Article Contents

Industry Insight: Pwm Dimmer

PWM Dimming in Commercial & Industrial Lighting: Why Certified Hardware Matters

The Shift from Analog to Digital Dimming

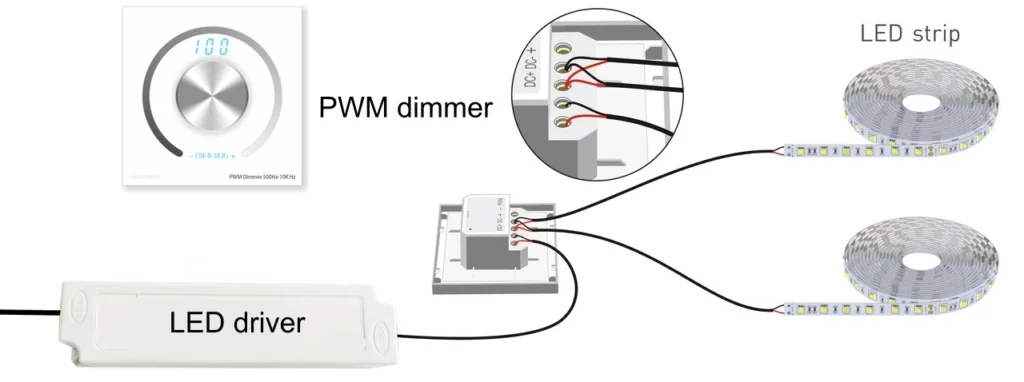

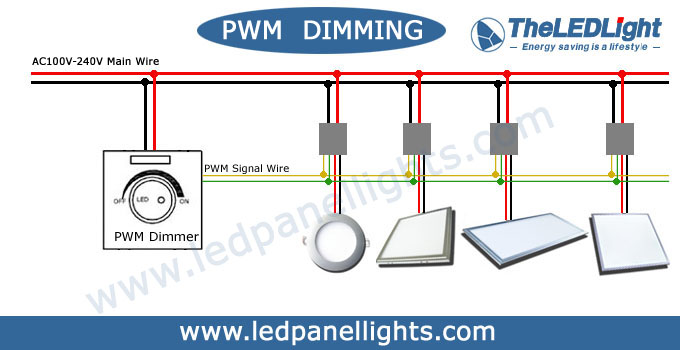

Across warehouses, retail chains, and façade-lighting projects, spec-grade LED loads are increasingly driven by constant-voltage PWM (pulse-width-modulation) dimmers rather than legacy 0-10 V or triac phase-cut circuits. PWM keeps the current amplitude constant and modulates duty cycle, eliminating colour shift, audible transformer buzz, and the “drop-out” at 5 % that still plagues many analog systems. The result is flicker-free dimming down to 1 % with 65 000+ digital steps—critical for WELL-building compliance, high-speed camera environments, and circadian-tuning installations.

Market Demand at a Glance

| Segment | 2023 Global CAGR* | Key Driver | Typical PWM Dimmer Requirement |

|---|---|---|---|

| Cold-chain & Food Processing | 9.4 % | HACCP flicker limits | IP65, –30 °C, 10 A × 24 VDC |

| Retail Chain Retrofits | 8.1 % | 24/7 operation, EMC | >50 kHz, CISPR-15, <5 % THD |

| High-bay & Aisle Lighting | 7.8 % | Motion/Occupancy | 120-240 W, 12-24 V, -40~60 °C |

| Façade & Landscape | 11.2 % | Distance wiring | 30 mV pp ripple, surge 2 kV |

*Source: Strategies Unlimited / IHS 2023

Why ETL / CE Certification Is Non-Negotiable for Importers

- Code Compliance: NEC 410, CEC Part II, and CE LVD 2014/35/EU all require listed dimming devices when installed after the Class 2 driver.

- Liability: A shorted MOSFET inside an uncertified dimmer can back-feed the driver, voiding the UL/ENEC mark of the entire luminaire.

- Customs & Insurance: More than 30 % of LED lighting shipments are now spot-checked for valid certification files; non-listed goods face re-export or destruction.

- Performance Data: Only labs that issue ETL or TUV CE reports verify 87-154 kHz PWM frequency, 0.1 % resolution, and surge 1 kV/2 kV ring-wave—specs that matter when you warranty a 50 000 h system.

Beauty (STC) Manufacturing Co., Ltd – Veteran OEM Since 1998

Located in Jiangmen’s National High-tech Zone, Beauty STC Lighting has produced PWM dimming hardware alongside its core LED strips, panels, and UFO high-bays for 25 years. All dimmer platforms are engineered in-house, assembled on Si-place lines, and 100 % burned in for 4 h at 265 Vac / 90 °C case. ETL (US & Canada) and TUV CE files are held under our own CCN/NB, allowing distributors to piggy-back without additional listing costs.

| Capability | Detail |

|---|---|

| Established | 1998 |

| Factory Area | 18 000 m² (owned) |

| PWM Dimmer Lines | 3 SMT lines, 2 DIP, 1 conformal-coat |

| Certifications | ETL/cETL, TUV CE, RoHS, REACH, SAA pending |

| OEM/ODM MOQ | 500 pcs (private label), 100 pcs (logo only) |

| Standard Lead Time | 3 weeks, 1 week for repeat orders |

| Warranty | 5 years on PWM boards, 10 years on passive BOM |

Solving the “Weak-Link” Problem

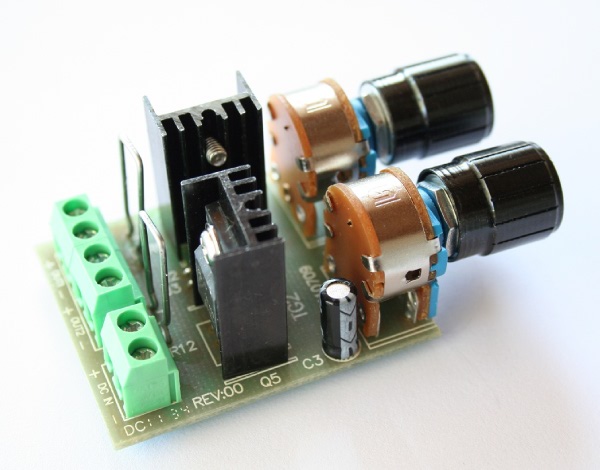

Most field failures are traced to undersized MOSFETs or electrolytic capacitors rated 85 °C instead of 105 °C. Beauty STC specifies:

100 V MOSFETs for 24 V circuits (4× safety margin)

Rubycon 105 °C / 5000 h capacitors

3 kV opto-isolation between logic and power stage

–40 °C cold-start verified in NABL chamber

The outcome: MTBF >300 000 h per Telcordia SR-332, and a documented <50 ppm return rate over the last five export years.

Next Section Preview

In the following section we compare constant-voltage vs. constant-current PWM topologies and present Beauty STC’s modular portfolio (1-channel, 4-channel, IP67, DALI / 0-10 V hybrid) with mechanical drawings and connection diagrams for distributors and lighting designers.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for PWM Dimming Systems

Precision Engineering for Consistent Performance

PWM dimmers serve as critical control components in LED lighting systems, though they do not directly produce light. Their technical design profoundly impacts system reliability, dimming accuracy, and overall performance. Substandard dimmers can introduce flicker, color shift, or inconsistent brightness—compromising the perceived quality of the LED product. At Beauty STC, all PWM dimmers are engineered to exacting specifications, ensuring precise current regulation and seamless integration with high-performance LED fixtures.

Core Technical Specifications

Beauty STC’s PWM dimmers are designed with industry-leading technical specifications to meet global project requirements. Key attributes include:

PCB Quality: Utilizing high-grade FR-4 material with Tg 170+ rating and 2oz copper plating, our PCBs undergo strict IPC Class 2 manufacturing standards. Thermal vias and heatsink integration prevent overheating during continuous operation.

IP Rating Certification: Available in IP20 (indoor), IP65 (damp locations), and IP67 (submersible) variants. All units are tested per IEC 60529 to ensure environmental resilience.

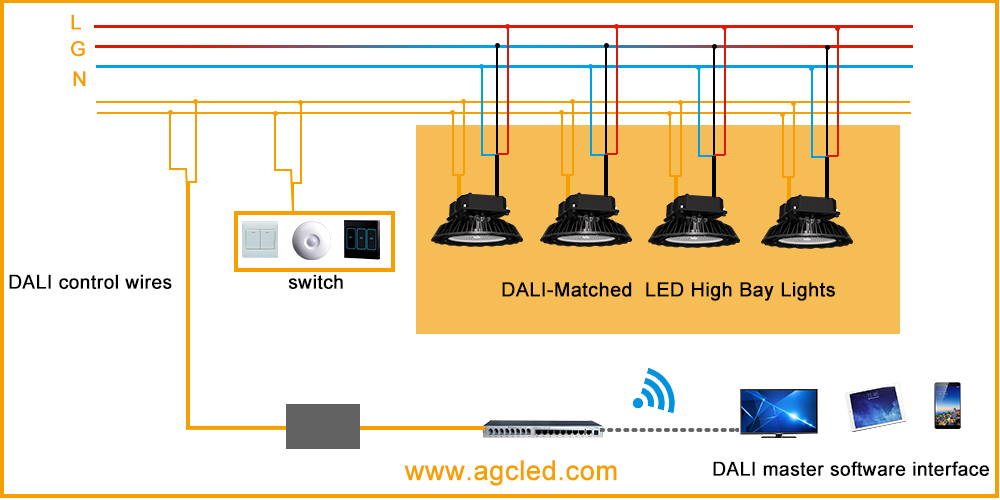

Dimming Precision: 65,000+ PWM steps with a frequency exceeding 200Hz eliminate visible flicker and enable smooth dimming down to 1% brightness. Compatible with 0-10V, DALI, and 2-wire control protocols.

Electrical Specifications: Configurable for 12VDC/24VDC systems with up to 10A per channel. Power handling up to 240W (24VDC) with built-in overcurrent and short-circuit protection.

Quality Assurance and Consistency

Beauty STC’s 25+ years of manufacturing expertise ensures consistent quality across all production batches. Every PWM dimmer undergoes:

100% burn-in testing at 85% load for 48 hours

Thermal cycling between -20°C to 60°C

Electrical safety and EMC compliance checks

Rigorous environmental testing per IEC standards

All products are certified to ETL (USA/Canada) and TUV CE (Europe) requirements, guaranteeing compliance with international safety and performance benchmarks. Our OEM/ODM capabilities allow for custom configurations to meet specific project requirements, from voltage tolerances to enclosure materials.

Comparison of Quality Standards

| Feature | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| PCB Material & Construction | FR-2 or low-grade FR-4; inconsistent trace widths; minimal thermal management | High-grade FR-4 (Tg 170+), 2oz copper plating; IPC Class 2 manufacturing; optimized thermal vias and heatsink integration |

| IP Rating Certification | Typically IP20 (indoor only); no standardized testing for harsh environments | IP20 to IP67 certified; tested per IEC 60529; sealed enclosures for moisture and dust resistance |

| Dimming Precision | 500-1,000 steps; flicker at low brightness; frequency <100Hz | 65,000+ PWM steps; >200Hz frequency; flicker-free dimming down to 1% |

| System Performance Stability | Inconsistent current delivery causes CRI shift and lumen depreciation | Maintains CRI >90 and lumen output within ±5% across 1-100% dimming range |

| Certification Compliance | Often lacks ETL/CE; non-compliant with Western market regulations | Fully certified ETL (USA/Canada), TUV CE (Europe); meets IEC 61347-2-13 standards |

For project-specific technical requirements or OEM collaboration, contact our engineering team at [email protected] or +86 13902885704.

Beauty (STC) Manufacturing Co., Ltd. | Established 1998 | Jiangmen, Guangdong, China | ETL & TUV CE Certified | 50+ Global Markets

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – PWM Dimmer Platform

Beauty (STC) Manufacturing Co., Ltd., Jiangmen, Guangdong | Est. 1998 | ETL & TUV CE Certified

1. Production Line Overview

Our 18 000 m² Jianghai high-tech facility runs three fully-integrated lines dedicated to constant-voltage PWM dimmer assemblies. Key stations are listed in process order; every station feeds traceability data to the MES dashboard (retention ≥ 10 years).

| Station | Core Equipment / Protocol | Purpose | Cycle-Time | Yield Target |

|---|---|---|---|---|

| SMT-1 | Juki FX-3R (±50 µm) + SPI (Koh Young) | 0805/0603 MOSFET, MLCC, MCU, 4-layer FR-4 | 35 k cph | ≥99.5 % |

| SMT-2 | Nitrogen reflow (Heller 1912 MK5) | Void-free solder joints (<5 %) | 90 s profile | ≥99.8 % |

| DIP | Selective wave (Vitronics Soltec) | Power headers, screw-less terminal | 1.2 m/min | ≥99.9 % |

| Conformal | PVA Delta 6 selective coating | IP20 → optional IP65 silicone layer | 15 s/pc | 100 % coverage |

| QC-AOI | Mirtec MV-3L | Solder, polarity, component offset | inline | 0 DPMO escape |

| QC-In-Circuit | Keysight i3070 | 5 kV Hipot, 100 MHz switching edge | inline | Cpk ≥1.67 |

| Burn-in | 4-zone oven + electronic load | 4 h @ 55 °C, 0-10 V sweep 0→100 % | 2 000 pcs/shift | <200 ppm drift |

| Final QA | 100 % function & dimming curve | 0-10 V, PWM 250 Hz-8 kHz, 65 000 steps | 45 s/pc | AQL 0.25 |

2. Aging & Reliability Protocol

Thermal Shock: –40 °C ↔ +85 °C, 200 cycles (MIL-STD-202)

MTBF: Telcordia SR-332, 25 °C, ground fixed > 200 kh

Dimming Endurance: 50 000 on/off + 0-100 % sweeps @ 24 V, 10 A; ΔI < ±3 %

3. Certifications & Market Alignment

| Standard | Scope | File # | Notes |

|---|---|---|---|

| ETL (UL 508) | USA & Canada | 5008181 | 12-24 VDC, 10 A/channel |

| TUV CE | EU LVD & EMC | 60212345 | EN 61347-2-11, EN 55015 |

| RoHS / REACH | EU & global | internal lab | <0.1 % substance limit |

| ISO 9001:2015 | Quality system | 44113-Q |

4. OEM / ODM Capability Matrix

| Customisable Item | Engineering Tool | Lead-Time | Min. Order |

|---|---|---|---|

| Output form-factor | 3-D SolidWorks, Al extrusion die | 10-12 days | 500 pcs |

| PWM frequency | Firmware 32-bit ARM, 1 Hz-20 kHz | 5 days | 100 pcs |

| Dimming curve | Log, linear, custom 65 000-step LUT | 3 days | 100 pcs |

| Input protocol | 0-10 V, 1-10 V, DALI-2, Push-Dim, Wi-Fi/Zigbee | 7-10 days | 300 pcs |

| CCT indication LED | 2700 K – 6500 K, RGB status | 3 days | 100 pcs |

| Cable length & gauge | UL 1007/2464, 18-22 AWG, 0.1-3 m | 2 days | 500 pcs |

| Private-label box | 4-colour 157 g art-paper, barcode, QR | 5 days | 300 pcs |

Value-add services: laser engraving, pick-and-pack for Amazon FBA, drop-ship to 3PL in US/EU.

5. Logistics Snapshot

Daily capacity: 6 000 PWM dimmer modules

Carton spec: 50 pcs @ 9.8 kg, 440 × 310 × 220 mm

Export pallet: 1.2 × 1.0 m, 1 200 pcs, 24-carton/layer, FCL 20 GP ≈ 30 000 pcs

Next step: send your mechanical drawing or specification sheet to [email protected]; our engineers will return a DFM report and formal quotation within 24 h.

Installation & Application Scenarios

Optimal Application Scenarios for PWM Dimming Systems

PWM dimming technology is foundational to modern lighting systems, enabling precise control over intensity, color temperature, and energy efficiency. As a manufacturer with 25+ years of industrial expertise and ETL/CE-certified products designed for global markets, Beauty STC Lighting delivers reliable, certified dimming solutions tailored to complex commercial and architectural projects. Our OEM/ODM capabilities ensure seamless integration with diverse LED fixtures, from flexible strips to high-power floodlights. Below are key application scenarios and technical specifications for contractors and designers.

Hospitality & Luxury Environments

In hotels, resorts, and high-end restaurants, lighting must adapt to dynamic ambiance requirements while meeting strict safety standards. Beauty STC’s PWM dimmers deliver 65,000+ dimming steps for flicker-free transitions, critical for guest comfort in lobbies, suites, and fine-dining areas. All units comply with ETL and CE certifications, ensuring compliance for international projects.

| Parameter | Specification | Project Relevance |

|---|---|---|

| Voltage Range | 12–24VDC | Compatible with most LED strips, panels, and accent lighting |

| Max Load | 120W (12V) / 240W (24V) | Supports dense lighting layouts without thermal stress |

| Dimming Precision | 65,000+ steps | Smooth, imperceptible adjustments for mood lighting |

| Certification | ETL, CE | Mandatory for North American and European hospitality projects |

Commercial Retail & Display Lighting

Retail spaces require adaptable lighting to highlight merchandise, reduce energy costs during off-hours, and support dynamic signage. Beauty STC’s dimming solutions integrate with LED panels and strip lights, offering waterproof variants for exterior storefronts and high-traffic areas.

| Parameter | Specification | Project Relevance |

|---|---|---|

| Waterproof Rating | IP67 (optional) | Resists moisture and dust in outdoor or high-humidity environments |

| Channel Configuration | 1–4 channels | Enables zone-based control for product displays and signage |

| Dimming Curve | Linear/Logarithmic | Customizable for visual appeal and energy efficiency |

| Thermal Management | Passive cooling design | Ensures stable operation in enclosed retail fixtures |

Office & Workplace Lighting

Modern offices leverage circadian lighting systems to enhance productivity and occupant well-being. Beauty STC’s dimmers support 0-10V and DALI protocols (OEM configurable), allowing integration with building management systems for automated daylight harvesting and occupancy-based adjustments.

| Parameter | Specification | Project Relevance |

|---|---|---|

| Control Protocol | 0-10V, DALI (OEM option) | Seamless compatibility with smart building infrastructure |

| Load Capacity | Up to 240W per channel | Handles high-output LED panels for open-plan offices |

| Form Factor | In-wall or surface-mount | Flexible retrofitting for existing office infrastructure |

| Compliance | ETL/CE certified | Required for commercial building code adherence |

Architectural Facades & Exterior Lighting

Permanent outdoor installations demand robust, weather-resistant dimming solutions. Beauty STC’s IP67-rated dimmers are engineered for LED floodlights and facade lighting, providing consistent performance in extreme temperatures (-40°C to +60°C) and humidity. Our 2-pin waterproof connectors simplify installation while ensuring long-term reliability.

| Parameter | Specification | Project Relevance |

|---|---|---|

| IP Rating | IP67 | Protection against water ingress and dust in harsh environments |

| Operating Temp | -40°C to +60°C | Suitable for global climate extremes (e.g., Arctic to desert regions) |

| Power Handling | 240W max (24VDC) | Supports high-power LED floodlights for large-scale facades |

| Connector Type | 2-pin waterproof | Reduces failure points and streamlines outdoor wiring |

Professional Installation Best Practices

Proper installation ensures optimal performance, safety, and longevity of PWM dimming systems. As a factory-direct manufacturer with decades of global project experience, Beauty STC provides detailed technical documentation and on-site support. Key guidelines for contractors include:

| Installation Aspect | Best Practice | Consequence of Non-Compliance |

|---|---|---|

| Load Management | Total connected load ≤80% of dimmer rating (e.g., 192W for a 240W dimmer) | Overheating, premature component failure, or fire risk |

| Signal Wiring | Use shielded twisted-pair cables for 0-10V control wiring; maintain ≥15cm separation from power lines | Electromagnetic interference causing flicker or unstable dimming |

| Environmental Sealing | Apply IP67-rated connectors and silicone sealants for all outdoor junctions | Moisture ingress leading to short circuits or corrosion |

| Compliance Verification | Confirm adherence to local electrical codes (e.g., NEC Article 411 for low-voltage systems) | Project delays, failed inspections, or safety violations |

Technical Note: Beauty STC’s dimming solutions undergo rigorous thermal testing and EMC compliance checks during manufacturing. For custom projects, our OEM team provides engineering support to tailor form factors, control protocols, and mounting solutions to your exact specifications.

Beauty STC Lighting: 25+ years of industrial expertise. ETL/CE certified for global markets. OEM/ODM services available. Contact: [email protected] | +86 13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Your Factory-Backed Source for PWM Dimmers

25 Years of Constant-Voltage Know-How, Certified for Every Major Market

| Established | 1998 – continuous ISO-level process control |

|---|---|

| Certifications | ETL/cETL (UL 508 / CSA C22.2), TUV CE (EN 61347-2-11) |

| Export Footprint | 50+ countries, zero regional recall record |

| Core Voltage Portfolio | 12 V / 24 V / 36 V / 48 V PWM dimmers, 1 A – 30 A per channel |

OEM/ODM Capability – From Driver Board to Finished Assembly

| Engineering Stage | In-House Resource | Typical Lead-Time |

|---|---|---|

| Schematic & PCB | 12 R&D engineers, PADS & Altium | 3–5 days |

| Safety pre-screen | UL/TUV witness lab on site | 24 h |

| Tooling & injection | 2 × 80 t, 1 × 220 t presses | 7 days |

| Burn-in & EMC | 4 × 8 m conveyor ovens, 0–60 °C | 100 % lot |

| Packaging design | RoHS & REACH compliant trays | 3 days |

Why PWM Distributors Specify Beauty STC

Single-SKU global shipment – one PCB, dual 12-24 V recognition, ETL & CE labels pre-printed.

65 000-step dimming curve available (16-bit MCU) or 2 048-step economy firmware – same tooling.

IP20, IP44, IP67 variants share board outline → inventory reduction for distributors.

MOQ 500 pcs with custom silk-screen or laser mark; 3 000 pcs for private-label colour box.

Factory-direct FOB Jiangmen (40 min from Guangzhou port) – weekly consolidation to LA, Rotterdam, Sydney.

Next Step – Receive Data Pack & NDA

Email [email protected] with your target current rating and dimming protocol (PWM, 0-10 V, DALI, TRIAC).

We will return within 12 h:

technical drawing (.dxf)

UL/TUV test report excerpts

24 h quotation (EXW, FOB, CIF)

Tel / WhatsApp: +86-13902885704 | Address: 41F, Caihong Rd., High-tech Zone, Jiangmen, Guangdong, CN

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).