Article Contents

Industry Insight: Short Led Light Strips

The commercial and industrial lighting sector increasingly demands highly specialized, space-constrained illumination solutions where standard linear fixtures fall short. Short LED light strips have emerged as a critical niche component, addressing precise needs like under-cabinet task lighting in commercial kitchens, status indicators within machinery and control panels, pathway marking in confined service corridors, and accent lighting within retail displays or architectural millwork. Unlike their longer residential counterparts, these compact segments must deliver robust, reliable performance under demanding operational conditions—resisting vibration, temperature fluctuations, and continuous duty cycles—while integrating seamlessly into tight mechanical designs. Crucially, adoption in professional settings hinges on uncompromising safety and regulatory compliance; products must carry recognized certifications such as ETL for North American markets and CE marking for Europe, verifying adherence to stringent electrical safety and electromagnetic compatibility standards. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to mastering this exacting segment. We engineer precision short LED light strips specifically for commercial and industrial applications, prioritizing reliability, certified safety, and seamless integration where space and performance are non-negotiable.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. produces high-performance short LED light strips engineered for precision lighting applications where efficiency, color accuracy, and durability are critical. These compact LED strips are ideal for under-cabinet lighting, display accenting, architectural detailing, and other space-constrained environments.

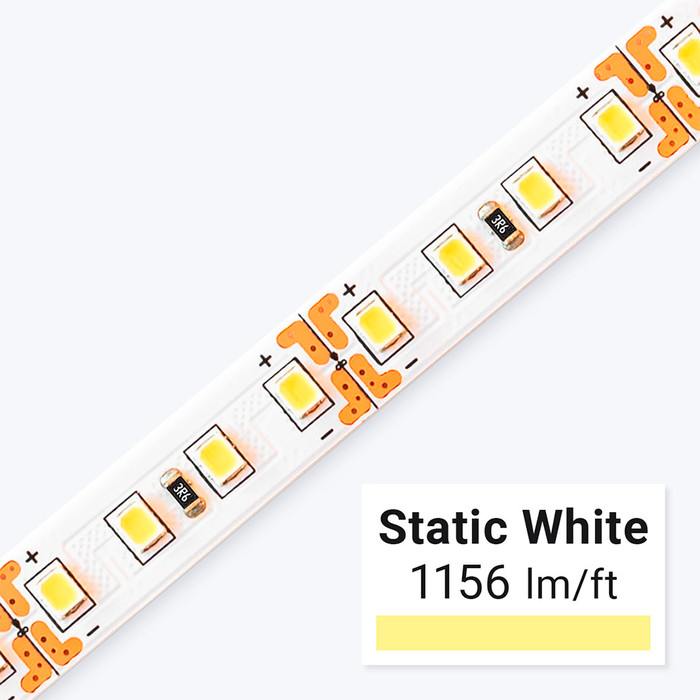

In terms of efficiency, Beauty STC’s short LED light strips achieve a luminous efficacy ranging from 110 to 130 lumens per watt, depending on the specific configuration and LED density. This high lumens-per-watt ratio ensures energy-efficient operation without sacrificing brightness, making them suitable for both residential and commercial installations where power consumption is a concern.

Color quality is a hallmark of Beauty STC’s LED technology. All short LED strips in this category are designed with a Color Rendering Index (CRI) greater than 90, with select models reaching CRI values of 95 or higher. This superior color fidelity ensures that illuminated objects appear vibrant and true to life, which is particularly important in retail displays, art galleries, kitchens, and healthcare environments.

Regarding environmental protection, Beauty STC offers short LED light strips in multiple IP (Ingress Protection) ratings to suit various installation conditions. The standard non-coated versions are rated IP20, suitable for dry indoor environments. For damp or outdoor applications, silicone-coated variants are available in IP65, providing protection against dust and low-pressure water jets. Fully encapsulated versions are offered in IP67, enabling temporary submersion and reliable performance in high-moisture areas such as bathrooms, outdoor signage, and marine environments.

Beauty STC maintains rigorous quality control throughout the manufacturing process, utilizing high-grade SMD LEDs (typically 2835 or 3528), precision-printed circuit boards, and consistent phosphor coating to ensure uniform light output and longevity. Their strips undergo thermal stress testing, solder joint verification, and photometric calibration to meet international standards. This commitment to quality results in LED strips with extended lifespans—typically rated at L70/B50 >50,000 hours—while maintaining stable lumen output and color consistency over time.

In summary, Beauty STC’s short LED light strips deliver exceptional lumens per watt, CRI >90 for accurate color representation, and flexible IP-rated options for diverse environments—all backed by robust engineering and manufacturing excellence.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is strategically located in Jiangmen, Guangdong Province, China. This modern factory serves as the core production hub for our LED lighting solutions, including our specialized short LED light strips. The Jiangmen site is designed for efficiency and quality, featuring a controlled cleanroom environment specifically for critical processes like surface-mount technology assembly, alongside dedicated areas for final assembly, rigorous testing, and packaging. Its location within Jiangmen benefits from strong regional supply chains for electronic components and skilled manufacturing labor, supporting our commitment to scalable and reliable production.

The SMT production line at the Jiangmen factory is a cornerstone of our manufacturing capability, utilizing state-of-the-art equipment from leading manufacturers such as Yamaha and Siemens. These high-precision machines handle the intricate placement of micro-components, including LEDs, resistors, capacitors, and ICs, onto flexible printed circuit boards (FPCBs) used for our light strips. The line supports multiple concurrent production runs with rapid changeover capabilities, essential for managing diverse OEM orders. Automated optical inspection (AOI) systems are integrated directly after the reflow soldering stage, providing 100% real-time inspection of solder joints and component placement accuracy. This ensures exceptional first-pass yield and minimizes defects before products proceed to subsequent stages, critical for maintaining the high reliability standards expected in LED lighting.

Aging testing is a non-negotiable phase in our quality assurance protocol at the Jiangmen facility, applied rigorously to all finished LED light strips, particularly short segments which can present unique thermal challenges. Completed strips undergo controlled aging burns for durations ranging from 24 to 72 hours under full operational load. This process occurs within dedicated, temperature-monitored aging chambers designed to simulate extended use. During aging, strips are continuously powered while thermal imaging cameras and automated monitoring systems track performance parameters like luminous flux stability, color consistency, and critical temperature points along the strip. Any unit exhibiting significant deviation in output or excessive heat generation is immediately flagged and removed from the production flow. This extended burn-in significantly reduces infant mortality rates and provides concrete data on product longevity before shipment.

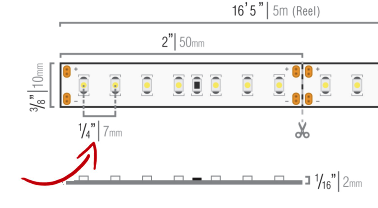

Our OEM capability for short LED light strips is a significant strength developed and executed at the Jiangmen factory. We define ‘short’ strips typically as segments under 1 meter in length, often cut-to-order from master reels or produced as discrete short runs. The facility excels in handling low-to-medium volume, high-mix OEM orders requiring custom specifications. This includes flexible production of strips with specific lengths (down to centimeters), tailored color temperatures, custom lumen outputs, unique voltage requirements, specialized connectors, or modified adhesive backing. Our engineering team works closely with clients during the design phase to optimize layouts for manufacturability on our SMT lines, even for very short segments. The factory’s agile production scheduling and quick tooling changeovers enable us to accommodate small batch sizes efficiently, often with lower minimum order quantities than larger competitors, while maintaining the same stringent quality controls applied to high-volume production. This makes us a preferred partner for clients needing bespoke, reliable short LED strip solutions.

Application Scenarios

Short LED light strips are versatile lighting solutions that can enhance both functionality and aesthetics in a variety of commercial environments including hotels, malls, and offices. Their compact size and flexibility make them ideal for targeted illumination in tight or discreet spaces.

In hotels, short LED light strips are commonly used under bed frames, inside wardrobe cabinets, beneath bathroom vanities, and along stair treads or handrails in guest rooms and hallways. These applications provide subtle ambient lighting that improves safety and convenience while contributing to a modern and luxurious feel. In hotel lobbies or reception desks, short strips can be installed to highlight architectural details or branding elements.

In malls, short LED light strips are effective for accent lighting in display cases, signage backlighting, and under handrails in escalators or walkways. They are also useful in service counters, kiosks, and fitting rooms, where focused, energy-efficient lighting improves visibility without generating excess heat. Their low profile allows integration into tight architectural spaces without disrupting the overall design.

In offices, short LED light strips can be installed under shelves, inside filing cabinets, beneath desks, or within conference room credenzas to provide task lighting and reduce shadows. They are also used to illuminate reception counters, internal shelving in meeting rooms, and even server racks where visibility is needed without overhead lighting. In modern office designs, they contribute to a clean, minimalist aesthetic when used to outline partitions or highlight design features.

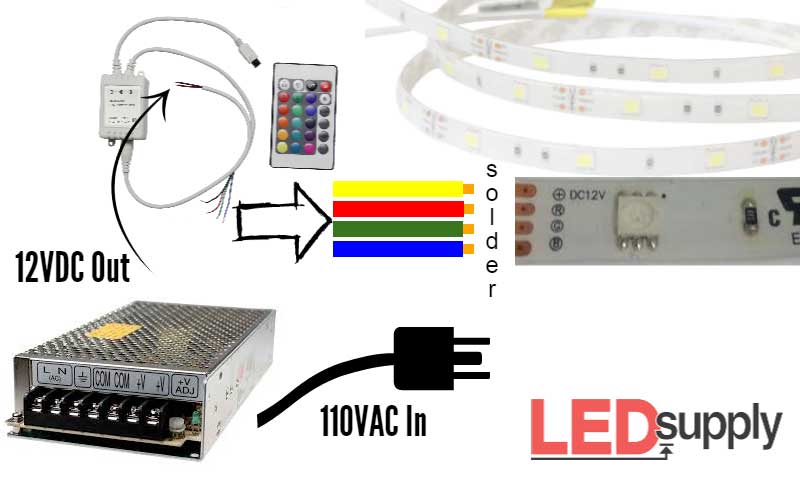

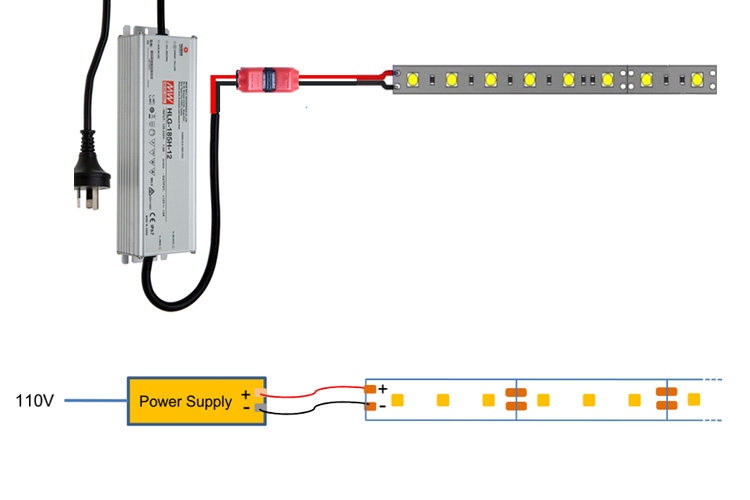

When installing short LED light strips, ensure the surface is clean, dry, and free of dust or grease to promote strong adhesion of the backing tape. For longer durability, especially in high-traffic or high-humidity areas, consider using mounting clips or aluminum channels which also help dissipate heat and protect the strip. Always check the voltage compatibility and use a suitable power supply or driver. Avoid sharp bends or kinks in the strip—follow the manufacturer’s minimum bending radius. If cutting the strip, only do so at designated cut points to avoid damaging the circuitry. For optimal performance and safety, connect the strips according to the recommended run lengths and avoid daisy-chaining beyond the manufacturer’s specifications. Finally, consider using a dimmable driver if adjustable lighting levels are desired for ambiance or energy savings.

Why Choose Beauty STC Lighting

Beauty STC Engineering specializes in precision short LED light strips engineered for demanding commercial and architectural applications where space constraints and performance cannot be compromised. Our strips deliver exceptional lumen density, thermal stability, and consistent color rendering in compact form factors that solve installation challenges standard strips cannot address. Partner with us to integrate rigorously tested, customizable short-strip solutions into your fixtures or projects, backed by our in-house optical engineering support and dependable manufacturing scale.

We understand the unique thermal management and mechanical integration hurdles of confined-space lighting. Beauty STC’s short strips feature proprietary circuit design and high-efficiency LEDs that maintain output without hotspots, even in sealed or low-clearance environments. Our engineering team collaborates directly with partners to refine specifications, ensuring your design intent is met without costly field failures or redesign cycles.

Contact our Lighting Solutions Manager today at [email protected] to discuss how our short LED light strips can enhance your next project’s performance and reliability. Include your application requirements and volume needs in your inquiry for a targeted technical proposal within 24 business hours. Let Beauty STC’s engineering expertise become your competitive advantage.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.