Article Contents

Industry Insight: Recessed Lighting Recessed Lighting

Recessed lighting has become a cornerstone of modern commercial and industrial lighting design, offering a sleek, space-saving solution that combines functional illumination with architectural elegance. In environments ranging from warehouses and manufacturing facilities to retail spaces and office buildings, recessed lighting delivers uniform light distribution, improved energy efficiency, and reduced glare—critical factors in enhancing both productivity and safety. As building standards grow more stringent, demand for compliant, high-performance lighting solutions has surged, making certifications such as ETL and CE essential benchmarks for quality, electrical safety, and international market access. These certifications ensure that recessed lighting systems meet rigorous North American and European safety standards, giving facility managers and contractors confidence in their long-term reliability and code compliance.

At the forefront of this evolving industry is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting innovation since its founding in 1998. With over two decades of engineering expertise, Beauty STC specializes in high-efficiency, durable recessed lighting solutions designed specifically for demanding commercial and industrial applications. Combining advanced thermal management, precision optics, and robust construction, their products are engineered to perform in challenging environments while maintaining compliance with global standards including ETL and CE. As sustainability and smart building integration continue to shape the future of commercial lighting, Beauty STC remains committed to delivering cutting-edge solutions that meet the needs of architects, engineers, and facility operators worldwide.

Technical Specs & Certifications

Recessed lighting fixtures, commonly referred to as downlights or can lights, are integral to modern architectural lighting design. At Beauty STC Manufacturing Co., Ltd., we engineer our recessed LED luminaires to deliver superior performance, energy efficiency, and visual quality, meeting the stringent demands of commercial and high-end residential applications. Our technical specifications are rigorously validated through in-house testing and third-party certification to ensure reliability and compliance.

Lumens per Watt (lm/W) efficiency is a critical metric for sustainable lighting. Beauty STC recessed fixtures consistently achieve high efficacy ranges of 110 to 130+ lumens per watt under standard operating conditions. This performance exceeds typical industry benchmarks through advanced thermal management systems, including optimized heat sinks using high-purity die-cast aluminum, and the integration of premium LED chips from tier-1 suppliers. Our drivers operate at >90% efficiency with low harmonic distortion, contributing to the overall system efficacy. Real-world output is validated per LM-79 standards, ensuring the lumens/Watt values quoted reflect actual installed performance rather than theoretical maximums, directly translating to reduced energy consumption and operational costs for the end user.

Color Rendering Index (CRI) is paramount in applications where accurate color perception is essential, such as retail, hospitality, and healthcare. All Beauty STC premium recessed lighting lines deliver a minimum CRI of 90+, with many models exceeding Ra 92. Crucially, we prioritize high R9 values (typically >50) to ensure vibrant, natural rendering of saturated reds, which is often deficient in lower-quality LEDs. This is achieved through proprietary phosphor formulations and stringent binning processes during LED manufacturing. Our fixtures also maintain excellent color consistency (within a 3-step MacAdam ellipse) across production batches, ensuring uniform appearance in multi-fixture installations. This commitment to spectral quality supports well-being and enhances the perceived value of illuminated spaces.

IP (Ingress Protection) ratings define a fixture’s resilience against dust and moisture, critical for safety and longevity. Beauty STC offers recessed luminaires across multiple IP classifications to suit diverse environments. For standard dry interior locations like offices and living rooms, our fixtures carry an IP20 rating, providing basic protection against finger contact. For damp or wet locations such as bathrooms, kitchens, covered outdoor porches, or retail refrigeration areas, we provide rigorously tested IP65-rated recessed solutions. These models feature fully sealed optical compartments, gasketed driver housings, and corrosion-resistant materials to prevent dust ingress and withstand low-pressure water jets from any direction. Every IP65 fixture undergoes extended environmental chamber testing, including 1000-hour humidity exposure and thermal cycling, far exceeding IEC 60598 minimum requirements.

Beauty STC’s quality differentiation stems from our vertically integrated manufacturing and obsessive attention to detail. We utilize aerospace-grade aluminum alloys for thermal pathways, ensuring consistent lumen maintenance beyond 50,000 hours (L90/B10). Each fixture undergoes 100% photometric verification and electrical safety testing on our production lines. Our commitment to zero-defect manufacturing is reinforced by a comprehensive 5-year warranty, reflecting confidence in the durability and performance of our recessed lighting systems. This engineering rigor guarantees that our luminaires not only meet but sustain the specified lm/W, CRI, and IP performance throughout their operational life, providing clients with predictable, high-quality illumination and significant lifecycle cost savings.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern LED lighting production facility strategically located within one of China’s key manufacturing hubs. The Jiangmen plant is equipped with advanced manufacturing technologies and processes designed to ensure high product quality, efficiency, and scalability, particularly for LED downlights and recessed lighting solutions.

At the core of the production line are state-of-the-art SMT (Surface Mount Technology) machines, which enable precise and automated placement of electronic components onto printed circuit boards (PCBs). These SMT lines operate with high speed and accuracy, supporting consistent assembly of LED drivers, control modules, and power supplies used in recessed lighting fixtures. The integration of automated optical inspection (AOI) systems further ensures component alignment and soldering quality, minimizing defects and enhancing reliability.

Quality assurance is reinforced through comprehensive aging tests conducted on finished recessed lighting products. Each unit undergoes extended operational testing under controlled thermal and electrical conditions to simulate real-world usage over time. This aging process typically lasts from 4 to 12 hours or more, depending on client specifications, and includes checks for lumen output stability, color consistency, thermal management, and driver performance. These rigorous tests help ensure that all products meet international safety and durability standards such as CE, RoHS, UL, and DLC.

Beauty STC has strong OEM capabilities specifically tailored for recessed lighting products. The company supports full customization including size, trim design, color temperature, lumen output, beam angle, housing material, and dimming functionality. Clients can provide technical specifications or work with Beauty STC’s engineering team to develop new designs from concept to mass production. The factory also offers custom labeling, packaging, and branding services to meet private-label requirements for global markets.

With a vertically integrated supply chain, experienced R&D team, and adherence to ISO9001 quality management standards, the Jiangmen factory is well-equipped to handle both small-batch prototyping and large-scale OEM orders for recessed LED lighting with consistent quality and on-time delivery.

Application Scenarios

Recessed lighting serves as a fundamental solution across commercial environments due to its clean aesthetics, space efficiency, and adaptability. Within hotels, its primary applications include lobbies for creating ambient washes over feature walls or reception desks using adjustable trims, corridors for uniform illumination with fixed downlights spaced to eliminate shadows, and guest rooms where low-profile trims provide general ambient light without visual intrusion, particularly effective when layered with wall sconces or bedside lamps. Critical here is selecting IC-rated airtight housings to prevent conditioned air loss into plenums and using baffled or reflector trims to minimize glare over beds or seating areas. For malls and retail environments, recessed lighting excels in general mall concourse lighting with high-lumen downlights maintaining consistent footcandle levels under high ceilings, while in individual retail stores, adjustable accent trims precisely highlight merchandise with narrow beam angles. Thermal management is paramount in these high-occupancy spaces; ensure adequate housing clearance from insulation and verify fire-rated trims are installed where required near sprinkler systems to comply with fire codes. Offices heavily rely on recessed lighting for uniform task lighting, with grid patterns in open-plan areas calculated to achieve even illuminance on work surfaces while avoiding screen glare, and in executive offices or conference rooms where tunable white trims support circadian lighting strategies. Always implement dimmable drivers with occupancy/vacancy sensors in these zones for energy compliance.

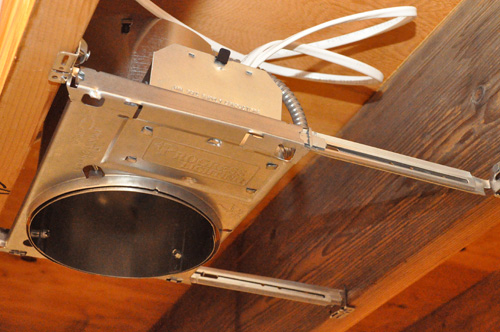

Installation demands rigorous attention to detail regardless of venue. Confirm housing compatibility with ceiling construction type—IC-rated housings are mandatory when insulation contacts the fixture, while non-IC housings require minimum 3-inch insulation clearance. Maintain strict adherence to thermal clearance specifications; overcrowding fixtures or burying housings in insulation causes premature LED lumen depreciation and driver failure. Calculate voltage drop meticulously for large commercial installations, especially with 12VAC/DC systems, using appropriate wire gauge and minimizing circuit lengths to prevent dimming inconsistencies. Ensure precise can alignment during rough-in using laser levels to avoid visible misalignment after drywall installation, and mandate airtight housing seals to prevent HVAC leakage which compromises energy efficiency. Finally, implement robust labeling of all junction boxes and circuit feeds per NEC Article 410.117 to facilitate future maintenance and prevent accidental damage during ceiling modifications. These steps collectively ensure optimal photometric performance, code compliance, and long-term reliability in demanding commercial settings.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality recessed lighting solutions from Beauty STC. As a trusted manufacturer, we specialize in durable, energy-efficient recessed lighting designed for seamless integration into residential, commercial, and industrial spaces. Partner with Beauty STC to access reliable products, expert support, and customized solutions tailored to your needs.

For inquiries and collaboration opportunities, contact us at [email protected]. Let’s illuminate the future together—choose Beauty STC as your trusted recessed lighting partner.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.