Article Contents

Industry Insight: Soft White Vs Daylight Led

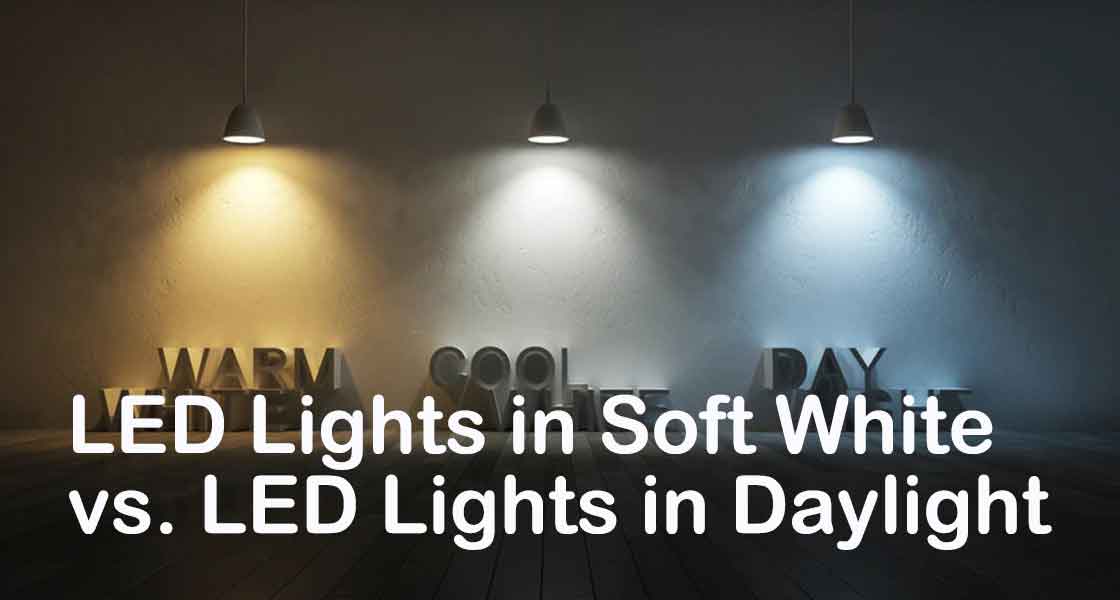

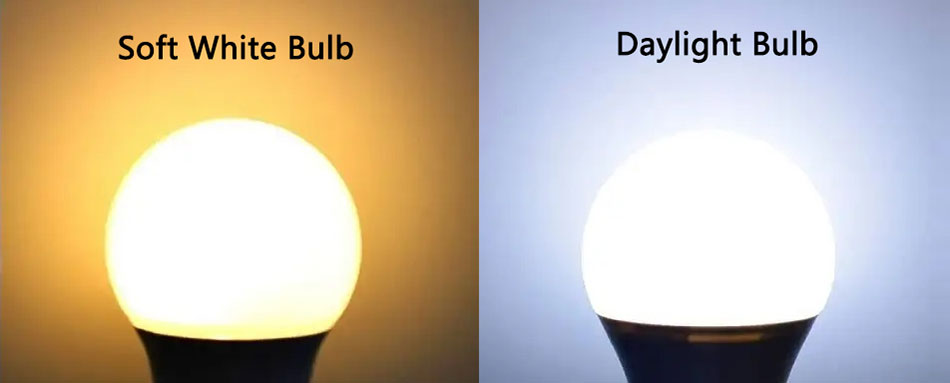

The strategic selection between soft white and daylight LED illumination represents a critical decision point in commercial and industrial facility design, directly impacting operational efficiency, worker well-being, and task performance. Understanding the nuanced applications of these color temperatures—soft white (typically 2700K-3000K) offering a warm, inviting ambiance, and daylight (5000K-6500K) providing vibrant, high-contrast clarity—is no longer merely an aesthetic choice but a functional necessity. In warehouses and manufacturing floors, daylight LEDs enhance visual acuity for precision tasks and improve safety by revealing hazards more effectively, while soft white often finds its place in break rooms or lobbies to foster relaxation. Crucially, specifying fixtures that meet rigorous safety and performance standards like ETL (North America) and CE (Europe) is non-negotiable for commercial deployments; these certifications ensure electrical safety, reliability under demanding conditions, and compliance with building codes, mitigating liability risks and avoiding costly project delays or retrofits.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of dedicated expertise in engineering high-performance, code-compliant LED lighting solutions specifically for the complex demands of commercial and industrial environments. We recognize that optimal lighting goes beyond simple illumination—it is an integral component of facility productivity and human-centric design. Our commitment to integrating essential certifications like ETL and CE directly into our product development process ensures our clients receive not only technically superior lighting tailored to the specific operational needs of spaces ranging from distribution centers to office complexes but also the absolute confidence that comes with fully compliant, rigorously tested fixtures built to last.

Technical Specs & Certifications

When comparing Soft White and Daylight LED lighting solutions, several key technical specifications must be considered to ensure optimal performance and suitability for different environments. Both color temperatures offer distinct advantages depending on application, but high-quality manufacturing—such as that delivered by Beauty (STC) Manufacturing Co., Ltd.—ensures consistent performance across critical metrics including lumens per watt, color rendering index (CRI), and ingress protection (IP) ratings.

Lumens per watt (lm/W) is a measure of luminous efficacy, indicating how efficiently an LED converts electrical power into visible light. Beauty STC’s Soft White (typically 2700K–3000K) and Daylight (typically 5000K–6500K) LED products are engineered to deliver high efficacy, with both variants achieving 110–130 lumens per watt. This efficiency is maintained across color temperatures due to advanced chip-on-board (COB) and surface-mounted device (SMD) technologies, ensuring energy savings without compromising light output. The slight variance in efficacy between color temperatures is minimized through proprietary phosphor coating and thermal management systems, a hallmark of Beauty STC’s engineering precision.

Color Rendering Index (CRI) is critical for applications where accurate color representation is essential, such as in retail, healthcare, and residential settings. Beauty STC ensures that both Soft White and Daylight LED products exceed CRI >90, with many fixtures achieving CRI values of 93–95. This high CRI is accomplished using multi-phosphor blends and rigorous binning processes during LED chip selection. As a result, both lighting types deliver natural, vibrant illumination—Soft White providing a warm, inviting ambiance with excellent skin tone rendering, and Daylight offering crisp, alertness-enhancing light ideal for task-oriented environments—all while maintaining superior color fidelity.

Ingress Protection (IP) ratings indicate the degree of protection against dust and moisture, crucial for durability in both indoor and outdoor applications. Beauty STC designs its LED fixtures with versatility in mind, offering Soft White and Daylight variants in multiple IP ratings. Standard indoor models are typically rated IP20 for basic protection, while outdoor, bathroom, or industrial-grade luminaires are available in IP65, IP66, and even IP67 for full dust tightness and resistance to water jets or temporary submersion. These robust enclosures, combined with high-quality silicone gaskets and aluminum heat sinks, ensure long-term reliability in challenging environments.

Beauty (STC) Manufacturing Co., Ltd. stands out in the LED industry through its unwavering commitment to quality, precision engineering, and compliance with international standards such as IEC, UL, and CE. Each Soft White and Daylight LED product undergoes stringent testing for lumen maintenance (L70 >50,000 hours), thermal performance, and color consistency. This ensures not only energy efficiency and visual comfort but also extended service life and reduced maintenance costs. With integrated driver solutions, uniform light distribution, and a focus on sustainable manufacturing, Beauty STC delivers premium LED lighting that performs reliably across residential, commercial, and industrial applications.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern LED lighting manufacturing facility in Jiangmen, Guangdong Province, designed to support high-volume production with stringent quality control. The factory occupies approximately 15,000 square meters and integrates advanced surface-mount technology lines, comprehensive testing laboratories, and dedicated R&D spaces to serve global OEM and ODM clients. Our Jiangmen site functions as the primary hub for LED module and luminaire assembly, emphasizing precision engineering and compliance with international safety and performance standards.

The SMT production line features multiple Yamaha YS series high-speed placement machines, capable of handling components down to 0201 package sizes with placement accuracy of ±25μm. These machines support triple-reel feeders for complex LED driver and optical board assemblies, achieving throughput rates exceeding 80,000 components per hour per line. Each SMT station incorporates 3D solder paste inspection (SPI) systems and automated optical inspection (AOI) to verify paste volume, component placement, and solder joint integrity before reflow. This infrastructure ensures consistent assembly of multi-channel LED arrays critical for color-tunable products, with particular attention to thermal pad alignment for optimal heat dissipation in high-power modules.

Aging tests are conducted in climate-controlled environmental chambers following IEC 62612 protocols. All finished LED modules undergo a dual-phase burn-in process: an initial 24-hour period at 60°C ambient temperature with full-rated current to identify infant mortality failures, followed by a 48-hour stability phase at 40°C to verify photometric consistency. Real-time monitoring tracks lumen maintenance, chromaticity shift, and driver performance using calibrated spectroradiometers. For color-critical products like soft white and daylight variants, we implement additional 100-hour extended aging with hourly spectral measurements to ensure Δu’v’ remains within MacAdam Step 3 tolerances throughout the operational life.

Our OEM capabilities for soft white (2700K–3000K) versus daylight (5000K–6500K) LED solutions extend beyond basic CCT selection. We provide full spectral engineering services where clients can specify exact chromaticity coordinates, CRI values (Ra ≥90 standard, up to Ra 98 available), and R9 requirements. The factory maintains separate phosphor blending stations and wavelength-binning lines to produce consistent batches within tight color bins—typically 3-step MacAdam for commercial products and 1-step for premium architectural lighting. For daylight variants requiring high circadian stimulus values, we adjust blue-pump intensity and phosphor ratios while maintaining lumen output stability. Soft white formulations incorporate red-enhanced phosphors to achieve warm appearance metrics (WSDM) below 0.45, with all OEM productions supported by spectral power distribution reports and LM-80/TM-21 lifetime projections tailored to client thermal management designs. This allows Beauty STC to deliver application-specific color solutions rather than generic temperature categories.

Application Scenarios

Soft white and daylight LED lighting serve different functional and aesthetic purposes depending on the environment. Choosing between them depends on the desired ambiance, task requirements, and occupant comfort in spaces such as hotels, malls, and offices.

In hotels, soft white LED lighting (2700K–3000K) is ideal for guest rooms, lobbies, and lounges where a warm, inviting, and relaxing atmosphere is desired. This color temperature mimics incandescent lighting and enhances comfort, making guests feel at ease. Daylight LEDs (5000K–6500K), on the other hand, are better suited for back-of-house areas such as laundry rooms, maintenance spaces, and staff workstations where high visibility and alertness are necessary. Some modern hotel bathrooms may also use daylight LEDs for better grooming visibility.

In malls and retail environments, daylight LEDs are often preferred in main walkways, display windows, and high-traffic retail areas. The cooler, brighter light enhances product clarity, improves color rendering, and creates an energetic, vibrant shopping experience. However, soft white lighting can be effectively used in boutique stores, lounges, or premium brand sections where a more intimate or luxurious feel is desired. A balanced approach using both temperatures strategically can guide customer experience and highlight different product types.

Offices typically benefit from daylight LED lighting in workspaces, conference rooms, and open-plan layouts. The cooler temperature promotes concentration, reduces drowsiness, and supports productivity, especially in environments with limited natural light. However, in reception areas or collaborative breakout zones, soft white LEDs can be introduced to create a more welcoming and less clinical environment. It is important to avoid overly harsh daylight lighting in areas where prolonged visual comfort is key.

When installing LED lighting, consider the following tips. First, ensure compatibility with existing dimmers and controls, especially when using soft white LEDs in adjustable lighting systems. Second, use appropriate luminaires that provide proper beam angles and light distribution to avoid glare and shadows. Third, maintain consistency in color temperature within a single space to prevent visual discomfort. Fourth, leverage natural daylight by integrating controls such as occupancy sensors and daylight harvesting systems to optimize energy efficiency. Finally, always follow local electrical codes and manufacturer guidelines for safe and reliable installation.

By carefully selecting between soft white and daylight LEDs based on the functional needs of each space, and applying sound installation practices, you can enhance both the aesthetic and operational performance of lighting in hotels, malls, and offices.

Why Choose Beauty STC Lighting

Confused about when to specify soft white versus daylight LED lighting for your projects? As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co. Ltd. I see this question daily from architects designers and retailers. The wrong color temperature choice directly impacts ambiance customer experience and even product sales whether illuminating a calming bedroom a vibrant retail display or a precise workspace. Soft white around 2700K-3000K creates warm inviting atmospheres ideal for hospitality and residential settings while daylight at 5000K-6500K boosts alertness and color accuracy critical for retail makeup counters healthcare facilities and task-oriented environments.

Selecting the optimal LED solution isn’t just about technical specs—it’s about understanding human perception and commercial outcomes. At Beauty STC we engineer tunable and fixed-color temperature LEDs with exceptional CRI and TM-30 fidelity ensuring your lighting intent translates perfectly to end users. Our team provides tailored photometric support spectral analysis and real-world application testing so you eliminate costly guesswork and returns.

Partner with Beauty STC to transform your lighting vision into a competitive advantage. Contact our engineering management team today at [email protected] to discuss custom solutions volume pricing and technical collaboration. Let us help you specify with confidence and illuminate success.

Senior LED Lighting Engineer

Beauty STC Manufacturing Co. Ltd.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.