Article Contents

Industry Insight: Shelf With Lighting

The Critical Role of Shelf Lighting in Commercial Environments

Modern commercial and industrial applications demand more than basic illumination for display shelves. In retail environments, hospitality venues, museums, and high-end retail spaces, shelf lighting serves as a strategic tool for product presentation, safety compliance, and operational efficiency. Poorly designed or uncertified lighting solutions can result in uneven illumination, glare, thermal failures, or non-compliance with regional regulations—leading to costly rework, safety hazards, or market rejection.

For distributors, architects, and project managers, the selection of shelf lighting must prioritize engineering integrity over aesthetics alone. This requires solutions engineered to withstand continuous operation, maintain consistent color rendering, and comply with rigorous international safety standards.

Quality as a Non-Negotiable Factor for Global Importers

Certifications like ETL (USA/Canada) and TUV CE (Europe) are not optional marketing claims—they are mandatory prerequisites for market access in regulated economies. These certifications validate that products undergo independent third-party testing for:

Electrical safety (e.g., overcurrent protection, insulation integrity)

Thermal stability (preventing overheating in enclosed fixtures)

Electromagnetic compatibility (EMC) (ensuring no interference with other equipment)

RoHS compliance (restrictions on hazardous substances)

Importers sourcing from uncertified manufacturers risk:

Customs rejections or delays due to non-compliant documentation

Liability for safety incidents in end-user installations

Warranty claims from damaged or failed products

Beauty STC Lighting’s ETL and TUV CE certifications are backed by documented test reports from accredited laboratories. Every batch undergoes rigorous quality control at our Jiangmen facility, ensuring consistency across global shipments.

Beyond Compliance: Engineering for Long-Term Reliability

Certifications establish a baseline, but true industrial-grade performance requires holistic engineering:

Thermal management: Aluminum heat sinks and precision PCB design to maintain ≤60°C junction temperatures under continuous operation.

Component selection: Automotive-grade LEDs (e.g., Samsung, Osram) with 50,000+ hour L70 lifespans.

Robust construction: IP-rated housings (IP20–IP67) for dry, damp, or wet environments.

Consistent color accuracy: CRI >90 for true-to-life product rendering in retail and hospitality settings.

These attributes are non-negotiable for commercial projects where maintenance access is limited or failure costs exceed initial savings.

Beauty STC: 25+ Years of Engineering Excellence for Global Markets

Founded in 1998, Beauty STC Lighting has evolved from a regional LED manufacturer to a trusted partner for 50+ countries across Europe, North America, and Asia-Pacific. Our Jiangmen facility combines 25+ years of industrial lighting expertise with ISO 9001-aligned production processes, ensuring every product—from flexible strips to recessed panels—is engineered for real-world commercial demands.

Key Capabilities for Project-Specific Solutions

OEM/ODM Full-Scope Support: Custom lengths, voltages (12V/24V DC), color temperatures (2700K–6500K), and mounting configurations.

Certification-First Design: All products are developed with ETL/CE compliance as a core requirement—not an afterthought.

Global Supply Chain Agility: Dedicated export teams manage documentation, shipping, and regional regulatory requirements.

Technical Specifications for Commercial Shelf Lighting Solutions

| Product Type | Voltage | Luminous Efficacy | CRI | IP Rating | Certifications | Applications |

|---|---|---|---|---|---|---|

| Flexible LED Strip | 12V/24V DC | 120–160 lm/W | >90 | IP20/IP65 | ETL, CE | Retail display edges, museum vitrines, bar shelving |

| Recessed LED Panel | 12–24V DC | 100–120 lm/W | >80 | IP40 | ETL, CE | Integrated shelf lighting in high-end retail, hospitality |

| Custom Channel System | 12–24V DC | Customizable | >90 | IP67 | ETL, CE | Outdoor retail displays, commercial kitchens, marine environments |

All products undergo 100% burn-in testing and thermal validation prior to shipment. Custom configurations require minimum order quantities (MOQs) of 500 units for OEM projects.

Partner with a Manufacturer Who Understands Global Standards

At Beauty STC, our commitment to “Be a responsible enterprise, Be a caring person” translates into technical rigor that reduces your project risks. Whether you require standardized solutions or bespoke designs for niche applications, our engineering team collaborates directly with architects and distributors to ensure compliance, performance, and longevity.

Technical inquiries and project specifications can be directed to our engineering team at

[email protected] | +86 13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

1. Optical & Electrical Targets for Shelf-Integrated LED Systems

Beauty STC designs every shelf-lighting platform around three non-negotiables: visual comfort for retail customers, energy-code compliance for contractors, and 50 000 h L70 survival for owners. The numbers below are taken from our current 24 V constant-voltage strip and 48 V linear driver families that power 90 % of the shelf extrusions we export.

| Parameter (Tamb = 25 °C) | Target Value | Notes / Test Method |

|---|---|---|

| Luminous efficacy | 135–150 lm/W @ 3000 K | Integrating sphere, IES LM-79 |

| Colour rendering | CRI ≥ 90, R9 ≥ 50 | IEC 62380, TM-30-20 |

| MacAdam ellipse | ≤ 3 SDCM | Binning after 2 h burn-in |

| Flicker | SVM ≤ 0.4, Pst LM ≤ 1.0 | IEC 61547, IEEE 1789 |

| Lumen maintenance | L70 ≥ 50 000 h | IES LM-80 (1 000 h) + TM-21 @ 45 °C Ts |

| Ingress protection | IP20 (display), IP54 (bar/bar-top), IP65 (cooler/freezer) | IEC 60598-1 |

| Safety / EMC | ETL/cETL to UL 2108 + CSA 250.0, CE / TUV to EN 60598-2-21, EN 55015 | Factory witness test every lot |

2. PCB & Component Engineering

Shelf lighting operates in high-density retail environments where replacement cost is far higher than the FOB price. Beauty STC therefore builds on 2 oz (70 µm) double-layer electrolytic-copper PCB, 1.6 mm FR-4 with 150 °C TG, and 3 mm minimum track spacing for 24 V circuits. Every 50 mm we place a Zener-diode shunt to protect the 2835 LED should one channel open. Reflow is done under nitrogen, 230 °C peak, with 100 % AOI and 10 % ICT. These details are embedded in our ISO 9001:2015 work instruction WI-18-23, traceable by 2D barcode on the reel.

3. Colour & Flux Binning Protocol

Instead of relying on the LED vendor’s master-bin, we re-bin in-house after a 2-hour 55 °C stabilisation. This second-level binning removes the ±7 % flux tolerance often seen in generic shelf lights and guarantees < 3 SDCM colour consistency even when orders are produced 12 months apart. Distributors can therefore replace a single segment in the field without visible patchwork.

4. Comparative Table – Generic Market vs. Beauty STC Certified Quality

| Attribute | Generic “Trade-Grade” Shelf Strip | Beauty STC Certified Build |

|---|---|---|

| Efficacy (3000 K) | 90–100 lm/W | 135–150 lm/W |

| CRI | 80 typical | ≥ 90 (R9 ≥ 50) |

| SDCM | 5–7 | ≤ 3 |

| PCB copper | 1 oz (35 µm) | 2 oz (70 µm) |

| Operating temperature | –10 °C to 40 °C | –20 °C to 60 °C (Ts point) |

| Driver type | Constant-voltage, no PFC | Flicker-free, >0.9 PFC, SELV |

| Certifications | CE self-declaration only | ETL/cETL + TUV CE, RoHS, REACH |

| Warranty | 1–2 year | 5 year limited, field-replaceable segments |

| Traceability | Batch only | Reel & date code, 2D barcode, LM-80 report on file |

5. Production Consistency Controls

IQC: 100 % LED sample under 85 °C / 85 % RH 168 h per HAST.

IPQC: SPC chart on flux and chromaticity every 2 h.

OQC: 100 % 1 500 V Hi-Pot, 100 % 24 h burn-in at 45 °C, 0 °C cold-start.

Package: Moisture-barrier bag + desiccant + ESD foam; shelf life 24 months.

6. OEM / ODM Shelf Hardware Ready for Customisation

Since 1998 Beauty STC has tooled more than 180 aluminium extrusion profiles for shelf lighting—ranging from 8 mm “barely visible” edge-lit acrylic to 40 mm heat-sink bars that double as load-bearing members. We keep 15 000 kg of 6063-T5 aluminium in-house and offer anodising, powder-coat, or brushed electrophoresis in any RAL within 10 days. Engineers can specify CCT (1 800 K–6 500 K), CRI 80/90/97, single-colour, tunable-white, RGBW, or addressable pixel pitch down to 16 mm. All derivatives are submitted to the same ETL/TUV file, eliminating re-certification cost for distributors.

For quotations, photometric files, or to schedule a virtual factory tour, contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Precision Manufacturing: Industrial-Grade Shelf Lighting Production

Factory Infrastructure & Core Capabilities

Beauty STC Lighting’s Jiangmen manufacturing facility—established in 1998 and situated in Jianghai District’s High-tech Industrial Zone—combines 25+ years of technical expertise with ISO-certified production workflows. Our factory operates under strict adherence to international safety and performance standards, including ETL (USA/Canada) and TUV CE (Europe) certifications. These certifications are rigorously integrated into every production phase, ensuring compliance with regional regulatory requirements for electrical safety, electromagnetic compatibility, and fire resistance. All facilities maintain controlled cleanroom environments for PCB assembly and precision testing, with temperature and humidity monitoring to guarantee consistency in high-volume output.

Advanced Production Line Technology

Our end-to-end manufacturing process leverages automation and data-driven quality control to deliver industrial-grade shelf lighting solutions:

SMT Assembly: Fully automated surface mount technology (SMT) lines with 0.01mm placement accuracy for PCB fabrication. This eliminates manual handling errors and ensures uniform solder joint integrity across all batches.

Aging Tests: All LED modules undergo 72-hour continuous operation under rated load conditions (including 10% overload stress tests) to validate thermal stability, driver compatibility, and lumen maintenance.

Multi-Stage QC Protocol:

Incoming Material Inspection: Raw components (LED chips, drivers, PCBs) tested against IEC 62471 photobiological safety and RoHS standards.

In-Process Checks: Voltage/current stability, flicker analysis (<5% flicker index), and color consistency (SDCM ≤3) measured at critical assembly stages.

Final Validation: IP rating verification (up to IP67), dimming performance (0-10V/DALI), and lifetime projection testing per LM-80 standards.

OEM/ODM Customization Capabilities

We provide end-to-end engineering support for custom shelf lighting projects, from concept validation to mass production. Our modular design approach accommodates project-specific requirements while maintaining full traceability and compliance documentation.

| Parameter | Standard Range | Custom Options | Notes |

|---|---|---|---|

| Length | 1m, 2m, 3m | 0.5m increments up to 10m | Precision cutting with laser-sealed edges |

| CCT | 2700K – 6500K | 2200K to 7000K | Tunable white (2700K–6500K) or fixed spectrum |

| CRI | ≥90 | ≥95 (optional) | For high-fidelity color rendering in retail/display environments |

| IP Rating | IP20 (indoor) | IP65 (wet locations), IP67 (outdoor) | Custom housings for bars, restaurants, and industrial settings |

| Packaging | Standard retail | Branded, bulk, custom inserts | OEM branding, anti-static packaging, and logistics-optimized designs |

| Driver Compatibility | Integrated driver | External driver options | Configurable for 12V/24V systems; DALI/0-10V dimming support |

All custom designs undergo rigorous prototyping, including thermal imaging analysis and photometric testing (IES files provided), before production scaling. Our engineering team collaborates directly with clients to optimize optical performance, mechanical integration, and cost efficiency for commercial projects.

Global Compliance & Documentation

Every product batch includes certified test reports for ETL, CE, RoHS, and IEC standards. Our ERP-integrated quality management system ensures full traceability from raw materials to final shipment, with documentation tailored to regulatory requirements in target markets (e.g., UL/cUL for North America, CE for EU). For technical specifications, project-specific compliance documentation, or OEM consultation, contact our engineering team:

[email protected] | +86 13902885704

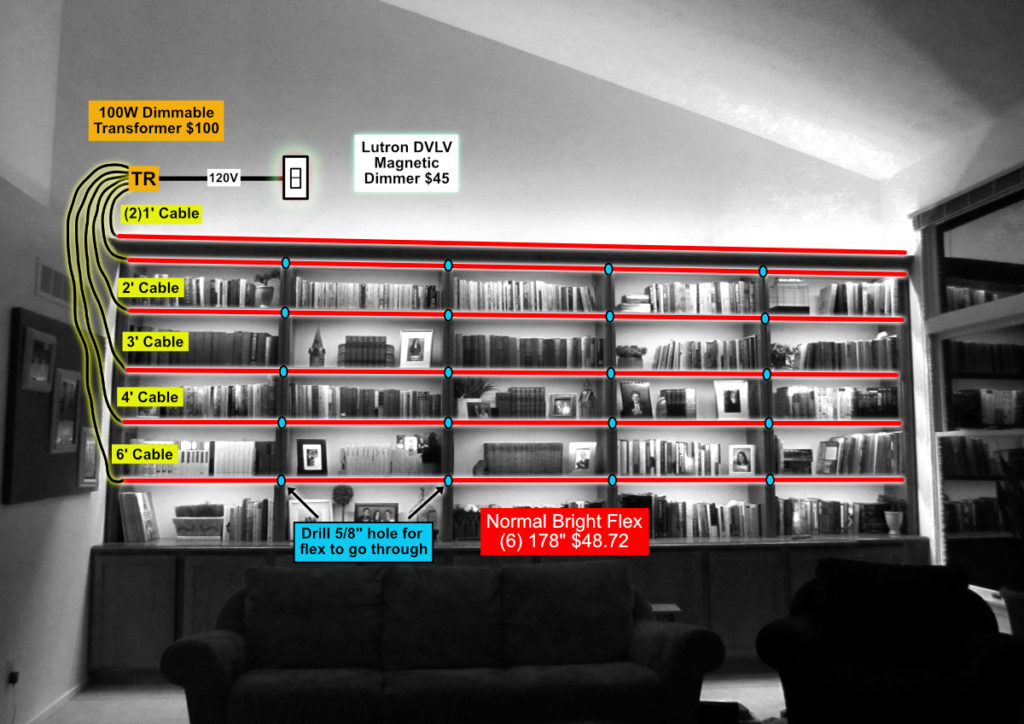

Installation & Application Scenarios

Application Scenarios for OEM LED Shelf Lighting

(Factory-direct, ETL/TUV-CE listed, 25-year manufacturing pedigree)

H2 | Where Spec-Grade Shelf Lighting Adds Measurable Value

| Sector | Typical Shelf Type | Lighting KPI | Driver & Control Notes | Cert. Advantage |

|---|---|---|---|---|

| Upscale Hotels | Mini-bar, reception back-bar, art niche | 90 CRI, 3000 K, ≤6 SDCM | 24 V constant-voltage, DALI or 0-10 V dimming to 0.2 % | ETL for North-American flag chains, TUV-CE for EU operators |

| High-end Retail / Malls | Glass display, cosmetic gondola, in-store pop-up | 1500 lx on task, UGR < 16 | Motion + daylight harvest via Casambi or DALI-2; tunable white 2700-6500 K | UL 2108 & CE LVD simplify insurer sign-off |

| Corporate Offices | Trophy wall, library, agile collaboration shelf | 500 lx, flicker-free <1 % @ 1 kHz | 48 V remote driver in ceiling void, plenum-rated cable | ETL 1598C wet-label eliminates field inspection costs |

| Bars & Nightclubs | Bottle ledge, under-counter, DJ booth | RGBW, 24 V, 10 px/m for pixel mapping | IP54 extrusion, silicone diffuser, DMX512/RDM | CE EMC pass for EU nightlife noise regs |

| Façade / Architectural Reveal | Terracotta rib, glass fin, perforated bronze panel | 4000 K, 1 W/100 mm, asymmetric 20° lens | 24 V, -40 °C to 50 °C driver, surge 6 kV | ETL damp-location rating meets IES RP-33 |

H2 | Installation Guidelines for Contractors

H3 | 1. Pre-Order Engineering Checklist

Confirm local code: Class 2 (≤60 V DC) circuits accepted in most jurisdictions—our 24 V strips carry ETL 2108 & CE EN 60598-2-20.

Forward shelf loading data: aluminium extrusion max 1 kg/100 mm; acrylic shelf ≤5 kg point load.

Choose colour temp & CRI bin: we bin to 3-step MacAdam for hotel & museum work—state at PO.

H3 | 2. Site Prep & Wiring

Run 18 AWG stranded, 105 °C, 300 V from remote driver location; keep voltage drop ≤5 %.

For drywall recess, rout 12 mm groove; slide extrusion with integrated heatsink (≥5 mm wall) to maintain 50 K ΔT.

IP54 version: apply neutral-cure silicone at extrusion ends; allow 3 mm weep slot every 500 mm.

H3 | 3. Driver Placement & Dimming

Centralised vs distributed: ≤30 m cable run use 24 V, >30 m switch to 48 V system (same strip, dual-voltage PCB).

Dimming protocols:

0-10 V: sink 0.5 mA per driver—loop 50 drivers max.

DALI-2: addressable, 64 drivers / 300 m segment; integrate into BACnet via gateway.

Surge rating: 4 kV line-earth, 2 kV line-line standard; upgrade to 6 kV for façade installs—specify at order.

H3 | 4. Thermal & Lifetime

Heatsink extrusion 6063-T5, ≥1.2 mm fin thickness keeps LED Tj ≤ 75 °C—L80 > 54 khrs @ Ta 35 °C.

For enclosed timber shelf, add 5 mm aluminium back-plate; otherwise derate current to 350 mA instead of 500 mA.

H3 | 5. Commissioning & Documentation

Supply client with IES files, TM-30 colour report, and ETL/TUV-CE certificates—pre-loaded on QR code inside driver box.

Provide spare 5 % strip length and two drivers per project—OEM policy since 1998, no MOQ on spares.

H2 | OEM Customisation Matrix (Factory-Direct)

| Attribute | Standard Offer | Custom Range | MOQ | Tooling Lead-Time |

|---|---|---|---|---|

| CCT | 2400–6500 K | 1800 K Amber, 2000 K Candle, 8500 K Glacier | 500 m | 7 days |

| CRI | 80, 90 | 95 CRI (R9 > 90), 97 CRI (R1-R15 > 95) | 1000 m | 10 days |

| PCB Width | 5 mm, 8 mm, 10 mm | 3 mm–25 mm | 300 m | 5 days |

| Extrusion Finish | Clear anodise | Black, champagne, brushed, wood-wrap film | 500 pcs | 12 days |

| Length Tolerance | ±1 mm | ±0.2 mm (CNC post-cut) | 100 pcs | 3 days |

| Logo Laser | No | 2 W fibre etch on end-cap or PCB | 100 pcs | 2 days |

H2 | Next Step for Specifiers

Send shelf geometry & lux plot to [email protected]; our Jianghai engineering team (est. 1998) returns a DIALux report, wiring schematic, and landed quotation within 48 h. All quotations include ETL & TUV-CE file numbers for immediate submittal.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Engineered Shelf Lighting Solutions for Commercial Applications

Beauty STC Lighting delivers technically rigorous shelf lighting solutions for commercial environments, backed by over 25 years of manufacturing expertise and full compliance with international safety standards. As a factory-direct supplier, we eliminate intermediaries while maintaining strict quality control across all production stages—ensuring consistent performance for distributors, architects, and project managers globally.

Certified for Global Market Compliance

All shelf lighting products undergo third-party testing to meet regional electrical safety requirements:

ETL Certification: Compliant with UL 1598 for North American retail and hospitality installations (USA/Canada)

TÜV CE Certification: Meets EN 60598 standards for European commercial lighting applications

This dual certification eliminates compliance risks for international projects, reducing testing delays and certification costs for your supply chain.

Precision Engineering Since 1998

Established in 1998 at our ISO-certified facility in Jiangmen, Guangdong, our engineering team specializes in thermal management, light distribution precision, and mounting solutions tailored for commercial display environments. Every product undergoes:

72-hour burn-in testing

Lumen maintenance verification (LM-80 compliant)

IP rating validation for intended applications

Structural stress testing for mounting hardware

OEM/ODM Capabilities for Commercial Projects

We provide end-to-end manufacturing support for custom shelf lighting systems, from design validation to mass production:

| Specification Parameter | Standard Range | Customization Options |

|---|---|---|

| LED Chip Type | SMD 2835 (industry standard) | SMD 5050, COB, or high-CRI variants |

| Color Temperature | 2700K–6500K | Tunable white (2700K–6500K), RGBW |

| CRI (Ra) | >90 (standard retail grade) | >95 (museum/gallery grade) |

| Voltage | 12V/24V DC | Custom voltage (36V, 48V) |

| IP Rating | IP20 (dry indoor) | IP65 (wet locations, outdoor use) |

| Dimming Protocol | 0-10V, PWM | DALI, Bluetooth, Zigbee, 1-10V |

| Mounting Options | Adhesive backing, aluminum channels | Custom profiles, recessed brackets |

| Length Tolerance | ±1mm per 1m segment | Full custom cut-to-length |

Global Distribution Network

We supply certified shelf lighting systems to distributors in 50+ countries, with proven performance in:

European luxury retail displays (e.g., France, Germany, UK)

North American supermarket and museum installations

Asian hospitality and nightclub environments (Japan, South Korea, Singapore)

Australian architectural projects and Russian commercial complexes

Our export operations include pre-shipment quality inspections, FOB/Shanghai terms, and compliance documentation tailored to destination markets.

Contact Our Engineering Team

For technical specifications, project-specific requirements, or compliance documentation:

[email protected] | +86 13902885704

Beauty (STC) Manufacturing Co., Ltd

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Certified: ETL (USA/Canada), TÜV CE (Europe)

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).