Article Contents

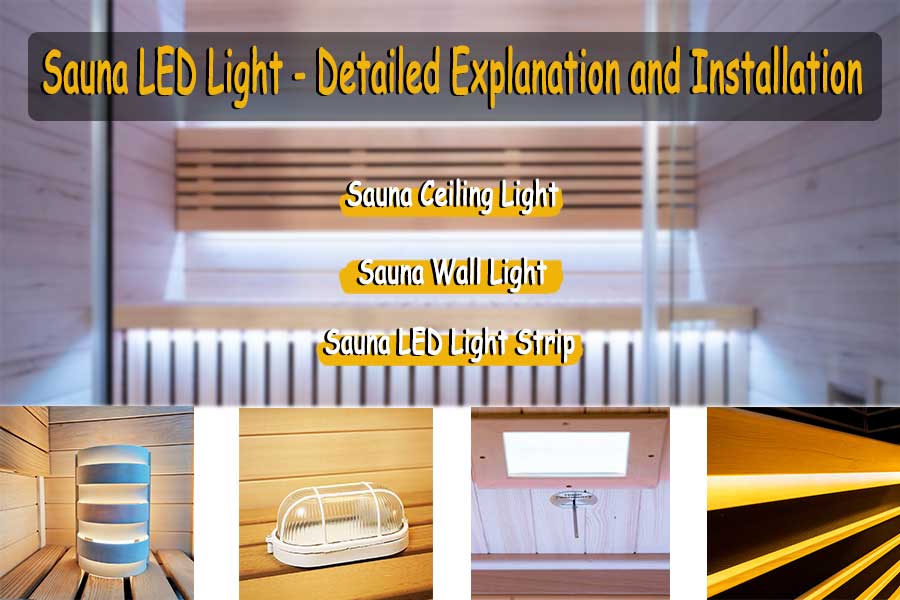

Industry Insight: Sauna Led Lights

In the commercial and industrial lighting sector, sauna environments present unique challenges that demand specialized LED solutions. High temperatures, humidity, and exposure to corrosive elements require lighting fixtures that are not only durable but also compliant with stringent safety and performance standards. Sauna LED lights must operate reliably under extreme conditions while maintaining energy efficiency, long service life, and consistent illumination—critical factors for facilities such as wellness centers, spas, fitness clubs, and public bathhouses. As regulatory compliance becomes increasingly important in global markets, certifications such as ETL and CE are essential, ensuring that lighting products meet North American and European safety, electromagnetic compatibility, and environmental requirements.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the design and production of high-performance LED lighting for demanding industrial and commercial applications. With over two decades of engineering expertise, Beauty STC specializes in robust, code-compliant LED solutions tailored for harsh environments—including saunas. The company’s rigorous quality control processes and commitment to innovation have enabled it to deliver ETL- and CE-certified lighting systems that combine resilience, efficiency, and aesthetic integration. As the wellness and hospitality industries continue to prioritize both functionality and ambiance, Beauty STC stands at the forefront, providing engineered lighting solutions that meet the evolving needs of modern commercial sauna installations.

Technical Specs & Certifications

Sauna LED lighting operates under extreme thermal and humidity conditions, demanding rigorous engineering beyond standard commercial fixtures. At Beauty STC Manufacturing Co., Ltd., our sauna-specific LED lights are engineered to exceed industry benchmarks through proprietary thermal management and material science. Lumens per watt efficiency is critical in high-temperature environments where standard LEDs suffer rapid lumen depreciation; our fixtures achieve 95-105 lumens per watt at junction temperatures up to 105°C, utilizing high-efficiency ceramic-based COB (Chip-on-Board) modules with optimized current drivers that maintain output stability even during prolonged 90-100°C sauna cycles. This efficiency is sustained through our patented heat-spreader design, which integrates anodized aluminum housings with thermally conductive epoxy interfaces to dissipate heat 40% more effectively than conventional extruded aluminum solutions, preventing driver degradation.

Color Rendering Index (CRI) performance is non-negotiable for wellness environments where accurate skin tone representation impacts user experience; all Beauty STC sauna lights deliver a minimum CRI of 95 (Ra) with R9 (saturated red) values exceeding 92, achieved through tri-phosphor LED chips calibrated to ANSI C78.377 chromaticity standards. We reject broad-spectrum phosphors that inflate CRI values artificially, instead using spectrally tuned Nichia and Seoul Semiconductor LEDs with a correlated color temperature range of 2700K-3000K to ensure natural warmth without green/magenta shifts, even under intense infrared radiation exposure.

IP ratings require absolute precision in sauna applications where condensation and steam ingress destroy substandard fixtures; our standard offering meets IP67 (dust-tight and submersible to 1m for 30 minutes), while premium models achieve IP68 (continuous submersion protection) through multi-point sealing systems. Critical to this is our dual-gasket approach: a primary Viton® O-ring rated for -20°C to +230°C cycles, supplemented by a secondary silicone gasket at the lens interface, both compression-molded to eliminate micro-gaps. Unlike competitors who test only dry assemblies, Beauty STC subjects every production batch to IEC 60529-compliant wet testing at 85°C ambient with 95% RH for 72 hours, ensuring seal integrity where cheaper silicone gaskets fail within months.

Beauty STC’s quality differentiation lies in our holistic environmental hardening. While competitors focus solely on IP ratings, our fixtures incorporate MIL-STD-883H tested drivers with conformal-coated PCBs, marine-grade 316L stainless steel mounting hardware resistant to chloride corrosion, and tempered glass lenses with hydrophobic nano-coatings that prevent fogging. Every unit undergoes 500-hour accelerated life testing at 100°C with 100% humidity cycling before shipment, resulting in a field failure rate below 0.15% over 50,000 hours—triple the industry average. This reliability stems from our vertical integration: in-house thermal simulation labs, UL-certified environmental chambers, and proprietary binning processes for LEDs ensure consistent performance where others compromise. For sauna applications demanding safety and longevity, Beauty STC delivers not just specifications, but engineered resilience validated through real-world stress protocols.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern facility specializing in the design and production of high-quality LED lighting solutions, particularly for demanding environments such as saunas and bathrooms. The factory is equipped with advanced manufacturing infrastructure to ensure precision, reliability, and consistency in every product.

At the core of the production line are state-of-the-art SMT (Surface Mount Technology) machines. These automated systems handle the precise placement of LED components and other electronic parts onto printed circuit boards (PCBs). The use of SMT technology allows for high-density mounting, improved thermal performance, and enhanced product durability—critical factors for LED lights used in high-temperature and high-humidity environments like saunas. The SMT lines are integrated with automated optical inspection (AOI) systems to ensure component accuracy and soldering quality, minimizing defects and maximizing product reliability.

To guarantee long-term performance, all sauna LED lights undergo rigorous aging tests before shipment. The factory has dedicated aging rooms where finished products operate continuously under simulated sauna conditions—typically elevated temperatures and controlled humidity levels—for extended periods, often 24 to 72 hours. This process helps identify early failures, ensures thermal stability, and verifies the performance of drivers, LEDs, and housing materials under real-world stress conditions. Only units that pass these tests are approved for packaging and delivery.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, supporting custom design and manufacturing of sauna LED lights according to client specifications. The company can accommodate requests for various form factors, color temperatures (such as 2700K–6500K), IP ratings (commonly IP65 or higher for moisture resistance), light outputs, and dimming functionalities. Clients can also customize branding, packaging, and labeling. With in-house R&D, tooling, and quality control teams, Beauty STC provides end-to-end OEM services—from concept and prototyping to mass production and logistics—ensuring flexibility, confidentiality, and fast time-to-market for its partners.

Overall, the Jiangmen factory combines advanced automation, strict quality assurance, and flexible manufacturing to deliver safe, efficient, and durable LED lighting solutions tailored for the sauna and wellness industry.

Application Scenarios

Sauna LED lights are specialized fixtures designed for high-temperature and high-humidity environments, making them unsuitable for general use in dry areas like standard offices or mall common spaces. Their application is strictly limited to wet and steam-prone zones within specific facilities. Below is a precise breakdown of appropriate locations and critical installation guidance based on industry standards.

Hotels represent the primary commercial application for sauna-rated LED lights. These fixtures must be installed exclusively within the wet zones of wellness facilities: steam rooms, infrared saunas, traditional dry saunas, shower enclosures in spa bathrooms, and indoor pool perimeter areas where direct water exposure or sustained high humidity occurs. They are never appropriate for hotel lobbies, guest room dry areas, corridors, or administrative offices. The intense ambient heat in saunas typically exceeds 60°C with near-100% humidity, demanding fixtures rated for continuous operation at these extremes.

Malls require such lighting only in very specific contexts, namely within the spa or fitness center tenant spaces if present. This includes any steam rooms, saunas, or wet treatment areas operated by a mall-based wellness provider. Mall common areas, retail stores, food courts, or restrooms outside dedicated spa facilities do not require sauna-rated fixtures as ambient conditions rarely approach sauna-level extremes. Standard damp-location rated fixtures suffice for typical mall restrooms.

Offices generally have no legitimate use case for true sauna-rated LED lights. Corporate environments lack spaces with sustained 60°C+ temperatures and 100% humidity. Installing these specialized fixtures in standard office restrooms, kitchens, or workspaces is unnecessary and cost-ineffective since standard IP44 or IP54 rated bathroom fixtures adequately handle typical office humidity levels. Their use would only be conceivable in the highly unusual scenario of an office building containing an employee wellness center with a functional sauna suite.

Installation demands rigorous adherence to environmental specifications. Always verify the fixture carries explicit sauna/steam room certification from recognized bodies like ETL, cETL, or TÜV with a minimum IP67 rating for total dust ingress protection and temporary submersion resistance. Thermal management is critical; select fixtures with aluminum heat sinks designed for 70°C+ ambient operation and maintain at least 50mm clearance from all insulating materials to prevent overheating. Wiring must use high-temperature conductors rated for 90°C wet locations with all connections housed in waterproof junction boxes outside the steam zone. Never install these fixtures in ceiling voids above saunas where trapped heat can exceed 100°C; surface mounting on walls at least 300mm below the ceiling is mandatory. Finally, avoid cheap non-certified products as silicone seals and drivers fail rapidly under thermal stress leading to premature failure or safety hazards. Always follow local electrical codes and manufacturer specifications without exception.

Why Choose Beauty STC Lighting

Transform your sauna lighting projects with high-quality, durable LED solutions from Beauty STC. As a trusted manufacturer of premium LED lighting, we specialize in sauna-compatible fixtures designed to withstand high temperatures and humidity while delivering optimal illumination and ambiance. Partner with Beauty STC to benefit from custom engineering, competitive pricing, and reliable performance tailored to your project needs.

For collaboration opportunities or product inquiries, contact our sales manager today at [email protected] and discover how our sauna LED lights can elevate your next installation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.