Article Contents

Industry Insight: Recessed Led Light

Recessed LED lighting has become a cornerstone of modern commercial and industrial illumination, offering superior energy efficiency, long-term durability, and sleek integration into architectural designs. As businesses and industrial facilities increasingly prioritize sustainability, reduced maintenance costs, and optimal light quality, recessed LED luminaires have emerged as the preferred solution across offices, warehouses, retail spaces, and manufacturing plants. These fixtures provide uniform light distribution, minimize glare, and support high ceilings and demanding environments—key requirements in large-scale applications. With strict regulatory standards governing electrical safety and performance, compliance with certifications such as ETL and CE has become essential, ensuring that lighting products meet rigorous North American and international requirements for safety, electromagnetic compatibility, and environmental resilience.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in commercial and industrial-grade recessed LED solutions, Beauty STC combines advanced thermal management, precision optics, and robust construction to deliver reliable, code-compliant lighting systems. As a certified manufacturer with ETL and CE listings across its product lines, the company serves global markets with a commitment to quality, energy efficiency, and engineered performance. With a legacy built on technical excellence and customer-driven design, Beauty STC continues to set benchmarks in recessed LED lighting for demanding commercial and industrial environments.

Technical Specs & Certifications

Recessed LED lights from Beauty STC Manufacturing Co., Ltd. are engineered to deliver superior performance for demanding architectural and commercial applications. Our technical specifications prioritize efficiency, color fidelity, and environmental resilience, ensuring consistent quality that meets stringent international standards.

Luminous efficacy is a core focus, with our standard recessed LED downlights achieving 110–130 lumens per watt across common wattages (6W to 24W). This efficiency is realized through advanced driver technology and optimized thermal management systems, minimizing energy waste while maintaining output stability over the product lifespan. Higher-wattage models (18W and above) consistently exceed 120 lm/W, validated under LM-79 testing protocols at 25°C ambient temperature. Efficacy may vary slightly based on optical configuration (e.g., reflector vs. lens) but remains within this high-performance range.

Color Rendering Index (CRI) is rigorously controlled to exceed 90, with most models achieving Ra >95 and R9 >90 for vibrant red rendition. This is accomplished using multi-phosphor LED chips and precise binning processes during manufacturing. Beauty STC employs spectrophotometer-verified testing on every production batch to ensure consistency, critical for retail, hospitality, and residential settings where accurate color representation is non-negotiable. Our lights also maintain excellent TM-30-15 scores (Rf >85, Rg >100), further guaranteeing natural and appealing illumination.

IP ratings are tailored to application needs. Standard indoor models carry IP20 for dry locations, while bathroom and covered outdoor variants are rated IP44 (splash-resistant) or IP65 (dust-tight and protected against low-pressure water jets). IP65-rated fixtures feature silicone-sealed optics and die-cast aluminum housings with integrated thermal pathways, allowing safe installation in wet zones like shower areas or exterior soffits without compromising thermal performance. All IP-rated models undergo 48-hour IP validation per IEC 60529, including pressure testing for IP65 compliance.

Beauty STC’s quality commitment is embedded in every unit. We utilize aerospace-grade aluminum heat sinks with anodized finishes for corrosion resistance and sustained thermal dissipation, preventing lumen depreciation. Our drivers incorporate 105°C-rated capacitors and surge protection (6kV), ensuring 50,000-hour L90 lifespan at 40°C ambient. Rigorous in-house testing includes 1,000-hour burn-in cycles, harmonic distortion analysis, and color consistency checks (MacAdam Step ≤3). This systematic approach, compliant with ISO 9001 and IEC 60598, guarantees that every recessed LED light meets the exacting performance metrics promised, reducing field failures and supporting sustainable building certifications like LEED and WELL.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern manufacturing facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen High-Tech Industrial Zone, the facility spans over 30,000 square meters and integrates advanced automation, strict quality control systems, and a highly skilled workforce to support both domestic and international markets.

The factory is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, featuring high-speed Siemens and Yamaha SMT machines. These machines ensure precise placement of LED components and electronic parts on PCBs, enabling efficient and reliable assembly of lighting modules. With multiple SMT lines operating in parallel, the facility achieves high throughput and consistency, essential for meeting large-volume orders while maintaining tight tolerances and product uniformity.

Quality assurance is a core focus at the Jiangmen plant. All LED lighting products, including recessed LED lights, undergo comprehensive aging tests before shipment. The aging process typically lasts from 8 to 24 hours under controlled conditions, simulating real-world operating environments at elevated temperatures and full load. This rigorous testing helps identify early failures, ensuring only durable and stable products reach customers. In addition to aging, the factory conducts photometric testing, electrical safety checks, and thermal performance evaluations to comply with international standards such as CE, RoHS, UL, and CCC.

Beauty STC has strong OEM and ODM capabilities, particularly for recessed LED lights. The company supports full customization, including light output (lumens), color temperature (CCT from 2700K to 6500K), CRI (Ra >80 or Ra >90 options), housing design, trim styles, dimming compatibility (0-10V, DALI, TRIAC), and driver configurations. Clients can provide their own specifications or work with Beauty STC’s engineering team to develop tailored solutions. The factory also offers custom labeling, packaging, and branding services, enabling seamless integration with the client’s market requirements.

With in-house mold making, aluminum extrusion, and tooling capabilities, Beauty STC maintains tight control over the supply chain and product development cycle. This vertical integration, combined with experienced R&D and design teams, allows the company to deliver innovative recessed LED lighting solutions efficiently and cost-effectively for global partners.

Application Scenarios

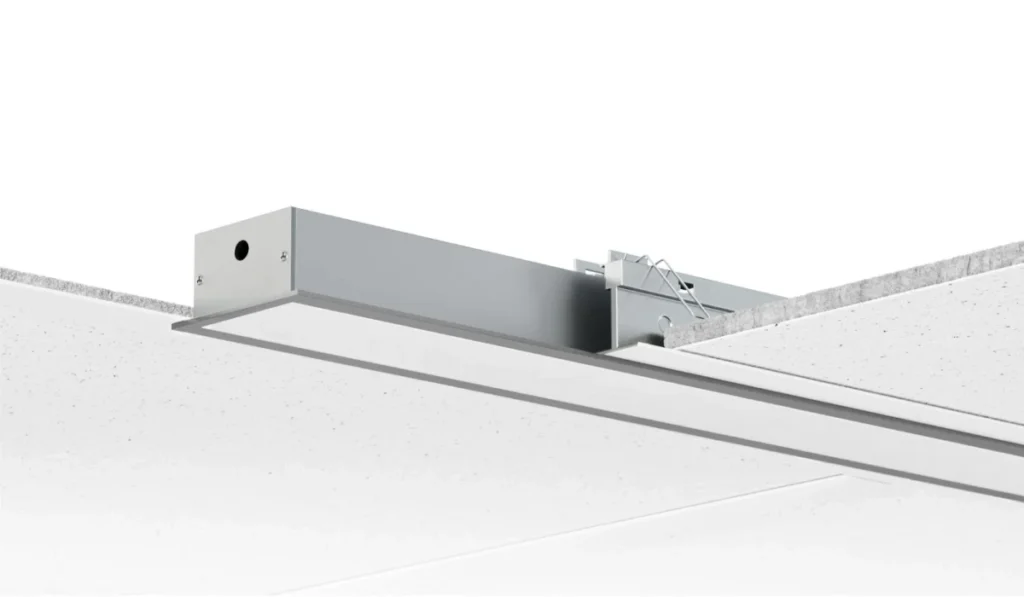

Recessed LED lighting serves as a versatile and efficient solution across commercial environments due to its clean aesthetic, directional control, and energy savings. In hotels, these fixtures are ideal for guest room corridors to provide unobtrusive, uniform illumination that guides guests without visual clutter. Within guest rooms themselves, recessed lights excel in layered lighting schemes, particularly when placed in bathroom ceilings for glare-free task lighting around vanities and in closets for even coverage. Lobby areas benefit from recessed downlights to highlight architectural features or reception desks while maintaining an open, spacious feel, though careful beam angle selection is necessary to avoid creating a “cave effect” in high-ceilinged spaces.

Malls utilize recessed LED lighting extensively in anchor store entrances and common corridors to establish consistent, welcoming pathways. Specialty retail spaces within the mall leverage them for general ambient lighting, especially where ceiling grids or bulkheads accommodate the fixtures without compromising merchandise visibility. Critical application areas include food court ceilings, where recessed fixtures provide focused illumination over seating areas while resisting grease and moisture when specified with appropriate IP ratings. It is essential in mall environments to select fixtures compatible with track adapters or adjustable trims to allow retailers flexibility in highlighting specific products as displays change.

Offices represent a primary application for recessed LED lighting due to their demand for uniform, glare-controlled illumination. Open-plan workspaces require precise fixture spacing and beam angles to minimize shadows on work surfaces and computer screens, typically using 4-inch or 6-inch aperture fixtures with medium flood beams. Private offices and conference rooms benefit from recessed layouts that support both general lighting and presentation modes, often integrated with dimming systems. Reception areas employ recessed lighting to create a professional atmosphere while avoiding direct glare for visitors, with careful attention to placement relative to glass partitions to prevent reflections.

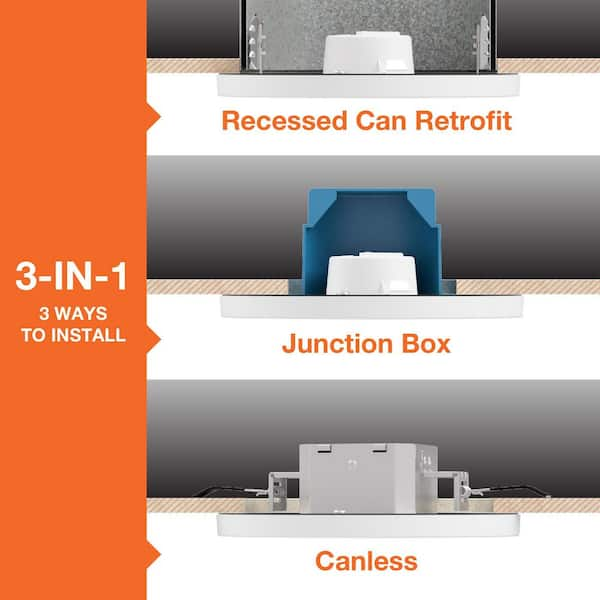

Installation requires strict adherence to several critical practices regardless of location. Always verify the fixture’s IC (Insulation Contact) rating matches the ceiling construction; non-IC rated housings installed in insulated ceilings create severe fire hazards and thermal throttling that drastically reduces LED lifespan. Maintain minimum clearance distances around the fixture housing and driver compartment as specified by the manufacturer—typically 3 inches on all sides—to prevent overheating, which is the leading cause of premature lumen depreciation. For grid ceilings, ensure the housing flange sits precisely on the grid cross-tee to avoid visible gaps or pressure on the fixture that causes flickering. Voltage drop must be calculated for long circuit runs, especially with 12V or 24V systems, using appropriate wire gauge to maintain consistent light output across the entire installation. Finally, always conduct a thermal test after installation by measuring housing surface temperature at peak ambient conditions; sustained temperatures exceeding 65°C indicate insufficient airflow or incorrect housing selection requiring immediate correction.

Why Choose Beauty STC Lighting

Upgrade your lighting projects with high-quality recessed LED lights designed for performance and durability. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. Our recessed LED lights offer energy efficiency, sleek design, and long-lasting performance—ideal for residential, commercial, and industrial applications.

To learn more or discuss custom solutions for your business, contact our sales manager at [email protected]. Let Beauty STC be your reliable lighting partner.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.