Article Contents

Industry Insight: Rgbww Meaning

Understanding RGBWW Technology in Commercial Lighting Applications

Defining RGBWW: Beyond Basic Color Mixing

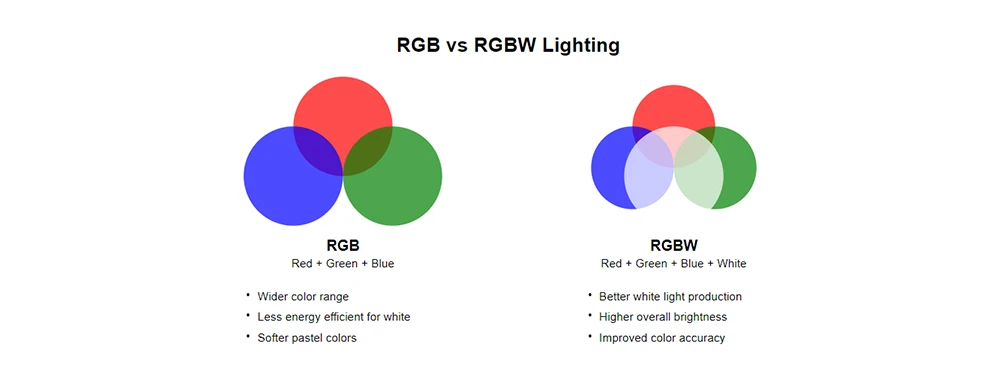

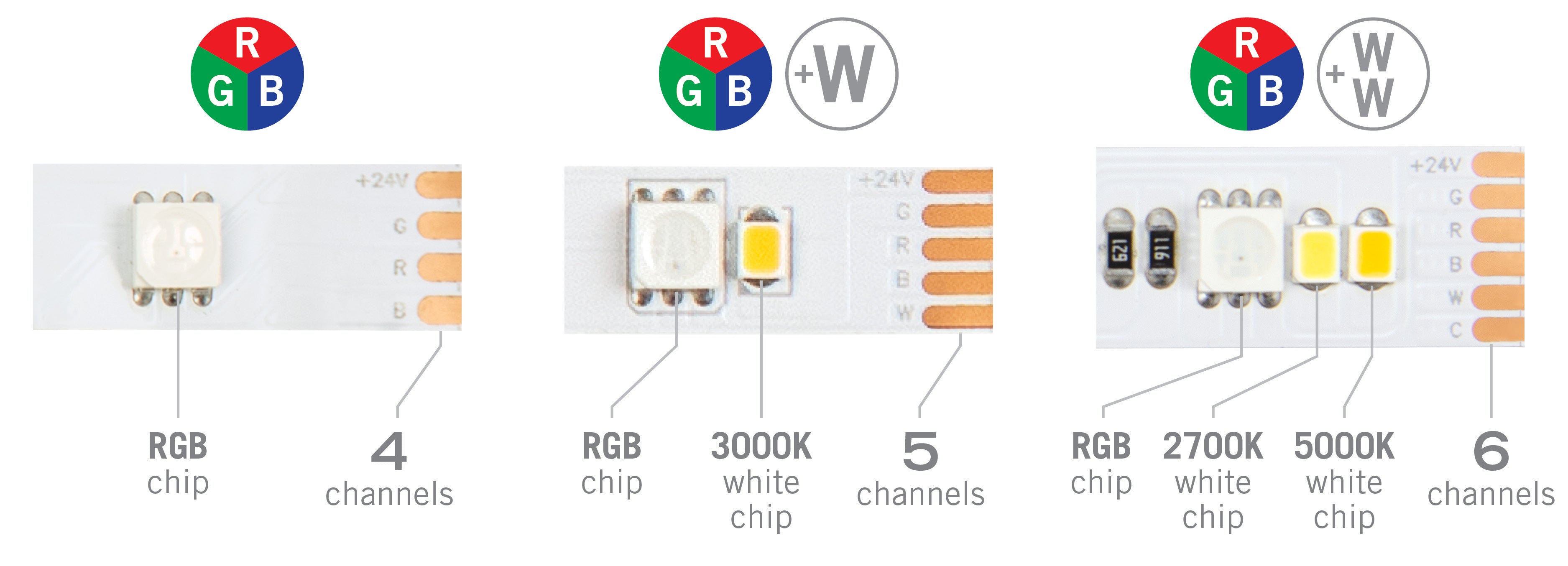

RGBWW (Red, Green, Blue, Warm White, Cool White) represents a 5-channel LED configuration that integrates individual red, green, blue, warm white, and cool white LEDs within a single strip or fixture. This configuration enables precise color tuning and seamless transitions between warm (2700K–3000K) and cool (5000K–6500K) white temperatures, alongside vibrant RGB color mixing. Unlike RGBW systems—which typically feature a single white channel (usually cool white)—RGBWW provides dual white channels for superior color temperature control, making it ideal for commercial applications where dynamic lighting scenarios are required.

Market Demand Drivers for RGBWW in Professional Installations

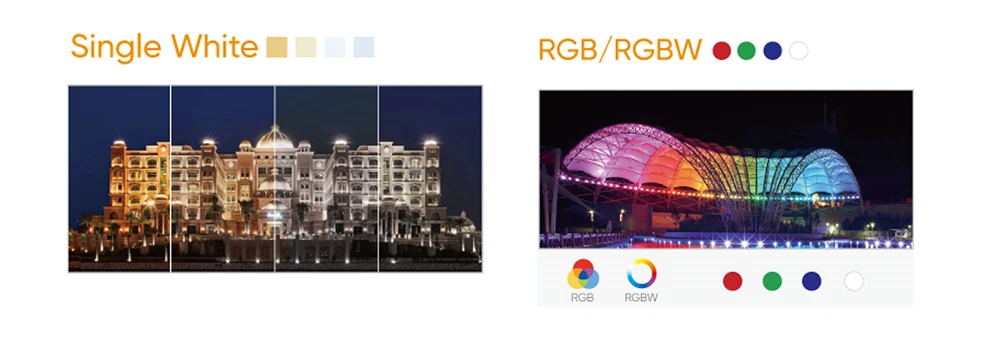

Modern commercial projects increasingly demand lighting systems that adapt to varying functional and aesthetic needs. Retail environments use RGBWW to highlight products with precise color accents while adjusting white temperature for different times of day. Hospitality venues require tunable white for ambiance control, from warm tones during dinner service to cooler temperatures for cleaning. Architectural installations leverage RGBWW for dynamic facades that respond to time of day or events. These applications require consistent color rendering and stable white temperatures—qualities that depend on high-quality manufacturing and certified components.

Why Certification Compliance is Non-Negotiable for Importers

Importers of LED lighting products face stringent regulatory requirements in Western markets. ETL certification (USA/Canada) and TÜV CE (Europe) are not optional—they are mandatory for market access and liability protection. Non-compliant products risk customs rejection, safety recalls, and reputational damage. Crucially, certified products undergo rigorous testing for electrical safety, thermal management, and electromagnetic interference (EMI). For RGBWW systems, certification ensures that the dual white channels maintain consistent color temperature across the entire product lifecycle, preventing issues like color drift or flickering that can occur with uncertified components.

Beauty STC: 25+ Years of Certified Manufacturing Excellence

Established in 1998, Beauty STC Manufacturing Co., Ltd. has delivered high-performance LED solutions to distributors across 50+ countries. Our 25+ years of experience in OEM/ODM manufacturing ensures rigorous quality control from component sourcing to final testing. All products undergo ETL and TÜV CE certification processes, guaranteeing compliance with North American and European safety standards. We specialize in flexible LED strip lights, panel lights, and high-bay fixtures with RGBWW capabilities, providing distributors with reliable, certified solutions that meet the exacting demands of commercial projects.

For OEM specifications and certification documentation, contact our engineering team at [email protected] or +86 139 0288 5704.

RGBW vs. RGBWW Technical Comparison

| Feature | RGBW | RGBWW |

|---|---|---|

| Channels | 4 (R, G, B, W) | 5 (R, G, B, WW, CW) |

| White Options | Single white channel (typically cool white, ~6500K) | Dual white channels (Warm White: 2700K–3000K; Cool White: 5000K–6500K) |

| Color Temperature Control | Fixed white temperature; limited adjustability | Smooth, precise tunable white across full spectrum |

| Typical Applications | Basic color lighting with fixed white | Commercial spaces requiring dynamic white and color mixing (retail, hospitality, architecture) |

| Certification Requirements | Must meet ETL/CE for safety and performance | Requires additional testing for consistent color rendering across dual white channels |

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for RGBWW LED Strips

(Red-Green-Blue-Warm White-Cool White – 5-in-1)

1. Definition & Optical Architecture

RGBWW, in professional procurement terms, is a 5-channel LED package that integrates

3× primary-color dies (R, G, B)

2× white dies (warm-white 2700-3000 K and cool-white 5700-6500 K)

The dual-white channel gives CCT tunability from 2200 K to 6500 K while maintaining RGB saturation ≥ 95 % of the CIE 1931 gamut.

Typical drive: 20 mA per color @ 24 VDC constant-voltage strip, 5-in-1 SMD 5050 package, 60 LEDs m⁻¹.

2. Key Metrics for Commercial Specification

| Parameter | Engineering Reference | Beauty STC Certified Range |

|---|---|---|

| Luminous Efficacy | 75-95 lm W⁻¹ (RGB mixed) | 85-95 lm W⁻¹ (24 V, 60 LED m⁻¹) |

| White Efficacy | 100-110 lm W⁻¹ (single-white) | 105-115 lm W⁻¹ |

| CRI (white channels only) | >80 (market entry) | Ra ≥ 90, R9 ≥ 60 |

| CCT Accuracy | ±300 K | ±150 K (MacAdam 3-step) |

| Binning Tolerance | 3 SDCM | 2 SDCM (automated SMD sorter) |

| PCB Copper Weight | 1 oz (35 µm) | 2 oz (70 µm) rolled annealed copper |

| Voltage Drop (5 m) | <10 % | <5 % (double-layer feed) |

| Ingress Protection | IP20 / IP65 (glue) / IP67 (tube) | IP65 (PU glue, UV-proof) & IP67 (silicone tube) |

| Certifications | CE self-declaration | CE (TUV SUD), ETL cETL (UL 2108 & CSA 250.13) |

| Lifetime (L70) | 25 000 h @ 25 °C | 50 000 h @ 45 °C solder point (TM-21 extrapolated) |

| Warranty | 1 year OEM average | 5 years factory-backed |

3. PCB & Component Consistency Controls (Beauty STC, est. 1998)

Copper: ED copper 70 µm, 0.2 mm thermal-conductive dielectric, 3-track parallel bus to suppress color shift on long runs.

Solder Mask: High-reflectance white mask (85 % reflectivity @ 450 nm) for color purity.

Pick & Place: Yamaha SMT line with AOI + SPI; every 5-in-1 LED is 100 % bin-verified for VF, wavelength, flux.

Color Calibration: Integrating-sphere batch test (Everfine ATA-500); each reel supplied with 3-point calibration report (CIE x, y, λd).

Aging: 100 % 4-hour 55 °C burn-in at 1.05 × rated current; <0.5 % dead-pixel rejection threshold.

Traceability: Reel ID links to die lot, phosphor lot, and driver IC; ERP code printed every 0.5 m.

4. Quick-Reference Compliance Matrix

| Market | Required Mark | Beauty STC Status |

|---|---|---|

| USA / Canada | cETL (UL 2108) | Certified (file 5016029) |

| Europe | CE, RoHS, REACH | TUV SUD audited (no. 44 78 138273 001) |

| Australia / NZ | RCM | Test reports to AS/NZS 61347 & 60598 |

| Russia | EAC | DoC TR CU 004/2011, 020/2011 |

| Japan | PSE (DC ≤ 30 V exempt) | Technical file held |

5. Procurement Notes for Distributors & Specifiers

MOQ: 500 m per CCT / IP version; custom CCT binning 2700-6500 K available within 3 weeks.

OEM options: PCB width 5 mm / 8 mm / 10 mm, 12/24 V, constant-current variant, 3-step or 5-step MacAdam ellipse.

Packaging: Anti-static aluminium foil bag + desiccant, 5 m reels, master carton ≤10 kg for air-freight optimisation.

Lead-time: Standard certified reels ex-works Jiangmen 7-10 days; custom binning or IP68 silicone extrusion 15-18 days.

For detailed LM-80 & ISTMT data, or to lock production slots, contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Manufacturing Precision: How Beauty STC Produces Certified RGBWW LED Strips

At Beauty STC Manufacturing, our 26-year legacy in LED production is built on precision engineering—not marketing claims. Our Jiangmen facility (41st Caihong Road, High-tech Industrial Zone) operates under ISO 9001:2015 protocols, with every RGBWW strip manufactured to meet ETL (UL 1598) and TÜV CE (EN 62471) safety and performance standards. Below is a technical breakdown of our end-to-end production process for RGBWW products.

SMT Assembly & Chip Integration

Our surface-mount technology (SMT) lines handle 5-in-1 RGBWW LED chips (typically SMD2835 or SMD3535) with micron-level accuracy:

Placement Precision: ±0.05mm tolerance using JUKI FX-5R machines

Soldering Control: Reflow profiles compliant with IPC-J-STD-001 (Class 2)

Chip Binning: Strict spectral consistency (MacAdam 3-step or tighter) for warm/cool white channels

Key Insight: RGBWW requires independent control of warm white (2700K–3000K) and cool white (5000K–6500K) channels alongside RGB. Our SMT process isolates these channels during assembly to prevent cross-contamination of phosphor coatings—critical for color accuracy.

Aging & Quality Control Protocols

All units undergo rigorous validation before shipment:

| Test Stage | Protocol | Acceptance Criteria |

|---|---|---|

| 72-Hour Burn-in | 40°C ambient temperature, 100% load | ≤5% luminous flux decay |

| Spectral Analysis | Integrating sphere test per CIE 127:2007 | ΔE < 1.5 (CIE 1976), CCT tolerance ±50K |

| IP Rating Validation | Water/dust ingress test (IP20–IP67 options) | No degradation at 100% load |

| Electrical Safety | Hi-Pot test (1.5kV AC for 1 min), insulation resistance >100MΩ | Zero dielectric breakdown |

Note: Each batch is traceable via serialized QC reports. ETL/TÜV certification requires these tests to exceed IEC 62560 standards for LED strips.

OEM/ODM Capabilities for Global Projects

We specialize in engineering-grade customization for architectural and commercial applications:

| Parameter | Standard Range | OEM Customization Options |

|---|---|---|

| Length | 1m–100m reels | 0.5m increments (min. 0.5m), custom splicing points |

| CCT Channels | 2700K–3000K (warm), 5000K–6500K (cool) | Tunable white points (e.g., 2200K–7000K), 100K steps |

| PCB Width | 8mm, 10mm, 12mm | 6mm–20mm (with thermal management design support) |

| Packaging | Standard anti-static rolls | Custom branding, OEM-specific labeling, bulk palletizing |

| Certification | ETL/TÜV CE (standard) | Regional compliance (e.g., UKCA, KC, PSE) |

Engineering Support: Our R&D team collaborates with architects on chromaticity coordinates (x/y values), flicker performance (<5% @ 100Hz), and thermal management solutions. All custom designs undergo FMEA (Failure Mode Effects Analysis) before tooling.

Why This Matters for B2B Clients

Consistency Across Batches: Our 26-year process refinement ensures <2% color shift between production runs—critical for large-scale projects like retail installations or smart buildings.

Certification-Ready Output: Every strip is pre-tested for Western market compliance, eliminating costly rework or delays.

Scalable Production: 500,000+ RGBWW strips monthly capacity with 15-day lead times for custom orders.

“Be a responsible enterprise, Be a caring person” isn’t just our principle—it’s embedded in our QC protocols. We reject 1.2% of units failing spectral consistency tests, even if they meet basic industry standards.

Contact Our Engineering Team

For technical specifications, sample requests, or project-specific validation:

[email protected] | +86 13902885704

Installation & Application Scenarios

Application Scenarios for RGBWW LED Strip & Module

(Factory-direct view, Beauty STC Lighting, ETL & CE certified since 1998)

Why RGBWW is the “All-Season” Light Engine

RGBWW = 5-in-1 chip (R-G-B-3000 K-6000 K).

One reel gives 16 M colours + 1800–6500 K tunable white, CRI ≥ 90 (typ.).

That eliminates the need to stock separate RGB and tunable-white reels, cutting SKU count by 60 % for distributors and reducing on-site wiring for contractors.

Where Contractors Should Specify RGBWW

| Segment | Typical Lux/CCT Range | Key RGBWW Advantage | Installation Note |

|---|---|---|---|

| 4 & 5-star hotels | 50–300 lx, 2700–4000 K | Warm-white lobby, colour accent in bar, scene recall for banquet | Mount in 15 mm ALU profile with opal diffuser; use 24 V, 12 W/m, 60 LED/m to avoid pixelation on marble surfaces |

| High-end retail / shopping malls | 300–500 lx, 3000–5000 K | Seasonal colour theme + accurate white for merchandise | Route DMX cable in parallel; place power feed every 5 m (24 V, 14.4 W/m) to keep < 5 % voltage drop |

| Corporate reception & boardrooms | 200–400 lx, 3200–4000 K | Brand colour in reception, neutral white for meetings | Integrate in plaster-in profile; use CCT channel for circadian schedule (DALI Type 8 driver) |

| Façade & hospitality exteriors | 10–50 lx (night), dynamic colour | Single reel delivers pastel tones and 4000 K architectural white | Use IP67 silicone-sleeve strip; add 3-core VDE cable for white channel; mount on 35 °C max surface, GFCI-protected 24 V supply |

| Cruise & marine | 150–300 lx, 2700–4000 K | One lighting type satisfies SOLAS white-light rule and entertainment colour | Select 24 V, 10 W/m, IP65; use tinned-copper 2.5 mm² cable to fight salt-spray |

Contractor Checklist – RGBWW Strip Installation

-

Voltage & Power Budget

24 V system recommended above 8 W/m to reduce current.

Inject power every 5 m (≤ 5 % drop).

Calculate:

Current (A) = (Total W) / 24 V × 1.2 (loss factor) -

Colour-Consistency Reel-to-Reel

Beauty STC bins to 3 SDCM for white, ±0.005 x-y for RGB.

Use same batch number per run; label reels sequentially. -

Thermal Management

Strip Tj max 85 °C; keep Alu-profile Tc ≤ 55 °C.

Apply 3 mm thermal tape, not generic double-sided. -

DMX Addressing (5-channel)

R-Ch 1, G-Ch 2, B-Ch 3, WW-Ch 4, CW-Ch 5.

Set footprint to 5, universe limit 512 → max 102 nodes per universe. -

Certification & Field Labels

Beauty STC RGBWW reels carry ETL cETL file #5013349 and TUV CE 2204-ETL-023.

Install with UL 2108 Class 2 driver ≤ 60 Vdc output; affix factory ETL label visible after trim.

Quick-Order Spec Sheet (Factory-Direct, OEM welcome)

| Parameter | Value |

|---|---|

| LED type | SMD 5050 5-in-1, 60 LED/m |

| Input | 24 Vdc ± 10 % |

| Power | 14.4 W/m (RGB all-on 9.6 W, White 4.8 W) |

| Lumen (white) | 1100 lm/m @ 4000 K, CRI 90 |

| Beam angle | 120 ° |

| IP grade | IP20 (indoor) / IP65 (silicone) / IP67 (silicone tube) |

| PCB width | 12 mm, 2 oz copper, double layer |

| Certifications | ETL/cETL, CE-EMC, LVD, RoHS, REACH |

| Cut unit | 100 mm (6 LED) |

| Reel length | 5 m standard, 10 m OEM |

| Warranty | 5 years (driver & strip) |

OEM / ODM Support from Beauty STC Lighting

25 years R&D since 1998, 16 SMT lines, 400 workers.

Custom CCT, CRI, pixel pitch, PCB colour, logo print, and kit-level assembly (strip + driver + controller + profile).

Full Western-market paperwork: ETL, CB, CE, RoHS, REACH, TM-30, ISTOB 50.000 h report.

Contact the factory export desk: [email protected] | +86 139 0288 5704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting for Certified RGBWW Solutions

As lighting professionals navigate the complexities of modern RGBWW implementation, technical reliability and regulatory compliance are non-negotiable. Beauty STC Lighting provides factory-direct RGBWW solutions engineered for global project requirements, with 26 years of manufacturing precision and full Western market certification.

25+ Years of Industrial Manufacturing Excellence

Established in 1998, our Jiangmen, China facility operates under strict ISO 9001 quality protocols. Our 26-year manufacturing heritage ensures:

Consistent binning of LED chips for color uniformity across batches

Automated SMT production lines with <0.5% defect rate

Full traceability from raw materials to finished products

Global Compliance & Quality Assurance

All RGBWW products undergo rigorous third-party testing for target markets:

| Certification | Scope | Regulatory Impact |

|---|---|---|

| ETL (USA/Canada) | UL 1598, UL 8750 standards | Direct market access without retesting |

| TÜV CE (Europe) | EN 60598, EN 62471 safety & photobiological | Compliance with EU Machinery Directive |

| Export Reach | 50+ countries including EU, US, Australia, Japan | Proven logistics for global shipments |

OEM/ODM Capabilities for Professional Projects

We engineer RGBWW solutions to meet architectural and technical specifications:

5-in-1 chip integration: Precise Red/Green/Blue/Warm White/Cool White channel control (2700K–6500K CCT range)

Custom firmware: DMX/RDM, 0-10V, or wireless protocols (Zigbee, Bluetooth) per project requirements

Thermal management: Aluminum PCB designs for 50,000+ hour L70 lifespan at 60°C ambient

Documentation: IES files, photometric reports, and RoHS/REACH compliance certificates

“Our engineers validate every RGBWW configuration against IESNA LM-80 and TM-21 standards before production. This eliminates field failures in high-end installations where color consistency is critical.”

— Beauty STC Engineering Team

For technical specifications, compliance documentation, or custom project quotes, contact our export team directly:

[email protected] | +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).