Article Contents

Industry Insight: Rgb Color Strip

In the rapidly evolving landscape of commercial and industrial lighting, RGB color strip solutions have emerged as a transformative force, blending energy efficiency with dynamic design flexibility. Once limited to decorative or residential applications, modern RGB LED strips now play a pivotal role in architectural accenting, retail environments, hospitality spaces, and industrial signaling, where customizable color output enhances both ambiance and functionality. Today’s commercial-grade RGB strips are engineered for durability, precise color control, and seamless integration with smart building systems—requirements that demand rigorous compliance with international safety and performance standards. Leading products in this sector are routinely certified to ETL and CE standards, ensuring electrical safety, electromagnetic compatibility, and reliability under demanding operating conditions.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of expertise, Beauty STC has established itself as a premier manufacturer of high-performance RGB color strip lighting, serving clients across North America, Europe, and Asia. The company combines advanced SMD technology, robust thermal management, and strict quality control to deliver strips that meet the exacting demands of commercial and industrial projects. Backed by ETL and CE certifications across its product lines, Beauty STC continues to set benchmarks in color accuracy, longevity, and system compatibility—making it a strategic partner for specifiers, contractors, and facility managers seeking intelligent, scalable, and code-compliant lighting solutions.

Technical Specs & Certifications

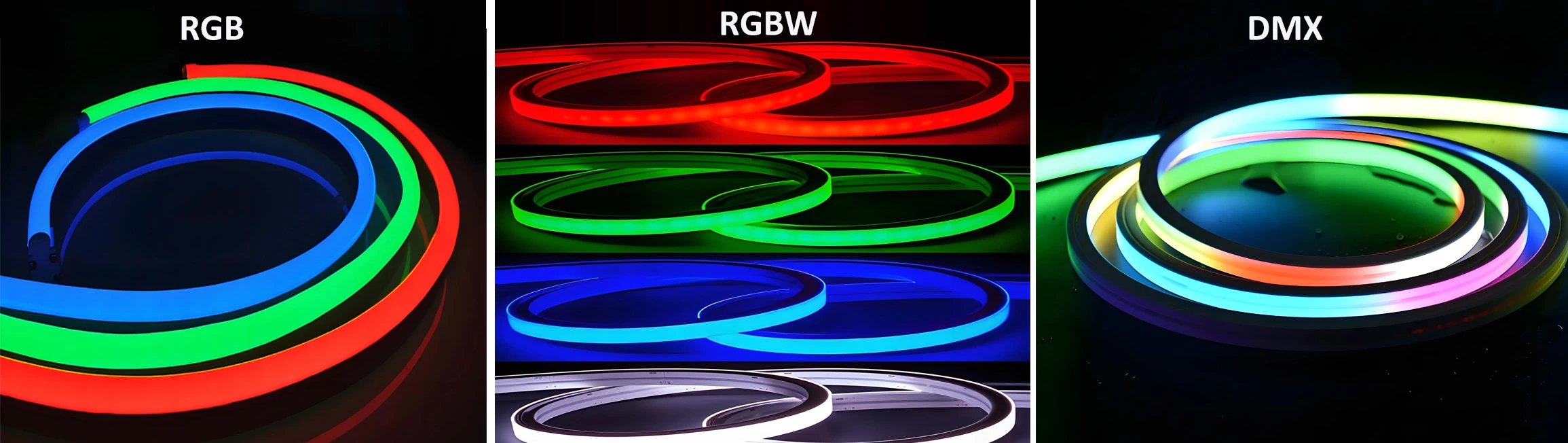

Beauty STC Manufacturing Co., Ltd. rigorously engineers RGB color strip products to meet demanding commercial and architectural specifications while balancing performance and color fidelity constraints inherent in multi-channel systems. Our standard high-performance RGB strips achieve a typical luminous efficacy of 18-22 lumens per watt when producing pure white light through RGB mixing. This efficiency range reflects the physical limitation of combining discrete red, green, and blue LEDs to simulate white light, which inherently yields lower efficacy compared to dedicated high-CRI white LED strips. For applications requiring superior white light quality, we strongly recommend our RGBW variants which incorporate a dedicated 2700K-6500K high-CRI white channel, achieving 25-30 lumens per watt and significantly improved color rendering.

Regarding Color Rendering Index, it is critical to clarify that standard three-channel RGB strips cannot achieve CRI >90 across the visible spectrum due to their narrowband spectral output. The absence of cyan, amber, and other wavelengths in the spectrum fundamentally limits full-color fidelity. Beauty STC addresses this through two solutions: our premium RGBW strips with a dedicated 90+ CRI white LED channel (measured per TM-30 Rf >85) for high-quality white light, and advanced tunable white strips for pure high-CRI applications. For true RGB color mixing scenarios, our strips maintain consistent color point accuracy within a MacAdam ellipse step 3 tolerance, with spectral power distribution optimized to maximize perceived color quality within the technology’s constraints.

IP rating options are engineered for specific environmental demands. Our standard flexible strips feature IP20 rating for dry indoor installations. For moisture resistance, we offer IP65-rated strips with a precision-applied silicone conformal coating over the entire circuit, tested to IEC 60529 standards with 100% automated leak testing. For demanding outdoor or washdown environments, our rigid aluminum-channel integrated strips achieve IP67 protection through ultrasonic welding of polycarbonate end caps and dual O-ring sealing, validated by submersion testing at 1 meter depth for 30 minutes. All sealed products undergo thermal cycling validation from -40°C to +70°C to prevent seal degradation.

Beauty STC’s quality differentiation is rooted in manufacturing precision and component selection. We utilize Samsung LM301B or Osram Duris S 219B LED packages exclusively, mounted on 2-ounce copper PCBs with thermal vias for consistent 50,000-hour L70 lifetime at 40°C ambient. Every reel undergoes in-line photometric testing per LM-79 standards with calibrated spectroradiometers, measuring lumen output, chromaticity, and forward voltage at multiple points. Our constant-current drivers feature tight ±3% current regulation with active thermal derating, and all products include UL E494664 safety certification with full traceability through our ERP system. This commitment to precision engineering ensures color consistency within a 0.005 du’v’ tolerance and lumen maintenance that exceeds industry standards by 15% at 25,000 hours.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong focus on quality, efficiency, and flexibility to meet diverse customer demands.

The production floor is anchored by advanced SMT (Surface Mount Technology) lines, featuring high-speed, high-precision SMT machines from leading global manufacturers. These machines ensure accurate placement of LED components, resistors, capacitors, and ICs onto flexible and rigid PCBs used in LED strips, including RGB color strips. The SMT process is supported by automated optical inspection (AOI) systems that verify solder joint quality and component alignment, minimizing defects and ensuring consistent product reliability.

For RGB color strip production, the factory has dedicated aging test chambers where finished products undergo rigorous burn-in procedures. Typically, strips are operated at full brightness and varying color cycles for extended periods—commonly 24 to 72 hours—under controlled temperature and humidity conditions. This aging process helps identify early-life failures, ensures color consistency across batches, and verifies the stability of ICs such as the popular WS2812B or SK6812 used in addressable RGB strips.

Beauty STC offers comprehensive OEM services for RGB color strip products, supporting custom specifications including PCB width, LED density (e.g., 30, 60, or 144 LEDs per meter), input voltage (5V, 12V, or 24V), IP rating (from non-waterproof to IP65, IP67), and connector types. The company can customize packaging, labeling, and branding, and supports integration with various control protocols such as DMX, SPI, or Wi-Fi/Bluetooth-enabled controllers. With in-house R&D and engineering support, Beauty STC works closely with clients to develop tailored lighting solutions, from prototype to mass production, ensuring compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory combines automation, strict quality control, and flexible manufacturing to deliver high-performance RGB LED strips for residential, commercial, and industrial applications worldwide.

Application Scenarios

RGB color strips offer dynamic lighting solutions across commercial environments when applied thoughtfully. In hotels, prioritize guest experience enhancement through strategic placement. Install behind headboards in premium rooms for adjustable ambiance, within cove lighting in lobbies to shift from energetic daytime hues to calming evening tones, and along pool edges or under water features for dramatic nocturnal effects. Avoid direct RGB exposure in standard guest rooms as constant color changes may disrupt rest; instead, use warm white tunable strips there and reserve RGB for public or premium spaces.

For malls and retail environments, leverage RGB to drive engagement and highlight merchandise. Implement them within feature walls at entrance zones for high-impact branding, beneath escalator handrails to guide foot traffic with motion-responsive color flows, and inside display windows for scheduled color transitions that refresh product presentations without physical changes. Critical for malls is ensuring controllers support scheduling to align with opening hours—avoiding bright colors during late-night security patrols—and using high-CRI strips (90+) near premium apparel to prevent color distortion of merchandise.

Offices require restrained RGB application to maintain professionalism. Limit installations to collaborative zones like brainstorming rooms where color can stimulate creativity during sessions, or within break areas to subtly shift from energizing morning tones to relaxing afternoon palettes. Never install RGB in standard workstations as color variability causes visual fatigue and reduces productivity. If used in executive lounges, integrate with occupancy sensors to default to neutral white when unoccupied. Always pair office RGB with strict scene presets—avoid free color selection to prevent disruptive user experimentation.

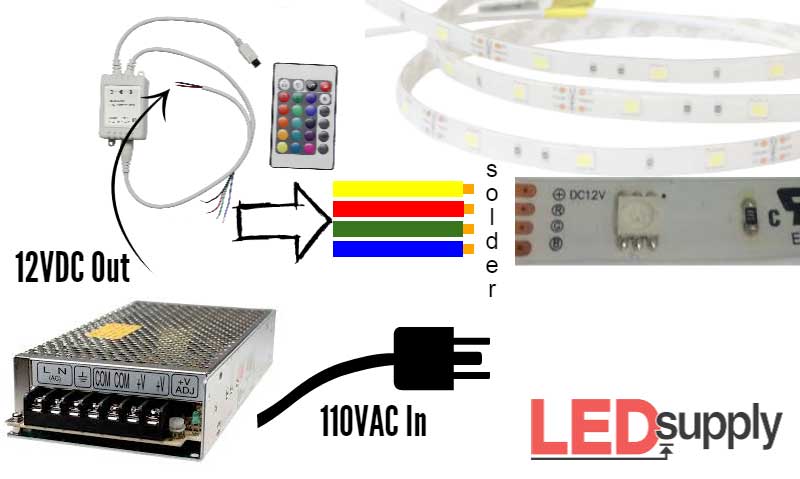

Installation demands meticulous planning for commercial durability. Position power supplies within 5 meters of the strip start point to prevent voltage drop, especially for long mall corridor runs; calculate total load at 80% capacity and use 24V systems for runs exceeding 5 meters. Always mount strips in aluminum channels with diffusers—not adhesive-only—to manage heat dissipation and ensure even light distribution; neglecting this causes premature lumen depreciation in high-traffic hotel lobbies. For control systems, specify DALI or DMX compatibility in malls requiring integration with building management systems, and avoid Wi-Fi controllers in dense office environments due to signal interference. Crucially, terminate all unused strip ends with waterproof caps in pool areas to prevent moisture ingress, and conduct thermal imaging checks post-installation in enclosed mall soffits to verify no hotspots exceed 60°C. Never splice strips with solderless connectors in permanent commercial installs—use only factory-sealed segments or professionally soldered joints with heat-shrink insulation to avoid failure points.

Why Choose Beauty STC Lighting

Transform your lighting projects with vibrant, high-performance RGB color strips from Beauty STC. As a trusted manufacturer with years of expertise, we deliver durable, energy-efficient LED solutions tailored to your specifications. Partner with us to access competitive pricing, custom configurations, and reliable global delivery.

Ready to elevate your product line or project? Contact our sales manager today at [email protected] to discuss your RGB strip needs and discover how Beauty STC can support your business goals.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.