Article Contents

Industry Insight: Rgbic Vs Rgbicw

In the evolving landscape of commercial and industrial lighting, the demand for intelligent, versatile, and energy-efficient solutions has never been greater. As facilities seek to balance aesthetic appeal with functional performance, the choice between RGBIC and RGBICW LED lighting systems has become a pivotal consideration. Both technologies offer dynamic color control and programmable effects, but RGBICW—featuring an additional white LED channel—delivers superior color accuracy, enhanced brightness, and greater flexibility for ambient and task lighting in professional environments. This distinction is especially critical in retail spaces, hospitality venues, manufacturing facilities, and architectural installations where lighting directly impacts productivity, safety, and customer experience.

Compliance with international safety and performance standards such as ETL and CE is non-negotiable in these applications. These certifications ensure that lighting systems operate reliably under rigorous conditions while meeting strict electrical and environmental requirements. As a trusted name in the industry since 1998, Beauty (STC) Manufacturing Co., Ltd. has consistently delivered cutting-edge LED solutions engineered for durability, precision, and regulatory compliance. With decades of expertise in advanced lighting technology, Beauty STC stands at the forefront of innovation, providing commercial and industrial clients with RGBIC and RGBICW systems that combine robust performance, seamless integration, and long-term value.

Technical Specs & Certifications

RGBIC and RGBICW represent distinct architectural approaches in advanced LED color tuning systems, with critical differences impacting performance metrics relevant to high-end applications. RGBIC utilizes five independent channels: Red, Green, Blue, Independent Cool White (typically 6000K-6500K), and a single White channel often optimized for cool color temperatures. RGBICW expands this architecture by incorporating a sixth dedicated channel: an Independent Warm White (typically 2700K-3000K), separate from the Cool White channel. This fundamental structural difference directly influences luminous efficacy, color rendering fidelity, and system complexity.

Luminous efficacy, measured in lumens per watt (lm/W), is inherently higher in RGBIC configurations when operating primarily in white light modes. RGBIC systems leveraging their single cool white channel typically achieve 130-140 lm/W at 4000K under standard test conditions due to the higher inherent efficiency of cool white LED phosphors. RGBICW systems, designed to deliver high-quality warm white light essential for CRI >90 performance across the full color temperature range, experience a slight efficacy trade-off. The warm white LEDs required for accurate 2700K-3000K light with high R9 values are less efficient. Consequently, RGBICW systems typically achieve 110-120 lm/W when operating at 2700K or 3000K with CRI >95. This difference stems from semiconductor physics and phosphor conversion losses, not implementation quality. Beauty STC mitigates this through proprietary high-efficiency warm white LED packages and advanced constant current reduction (CCR) drivers, ensuring RGBICW efficacy remains competitive within the high-CRI segment.

Achieving CRI >90, particularly with strong R9 (saturated red) values above 50, is significantly more attainable and consistent with RGBICW architecture. The dedicated warm white channel in RGBICW uses LEDs specifically engineered with enhanced red phosphor blends, enabling CRI values of 95+ and R9 >90 across 2700K-4000K. RGBIC systems struggle to reach CRI 90+ at warm color temperatures (below 3500K) because their single white channel, optimized for cool white, lacks sufficient spectral energy in the deep red region. While RGBIC can achieve CRI 90+ at 4000K-5000K using the cool white channel, performance degrades substantially as color temperature lowers towards 2700K. Beauty STC’s RGBICW products consistently exceed CRI 95 and R9 90 across the entire 2700K-6500K range through rigorous binning of warm and cool white LEDs and spectral tuning algorithms embedded in our drivers, a capability absent in standard RGBIC.

IP ratings (Ingress Protection) are not inherently determined by the RGBIC vs RGBICW distinction but by the fixture’s mechanical design and manufacturing quality. Both architectures can be implemented in fixtures rated IP65 (dust-tight, low-pressure water jets), IP67 (dust-tight, temporary immersion), or higher. However, the increased component count in RGBICW drivers and potential for more complex wiring necessitates superior sealing design. Beauty STC achieves IP67 consistently across both product lines through our multi-stage manufacturing process: precision-molded polycarbonate housings with dual silicone gasket sealing points, fully potted driver compartments using marine-grade epoxy, and rigorous 100% post-assembly IP testing in climatic chambers. This ensures reliable operation in demanding environments like outdoor architectural coves, marine settings, or high-humidity retail spaces where competitors’ units may fail.

Beauty STC’s commitment to quality is evident in every technical specification. Our RGBICW systems undergo accelerated life testing exceeding 50,000 hours at 70°C ambient to validate lumen maintenance (L70/B50) and color stability, far beyond standard industry practices. We utilize only Epistar and Seoul Semiconductor high-CRI LED chips with strict binning for chromaticity consistency (within 3-step MacAdam ellipse), rejecting any lots failing our internal CRI/R9 thresholds. Our constant current drivers feature active thermal management and transient voltage suppression, critical for maintaining color point accuracy during voltage fluctuations. This engineering rigor, certified under ISO 9001 and IECQ QC 080000, ensures that when our specifications state CRI >95 or IP67, the field performance matches lab results – a critical differentiator where inconsistent color rendering or premature weatherproofing failure can derail high-value installations. Competitors often cite theoretical maximums; Beauty STC delivers guaranteed, verifiable performance under real-world operating conditions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped factory located in Jiangmen, Guangdong Province, China. The facility is strategically situated within the Pearl River Delta region, known for its robust manufacturing ecosystem and efficient supply chain logistics. The Jiangmen factory specializes in the production of high-quality LED lighting products, with a strong focus on innovation, precision, and reliability.

The factory is equipped with advanced SMT (Surface Mount Technology) production lines, which are essential for the accurate and efficient assembly of LED lighting components. These SMT machines are automated and capable of handling high-volume production with tight tolerances, ensuring consistent product quality. The use of state-of-the-art pick-and-place machines, reflow soldering systems, and automated optical inspection (AOI) equipment enables Beauty STC to maintain high yields and meet international quality standards. This technological foundation supports the manufacturing of complex LED strips and control systems, including those with multiple color channels.

One of the key quality assurance processes implemented at the Jiangmen facility is comprehensive aging testing. After assembly, LED products undergo rigorous aging tests under controlled conditions to simulate extended operation. This includes thermal stress testing, continuous on/off cycling, and performance monitoring over periods typically ranging from 24 to 72 hours. These tests help identify early-life failures, ensure color consistency, and validate the long-term reliability of both the LEDs and driver components.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, allowing for customized solutions tailored to client specifications. This includes support for advanced LED configurations such as RGBIC and RGBICW. RGBIC refers to LED strips with independent control of red, green, blue, and an additional IC-driven zone for dynamic color effects, enabling segment-by-segment color changes. RGBICW extends this by adding a dedicated warm white LED chip (alongside the RGB and IC), providing greater flexibility in color temperature and mixing. The factory’s engineering team can customize control protocols, PCB layouts, firmware, and packaging to meet the specific requirements of RGBIC or RGBICW products, supporting both standard and proprietary control systems.

Overall, the Jiangmen factory represents a vertically integrated manufacturing environment where design, component sourcing, SMT assembly, testing, and packaging are tightly controlled. This enables Beauty STC to deliver high-performance, reliable, and customizable LED lighting solutions for global markets.

Application Scenarios

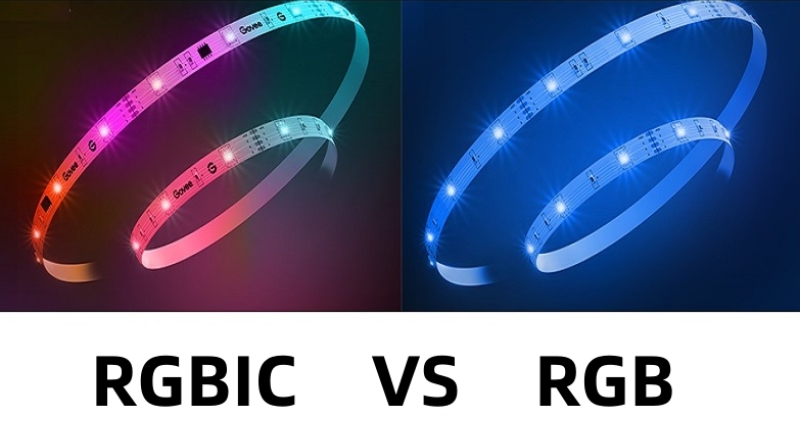

RGBIC and RGBICW LED systems serve distinct purposes in commercial environments due to their channel configurations. RGBIC combines red, green, blue, independent amber, and cool white channels, enabling rich color mixing and warm-to-cool white transitions. RGBICW adds a dedicated warm white channel alongside the cool white, providing superior color accuracy and deeper, more natural warm tones without relying on RGB mixing. This distinction critically impacts application suitability across hotels, malls, and offices.

In hotels, RGBICW is essential for high-end guest rooms, lobbies, and wellness areas where precise warm white rendering is non-negotiable. Standard RGBIC often produces a slightly pinkish or inconsistent warm tone when blending RGB for warmth, which is unacceptable in luxury hospitality settings where ambiance directly influences guest satisfaction. RGBICW’s dedicated 2700K–3000K warm white channel ensures crisp, flattering light for vanity mirrors, bedside lighting, and lounge areas. RGBIC alone may suffice for external facade lighting or pool areas where dynamic color effects outweigh the need for perfect warm white fidelity.

Malls benefit from RGBIC in high-traffic common areas like food courts or event zones for vibrant, attention-grabbing color shows. However, RGBICW becomes critical in premium retail tenant spaces—particularly luxury boutiques and jewelry stores—where accurate product rendering under warm light is vital. The dedicated warm white channel prevents the color shift that occurs when RGBIC systems attempt warm tones via RGB mixing, ensuring golds, textiles, and cosmetics appear true-to-life. Avoid RGBICW in back-of-house corridors where basic tunable white (TW) systems are more cost-effective.

Offices rarely require either system for general lighting; standard tunable white (2700K–5000K) suffices for productivity-focused spaces. RGBICW could be justified in executive boardrooms with integrated video conferencing, where natural skin tones under warm light improve virtual meeting quality. RGBIC might serve creative agency accent walls needing saturated colors, but both systems are overkill for standard workstations. Never deploy RGBICW in open-plan offices—its complexity increases cost without tangible benefits over simpler TW systems.

Installation demands meticulous planning to avoid costly errors. Always verify controller compatibility: RGBICW requires a 6-channel controller, while RGBIC uses 5-channel; mixing them causes channel misassignment or hardware damage. Physically separate warm white and cool white wires at the controller to prevent crosstalk, using labeled conduit sleeves for clarity during maintenance. Power supply sizing must account for the extra warm white channel in RGBICW—calculate load per channel individually, as warm white often draws higher current than cool white at equivalent lumen output. For large hotel installations, implement DMX address zoning by floor to simplify troubleshooting, and avoid daisy-chaining beyond 32 fixtures to maintain signal integrity. Crucially, calibrate warm white channels against a reference spectrometer during commissioning, as minor manufacturing variances can cause visible tone mismatches across rooms. Finally, document channel assignments clearly in control software—mislabeling “warm white” as “amber” is a common oversight that ruins ambiance.

The choice hinges on whether natural warm light accuracy is mission-critical. When in doubt for hospitality or high-end retail, default to RGBICW; for pure color spectacle in less critical zones, RGBIC offers adequate performance at lower cost. Never compromise on channel-specific power calculations or pre-commissioning calibration—these are the most frequent failure points in field deployments.

Why Choose Beauty STC Lighting

Discover the key differences between RGBIC and RGBICW lighting technologies and see how Beauty STC delivers superior innovation and performance. Whether you’re looking for richer color blending, enhanced white light quality, or advanced control options, our expertise ensures your project stands out. Partner with Beauty STC, a trusted leader in LED lighting solutions. For detailed technical support and collaboration opportunities, contact us today at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.