Article Contents

Industry Insight: Remote Led Strip

The commercial and industrial lighting sector is undergoing a significant transformation, driven by the relentless pursuit of energy efficiency, operational reliability, and reduced lifecycle costs. Within this evolution, remote LED strip systems are emerging as a critical architectural solution, moving beyond simple illumination to address fundamental challenges inherent in demanding environments. Unlike traditional integrated LED strips, remote systems strategically separate the light-emitting diodes from their power drivers. This design innovation is particularly vital for commercial and industrial applications where thermal management is paramount; by isolating the heat-generating driver from the sensitive LED module, remote configurations prevent thermal runaway, significantly extend component lifespan, and maintain consistent lumen output even in enclosed fixtures or high-ambient-temperature settings like warehouses, manufacturing floors, and retail displays. Crucially, for any lighting solution to be viable in these professional markets, adherence to stringent safety and performance standards is non-negotiable. Compliance with certifications such as ETL, verifying adherence to North American safety standards, and CE marking, indicating conformity with European health, safety, and environmental requirements, is essential for project specification, code compliance, and end-user safety. These certifications are not mere checkboxes but foundational requirements that ensure the product can be legally and safely deployed in critical infrastructure.

Beauty STC Manufacturing Co., Ltd. stands at the forefront of this advancement. Established in 1998, we bring over 25 years of deep engineering expertise and manufacturing excellence specifically focused on high-performance LED lighting solutions for the commercial and industrial sectors. Our commitment to rigorous quality control, innovative thermal management strategies, and unwavering adherence to global safety certifications like ETL and CE positions Beauty STC as a trusted partner for specifiers, contractors, and facility managers who demand reliability, longevity, and seamless integration in their lighting infrastructure. We understand that in professional environments, lighting is not just an amenity but a critical operational asset, and our remote LED strip systems are engineered to deliver precisely that.

Technical Specs & Certifications

The remote LED strip offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in a range of residential, commercial, and architectural lighting applications. Designed with precision and manufactured under strict quality control standards, these LED strips deliver exceptional efficiency, color accuracy, and environmental protection.

In terms of efficiency, our remote LED strips achieve a luminous efficacy of up to 130 lumens per watt, depending on the specific configuration and color temperature. This high lumens-per-watt ratio ensures optimal energy savings without compromising brightness, making the strips ideal for long-term installations where operational cost and sustainability are key considerations.

Color rendering is a critical factor in premium lighting, and Beauty STC’s remote LED strips exceed industry benchmarks with a Color Rendering Index (CRI) greater than 90. This high CRI ensures that colors appear natural, vibrant, and true to life under the illumination, which is especially important in retail, hospitality, and residential environments where visual appeal matters. Some variants even reach a CRI of 95+, offering superior color fidelity for applications requiring the most accurate color representation.

Regarding environmental protection, our remote LED strips are available in multiple IP (Ingress Protection) ratings to suit various installation conditions. Common configurations include IP20 for dry indoor environments, IP65 for resistance to dust and low-pressure water jets—ideal for kitchens or semi-outdoor areas—and IP67 for full dust tightness and temporary immersion in water, making them suitable for outdoor or demanding installations. The silicone coating or extruded profiles used in higher IP-rated versions ensure long-term durability and protection against moisture, dust, and mechanical impact.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality assurance throughout the production process. Our LED strips utilize high-grade SMD chips from trusted suppliers, precision-printed circuit boards, and thermally stable materials to ensure consistent performance and extended lifespan—typically rated at 50,000 hours or more under normal operating conditions. All products undergo comprehensive testing for electrical safety, thermal management, and photometric performance to meet international standards including CE, RoHS, and UL compliance where applicable.

With a focus on innovation, reliability, and customer satisfaction, Beauty STC delivers remote LED strips that combine superior technical specifications with exceptional build quality, ensuring optimal lighting solutions for diverse project requirements.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as the company’s primary production hub for LED lighting solutions, including specialized products like remote-controlled LED strips. The factory spans a significant footprint designed for efficiency and scalability, incorporating modern cleanroom environments for critical processes and adhering to international quality management standards such as ISO 9001. Its strategic location within Jiangmen’s industrial corridor provides robust logistical support for both domestic and global supply chains, with easy access to major ports and transportation networks.

The Surface Mount Technology (SMT) production lines form the backbone of the factory’s electronic assembly capabilities. We operate multiple high-speed Fuji NXT III SMT placement machines, capable of handling components as small as 0201 metric package sizes with micron-level precision. These automated lines achieve placement speeds exceeding 100,000 components per hour per machine while maintaining stringent accuracy tolerances of ±25μm. Each line integrates automated solder paste inspection (SPI) and 3D AOI (Automated Optical Inspection) systems to verify solder paste deposition and component placement in real time. This setup ensures consistent solder joint quality and minimizes defects for complex PCB assemblies used in LED strips and associated remote control circuitry. The SMT area supports flexible batch processing, accommodating both high-volume production runs and smaller prototype builds for OEM clients.

Aging and reliability testing represent a critical phase in our quality assurance protocol, particularly for LED products where longevity is paramount. The Jiangmen factory maintains dedicated aging chambers with precisely controlled thermal and electrical conditions. Completed LED strip assemblies undergo mandatory burn-in testing for 48 to 72 hours at elevated temperatures (typically 60-70°C) under constant current drive conditions that simulate real-world stress. During this period, luminance output, color consistency, and thermal performance are continuously monitored using spectroradiometers and thermal imaging cameras. Units exhibiting any deviation from predefined performance thresholds are automatically flagged for root-cause analysis and rework. This rigorous aging process significantly reduces infant mortality rates in the field and validates the 50,000+ hour lifespan claims for our LED strip products.

Our OEM capabilities for remote-controlled LED strips are highly developed and client-centric. The engineering team collaborates closely with partners from initial concept through to mass production, offering full customization of electrical architecture, optical performance, and control protocols. We support integration of various remote control technologies including RF (2.4GHz), infrared, Bluetooth LE, and proprietary wireless systems, with flexibility to adopt client-specific communication protocols or firmware. Customization extends to PCB design iterations for unique form factors, specialized IC selection for dynamic effects like music synchronization or scene programming, and tailored dimming curves. The factory accommodates requests for custom wavelengths, CCT tuning, and CRI optimization while ensuring electromagnetic compatibility compliance. Packaging and branding services include private-label reels, custom controller housings, and multilingual instructional materials, all managed under strict confidentiality agreements. This end-to-end OEM support enables clients to bring differentiated remote LED strip solutions to market with minimized development risk and accelerated time-to-volume production.

Application Scenarios

Remote LED strips are versatile lighting solutions that can be used in a wide range of commercial environments including hotels, malls, and offices. Their flexibility, energy efficiency, and design adaptability make them ideal for both functional and decorative lighting applications.

In hotels, remote LED strips are commonly used in guest rooms to highlight architectural features such as coves, headboards, or under-cabinet areas in minibars. They enhance ambiance and provide soft, indirect lighting that contributes to a relaxing atmosphere. In lobbies and corridors, LED strips can be installed along ceiling perimeters or within signage to create a welcoming and modern aesthetic. Back-of-house areas like service corridors and storage rooms also benefit from their low maintenance and long lifespan.

Malls utilize remote LED strips extensively for accent lighting in retail displays, cove lighting in ceilings, and illuminated signage. The strips are ideal for highlighting product areas or guiding customer flow through walkways and staircases. Their ability to be cut to length and installed in tight or curved spaces makes them perfect for dynamic architectural designs often seen in modern shopping centers.

In office environments, remote LED strips support both task and ambient lighting needs. They are frequently installed under shelves, in suspended ceilings, or within partition systems to provide even, glare-free illumination. In reception areas and meeting rooms, they contribute to a professional and contemporary look. Their low heat output and energy efficiency also support sustainable building goals.

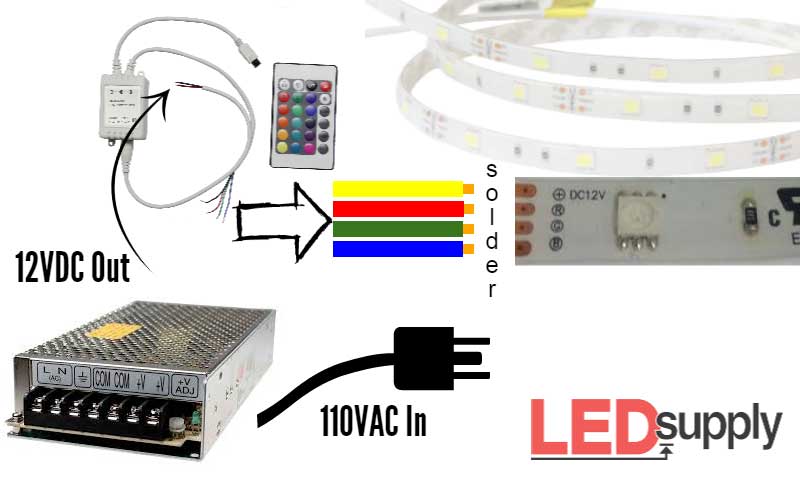

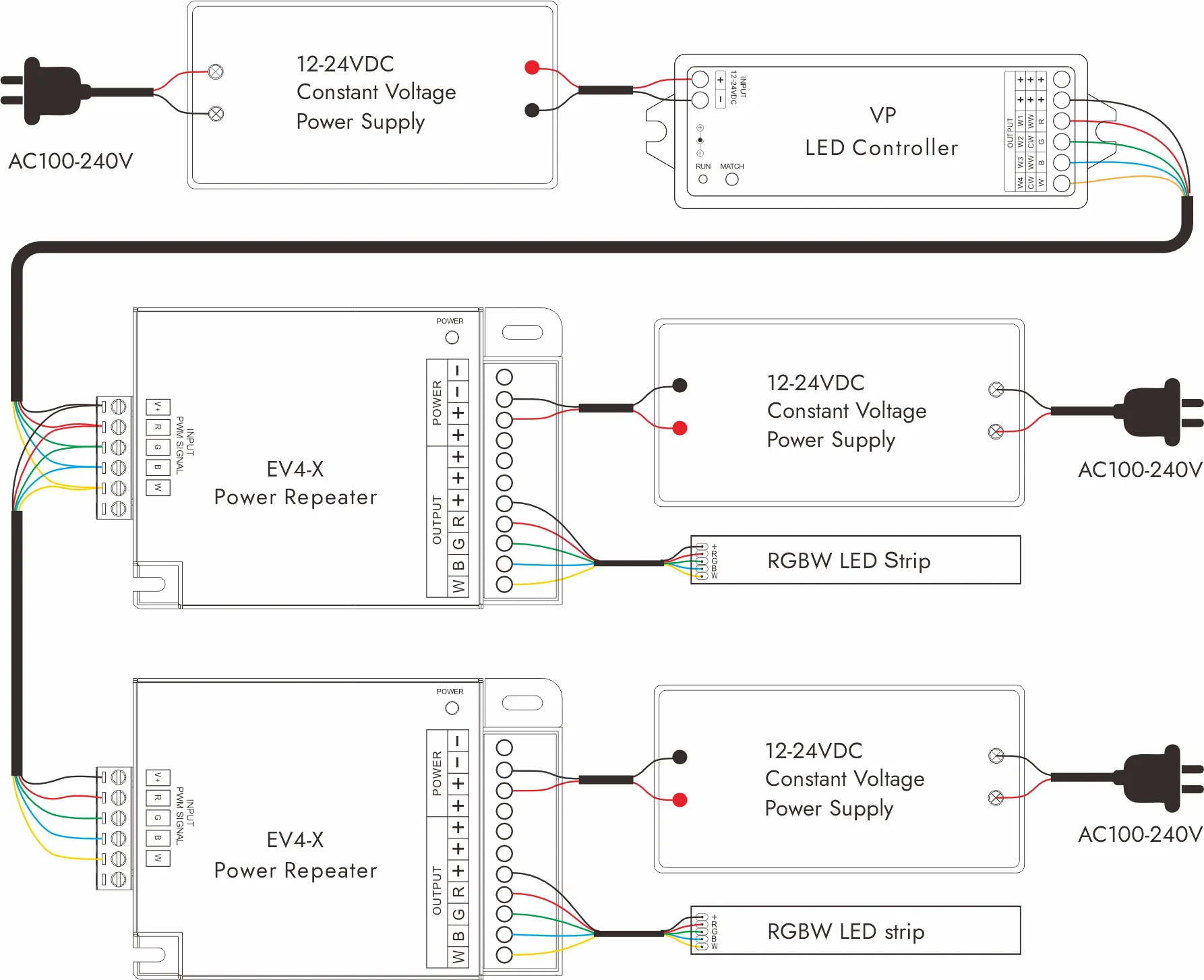

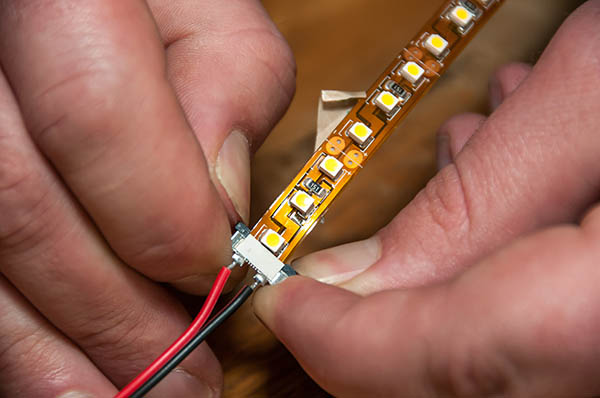

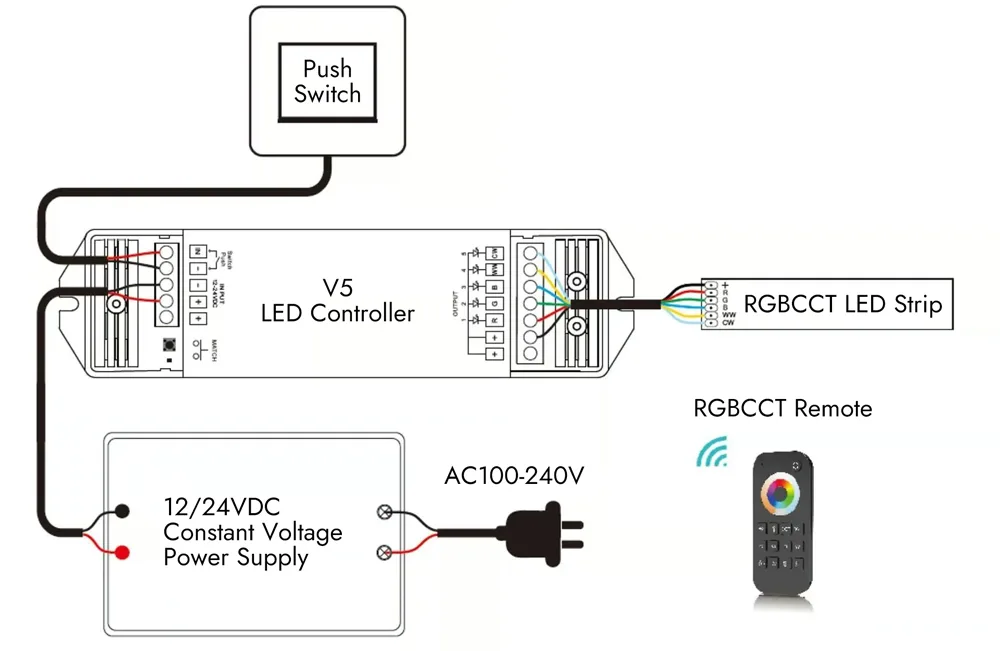

When installing remote LED strips, proper planning is essential. First, ensure the power supply is correctly sized and located within the recommended distance to avoid voltage drop, especially for longer runs. Use aluminum channels to improve heat dissipation and extend LED life, particularly in enclosed or high-temperature areas. Always clean the surface before applying the adhesive backing, and consider using mechanical fasteners for added security in high-traffic or vibration-prone areas. For optimal performance, connect the strips to a compatible dimmer or controller, and protect any outdoor or high-humidity installations with IP-rated housings. Finally, follow local electrical codes and consider hiring a qualified electrician for final connections to ensure safety and compliance.

Why Choose Beauty STC Lighting

Elevate your lighting solutions with Beauty STC’s advanced remote-controlled LED strip technology, engineered for seamless integration, exceptional color accuracy, and reliable performance in diverse applications. Partnering with us provides access to our rigorous quality control processes, customizable product configurations, and dedicated engineering support to meet your specific project requirements and market demands.

Contact our partnership manager directly at [email protected] to discuss how Beauty STC can become your trusted manufacturing ally for high-performance remote LED strip systems. We look forward to collaborating with you to deliver innovative lighting experiences to your customers.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.