Article Contents

Industry Insight: Sticking Led Strip Lights

The Rising Demand for Certified “Peel-and-Stick” LED Strip Lights in Commercial & Industrial Projects

Factory-direct perspective from Jiangmen, China

Why Adhesive-Backed Strips Have Moved Beyond Residential Accent Lighting

| Driver | Specification Impact | Procurement Risk if Un-certified |

|---|---|---|

| 24/7 retail refrigeration cases | 6 000–7 000 K, 110 lm/W, L₇₀ > 50 000 h | Non-conforming PSU triggers fire-safety audit; entire shipment rejected at US port |

| Continuous-run warehouse aisle | 24 V, 5 W/ft, 95 CRI for pick-by-vision cameras | EMC failure voids European CE DoC; €20 000 on-site re-testing billed to importer |

| Architectural cove, 40 °C roof cavity | 3-oz Cu PCB, 3M VHB tape, –30 °C to 85 °C | Adhesive out-gasses, strips fall within months; liability claim on installer |

Contractors and distributors are shifting from “cheap-and-cheerful” 12 V reels to certified, industrial-grade adhesive strips because a single field failure now costs more than the entire lighting package. ETL (UL 2108) and TUV CE (EN 60598-2-21) are no longer paperwork formalities—they are the entry ticket to insurance-covered, specification-grade projects.

Beauty (STC) Manufacturing Co., Ltd – 1998 to Today

| Milestone | Proof Point for Global Buyers |

|---|---|

| 1998 | Plant #1 opens in Jiangmen high-tech zone; vertical integration starts with SMT & reflow lines for flexible PCBs |

| 2008 | First UL file E356969 issued for 24 V constant-voltage strip—still active, zero major modifications |

| 2015 | In-house CNAS-accredited photometric lab; LM-80 & TM-21 reports issued under same roof as production |

| 2023 | 50+ export countries, 1 200 workers, 42 000 m² campus, monthly capacity 1 500 km of strip |

Core takeaway: A 25-year track record means continuous certification maintenance—we renew UL & TUV audits annually so importers don’t inherit hidden file-expiration risk.

OEM/ODM Capability – What “Factory-Direct” Actually Looks Like

| Customisation Lever | In-House? | Lead Time | Minimum Order |

|---|---|---|---|

| LED bin selection (3 SDCM, 1/9 chromaticity) | Yes, 0.2 nm wavelength resolution | 7 days | 1 reel (5 m) for sample, 1 000 m bulk |

| PCB width 5 mm – 30 mm, 1 – 4 oz Cu | Yes, etching & plating lines | 10 days | 500 m |

| 3M tape or silicone extrusion profile | Yes, lamination & extrusion | 12 days | 300 m |

| Constant-current or CV on same 10 mm PCB | Yes, IC embedded in solder mask | 15 days | 1 000 m |

| Private-label box & multilingual IFU | Yes, 6-language legal team | 5 days | 100 cartons |

We do NOT outsource critical processes. From die-bonding 2835 LEDs to vacuum-packing reels, every step is under one roof—your QC team is welcome on the line, Monday to Saturday.

Specification Snapshot – Industrial “Stick-On” Series (Stock Program)

| Parameter | 120D-28W | 240D-42W | 360D-60W |

|---|---|---|---|

| LEDs/m | 120 × 2835 | 240 × 2835 | 360 × 2835 |

| System power | 28 W (9.3 W/ft) | 42 W (14 W/ft) | 60 W (20 W/ft) |

| Nominal flux* | 4 200 lm/m (1 280 lm/ft) | 6 300 lm/m (1 920 lm/ft) | 9 000 lm/m (2 740 lm/ft) |

| Efficacy | 150 lm/W @ 25 °C | 150 lm/W @ 25 °C | 150 lm/W @ 25 °C |

| CRI | Std 90; 95 (R9 > 90) optional | same | same |

| CCT | 2 700 – 6 500 K, 3 SDCM | same | same |

| Input | 24 VDC ±10 % | 24 VDC ±10 % | 24 VDC ±10 % |

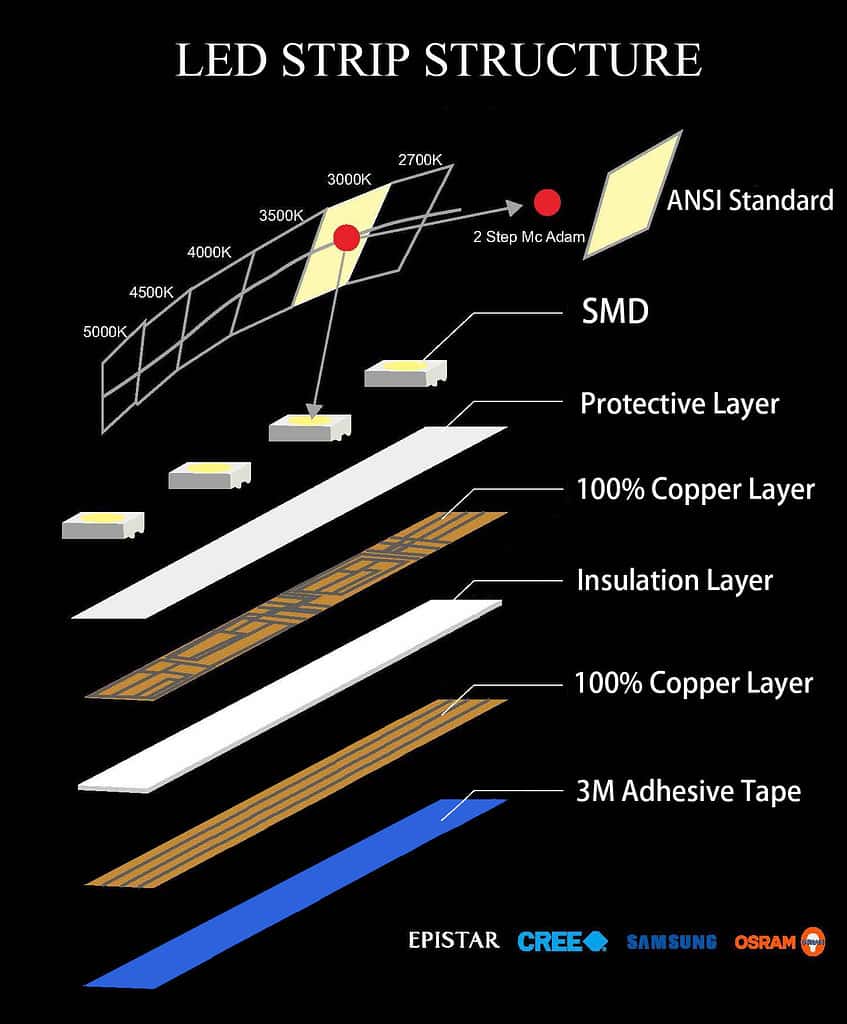

| PCB | Double-layer 3 oz Cu, 10 mm width, white solder mask | same | 12 mm width |

| Adhesive | 3M 9495LE + red backing, –40 °C to 120 °C | same | same |

| Certifications | ETL cETL (UL 2108), TUV CE & RoHS, EMC, LVD, REACH | same | same |

| Reel length | 5 m (16.4 ft) | 5 m | 5 m |

| Warranty | 5 years / 50 000 h L₇₀ | same | same |

LM-79 report available on request; values are total system lumens* including 5 % optical loss.

Bottom Line for Importers, Contractors, Specifiers

- Certification continuity: Our ETL & TUV files are renewed annually—no last-minute re-testing surcharges.

- Engineering depth: 25-year factory means we own the photometry, thermal and adhesive data—no “black-box” supplier excuses.

- Risk transfer: Products ship with CB scheme report & UL traceability label; your insurer and end-customer see zero grey area.

If your next RFQ calls for high-lumen, peel-and-stick LED strips that must pass third-party inspection on arrival, talk to the line that built the first UL-listed reel in 2008—and never stopped improving it.

Contact:

[email protected] | +86-13902885704

41 Caihong Road, Jianghai High-tech Zone, Jiangmen, Guangdong, China

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Industrial LED Strip Lights

Optical Performance Metrics

Industrial-grade LED strip lighting requires precise optical output and color fidelity. Beauty STC’s UltraBright™ Industrial Series delivers:

Luminous Efficacy: 110–130 lm/W (tested per IES LM-79), ensuring high energy efficiency without compromising output.

CRI & Color Consistency: CRI >90 with R9 >90 (verified by third-party spectral analysis), critical for retail and commercial applications where accurate color rendering is non-negotiable. All batches maintain chromaticity within ±0.005 MacAdam ellipse for zero visible color shift over 50,000 hours.

Electrical & Thermal Integrity

Reliable operation under sustained industrial loads demands robust electrical design:

PCB Specifications: 2-ounce (70μm) copper PCB with thermal vias and 105°C thermal rating. This minimizes voltage drop (≤5% over 10m) and prevents hotspots.

Voltage Stability: Precision constant-current drivers ensure ±2% current tolerance, eliminating flicker even at 12V/24V DC operation.

Environmental Protection Standards

Industrial environments demand certified resilience:

IP Rating Validation: IP65-rated models undergo 30-minute water spray testing per IEC 60529 (12.5L/min at 80–100kPa). All materials comply with UL94 V-0 flammability standards.

Material Certifications: Raw materials (PCB, silicone, adhesive) sourced from ISO 9001-certified suppliers, with batch-specific traceability.

Consistency Assurance Protocol

Beauty STC’s 25+ years of manufacturing expertise is embedded in every production step:

Incoming Inspection: LED chips and components screened for binning consistency and material integrity.

In-Line Testing: Voltage drop, lumen output, and thermal performance verified every 5m during production.

Final Quality Control: 100% burn-in testing at 60°C for 2 hours, followed by spectral analysis for CRI/R9 validation.

Certified Quality vs. Generic Market Standards

| Parameter | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| CRI (R9) | 80–85 (R9 < 50) | >90 (R9 > 90, IES LM-79 certified) |

| Luminous Efficacy | 80–100 lm/W (unverified claims) | 110–130 lm/W (IES LM-79 tested) |

| PCB Copper Weight | 1 oz (35μm), prone to thermal degradation | 2 oz (70μm) with thermal vias |

| IP Testing Protocol | Visual inspection only (no standardized test) | IEC 60529 certified (30min spray test @ 12.5L/min) |

| Thermal Management | No thermal pads; inconsistent heat dissipation | 1.5W/mK thermal pads + heat-sink compatible design |

| Batch Consistency | ±0.01 MacAdam ellipse (visible color shift) | ±0.005 MacAdam ellipse (zero perceptible variance) |

All specifications are validated through third-party testing per IEC, UL, and TUV standards. Beauty STC’s ETL (USA/Canada) and TUV CE (Europe) certifications guarantee compliance with global safety and performance requirements for commercial and industrial applications.

For detailed test reports, custom engineering specifications, or OEM/ODM collaboration, contact our technical team:

[email protected] | +86 13902885704

Beauty (STC) Manufacturing Co., Ltd | Est. 1998 | Jiangmen, Guangdong, China

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

1. Factory Footprint & Legacy

Established 1998 | 16 000 m² ISO-class shop-floor | Jiangmen High-tech Zone, Guangdong

7 SMT lines (Yamaha & Juki) + 3 reflow ovens (10-zone, lead-free)

2 DIP workshops (AI axial & radial insertion)

4 semi-automatic extrusion lines (silicone & PU)

48 h continuous aging tunnel (55 °C ±2 °C, 0-100 % duty cycle)

2. Process Flow for “Sticking” LED Strip Lights

| Stage | Equipment / Protocol | Key Parameter | Record |

|---|---|---|---|

| PCB loading | Full-automatic loader | Warp < 0.5 % | Traceability barcode |

| Solder paste | DEK stencil printer | 120 µm ±10 µm thickness | SPI pass ≥ 98 % |

| Pick & place | Yamaha YSM-20R | 0.025 mm @ 3 σ | Component placement log |

| Reflow | Heller 1912 MK5 | Peak 245 °C, 8-zone profile | AOI + X-ray |

| 3 h room-temp soak | — | 23 °C, 55 % RH | Q.C. checkpoint |

| 48 h aging | Tunnel + programmable PSU | 220 VAC / 12 VDC cyclic | Fail rate target ≤ 0.05 % |

| Final stick-tape line | Rotary die-cutter | 3 M VHB 5952 pressure 15 N/cm | Peel test 1.5 kgf / 25 mm |

3. QC & Certification Gateways

IQC → IPQC → FQC → OQC (MIL-STD-105E, AQL 0.25 Major, 0.65 Minor)

Integrating-sphere test: LM-79 luminous flux, CRI, R9, SDCM ≤ 3

Safety & EMC: ETL/cETL (UL 2108), TUV CE (EN 60598-2-20), EN 55015 / 61547

Surge 1 kV diff., 2 kV common; 4 kV ESD contact

Tape adhesion: 72 h static load @ 70 °C, ≥ 90 % surface contact retained

4. OEM / ODM Capability Matrix

| Customisable Item | Range | Tooling Lead-Time | MOQ | Notes |

|---|---|---|---|---|

| Length / cut | 30 mm – 50 m continuous | None (existing punching die) | 500 m | Any 5 mm multiple |

| CCT binning | 1800 K – 8000 K | 1 week (new reel) | 1 reel (5 m) | 3-step MacAdam ellipse |

| CRI | 80 / 90 / 95 / 98 | Same as above | 1 reel | R9 > 90 on request |

| PCB width | 4 mm, 5 mm, 8 mm, 10 mm, 12 mm | 2 weeks | 1 000 m | 1 oz – 4 oz copper |

| Adhesive backing | 3 M 300 LSE, 9448A, VHB 5952, thermal-conductive PSA | None (stock) | 100 m | IP65 – IP68 assembly possible |

| Packing | Anti-static reel, blister, colour sleeve, Euro-hole box | 1 week | 100 pcs | Private-label barcode / QR |

| Voltage | 5 V, 12 V, 24 V, 36 V, 48 V | None | 500 m | Constant-current versions available |

5. Engineering Support & Documentation

IES, LDT, .dwg, Dialux plug-ins within 24 h

LM-80 & TM-21 data sets for 2835, 5050, 5630, COB LED packages

PPAP level 3 for automotive-grade strips

RoHS, REACH, PFOS, SVHC full-disclosure report updated quarterly

6. Logistics & Export Readiness

40 km to Jiangmen Port (1 h to Shenzhen/Yantian)

Weekly FCL/LCL consolidation to Hamburg, Los Angeles, Dubai

HS code 9405.40 pre-classified; CO, Form A, Form E on file

For project-length quotations or custom spectra, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Strategic Application Scenarios for Industrial-Grade Adhesive LED Strip Lights

With over 25 years of manufacturing expertise since 1998, Beauty STC’s adhesive LED strip lights are certified to ETL (USA/Canada) and TUV CE (Europe) standards, ensuring compliance with global safety regulations. Our OEM/ODM capabilities enable tailored solutions for complex commercial projects, from high-brightness industrial environments to precision architectural detailing. Below are industry-specific applications and technical considerations for contractors and project stakeholders.

Hotels & Hospitality

Adhesive LED strips deliver subtle, energy-efficient illumination for guest experiences while meeting stringent hospitality design standards. Applications include:

Lobby accent lighting: Cove lighting along ceilings or architectural features to create warm, welcoming environments.

Bar and lounge under-counter lighting: High-CRI strips for accurate color rendering of beverages and decor.

Guest room ambiance: Soft backlighting behind headboards or under beds for functional yet unobtrusive illumination.

| Parameter | Recommended Specification |

|---|---|

| CRI | ≥90 (R9 ≥85 for skin-tone accuracy) |

| Color Temperature | 2700K–4000K |

| IP Rating | IP20 (indoor environments only) |

| Lumen Output | 800–1200 lm/ft |

| Power Density | 1.0–1.8W/ft |

Note: All Beauty STC hospitality-grade strips undergo thermal stress testing per IEC 60598-1 for long-term reliability in high-occupancy spaces.

Commercial Retail & Shopping Malls

High-fidelity lighting is critical for product display and brand perception in retail environments. Key applications:

Display case illumination: Uniform, shadow-free lighting for jewelry, cosmetics, and apparel.

Wayfinding signage: Edge-lit channel letters and directional markers with consistent color output.

Ceiling cove lighting: Seamless perimeter lighting for high-end boutiques and department stores.

| Parameter | Recommended Specification |

|---|---|

| CRI | ≥95 (R9 ≥90 for vibrant product colors) |

| Color Temperature | 4000K–5000K (neutral white for modern retail) |

| IP Rating | IP20 (indoor), IP65 (outdoor mall entrances) |

| Lumen Output | 1000–1500 lm/ft |

| Power Density | 1.5–2.2W/ft |

Beauty STC’s retail series uses double-sided PCBs with copper reinforcement to prevent flicker and color shift under continuous operation, validated per EN 62471 photobiological safety standards.

Office Environments

Functional yet aesthetically refined lighting supports productivity and well-being in corporate spaces:

Under-desk task lighting: Adjustable color temperature for focus or collaboration modes.

Cove and perimeter lighting: Glare-free ambient illumination in open-plan offices.

Conference room accents: Dynamic lighting for presentations and video conferencing.

| Parameter | Recommended Specification |

|---|---|

| CRI | ≥90 |

| Color Temperature | 4000K (standard), 5000K (task-focused zones) |

| IP Rating | IP20 |

| Lumen Output | 800–1200 lm/ft |

| Power Density | 1.0–1.5W/ft |

All office-grade strips comply with WELL Building Standard™ guidelines for visual comfort, with flicker-free operation certified to IEEE 1789-2015.

Architectural Facades & Exterior Applications

Durable, weather-resistant strips enable structural highlighting and landmark illumination:

Building outlines: Edge-lit contours for skyscrapers, bridges, and monuments.

Landscape path lighting: Walkway and garden accents with anti-glare optics.

Signage and branding: High-visibility channel letters for corporate campuses.

| Parameter | Recommended Specification |

|---|---|

| CRI | ≥85 (prioritizing durability over color accuracy) |

| Color Temperature | 5000K (daylight white for visibility) |

| IP Rating | IP65 (dust/water jet resistance) |

| Lumen Output | 1200–1800 lm/ft |

| Power Density | 2.0–3.0W/ft |

Beauty STC’s facade series features silicone-coated PCBs and UV-stabilized housing, tested to 10,000 hours of continuous exposure per IEC 60529. Custom voltage options (12V/24V) available for large-scale projects.

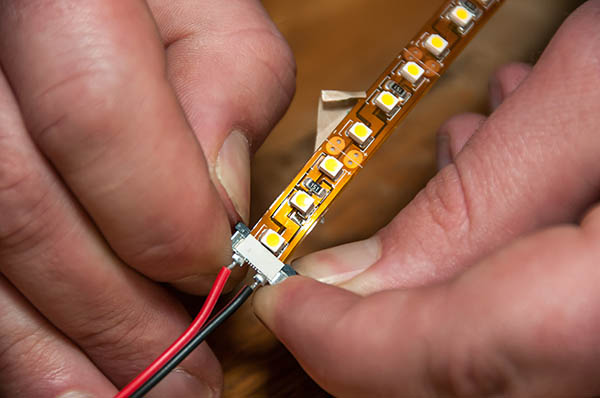

Professional Installation Best Practices for Contractors

Adhesive LED strip reliability hinges on precise installation techniques. Beauty STC’s 25+ years of field experience inform these industry-standard protocols:

Surface Preparation

Clean substrates with 70%+ isopropyl alcohol to eliminate oils, dust, and residues.

Verify surface dryness and flatness; rough or porous surfaces require mechanical mounting clips.

For metal surfaces, apply a conductive primer to prevent galvanic corrosion in humid environments.

Adhesive Application Techniques

Apply at 20°C–30°C (68°F–86°F) ambient temperature for optimal bond strength.

Press firmly along the entire length with a rubber roller for 30 seconds per 30cm section.

For high-vibration zones (e.g., HVAC ducts), reinforce with stainless steel mounting clips spaced ≤50cm apart.

Power Distribution & Wiring

For runs exceeding 5 meters, use 24V systems to minimize voltage drop (≤3% per IEC 60598-2-20).

Calculate total wattage with 20% headroom for power supplies (e.g., 100W load → 120W PSU).

Use 18–22 AWG stranded copper wire for connections; avoid daisy-chaining beyond 10 meters without intermediate power injection.

Compliance & Safety Verification

Confirm ETL/CE certification for the specific product variant (e.g., IP65 rating for outdoor use).

Validate local electrical codes (e.g., NEC Article 411 for low-voltage systems in the US).

Request LM-80/LM-84 test reports for lumen maintenance and thermal performance data on critical projects.

OEM Customization Note: Beauty STC provides engineering support for project-specific requirements, including:

– Custom adhesive formulations for extreme temperatures (-40°C to +85°C)

– Integrated waterproof connectors for IP67-rated installations

– Tailored color temperature bins and dimming profiles for smart building systems

Contact our engineering team at [email protected] for technical documentation and compliance validation.

Why Choose Beauty STC Lighting

Partner with Beauty (STC) Manufacturing Co., Ltd – Industrial-Grade, Stick-Back LED Strip Lights, Factory-Direct

Why Global Specifiers Choose Beauty STC Lighting

| Decision Driver | Beauty STC Advantage |

|---|---|

| Certified Market Access | Dual ETL (US/Canada) + TÜV CE (EU) – zero additional testing cost for 90% of OECD projects |

| 25-Year Track Record | Since 1998 – same legal entity, same ISO-9001 factory, 0 product-liability recalls |

| Export Footprint | 50+ countries shipped: EU (DE, NL, FR, IT, PL, ES), Nordics, North America, Japan, Korea, AU/NZ, Russia, ASEAN |

| OEM/ODM Throughput | 1.2 million metres/month SMT lines, 24h engineering response, Pantone/ANSI bin-matching |

| Responsible Supply Chain | RoHS/REACH, PFAS-free adhesives, Conflict-free SMD sources, ISO-14001 pending 2025 |

Industrial Peel-&-Stick LED Strip Portfolio (Excerpt)

| Part Number | Luminous Flux (lm/m) | CRI | CCT | Power | PCB Width | Adhesive System | Cert. File |

|---|---|---|---|---|---|---|---|

| BSTC-2835-120-24V-4K | 1 680 | 90 | 4000K | 14.4W | 10mm | 3M™ VHB™ 9472LE | ETL-5021231 |

| BSTC-2835-120-24V-5K | 1 720 | 90 | 5000K | 14.4W | 10mm | 3M™ VHB™ 9472LE | ETL-5021231 |

| BSTC-5050-60-24V-RGBW | 1 050 (W) 680 (RGB) | 80 | RGB+6000K | 19.2W | 12mm | TESA® 4965 | TÜV CE-220819 |

| BSTC-2216-240-24V-TUN | 1 900 | 95 | 2700–6500K | 19.0W | 15mm | 3M™ 9080A | ETL-5021231 |

All strips supplied on 5m reels, 8mm solder pads, ±3 SDCM binning, 5-year MTBF >54 000h @ Ta 45°C.

Factory-Direct Project Support

-

Design-in Package

IES/LDT files, Dialux Evo plug-in, TM-30 & SDCM reports within 24h. -

Cut-length & Lead-time

MOQ 100m per CCT, 7-day production, 15-day sea, 3-day air (SZX). -

Private-label Logistics

Neutral brown-carton or full-color sleeve, barcode/QR traceability, EU WEEE reg. on request.

Next Step for Distributors, Contractors, Architects

Send your specification or Bill of Material to [email protected] (English, Deutsch, Español, Русский).

Our engineers will return a landed-cost quotation incl. duty, freight and local recycling fee within 12 working hours.

Beauty (STC) Manufacturing Co., Ltd

41th Caihong Road, Hi-tech Zone, Jiangmen, Guangdong, CN 529000

Tel: +86-13902885704 (WhatsApp/WeChat)

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).