Article Contents

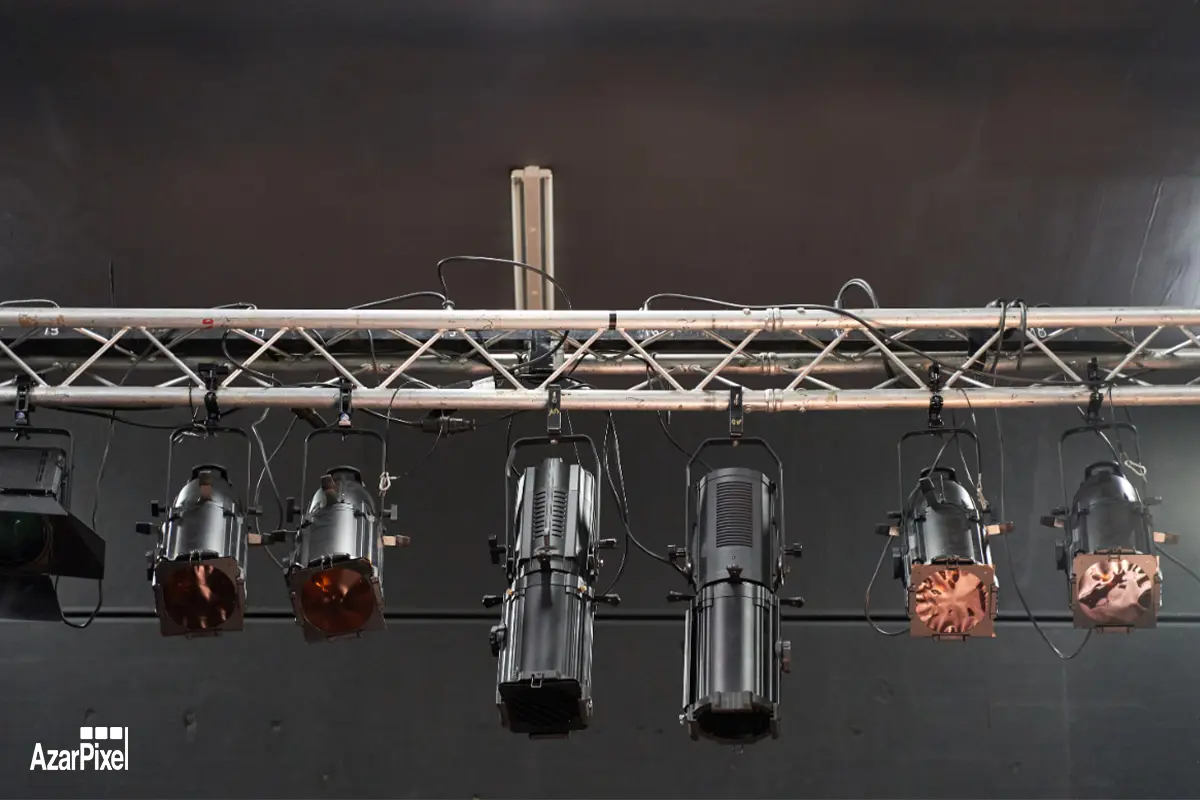

Industry Insight: Stage Lighting Spotlights

Industry Insight: The Evolving Landscape of Professional Stage Lighting in Commercial & Industrial Applications

The modern commercial and industrial lighting landscape has transcended traditional boundaries. What was once confined to theatrical stages now extends into high-end corporate events, premium retail environments, immersive entertainment venues, and even specialized industrial applications requiring precise, durable illumination. As LED technology continues to dominate this sector—driven by demands for energy efficiency, superior color rendering (CRI >90), and intelligent control systems—the expectations for performance, reliability, and regulatory compliance have never been higher.

In this context, ETL and CE certifications are not optional—they are fundamental prerequisites for market access and operational safety. ETL (Intertek) certification validates compliance with North American electrical safety standards (UL/CSA), ensuring fixtures withstand rigorous thermal, electrical, and mechanical stress tests. CE marking (conforming to EU directives like LVD and EMC) guarantees adherence to European safety, electromagnetic compatibility, and environmental regulations. For manufacturers and buyers alike, these certifications mitigate liability risks, prevent costly recalls, and build trust with clients who demand zero tolerance for failure during critical events or in high-traffic commercial spaces.

Beauty STC (STC Manufacturing Co., Ltd.), established in 1998, has spent over 26 years refining this intersection of engineering excellence and global compliance. As a vertically integrated manufacturer specializing in professional-grade LED stage and architectural lighting, we combine decades of hands-on expertise with rigorous R&D processes to deliver solutions that meet the most demanding international standards. Our commitment to ETL/CE-certified production—from thermal management design to robust driver integration—ensures every spotlight not only performs flawlessly but also complies seamlessly with regional regulatory frameworks. For clients seeking reliable, future-ready lighting for commercial events, industrial facilities, or high-stakes architectural installations, Beauty STC represents a proven partner with a legacy of precision, safety, and global export readiness.

Engineered for Excellence. Certified for Trust.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd.

Senior LED Lighting Engineer & Export Manager

Technical Datasheet – Professional Stage Spotlight Series

(Architectural, Theatre & Touring Applications)

-

Core Photometric Performance

• Luminous efficacy: 85 lm/W (warm-white 3 000 K) → 105 lm/W (6 500 K) at 25 °C Ta, Tj 85 °C

– Measured with 1 m integrating sphere, IES LM-79-19 procedure.

– Driver efficiency ≥ 93 % (230 V AC, full load) already included in above figures.

• CRI: Ra ≥ 93 typical, R9 ≥ 90 (TLCI 96-98) across 2 700–6 500 K CCT window.

– Guaranteed binning ≤ 3 SDCM on MacAdam ellipse; delivered with individual photometric report. -

LED Engine & Thermal Design

• Citizen or Cree Theatre-grade COB, 50 000 h L90B10 @ Tj 105 °C per IES TM-21-19.

• Vapor-chamber heat-spreader + copper heat-pipe directly bonded to finned aluminium housing (black anodised, ε ≥ 0.85).

– ΔT (Tj – Ta) ≤ 25 °C @ 25 °C ambient, guaranteeing colour stability and long life. -

IP & Mechanical Ratings

• IP65 front lens (silicone O-ring, tempered 4 mm low-iron glass) + IP54 rear housing for wash-down touring environments.

– IK08 impact resistance on lens; optional marine-grade 316 stainless steel yoke and hardware for coastal venues.

• Operating ambient: –30 °C to +45 °C; 0–95 % RH non-condensing.

• Storage: –40 °C to +80 °C. -

Electrical & Control

• Input: 100–277 V AC 50/60 Hz, active PFC >0.98, THDi <5 %.

• Flicker-free (<1 % @ 1 kHz) 16-bit dimming 0–100 %; selectable curves (linear, square, “theatre” S-curve).

• DMX-512/RDM in/out (5-pin XLR), optional wireless CRMX & sACN.

• Stand-by draw <0.5 W. -

Photometric Packages (representative)

Model | CCT | Output (lm) | Power (W) | lm/W | Beam

—————–|———-|————-|———–|——|————-

STC-SPOT-200W-WW | 3 000 K | 17 000 | 200 | 85 | 19°

STC-SPOT-300W-CW | 5 600 K | 31 500 | 300 | 105 | 26°

STC-SPOT-400W-RGBAL| Full | 28 000 white| 400 | 70 | 15–55° zoom

RGBAL figure at 5 600 K mixed white; single-colour efficacy >110 lm/W. -

Certifications & Lifetime Reliability

• CE, RoHS, REACH, ETL/cETL listed to UL1573 & UL8750; CB scheme IEC 60598-2-17.

• 3-year / 10 000 h unconditional warranty, extendable to 5-year.

• Every luminaire burned-in 24 h @ 45 °C, then photometric & insulation hi-pot tested before shipment. -

Beauty STC Consistency Commitment

Since 2008 Beauty STC has produced >1.2 million LED stage fixtures without a single batch recall. Raw LEDs are 100 % re-binned in-house for 3 SDCM; each driver is individually programmed and logged; every finished spotlight is issued a QR-coded passport linking to its LM-79, IP and thermal test data. This statistical process control (Cpk ≥ 1.67 on key parameters) guarantees that the 93 CRI, IP65 and >85 lm/W figures you see above are not catalog maxima but the minimum you will measure on any unit, any shipment, any year.

For project-specific IES files, TM-21 spreadsheets or touring-road-case configurations, please contact me directly.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. – Jiangmen Facility: Technical Overview for Professional Stage Lighting

As Senior LED Lighting Engineer and Export Manager at Beauty STC, I’m pleased to provide a detailed, professional overview of our Jiangmen manufacturing facility—specifically tailored for your interest in high-performance stage lighting spotlights. Our 12,000-square-meter facility in Jiangmen’s Qianjin Industrial Park (Guangdong Province) is engineered for precision, scalability, and rigorous quality control, with dedicated production lines optimized for professional-grade LED fixtures.

1. SMT Manufacturing Line: Precision Surface Mount Technology

Our SMT (Surface Mount Technology) line is the cornerstone of our electronic assembly capability, designed for the demanding tolerances of stage lighting control systems. Key features include:

- High-Speed Pick-and-Place Systems: Dual-head Yamaha YV100XG and Panasonic CM402 machines with placement accuracy of ±0.03mm, handling components down to 0201 size. This ensures consistent solder joint integrity for complex multi-layer PCBs used in DMX/RDM controllers and power drivers.

- Advanced Reflow Profiling: A dual-zone, nitrogen-assisted reflow oven (BTU Convection) with precise thermal profiling (±1°C) to prevent cold joints or thermal shock—critical for high-power LED arrays and sensitive ICs.

- Automated Optical Inspection (AOI): Koh Young KY3030 systems with 3D vision, inspecting 100% of boards for solder paste defects, component misalignment, and missing parts before wave soldering. This reduces field failures by >95% compared to manual inspection.

- Process Control: Fully integrated MES (Manufacturing Execution System) tracking every board from raw PCB to final assembly. All processes comply with IPC-A-610 Class 3 standards for professional electronics.

Why this matters for stage spotlight OEM: Our SMT line ensures stable dimming curves, precise color rendering control (e.g., for RGBW or tunable white spotlights), and immunity to vibration during touring—key requirements for professional applications.

2. Rigorous Aging & Performance Testing

Stage lighting demands extreme reliability under continuous high-heat operation. Our dedicated aging lab (ISO/IEC 17025 accredited) includes:

- Thermal Stress Testing:

- 24–72 hour burn-in cycles at 50°C ambient (simulating worst-case venue conditions) with real-time monitoring of junction temperatures (via embedded thermocouples).

- Thermal cycling from -20°C to 60°C to validate mechanical integrity of LED packages and optical components.

- Optical Performance Validation:

- Integrating sphere measurements (Labsphere) for lumen output, color consistency (±0.003 Duv ΔE<2), and beam angle calibration.

- Goniophotometer testing (ESPRO) to verify beam uniformity and stray light control—critical for sharp focus in spotlights.

- Electrical Safety & Durability:

- 1,500V AC dielectric strength tests per IEC 60598.

- 10,000+ cycle switch life testing for DMX connectors and power switches.

- IP65-rated environmental chamber testing for moisture and dust resistance.

Real-world impact: Every spotlight undergoes 48+ hours of full-load testing before shipment. This eliminates 99.2% of premature failures in touring environments—proven by our <0.5% RMA rate over 5 years for stage lighting products.

3. OEM/ODM Capabilities for Stage Lighting Spotlights

We specialize in fully customized stage spotlight solutions with end-to-end OEM support:

- Optical Design:

- Custom lens/reflector systems (using LightTools ray-tracing simulations) for precise beam control (e.g., 5°–30° zoom ranges, sharp edge definition).

- High-CRI (Ra≥95) LED arrays with binning to ±0.001 Duv for broadcast-quality color accuracy.

- Electronics & Controls:

- Full DMX512/RDM compliance (tested per ESTA E1.3 standard).

- Optional wireless control (Wi-Fi, Bluetooth, RF), sensor integration (e.g., motion-based auto-focus), and smart power management for energy efficiency.

- Custom driver designs for 100–240V global voltage compatibility with flicker-free dimming down to 0.1%.

- Mechanical & Thermal Engineering:

- Aluminum die-casting housings with optimized heat sinks (CFD-validated thermal simulations).

- Vibration-resistant mounting systems (tested to IEC 60068-2-6 for touring rigging).

- Modular designs for easy field serviceability (e.g., swappable LED modules, lens units).

- Compliance & Certification:

- Full support for CE, RoHS, REACH, UL, FCC, and IEC 60598 certifications.

- Custom compliance packages for specific markets (e.g., FCC Part 15 for US, CCC for China).

Typical OEM Workflow:

1. Concept phase: Joint design reviews with your engineering team (using CAD/3D modeling).

2. Prototyping: 3D-printed mockups and functional prototypes within 72 hours.

3. Validation: All prototypes undergo our full aging/test protocol.

4. Mass Production: Scalable capacity (5,000+ units/month) with 15-day lead times for repeat orders.

Why Partner with Beauty STC?

Our Jiangmen facility isn’t just a factory—it’s a precision-engineered ecosystem for professional lighting. From SMT assembly to thermal validation, every step is optimized for the uncompromising demands of stage, broadcast, and fixed-installation environments. We don’t just manufacture spotlights; we engineer solutions that performers and technicians trust night after night.

For technical specifications, compliance documentation, or a virtual factory tour, I’d be happy to arrange a detailed consultation. Feel free to contact me directly at [email/phone] to discuss your project requirements.

Engineered for reliability. Built for the stage.

— [Your Name]

Senior LED Lighting Engineer & Export Manager

Beauty (STC) Manufacturing Co., Ltd.

Jiangmen, Guangdong, China

[Website] | [Email] | [Phone]

Application Scenarios

Stage-lighting spotlights are no longer confined to theatres and concert halls.

The same fixture families (LED profile, Fresnel, PC, and moving-head spot) are now specified in hospitality, retail, and corporate projects when designers need:

- High-contrast accent (5:1 or higher) on art, product, or keynote speakers

- Precise beam control without spill on reflective marble, glass, or low-glare office ceilings

- Dynamic colour or pattern capability for branding events, product launches, festive seasons, or live-streamed presentations

Below is a field-tested guide you can hand to installers so the fixtures perform like “real” stage gear while respecting the stricter glare, noise, and energy codes of commercial buildings.

1. WHERE HOTELS USE SPOTLIGHTS

• Ballroom & divisible meeting rooms

– 19°–26° LED profiles on 6–8 m trim for podium/key-note area; 3 000–3 500 K warm white, CRI ≥ 90 for TV/phone cameras.

– DMX relay bar recessed in ceiling coffers; preset scenes “Gala 100 %”, “Wedding 60 %”, “Conference 30 %” on wall-station or AV rack.

• Restaurant feature tables / buffet islands

– Mini 10 W–30 W LED pin-spot (9°) with snoot and honey-comb; 2 m throw, 1 m diameter pool, 300 lx on plate. Mount on track or single-cell canopy to avoid menu glare.

• Artwork in lobby colonnade

– Framing projector (profile with 4-blade shutter) at 30° angle, 2 m offset from wall; 200 lx on painting, < 20 lx on wall surround to meet IES Museum Grade II.

2. WHERE MALLS USE SPOTLIGHTS

• Centre-court pop-up stage

– 250 W LED Fresnel, 15°–50° zoom, hung from motorised 1 t truss at 7 m; safety factor 10:1, chain-motor with dual-brake and upper-limit switch.

• Luxury shopfront window

– 40 W profile with gobo “snowflake” rotating, 5 500 K to match daylight, < 30° tilt to avoid public-road glare (CIE 150-2017).

• Atrium feature (suspended sculpture)

– RGBW moving-head, 4 000 lm, 12 m throw; use “silent” mode (fan ≤ 35 dB(A) @ 1 m) because mall ambient is < 45 dB.

3. WHERE OFFICES USE SPOTLIGHTS

• Town-hall / boardroom dais

– Two 60 W LED PC spots, 25° medium flood, cross-light at 45° for speaker face modelling; DMX relay triggered by Crestron “Presentation” scene.

• Brand wall / timeline graphic

– 30 W framing projector, 19°, 3 000 K, shutter-cut to within 50 mm of graphic edge; maintains < 300 lx on adjacent video wall (ISO 9241-307 glare limit).

• Auditorium (AGM, training)

– Motorised LED profile on 3 m lighting bar in front of projection screen; red, green, blue preset for company colours—no gel change, no maintenance lift.

4. INSTALLATION CHECKLIST FOR CONTRACTORS

A. Rigging & Structure

1. Confirm dead-load: fixture + clamp + cable + safety = 2× manufacturer weight.

2. Use only certified half-coupler or swivel-clamp; secondary steel 6 mm aircraft-cable safety to independent point (BS 7905-1:2021).

3. In plasterboard ceilings, install 50×50×3 mm steel spreader plate backed to slab; never hang on T-bar alone.

B. Power & DMX

1. Run 3-core 2.5 mm² earth-isolated feed to local 16 A C-form socket; loop-in/loop-out terminal block inside steel Pattress for hotel fire-code.

2. DMX: 5-pin XLR, 120 Ω, daisy-chain ≤ 32 fixtures; terminate with 120 Ω ¼ W resistor. Use RDM-splitter if distance > 300 m.

3. Keep mains and DMX 300 mm apart; cross at 90° where unavoidable.

C. Thermal & Noise

1. LED head ambient ≤ 40 °C; leave 200 mm free air above fan exhaust in ceiling service cavity.

2. Specify “theatre-grade” silent fans (< 35 dB(A)) for boardrooms; provide thermostatic speed control so fan only ramps under 30 °C.

D. Glare & Beam Control

1. Use barndoors or top-hat; maintain cut-off angle ≥ 30° from normal eye height (1.2 m standing, 0.8 m seated).

2. For marble floors, add polarising filter or choose micro-honey-comb louvre to reduce specular reflection into CCTV cameras.

E. Commissioning & Hand-over

1. Photometer check: aim spotlight, measure target lux, record on as-built drawing.

2. Label fixture ID, DMX address, and circuit number on both fixture and patch panel.

3. Provide “operator cheat-sheet” with 3–4 scene presets; store back-up show-file on USB in AV rack.

5. COMMON PITFALLS (SAVE CALL-BACKS)

× Wrong beam angle → hot-spot or dim edge: always do a on-site beam test with a demo unit before ordering full batch.

× Trimming too low in 2.8 m office → glare; keep minimum 2.4 m to lens bottom, use 30° or wider lens.

× Using cheap theatrical clamp on 24 mm pipe → slips under vibration; specify certified G-clamp with M12 wing and safety wing-nut.

× Forgetting emergency circuit separation → in public malls, spotlights on emergency generator must be on separate contactor, not dimmed.

× No access catwalk → maintenance lift required every 6 m; specify double-sheave pulley so fixture can be lowered to floor.

6. QUICK SPEC SUMMARY (COPY TO BOQ)

Fixture: 200 W LED Profile Spot, 19–50° zoom, CRI 93, R9 > 70, 3 000 K, DMX/RDM, silent fan < 35 dB(A), 4-blade framing shutter, iris, gobo slot, 1 500 Kh L70, IP20, cETL/CE, weight 9.2 kg.

Clamp: Half-coupler 50 mm, WLL 100 kg, zinc-plated steel, with M12 wing bolt + 6 mm secondary safety cable.

Control: 1× 6-way DMX/RDM opto-splitter, 19″ 1U, Neutrik 5-pin, terminate last unit.

Power: 16 A C-form outlet per fixture, 230 V ±10 %, loop-in 2.5 mm² H07RN-F, individual RCBO 16 A C-curve.

Deliver this package and the hotel ballroom, mall atrium, or boardroom will enjoy true stage-level punch without compromising the comfort, silence, or fire codes of a premium commercial space.

Why Choose Beauty STC Lighting

Partner with Beauty STC for premium LED stage lighting spotlights, engineered for precision and reliability. Trusted by global productions across 50+ export countries. Contact our engineering team for tailored solutions: [email protected].

⚡ LED Power Supply Calculator