Article Contents

Industry Insight: Pwm Led Controller

Precision matters in commercial and industrial lighting environments where operational efficiency, visual comfort, and long-term reliability are non-negotiable. Pulse Width Modulation (PWM) LED controllers have emerged as a critical technology addressing these demands, offering superior dimming performance without the color shift or audible noise often associated with alternative methods. In settings ranging from expansive warehouses and manufacturing facilities to high-end retail spaces and office complexes, PWM ensures smooth, flicker-free light output across the entire dimming range, directly contributing to energy savings, enhanced worker productivity, and reduced maintenance costs. Crucially for specifiers and facility managers, compliance with stringent safety and performance standards like ETL and CE is not optional; it is a fundamental requirement for project approval and liability mitigation in North American and global markets, ensuring controllers operate safely within complex building systems and adhere to rigorous electromagnetic compatibility regulations.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of specialized engineering expertise to develop robust, standards-compliant LED control solutions. As a trusted partner to lighting manufacturers and system integrators worldwide, we understand the unique challenges of commercial and industrial applications – from the need for seamless integration with building management systems to the relentless demand for durability in harsh environments. Our PWM LED controllers are engineered from the ground up to meet and exceed ETL and CE requirements, providing the stability, precision, and regulatory assurance that define professional-grade lighting infrastructure. This deep-rooted commitment to quality and innovation positions Beauty STC as a cornerstone supplier for projects where performance and compliance are inseparable.

Technical Specs & Certifications

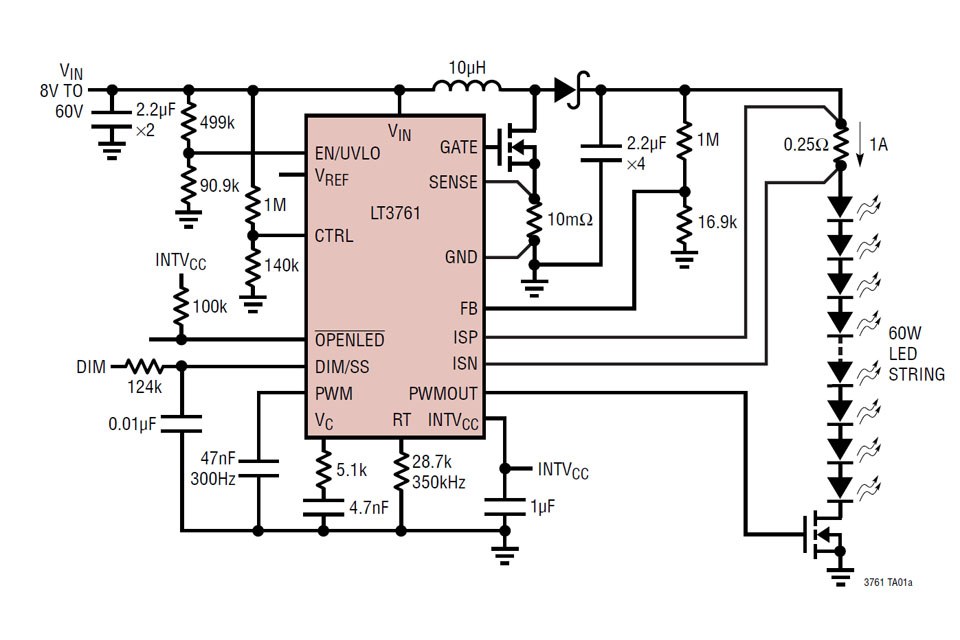

The PWM LED controller offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for precision dimming and high-efficiency performance in modern LED lighting systems. At its core, the controller utilizes Pulse Width Modulation (PWM) technology to deliver smooth, flicker-free dimming by rapidly switching the current to the LEDs on and off at varying duty cycles. This method ensures stable light output across dimming ranges while maintaining consistent color temperature and minimizing thermal stress on the LED components.

In terms of system efficiency, when paired with high-performance LEDs, the overall lumens per watt (lm/W) output of lighting fixtures using our PWM controllers typically exceeds 120 lm/W, with top-tier configurations reaching up to 140–150 lm/W depending on the LED package and thermal design. This high efficacy is achieved through optimized driver circuitry that minimizes power loss and supports constant current regulation, ensuring maximum energy conversion from electrical input to visible light.

Beauty STC places strong emphasis on light quality, and our PWM controllers are specifically designed to work seamlessly with LEDs that achieve a Color Rendering Index (CRI) greater than 90. This high CRI ensures accurate and vibrant color representation, making the lighting ideal for applications in retail, healthcare, studios, and premium residential environments where true color perception is critical. The controller maintains stable current delivery, preventing color shift even at low dimming levels, thereby preserving the high CRI performance across the entire dimming range.

Regarding environmental protection, the PWM LED controllers from Beauty STC are available in multiple configurations with IP ratings to suit diverse installation conditions. Standard indoor units are rated at IP20, providing basic protection against touch and dust ingress. For outdoor or harsh environments, we offer sealed driver-controller combinations with IP65, IP66, and IP67 ratings, ensuring full protection against dust, water jets, and temporary immersion. These ruggedized versions are commonly used in outdoor architectural lighting, parking structures, and industrial facilities.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its commitment to quality, reliability, and compliance with international standards. Our PWM LED controllers undergo rigorous testing for thermal performance, electrical safety, and long-term durability. Built with high-grade components and conformal-coated PCBs where applicable, our products deliver stable operation across wide temperature ranges (-20°C to +60°C) and extended lifespans exceeding 50,000 hours under normal operating conditions. With ISO-certified manufacturing processes and adherence to CE, RoHS, and UL standards, Beauty STC ensures every controller meets the highest benchmarks for performance and safety in the LED lighting industry.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a primary production hub for our LED lighting and control products. This modern factory is strategically located within a major industrial zone, benefiting from excellent infrastructure and a skilled regional workforce. The facility operates under stringent ISO 9001 quality management standards, with dedicated clean rooms for critical processes and comprehensive environmental controls to ensure consistent manufacturing conditions.

Our Surface Mount Technology (SMT) production lines form the backbone of electronic assembly at the Jiangmen site. We utilize multiple high-speed, precision Yamaha YS series machines, specifically the YSM20 and YSM10 models, configured in optimized lines. These machines handle components ranging from 0201 passives up to larger connectors and ICs with high placement accuracy (±25µm @ 3σ) and throughput exceeding 60,000 components per hour per line. The lines integrate automatic optical inspection (AOI) stations immediately post-reflow for comprehensive solder joint and component placement verification, ensuring defect detection before products proceed to subsequent stages. This capability supports both high-volume production runs and flexible small-batch manufacturing for specialized controllers.

Rigorous aging and reliability testing is a non-negotiable step for all our LED drivers and controllers, including PWM units. Completed PCB assemblies undergo a mandatory 48 to 72-hour burn-in process within our dedicated aging chamber area. Units operate at elevated temperatures (typically 65-75°C ambient) and under full rated load conditions. During this period, sophisticated monitoring systems continuously track critical parameters such as output voltage stability, current ripple, thermal performance of key components, and overall functional integrity. Any unit exhibiting parameter drift beyond tightly controlled thresholds is automatically flagged and removed from the production flow for root cause analysis. This extended stress testing significantly weeds out infant mortality failures before products reach customers.

Beauty STC possesses extensive OEM and ODM capability specifically for PWM LED controllers, leveraging our Jiangmen factory’s full vertical integration. We offer complete turnkey solutions starting from initial concept or provided specifications. Our engineering team collaborates closely with clients to develop custom PWM controllers meeting exact requirements for dimming frequency range (typically 200Hz to 20kHz, adjustable), dimming resolution (up to 16-bit), control protocols (0-10V, DALI, DMX, wireless RF/Zigbee), form factor, thermal management, and safety certifications (UL, CE, TUV, CCC). We handle all aspects including PCB layout optimization for minimal EMI, component sourcing from approved vendors, SMT assembly, in-circuit testing (ICT), functional testing tailored to the PWM profile, and final packaging. Clients benefit from our deep expertise in stable, flicker-free PWM implementation, robust thermal design, and strict adherence to agreed-upon quality gates throughout the manufacturing process. All OEM projects are executed under strict confidentiality agreements with dedicated project management.

Application Scenarios

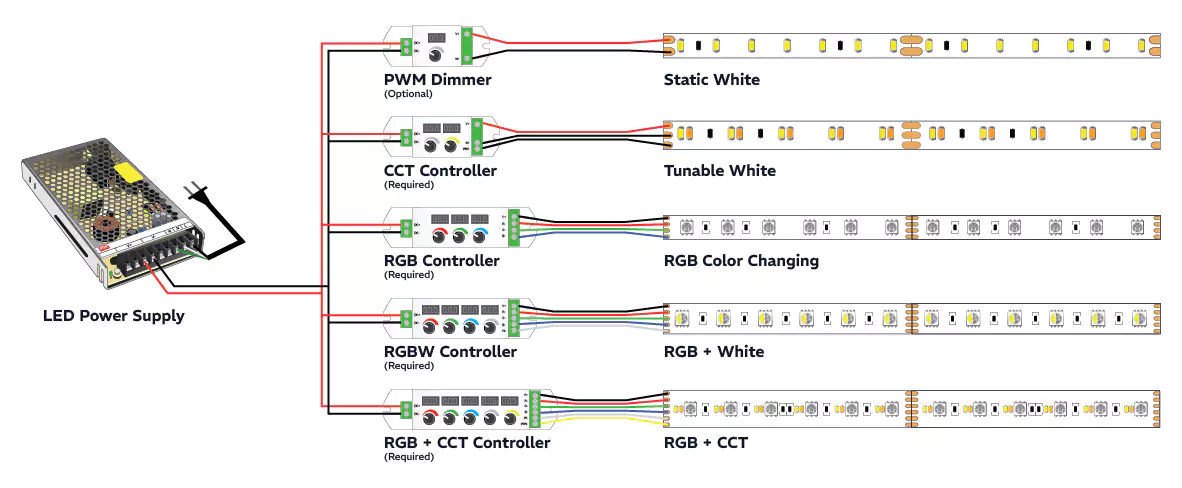

PWM LED controllers are widely used across various commercial and hospitality environments due to their precision in dimming, energy efficiency, and smooth light control without flicker or color shift. Their ability to deliver consistent and high-quality dimming makes them ideal for settings where ambiance, functionality, and energy savings are critical.

In hotels, PWM LED controllers are commonly used in guest rooms, lobbies, corridors, and banquet halls. They allow for adjustable lighting scenes that enhance guest comfort and experience—such as dimming lights for relaxation or brightening them for reading. In lobbies and public areas, they help create dynamic lighting moods that align with branding or time of day. For banquet and conference spaces, lighting can be tuned to suit different events, improving versatility.

In malls and retail environments, PWM controllers are employed in display lighting, walkways, and common areas. Precise dimming helps highlight merchandise effectively, drawing customer attention while maintaining visual comfort. The flicker-free performance of PWM ensures that lighting appears stable on camera, which is important in security and marketing video footage.

In offices, these controllers are used in open-plan workspaces, meeting rooms, and executive suites. They support human-centric lighting strategies by enabling daylight harvesting and tunable white levels that can boost productivity and reduce eye strain. Integration with occupancy and daylight sensors further enhances energy efficiency.

When installing PWM LED controllers, ensure compatibility between the controller, LED drivers, and fixtures. Always verify that the LEDs are dimmable and designed to work with PWM signals. Use shielded cables in environments with high electromagnetic interference to prevent signal noise. Mount the controller in a location that is accessible for maintenance but protected from dust and moisture. For large installations, consider segmenting lighting zones to allow for independent control and easier troubleshooting. Proper grounding is essential to avoid flickering or erratic behavior. Finally, follow local electrical codes and manufacturer guidelines to ensure a safe and reliable installation.

Why Choose Beauty STC Lighting

Upgrade your LED systems with precision dimming and flicker-free performance through Beauty STC’s advanced PWM LED controllers. Our engineered solutions deliver unmatched reliability for demanding commercial, industrial, and architectural lighting applications. Partner with Beauty STC Manufacturing Co., Ltd. to integrate seamless dimming control, optimize energy efficiency, and enhance product value with customizable technical support. As your dedicated manufacturing partner, we provide rigorous quality assurance and scalable production tailored to your specifications. Elevate your lighting projects with industry-leading PWM technology designed for real-world performance. Reach out to our engineering team today to discuss your requirements and discover how Beauty STC can power your next innovation. Contact Manager at [email protected] to initiate a technical consultation and partnership discussion.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.