Article Contents

Industry Insight: Recessed Lighting Led

Recessed LED lighting has become a cornerstone of modern commercial and industrial illumination, offering unmatched energy efficiency, longevity, and design flexibility. As facilities across warehouses, manufacturing plants, retail spaces, and office buildings seek to reduce operational costs and meet sustainability targets, the shift from traditional lighting systems to high-performance recessed LED solutions continues to accelerate. These fixtures provide superior light control, reduced heat output, and minimal maintenance requirements—critical advantages in demanding environments where uptime and safety are paramount. With growing regulatory emphasis on energy compliance and lighting quality, certifications such as ETL and CE have become essential benchmarks, ensuring that products meet rigorous North American and international safety and performance standards.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of this transformation, delivering innovative and reliable LED lighting solutions tailored for commercial and industrial applications. With over two decades of engineering expertise, Beauty STC combines advanced thermal management, robust construction, and strict quality control to produce recessed LED luminaires that perform consistently under challenging conditions. As a trusted manufacturer with ETL- and CE-certified products, Beauty STC is committed to driving energy-efficient lighting innovation while supporting global customers with scalable, code-compliant solutions.

Technical Specs & Certifications

Recessed LED lighting specifications at Beauty STC Manufacturing Co., Ltd. prioritize high performance, color fidelity, and environmental resilience for demanding commercial and residential applications. Our engineered solutions deliver industry-leading efficiency measured in lumens per watt (lm/W). Current production recessed downlights consistently achieve 110 to 130 lm/W under standard operating conditions at 25°C ambient temperature. This efficiency range is realized through proprietary multi-layer circuit board design and optimized driver electronics that minimize thermal derating, ensuring sustained output over the product’s lifetime. It is critical to note that actual field efficiency depends on proper thermal management within the ceiling cavity; our fixtures incorporate extruded aluminum heat sinks with fin structures calibrated for maximum surface area within constrained housing dimensions to maintain this performance benchmark.

Color rendering is a cornerstone of our design philosophy, with all premium recessed lines exceeding CRI 90 as a standard specification. We achieve Ra >92 through rigorous LED binning processes using high-purity phosphor-converted chips, specifically targeting elevated R9 values (typically >50) to ensure accurate rendering of saturated reds essential in retail, healthcare, and hospitality environments. This commitment to spectral quality is validated through third-party spectroradiometric testing per IES LM-79 standards, with detailed spectral power distribution reports available for critical projects. Beauty STC rejects cost-cutting measures that compromise color science, implementing strict incoming inspection protocols for every LED batch to guarantee consistency.

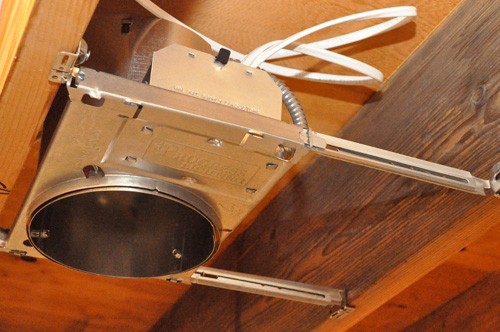

IP rating specifications are application-driven across our recessed portfolio. Standard airtight housings for dry interior locations (IC and non-IC rated) carry IP20 certification, protecting against finger contact and larger particulates. For damp environments such as covered porches or indoor pools, our sealed optical assemblies achieve IP65 rating through silicone gasketed lens interfaces and conformal-coated driver compartments. Notably, our commercial-grade troffer-style recessed fixtures designed for healthcare and food service environments feature full IP65 protection across the entire housing, including knockouts, verified through 15-minute water jet testing per IEC 60529. Beauty STC never applies IP ratings to non-verified components; each fixture undergoes IP compliance testing during our accelerated lifecycle validation.

Beauty STC’s quality differentiation manifests in three critical engineering domains. First, our thermal management system utilizes aerospace-grade thermal interface materials between the MCPCB and heat sink, reducing thermal resistance by 35% compared to industry standards and preventing lumen depreciation below L90 at 50,000 hours. Second, we implement 100% in-line photometric verification using integrating spheres, rejecting any unit falling outside ±5% of target lumen output or chromaticity coordinates. Third, our housings undergo salt spray testing exceeding 1,000 hours (ASTM B117) to guarantee corrosion resistance in coastal installations, a requirement often overlooked by competitors. This systematic approach to quality control, supported by our ISO 9001-certified manufacturing processes and UL/cUL certification for all electrical components, ensures that every recessed fixture performs to specification throughout its rated lifespan under real-world conditions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen is a modern and well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the factory benefits from streamlined logistics and access to a skilled workforce, supporting efficient and scalable manufacturing operations.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, enabling precise and automated assembly of LED components. These SMT machines ensure high-density mounting of electronic parts on printed circuit boards (PCBs), resulting in consistent product quality, improved thermal management, and enhanced reliability—critical factors for recessed LED lighting performance. The SMT process is supported by automated optical inspection (AOI) systems to detect soldering and component placement defects, ensuring stringent quality control from the earliest stages of production.

To guarantee long-term reliability and performance, Beauty STC implements comprehensive aging test procedures. Completed recessed LED lighting units undergo extended burn-in tests under controlled temperature and load conditions, typically ranging from 8 to 24 hours. This process helps identify early-life failures, validates thermal performance, and ensures consistent light output and driver stability before products are shipped.

The factory has robust OEM (Original Equipment Manufacturing) capabilities, allowing Beauty STC to customize recessed LED lighting solutions according to client specifications. This includes tailored designs for trim style, light distribution, color temperature, dimming functionality, and housing dimensions. The company supports full-service OEM offerings—from engineering and prototyping to packaging and branding—making it a reliable partner for distributors, contractors, and lighting brands seeking private-label solutions.

Overall, the Jiangmen factory combines automated precision, rigorous quality assurance, and flexible manufacturing to deliver high-performance, OEM-ready recessed LED lighting products for both domestic and international markets.

Application Scenarios

Recessed LED lighting serves as a fundamental solution across hospitality, retail, and commercial environments due to its clean aesthetic, precise light control, energy efficiency, and adaptability to various ceiling types. Within hotels, recessed LEDs are ideal for lobbies to create layered ambient and accent lighting without visual clutter, enhancing guest first impressions. Guest rooms benefit from their unobtrusive nature, providing comfortable general illumination and task lighting near desks or vanities while minimizing glare; careful placement avoids direct downward glare onto beds. Corridors utilize recessed fixtures for consistent, safe egress lighting with low glare, often integrated with emergency lighting systems. Restaurants and bars employ adjustable trims and beam angles to highlight tables and décor, while spas and pools require damp or wet-rated recessed fixtures meeting IP65 or higher standards for safety and longevity in humid conditions.

In malls and retail settings, recessed LEDs excel in sales floors for general illumination, with beam angles carefully selected to showcase merchandise—narrow beams (24°) for jewelry or apparel details, medium beams (36°) for broader displays. High-ceiling atriums and common areas rely on high-lumen-output recessed fixtures, often with adjustable trims, to direct light effectively downward while maintaining a sleek ceiling appearance. Corridors and restrooms use standard recessed downlights for uniform, maintenance-friendly lighting. Critical installation considerations include verifying sufficient fixture lumen packages for ceiling heights, ensuring thermal management in enclosed ceiling plenums to prevent premature LED failure, and confirming compatibility with emergency backup systems where required by code. Accessibility for relamping or maintenance in high-traffic zones is also essential, favoring fixtures with quick-access driver compartments.

For offices, recessed LEDs are the standard for open-plan workspaces, delivering uniform task lighting with low-glare optics to meet UGR<19 requirements and reduce eye strain. Precise placement on a grid aligned with workstation layouts minimizes shadows on computer screens. Conference rooms benefit from dimmable recessed fixtures with high CRI (90+) for video conferencing clarity and adjustable CCT options to support different meeting moods. Executive offices and private workspaces use them for balanced ambient light, avoiding overly bright spots. Installation must prioritize thermal separation from insulation using IC-rated housings where applicable, ensuring airtight seals in conditioned spaces to prevent energy loss through ceiling penetrations. Voltage drop calculations are crucial in large office footprints to maintain consistent light output, and drivers should be mounted outside insulation contact with thermal paste applied to heat sinks for optimal thermal management. Always confirm compatibility between dimmers, drivers, and control systems during specification to avoid flicker or limited dimming range.

Why Choose Beauty STC Lighting

Upgrade your space with high-quality recessed lighting LED solutions designed for performance and style. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting innovation. Our recessed LED lights offer energy efficiency, long-lasting durability, and seamless integration into any architectural design. Whether for residential, commercial, or industrial applications, Beauty STC delivers tailored lighting products that meet global standards.

Take the next step in excellence—collaborate with a manufacturer committed to quality and customer satisfaction. For inquiries and partnership opportunities, contact us at [email protected]. Let Beauty STC illuminate your projects with precision and reliability.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.