Article Contents

Industry Insight: Pwm Dimmer

The commercial and industrial lighting sector faces increasing demands for energy efficiency, occupant well-being, and precise environmental control, making advanced dimming technologies essential. Pulse Width Modulation (PWM) dimming has emerged as the critical solution for high-performance LED applications in these demanding environments, offering superior flicker-free operation across the entire dimming range compared to alternative methods like TRIAC or 0-10V. This precision is non-negotiable in settings like office spaces, retail environments, warehouses, and manufacturing facilities where inconsistent light output can cause eye strain, reduce productivity, and even compromise safety during critical tasks. Achieving this level of performance requires dimming components engineered to stringent international safety and electromagnetic compatibility standards, with ETL certification being mandatory for market access in North America and CE marking essential for the European Union, ensuring reliable, interference-free operation within complex building management systems. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep expertise in designing and manufacturing such mission-critical lighting control solutions. We understand the unique challenges of commercial and industrial infrastructure and are committed to delivering PWM dimmers that not only meet but exceed these rigorous ETL and CE requirements, providing facility managers and electrical contractors with the confidence of proven reliability and seamless integration for sustainable, human-centric lighting environments.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. offers high-performance PWM (Pulse Width Modulation) dimmers designed for precision control of LED lighting systems, ensuring optimal efficiency, color fidelity, and durability. When integrated with compatible LED drivers and fixtures, these PWM dimmers enable smooth, flicker-free dimming from 0% to 100%, preserving the full potential of modern LED performance.

In terms of lumens per watt (lm/W), Beauty STC’s PWM dimmer systems are engineered to maintain the high efficacy of the connected LED fixtures. While the dimmer itself does not generate light, it ensures minimal power loss during dimming operations—typically less than 2%—allowing LED systems paired with our dimmers to consistently achieve 120–180 lm/W depending on the fixture design and LED components used. This efficiency is critical for energy-saving applications across commercial, industrial, and high-end residential environments.

Color Rendering Index (CRI) performance is preserved exceptionally well with Beauty STC’s PWM technology. Unlike phase-cut dimming methods that can distort current waveforms and affect color stability, PWM dimming rapidly switches the LED current on and off without altering the drive current amplitude. This method maintains stable junction temperatures and consistent spectral output, ensuring that LEDs operated via Beauty STC PWM dimmers retain a CRI greater than 90 throughout the dimming range. This makes the solution ideal for applications where accurate color representation is essential, such as retail lighting, art galleries, and healthcare facilities.

Regarding environmental protection, Beauty STC designs its PWM dimmer modules and associated control systems with robust ingress protection (IP) ratings to ensure reliability in demanding conditions. Standard models are available with IP20 for indoor use, while industrial-grade versions offer IP65 and IP67 ratings, providing complete protection against dust and resistance to water jets or temporary submersion. These high IP-rated units are suitable for outdoor installations, wet locations, and harsh industrial environments.

Beauty STC’s commitment to quality is evident in every stage of manufacturing. Our PWM dimmers are built using premium-grade components, undergo rigorous thermal and electrical testing, and comply with international safety and EMC standards including CE, RoHS, and UL. With decades of expertise in LED driver and control system innovation, Beauty STC delivers reliable, long-lasting solutions known for stability, precision, and seamless integration with a wide range of LED systems. Our products are trusted globally for their consistency, performance, and engineering excellence.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a key production hub for our LED lighting and control systems. Strategically located within the Pearl River Delta region, the Jiangmen factory benefits from robust infrastructure and supply chain access while maintaining efficient operations for both domestic and international markets. The facility is designed to stringent ISO 9001 quality management standards, ensuring consistent output across all production stages.

Our Surface Mount Technology (SMT) assembly lines form the backbone of precision electronics manufacturing at this site. We operate multiple high-speed Yamaha YS series SMT placement machines, specifically the YS12F and YSM20 models, capable of handling components down to 0201 package sizes with exceptional accuracy. These machines achieve placement speeds exceeding 60,000 components per hour per line while maintaining placement precision within ±25μm. The SMT process includes automated solder paste inspection (SPI) and 3D automated optical inspection (AOI) stations to verify paste deposition quality and component placement before reflow soldering, minimizing defects at the earliest possible stage. This capability is critical for assembling the densely populated control boards used in our PWM dimmer modules and integrated lighting systems.

Rigorous aging and reliability testing is a non-negotiable part of our quality assurance protocol at the Jiangmen plant. All finished LED drivers, control modules including PWM dimmers, and complete luminaires undergo a minimum 48-hour continuous aging test under controlled thermal and electrical load conditions. Products are subjected to elevated temperatures within environmental chambers while operating at nominal and peak input voltages. During this burn-in phase, we monitor critical parameters such as output current stability, thermal performance at key component junctions, and PWM signal integrity. Any units exhibiting parameter drift beyond our tight tolerances or functional instability are automatically flagged and removed from the production stream. Post-aging, thermal imaging verification ensures no abnormal hotspots exist on PCBs, confirming robust thermal design and manufacturing execution.

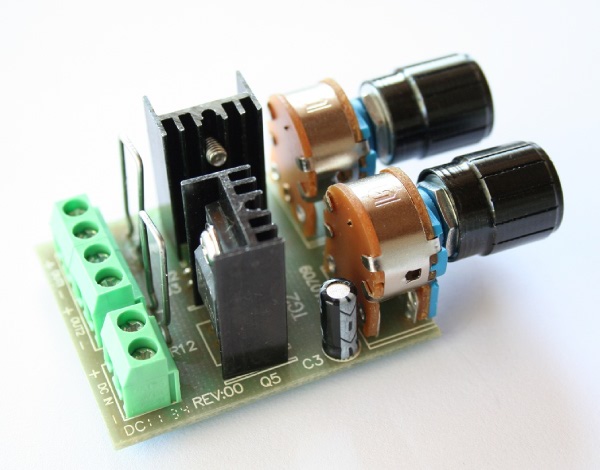

Regarding OEM capabilities for PWM dimmers, Beauty STC possesses comprehensive turnkey manufacturing expertise at the Jiangmen facility. We support full OEM/ODM services for custom PWM dimmer solutions, from initial concept and electronic design through to volume production and certification. Our engineering team works closely with clients to develop dimmers meeting specific requirements for dimming range, frequency stability (typically 1-3kHz range), compatibility with various LED loads, and integration with control protocols like 0-10V, DALI, or wireless systems. We handle all aspects including custom PCB layout, component sourcing to client specifications, firmware adaptation if required, and final assembly. The facility is equipped to produce PWM dimmers ranging from simple standalone modules to complex integrated driver-dimmer units, supporting both trailing-edge and leading-edge dimming topologies as needed. We maintain full traceability throughout production and can accommodate certifications including CE, UL, ETL, and CCC as required by the target market, providing complete test reports validating PWM performance characteristics such as flicker index and dimming smoothness. Clients receive dedicated production lines when volumes warrant, ensuring confidentiality and priority handling for their specific dimmer programs.

Application Scenarios

PWM dimmers are widely used in commercial and hospitality environments such as hotels, malls, and offices due to their precise control, energy efficiency, and ability to maintain consistent light color across dimming levels. In hotels, PWM dimmers are ideal for guest rooms, lobbies, and corridors where mood lighting and energy savings are important. They allow smooth dimming of LED lighting in bedside lamps, ceiling fixtures, and accent lighting, enhancing guest comfort while reducing power consumption. In malls, PWM dimmers are commonly used in display lighting, cove lighting, and signage where accurate light control is needed to highlight merchandise and create appealing visual environments. Their flicker-free performance at low light levels ensures a comfortable shopping experience. In office spaces, PWM dimmers help regulate ambient lighting in workstations, meeting rooms, and common areas, contributing to occupant well-being and productivity by enabling daylight harvesting and customizable lighting scenes.

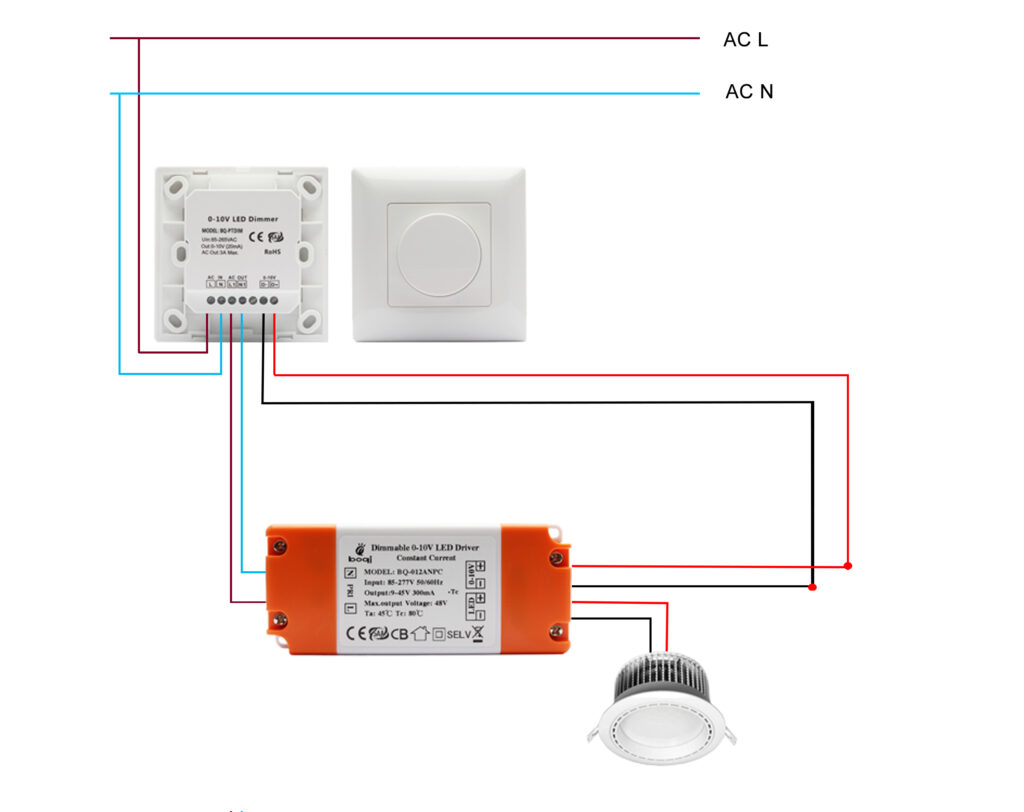

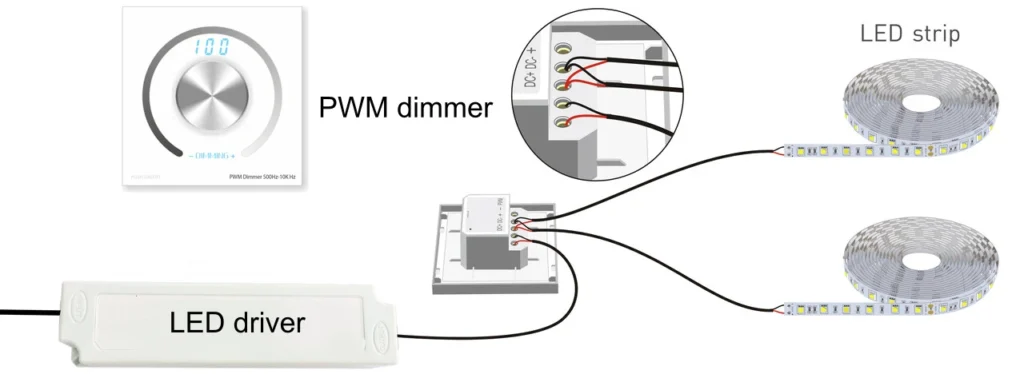

When installing PWM dimmers, it is essential to ensure compatibility with the LED drivers and fixtures being used, as not all LEDs support PWM dimming. Always verify that the lighting system supports PWM signals, typically through 0–10V, DALI, or direct PWM input. Use shielded cables for signal wiring to minimize electromagnetic interference, especially in environments with sensitive electronic equipment. Keep PWM control wires separated from high-voltage power lines to prevent noise coupling. Proper grounding of the dimmer and control system is critical to avoid signal instability. Mount the dimmer in a well-ventilated area to prevent overheating, and follow the manufacturer’s wiring diagrams precisely. For large installations, consider using centralized control systems that integrate PWM dimming for uniform performance across zones. Regular testing during commissioning ensures smooth dimming curves and eliminates flickering. Lastly, label all circuits and dimmer channels clearly for easier maintenance and troubleshooting.

Why Choose Beauty STC Lighting

Elevate your LED lighting projects with flicker-free precision dimming through Beauty STC’s advanced PWM dimmer solutions. Our engineered PWM technology ensures smooth, silent, and reliable dimming performance across diverse commercial and architectural applications, eliminating visible flicker and extending LED system longevity. Partner with Beauty STC to integrate superior dimming control into your next project and deliver exceptional light quality to your clients. Contact our dedicated engineering team today at [email protected] to discuss your specific requirements and discover how our PWM dimmer expertise can enhance your product offerings. Reach out now to initiate a collaboration focused on innovation and performance.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.