress, making them ideal for kitchens, bathrooms, or outdoor signage. Fully encapsulated IP67 and IP68-rated versions are also available, offering complete dust tightness and the ability to withstand temporary or continuous submersion in water—perfect for landscape lighting, pool perimeters, or marine applications.

Beauty STC maintains rigorous quality control throughout the manufacturing process. Their LED strips are built with high-grade flexible PCBs, stable adhesive backings (3M tape or equivalent), and consistent soldering practices to prevent premature failure. Each batch undergoes thermal, electrical, and photometric testing to ensure long life—typically rated at 50,000 hours—and stable lumen maintenance (L70 or better). The company adheres to international standards including RoHS, CE, and UL certifications where applicable, reflecting their commitment to safety, sustainability, and performance.

In summary, Beauty STC’s sticking LED strip lights offer high efficacy (100–130 lm/W), excellent color fidelity (CRI >90), and versatile IP ratings from IP20 to IP68. Combined with durable materials and stringent quality assurance, these strips represent a premium lighting solution for both residential and commercial applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in advanced LED lighting production, specifically engineered to support high-volume, precision manufacturing with stringent quality control. This modern factory spans over 30,000 square meters and serves as the company’s primary hub for LED strip light production, integrating state-of-the-art automation with rigorous testing protocols to ensure product reliability and performance.

The SMT (Surface Mount Technology) production lines within the Jiangmen factory are a cornerstone of our capability. We operate multiple high-speed Yamaha YS series SMT machines, configured for optimal throughput and precision handling of miniature components critical to LED strip manufacturing. These lines are fully automated, featuring advanced vision systems capable of accurately placing components as small as 0201 metric package size, which is essential for the dense circuitry found in high-CRI and high-power density LED strips. The SMT process includes precise solder paste application via stencil printers, component placement, and reflow soldering in nitrogen-enriched ovens to minimize oxidation and ensure robust solder joints. This setup allows for continuous, high-yield production runs exceeding 12 hours, maintaining tight tolerances for consistent light output and color uniformity across every meter of strip produced.

Aging and reliability testing are deeply embedded in our manufacturing workflow at the Jiangmen site. All LED strip lights undergo a mandatory 72-hour burn-in test at elevated temperatures, typically 50°C, significantly exceeding standard industry practice. This extended aging process occurs in dedicated environmental chambers with automated monitoring systems that track voltage, current, and luminous flux in real-time, identifying early-life failures or performance drift before products leave the factory. Following the high-temperature aging phase, strips undergo a second functional verification test at nominal operating conditions to confirm stability. This dual-stage aging protocol, combined with 100% in-line automated optical inspection (AOI) after SMT and final electrical testing, ensures that only strips meeting our strict lumen maintenance and color consistency specifications are approved for shipment, minimizing field failures and supporting our long-term warranty commitments.

Our OEM capability for adhesive-backed LED strip lights is a key strength developed and refined at the Jiangmen facility. We offer comprehensive customization services starting from the reel-to-reel manufacturing stage, including tailored lengths cut to precise customer specifications, custom connector types and placements, bespoke PCB widths and copper weights, specialized silicone encapsulation profiles, and formulation of adhesive compounds for specific substrates or environmental conditions. The factory supports rapid prototyping with quick-turn SMT changeovers, allowing clients to validate designs efficiently. Crucially, we handle all aspects of OEM production in-house, from raw material sourcing through final packaging with custom branding, without requiring minimum order quantities for standard strip configurations, providing significant flexibility for partners seeking differentiated lighting solutions. This integrated approach ensures consistent quality control throughout the entire value chain for every OEM project.

Application Scenarios

Sticking LED strip lights are highly versatile and can enhance both the functionality and aesthetics of various commercial environments including hotels, malls, and offices. In hotels, they are ideal for illuminating guest room coves, under-bed frames, headboards, and bathroom vanities to create a welcoming and luxurious ambiance. They also work well in hotel corridors, lobbies, and reception desks, providing soft indirect lighting that improves wayfinding while contributing to a modern design.

In malls, LED strip lights are commonly used in retail displays, signage backlighting, and architectural coves to highlight products and brand elements. They can be installed beneath shelves, in display cases, and along escalator handrails or stair treads to improve visibility and create visual interest. Their flexibility allows them to follow curved structures, making them perfect for dynamic architectural features in common areas.

In offices, sticking LED strip lights are effective for under-cabinet lighting, desk grommets, conference room accents, and suspended ceiling perimeters. They contribute to a well-lit workspace without glare and can support circadian lighting strategies when tunable white strips are used. Accent lighting in reception areas or breakout zones also helps create a professional yet inviting atmosphere.

When installing sticking LED strip lights, ensure the surface is clean, dry, and free of dust or grease to maximize adhesive bond strength. Wipe the area with isopropyl alcohol before application. Press the strip firmly along its entire length for at least 30 seconds to ensure proper adhesion. Avoid installing on textured, porous, or uneven surfaces unless using mounting clips or aluminum channels for better support and heat dissipation. For longer runs, use a power supply with adequate capacity and consider central power injection to prevent voltage drop. Always follow the manufacturer’s instructions for cutting, connecting, and waterproofing if applicable. In high-traffic or public areas, consider using protective diffusers or channels to shield the strips from damage and reduce maintenance needs.

Why Choose Beauty STC Lighting

Transform your lighting installations with professional-grade reliability by partnering with Beauty STC for your LED strip light projects. Our engineering expertise ensures optimal adhesion and performance across diverse applications, from residential cove lighting to commercial architectural features. We rigorously test mounting solutions for surface compatibility, thermal stability, and long-term durability, eliminating common failure points like tape delamination or uneven light distribution.

Partnering with Beauty STC means accessing tailored technical guidance on surface preparation, optimal mounting methods, and environmental considerations specific to your project requirements. Our team provides certified adhesive solutions validated for challenging conditions including high humidity, temperature fluctuations, and textured surfaces. This engineering-first approach prevents costly rework and ensures consistent illumination quality throughout the product lifecycle.

Contact our dedicated technical partnership manager at [email protected] to discuss your specifications. We will provide comprehensive support including substrate analysis, adhesive selection protocols, and installation best practices to guarantee flawless integration of your LED strip lighting systems. Rely on Beauty STC’s engineering rigor to deliver installations that perform as intended from day one through years of operation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.