Article Contents

Industry Insight: Solid Led Strip

The solid LED strip lighting market has experienced significant growth in recent years, driven by increasing demand for energy-efficient, durable, and versatile lighting solutions across commercial and industrial applications. From retail environments and office spaces to manufacturing facilities and cold storage warehouses, solid LED strips offer consistent illumination, long service life, and low maintenance—critical factors in high-performance settings. As building operators seek to reduce energy consumption and comply with stringent safety standards, certifications such as ETL and CE have become essential markers of product reliability, electrical safety, and regulatory compliance. These certifications ensure that LED strip solutions meet rigorous North American and international standards, giving facility managers and lighting designers confidence in their installations.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting innovation since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leading manufacturer of high-quality solid LED strip products tailored for demanding commercial and industrial environments. Combining advanced thermal management, robust construction, and full compliance with ETL and CE requirements, Beauty STC’s lighting solutions deliver superior performance, scalability, and peace of mind for projects worldwide.

Technical Specs & Certifications

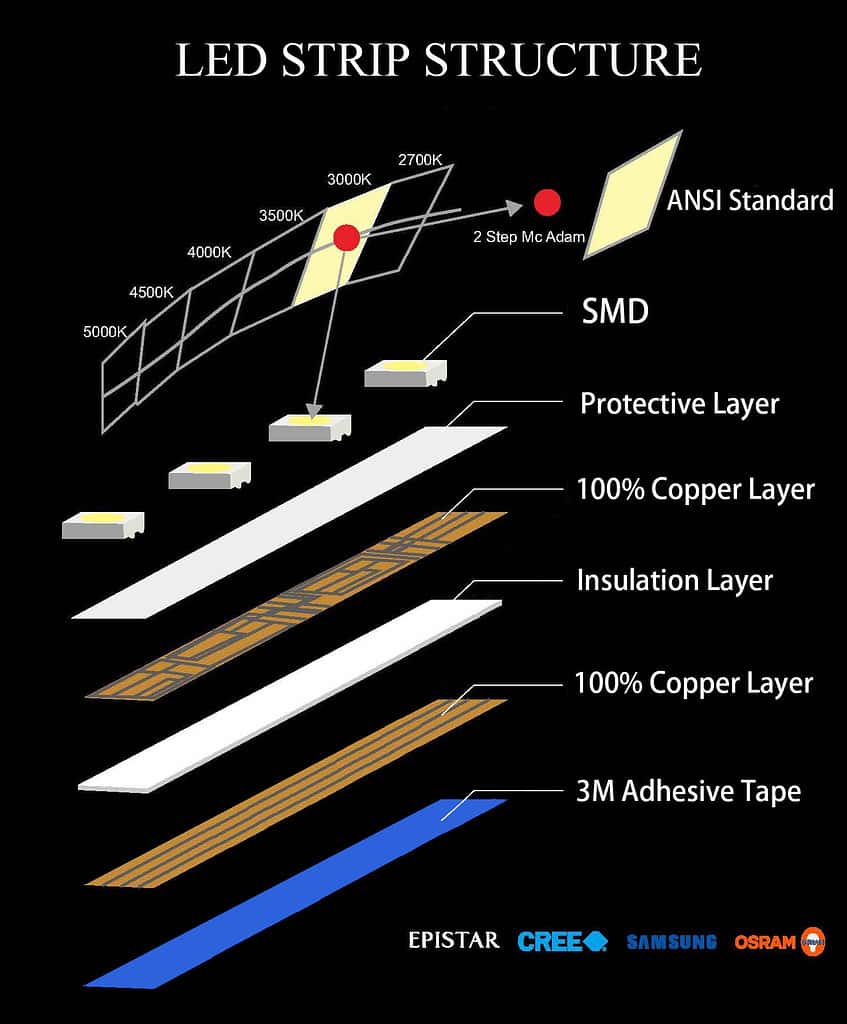

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance rigid LED strips, often referred to as “solid LED strips” due to their robust aluminum substrate construction. These strips utilize a rigid FR4 or metal-core printed circuit board (MCPCB) mounted onto an extruded aluminum profile, providing superior thermal management compared to flexible alternatives. Key technical specifications meeting your requirements are detailed below, reflecting our engineering standards.

Lumens per Watt efficacy for our standard high-CRI rigid LED strips typically ranges from 110 to 125 lumens per watt under real-world operating conditions. This measurement represents the complete system efficacy, including the LED package, driver losses, and thermal performance at a stabilized junction temperature of 85°C, not just theoretical chip-level performance. Achieving this efficiency while maintaining high CRI requires precise binning of Samsung LM301B or Nichia 757G LED chips, coupled with our proprietary thermal pathway design using 1.5mm thick 6063-T5 aluminum profiles. Efficacy is validated using integrating sphere measurements per IES LM-79-19 standards at 50°C ambient temperature, ensuring specifications reflect actual installation performance rather than idealized lab conditions.

Color Rendering Index (CRI) is a core focus for Beauty STC, with all premium rigid strip lines exceeding CRI Ra 90 as standard. We achieve CRI Ra 95+ and R9 >90 through stringent LED binning protocols using high-fidelity phosphor-converted blue chips. This ensures accurate rendition of saturated reds critical for retail, gallery, and hospitality applications. Furthermore, our strips maintain a consistent Color Quality Scale (CQS) above 85 and a TM-30 Rf value of 92+, with fidelity index Rg near 100. Crucially, we control chromaticity within a tight 3-step MacAdam ellipse (SDCM ≤ 3) across production batches, preventing visible color shifts in continuous installations. For specialized applications like film production, we offer variants meeting TLCI >95.

IP ratings for our rigid LED strips are rigorously engineered for environmental resilience. Standard production lines include IP65-rated strips featuring a continuous silicone encapsulation along the LED array, protecting against low-pressure water jets and dust ingress for outdoor canopy or cove lighting. For demanding environments requiring submersion resistance, we manufacture IP67-rated variants with hermetic end caps and fully potted internal components, tested to withstand temporary immersion up to 1 meter depth for 30 minutes per IEC 60529. It is critical to note that higher IP ratings inherently impact thermal performance; our IP67 designs maintain 105-115 lm/W through optimized thermal vias in the MCPCB and direct thermal coupling to the aluminum housing. We explicitly avoid misleading “IP68” claims unless validated by third-party testing for specific duration/depth parameters.

Beauty STC’s quality differentiation stems from our vertical integration and uncompromising process controls. Every rigid strip undergoes 100% automated optical testing for flux, chromaticity, and forward voltage before aging. Our thermal management system, featuring anodized aluminum profiles with thermal conductivity of 180 W/mK and engineered air channels, ensures lumen maintenance of L90 > 50,000 hours at 25°C ambient per TM-21 projections. Unlike competitors, we validate performance at 50°C ambient during accelerated life testing, simulating real tropical or enclosed installations. Component traceability via laser-etched QR codes on every 0.5m segment, coupled with a 5-year warranty backed by UL/cUL and CE certification, demonstrates our commitment to reliability. This engineering rigor ensures consistent photometric performance throughout the product lifecycle, making Beauty STC strips the preferred choice for architects specifying critical lighting applications where color fidelity and longevity are non-negotiable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is fully dedicated to the development and mass production of high-quality LED lighting products, with a particular focus on flexible and reliable solutions such as solid LED strips.

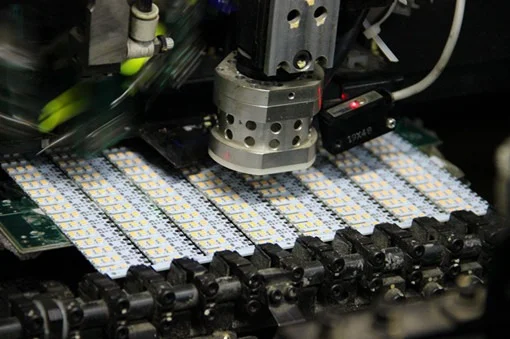

The facility is outfitted with advanced Surface Mount Technology (SMT) production lines that ensure precision and consistency in component placement. These SMT machines are capable of handling high-speed, high-accuracy mounting of LED chips, resistors, and other surface-mounted devices onto flexible printed circuit (FPC) boards used in LED strips. The automated SMT process is supported by automated optical inspection (AOI) systems to verify solder joint quality and component alignment, minimizing defects and ensuring top-tier product reliability.

To guarantee long-term performance and durability, every batch of solid LED strips undergoes rigorous aging tests within the Jiangmen factory. These tests simulate extended operation under various thermal and electrical conditions, typically running products at full power for 24 to 72 hours. This process helps identify early failures, validates thermal management design, and ensures that only stable, high-performing LED strips are shipped to customers.

Beauty STC also offers comprehensive OEM services for solid LED strips, allowing clients to customize parameters such as LED density, color temperature, input voltage (12V or 24V), IP rating (from non-waterproof to IP68), and cuttable lengths. The company supports private labeling, custom packaging, and tailored technical specifications to meet diverse market requirements. With in-house R&D, tooling, and quality control, the Jiangmen factory is well-equipped to manage small prototyping runs as well as large-scale OEM production efficiently and cost-effectively.

Application Scenarios

Solid LED strips, which we manufacture as rigid aluminum-backed linear lighting modules at Beauty (STC), offer superior thermal management, precise optical control, and consistent lumen maintenance compared to flexible strips. Their robust construction makes them ideal for permanent architectural installations where high performance and longevity are critical. In hotels, focus on guest room cove lighting for ambient illumination, particularly in plaster or gypsum ceilings where the rigid form factor ensures straight lines and eliminates sagging. They excel in high-end lobby feature walls, reception counters, and under-bar millwork, where our 2700K to 3000K CCT options with CRI >90 create a warm, inviting atmosphere without visible dotting. Avoid direct installation in high-moisture zones like bathrooms unless using our IP65-rated variants, and always maintain a minimum 5mm air gap between the strip’s aluminum base and any surface to prevent thermal throttling.

For malls, solid LED strips are indispensable in storefront signage illumination, where their high lumen density (typically 1800-2200 lumens per meter) ensures vibrant brand visibility even in daylight. Install them within deep channel letters or as indirect light sources behind translucent facades, using our narrow-beam optics to eliminate hotspots. In corridor soffits and escalator undersides, parallel wiring is non-negotiable—never exceed 5-meter runs per circuit to avoid voltage drop, and pair with constant-voltage 100W drivers featuring surge protection for reliability in high-traffic environments. Crucially, specify our matte white diffusers to minimize glare in retail aisles; glossy finishes cause reflections on polished floors that degrade the shopping experience. Always verify local fire codes—our aluminum extrusions meet ASTM E84 Class A requirements, but improper mounting near combustible materials voids compliance.

In offices, these strips solve critical glare and uniformity challenges. Use them for suspended ceiling perimeter coves to provide shadow-free task lighting, selecting 4000K CCT with TM-30 Rf >80 for visual clarity during screen work. For under-cabinet task lighting in workstations, mount with thermal adhesive tape directly to metal surfaces but confirm the substrate temperature stays below 60°C during operation—overheating in enclosed metal cabinets is a common failure point we see in field returns. When installing above whiteboards or presentation areas, integrate our micro-prismatic diffusers to achieve UGR <19 compliance; standard diffusers cause distracting reflections. Never daisy-chain more than three 2-meter sections without a mid-run power injection point, as voltage drop causes noticeable dimming at the strip’s end. Always use our J-box connectors for clean driver integration—field splices are the top cause of flicker complaints in corporate environments. Remember that solid strips require precise alignment during mounting; we supply laser-guided brackets to ensure sub-millimeter tolerances for seamless light lines in executive suites.

Why Choose Beauty STC Lighting

Looking for high-quality solid LED strip solutions? Partner with Beauty STC, a trusted manufacturer in the LED lighting industry. Our solid LED strips deliver consistent performance, durability, and brilliant illumination for a wide range of applications. Whether you’re working on residential, commercial, or industrial projects, we provide reliable products tailored to your needs.

Take the next step in lighting excellence. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can support your business with premium solid LED strip lighting.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.