Article Contents

Industry Insight: Roll Of Led Strip Lights

The commercial and industrial lighting landscape has undergone a transformative shift with the widespread adoption of LED technology, and among the most versatile solutions driving this evolution is the roll of LED strip lights. Valued for their flexibility, energy efficiency, and seamless integration into a wide range of applications—from warehouse task lighting and retail accenting to architectural cove lighting and industrial signage—LED strip lights offer unmatched adaptability in both form and function. As facility managers and lighting designers prioritize sustainability, longevity, and compliance, certifications such as ETL and CE have become critical benchmarks, ensuring that products meet rigorous North American and international safety and performance standards.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions since its founding in 1998. With over two decades of engineering excellence and a commitment to quality-driven manufacturing, Beauty STC delivers high-performance LED strip lights designed specifically for demanding commercial and industrial environments. Combining cutting-edge technology with strict adherence to ETL and CE regulations, Beauty STC continues to set the standard for reliability, efficiency, and scalable lighting solutions across global markets.

Technical Specs & Certifications

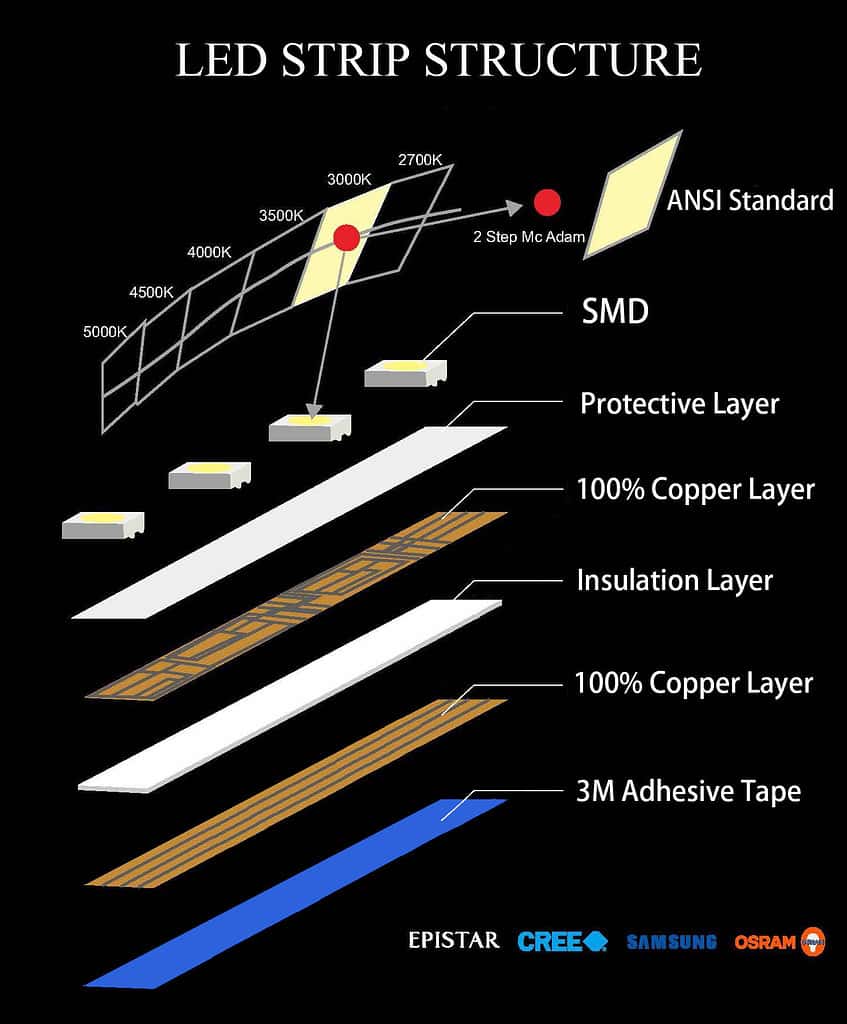

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance LED strip lights with rigorous attention to efficiency, color fidelity, and environmental resilience. Our standard rolls (typically 5-meter reels on reels) for commercial and premium residential applications deliver the following verified technical specifications under controlled laboratory conditions at 25°C ambient temperature. Lumens per Watt efficiency is a core focus, with our standard 24VDC high-density strips (e.g., 120 LEDs/m) achieving a consistent range of 120-140 lumens per watt at full drive current. This efficiency is maintained through the use of premium Epistar or Samsung LED chips coupled with optimized constant-current drivers and thermally efficient flexible printed circuit boards, ensuring minimal lumen depreciation over time even under sustained operation. Crucially, this lm/W figure represents real-world performance measured at the strip level, not theoretical chip-level values, and accounts for all optical and electrical losses inherent in the complete system.

Color Rendering Index performance exceeds the stringent CRI >90 requirement across our premium product lines. We consistently achieve CRI values of 92-95 (Ra) using a minimum of 90 CRI binning for all LEDs. More importantly, Beauty STC prioritizes critical color fidelity by ensuring high R9 values (saturated red rendering) of at least 50, often reaching 70+, which is essential for accurate skin tones and vibrant color representation in retail, hospitality, and healthcare settings. This is validated using spectroradiometer-based measurements per IES LM-79 standards, and we provide full spectral power distribution data and TM-30-15 reports upon request to confirm fidelity beyond the basic Ra metric.

Regarding environmental protection, Beauty STC offers multiple IP-rated options to suit diverse installation environments. Our standard silicone-jacketed strips achieve IP65 rating, providing robust protection against low-pressure water jets and complete dust ingress prevention, suitable for most indoor damp locations and protected outdoor eaves. For fully exposed outdoor or washdown environments, our rigorously tested IP67 strips withstand temporary immersion up to 1 meter for 30 minutes, validated through third-party salt spray and thermal cycling tests far exceeding basic IP certification requirements. All encapsulated strips utilize medical-grade silicone with UV inhibitors and undergo 100% automated optical inspection and high-potential testing to guarantee coating integrity and electrical safety. Beauty STC’s quality differentiation lies in our vertically integrated manufacturing process, where we control LED binning, phosphor application, soldering under nitrogen atmosphere to prevent oxidation, and final assembly within our ISO 9001-certified facility. This results in strip lights exhibiting less than 3% lumen maintenance variation across reels, superior thermal management preventing localized hot spots, and a minimum 50,000-hour L70 lifetime at 45°C case temperature, significantly outperforming industry averages and ensuring consistent, reliable illumination for demanding professional applications.

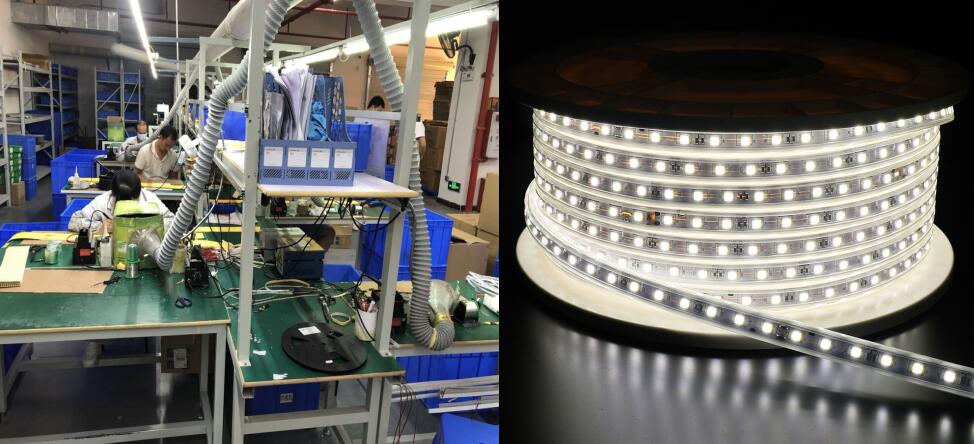

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is fully equipped to support high-volume, precision manufacturing of LED lighting products, with a strong focus on quality, efficiency, and customization.

The facility is outfitted with advanced SMT (Surface Mount Technology) production lines, utilizing high-speed, high-precision SMT machines from leading manufacturers. These machines ensure accurate placement of LED components, resistors, capacitors, and ICs onto flexible and rigid PCBs used in LED strip lights. The SMT process is supported by automated optical inspection (AOI) systems to detect placement errors and soldering defects in real time, maintaining consistent product quality and reducing failure rates.

For reliability assurance, the factory implements rigorous aging tests as part of its quality control protocol. Finished LED strip lights undergo extended burn-in periods—typically 24 to 72 hours—under controlled temperature and load conditions. This process helps identify early-life failures, verifies thermal performance, and ensures long-term stability of light output and color consistency. Additional testing includes waterproof validation for relevant IP-rated strips, electrical safety checks, and photometric measurements using integrating spheres.

Beauty STC has robust OEM/ODM capabilities tailored specifically for roll-based LED strip light products. The company supports full customization including LED density (e.g., 60, 120, 240 LEDs/m), color temperature options (from 2200K to 6500K), RGB and RGBIC configurations, silicone coating thickness, copper traces, input voltage (12V or 24V), and cut marks. Clients can request private labeling, custom packaging (such as branded reels, cartons, and instruction sheets), and tailored lengths per roll (commonly 5m, 10m, or 16.4ft). The factory also accommodates special requirements such as low-glare diffusers, enhanced UV resistance, or high CRI (90+).

With integrated design, engineering, and production teams, Beauty STC efficiently manages turnkey OEM projects from prototype development to mass production, offering reliable supply chain management and on-time delivery for global clients.

Application Scenarios

LED strip lights offer versatile lighting solutions across commercial environments due to their flexibility, energy efficiency, and design adaptability. In hotels, they excel in creating ambiance and functionality. Install them under bed frames in guest rooms for subtle night lighting, along corridor ceilings to guide guests without harsh glare, within cove lighting in lobbies for a welcoming glow, and beneath bar counters in lounges for dramatic effect. For malls, focus on visual merchandising and safety. Use them to highlight product displays in retail stores, outline escalator handrails for safety, illuminate ceiling coves in food courts to enhance the dining atmosphere, and backlight signage for high-impact branding. In offices, prioritize productivity and well-being. Install under desk edges to reduce eye strain during screen work, within suspended ceiling trays for even ambient light, along stairwells for safety, and in meeting rooms to accentuate architectural features without distracting from presentations.

Installation requires careful planning to ensure longevity and performance. Always use aluminum channels to dissipate heat effectively; direct adhesion to surfaces without channels causes overheating and premature failure. For runs exceeding 5 meters on 12V systems or 10 meters on 24V systems, implement power injection at multiple points to prevent voltage drop, which manifests as dimming at the strip’s end. Verify compatibility between the strip’s IP rating and the environment—IP65 minimum for damp areas like hotel bathrooms or mall food courts, and IP20 only for dry, enclosed office channels. Secure strips firmly using the manufacturer’s recommended adhesive or mechanical clips, ensuring surfaces are clean, dry, and degreased before application. Double-check polarity during connections, as reversed wiring damages LEDs instantly. Finally, conduct a full-power test for at least 15 minutes before final mounting to catch defects or connection issues early. Partner with reputable manufacturers like Beauty (STC) for strips with consistent color rendering and robust thermal management, critical for commercial reliability.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality LED strip lights from Beauty (STC) Manufacturing Co., Ltd. As a trusted partner in innovative lighting solutions, we offer premium rolls of LED strip lights designed for flexibility, efficiency, and long-lasting performance. Whether for residential, commercial, or industrial applications, our products meet the highest industry standards.

Partner with Beauty STC to access competitive pricing, custom OEM options, and reliable global shipping. Our team is ready to support your business with expert guidance and tailored lighting solutions.

For partnership inquiries and product details, contact our sales manager at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.