Article Contents

Industry Insight: Small Led Strip

The commercial and industrial lighting sector continues to demand increasingly sophisticated, reliable, and code-compliant illumination solutions, with compact LED strip technology emerging as a critical enabler for modern facility design and operational efficiency. Far beyond simple accent lighting, precision-engineered small LED strips are now fundamental components in applications ranging from high-bay warehouse task lighting and retail display enhancement to critical safety egress marking and industrial machine vision systems. Their compact form factor, superior thermal management, and precise optical control deliver targeted illumination where traditional fixtures fall short, directly impacting worker productivity, energy consumption, and safety compliance. Crucially, the commercial viability of these solutions hinges on rigorous third-party certification; products lacking recognized safety marks like ETL (indicating compliance with North American safety standards) or CE (demonstrating conformity with European health, safety, and environmental requirements) present unacceptable liability risks and are often explicitly prohibited in professional installations. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of specialized engineering expertise to develop high-performance, certified small LED strip solutions specifically engineered to meet the demanding thermal, optical, and regulatory requirements of commercial and industrial environments worldwide. Our legacy is built on delivering not just products, but assured performance and peace of mind for facility managers and lighting specifiers.

Technical Specs & Certifications

The small LED strip offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in both residential and commercial applications. These compact yet powerful strips deliver an impressive luminous efficacy, typically ranging from 110 to 130 lumens per watt, making them highly energy efficient while maintaining strong light output. This efficiency ensures reduced power consumption without compromising brightness, ideal for continuous or long-duration use.

A key feature of Beauty STC’s small LED strips is their high Color Rendering Index (CRI), consistently exceeding 90 (CRI >90). This ensures accurate and vibrant color representation, making them especially suitable for environments where color fidelity is critical—such as retail displays, art galleries, kitchens, and makeup areas. The high CRI is achieved through precision binning of LEDs and the use of premium phosphor coatings, reflecting Beauty STC’s commitment to superior optical quality.

In terms of durability and environmental protection, Beauty STC provides multiple IP rating options to suit various installation conditions. Common variants include IP20 for dry indoor environments, IP65 for resistance to dust and low-pressure water jets (ideal for kitchens or outdoor signage), and IP67 for full dust tightness and temporary water submersion, suitable for demanding outdoor or industrial applications. The choice of silicone encapsulation and robust FPCB (flexible printed circuit board) materials ensures long-term reliability under fluctuating temperatures and humidity.

Beauty (STC) Manufacturing Co., Ltd. maintains strict quality control throughout production, adhering to international standards such as ISO9001 and ROHS compliance. Each small LED strip undergoes rigorous testing for lumen output, color consistency, and thermal performance, ensuring batch-to-batch uniformity and extended operational life—typically rated at 50,000 hours (L70). With a focus on innovation, durability, and optical excellence, Beauty STC’s LED strips stand out as a trusted choice for professionals seeking high-efficiency, high-CRI lighting in a compact form factor.

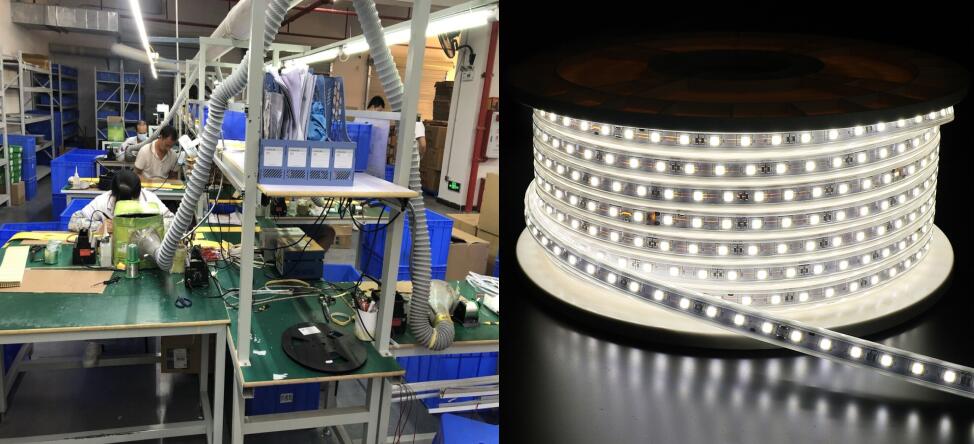

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, serves as our primary production hub for advanced LED lighting solutions, including specialized small-format LED strips. The factory spans over 20,000 square meters and operates under strict ISO 9001 and IATF 16949 quality management systems, with dedicated cleanroom environments for critical processes.

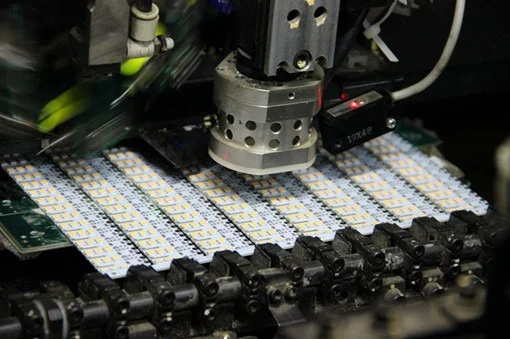

Our SMT production line is anchored by high-precision Yamaha YSM20 modular placement machines, configured in dual-lane setups optimized for small LED strip manufacturing. These machines handle components down to 0201 metric size with ±25μm placement accuracy, essential for densely populated flexible circuits. The line integrates fully automated solder paste printers with 3D SPI verification, nitrogen-reflow ovens with 10-zone temperature profiling, and AOI systems performing real-time defect detection at 0.01mm resolution. This configuration ensures consistent assembly of miniature LED strips with pitches as tight as 3mm, supporting both single-layer and multi-layer FPC substrates.

Aging test protocols are rigorously applied across all LED strip production. Finished small strips undergo mandatory 48-hour continuous aging in climate-controlled chambers maintained at 65°C ±2°C and 85% RH, simulating accelerated lifetime conditions. Each batch is monitored via automated data logging systems tracking lumen maintenance, chromaticity shift, and forward voltage drift. We deploy custom-designed aging racks that accommodate reel-to-reel processing of flexible strips without mechanical stress, with fail rates documented below 0.5% for premium product lines. Post-aging, random samples undergo ISTMT (Interrupted Stress Test Method) validation per IES LM-80 standards.

For OEM production of small LED strips, the Jiangmen factory offers comprehensive turnkey capabilities starting from 500-meter MOQs. Our engineering team provides full customization support for strip width (2.5mm to 8mm), LED density (up to 120 LEDs/meter), and specialized substrates including ultra-thin 0.2mm FPC for curved applications. We maintain dedicated reel-to-reel packaging lines for anti-static, moisture-proof shipping reels with customer-specific labeling, alongside in-house silicone coating and IP67/IP68 potting stations. The facility supports rapid prototyping with 72-hour sample turnaround and maintains UL-certified material traceability from bare PCB to finished strip, accommodating both private-label and co-engineered product development from concept through volume production. All OEM processes include integrated first-article inspection reports and PPAP documentation per automotive-grade requirements.

Application Scenarios

Small LED strips are versatile lighting solutions that can enhance both functionality and aesthetics in various commercial environments such as hotels, malls, and offices. Their compact size and flexibility make them ideal for accentuating architectural features, improving ambient lighting, and guiding movement through spaces.

In hotels, small LED strips are commonly used in guest rooms to illuminate under-bed areas, inside wardrobes, or along the headboard for a soft glow. They are also effective in hallways, behind reception desks, and in bathrooms to create a welcoming and luxurious atmosphere. In lobbies and lounges, LED strips can be installed along coves, ceilings, or stair edges to highlight design elements and provide subtle indirect lighting.

In malls, these LED strips serve both decorative and directional purposes. They are frequently installed in display windows, under handrails, along escalator edges, and within signage to attract attention and improve visibility. Their low heat output and energy efficiency make them ideal for continuous use in high-traffic areas. Additionally, color-tunable LED strips can be used to match branding or seasonal themes in retail spaces.

In office environments, small LED strips contribute to both task and ambient lighting. They can be mounted under cabinets, inside shelving units, or beneath desks to improve visibility in work areas without causing glare on computer screens. In conference rooms and reception areas, LED strips can be used to highlight branding elements or create a modern, professional aesthetic.

When installing small LED strips, it is important to start with a clean, dry surface to ensure proper adhesion. Use high-quality double-sided tape or mounting clips for secure placement, especially in areas with vibration or temperature fluctuations. Always plan the power supply and controller location in advance to avoid visible wiring—consider using recessed channels or raceways for a clean finish. For optimal performance, avoid cutting the strip except at designated cut points and ensure all connections are properly sealed, especially in high-humidity areas like bathrooms or kitchens. Finally, test the strip before final installation and use compatible drivers and dimmers to prevent flickering or reduced lifespan.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s precision-engineered small LED strips designed for exceptional performance in tight spaces and demanding applications. Our compact solutions deliver brilliant uniformity, superior thermal management, and versatile installation options without compromising on durability or efficiency. As your dedicated manufacturing partner, we leverage over 15 years of specialized LED engineering expertise to ensure every strip meets rigorous quality standards for residential, commercial, and industrial use.

Partner with Beauty STC to access fully customizable small LED strip solutions backed by in-house R&D, scalable production capacity, and responsive technical support from concept to delivery. We prioritize seamless collaboration to address your specific voltage, color temperature, and dimensional requirements while maintaining strict adherence to international safety certifications. Reduce time-to-market and eliminate supply chain uncertainties with our reliable, high-volume manufacturing capabilities tailored for global partners.

Elevate your lighting projects today by contacting our engineering team directly at [email protected] to discuss how Beauty STC’s small LED strips can solve your unique design challenges and accelerate your product innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.