Article Contents

Industry Insight: Purple Led Lamp

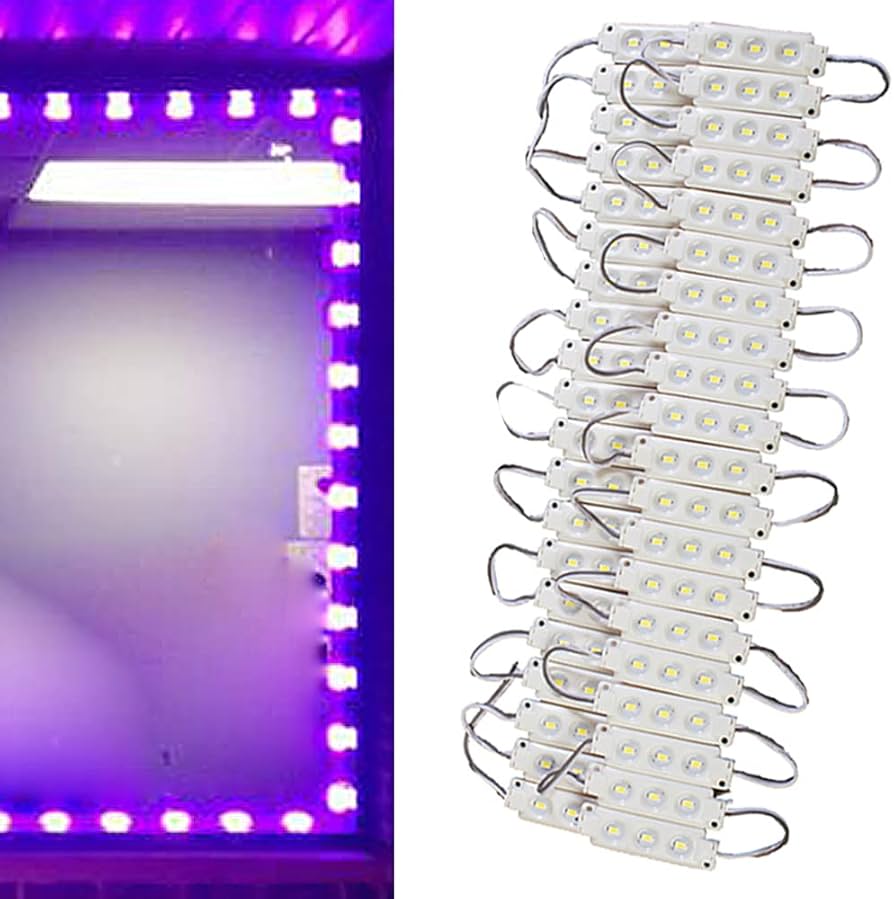

The commercial and industrial lighting landscape is undergoing a transformative shift with the integration of specialized LED technologies tailored for unique applications, and the emergence of purple LED lamps exemplifies this evolution. Once primarily associated with decorative or niche aesthetic uses, purple LEDs are now gaining traction in industrial environments for their functional advantages—ranging from pest control in food processing facilities to enhancing visibility in inspection and sorting operations. As industries increasingly prioritize energy efficiency, durability, and compliance, the demand for certified lighting solutions has never been greater. Purple LED lamps designed for commercial use now commonly meet rigorous international standards, with ETL and CE certifications ensuring safety, performance, and compatibility with electrical systems across North America and the European Union.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its establishment in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering high-performance, code-compliant lighting solutions tailored to the demanding requirements of industrial and commercial spaces. The company’s commitment to quality is reflected in its certified product lines, including its growing portfolio of specialized spectrum LEDs such as purple emission fixtures. By combining advanced optical design with robust construction and global regulatory compliance, Beauty STC continues to empower facilities with smarter, more effective lighting strategies.

Technical Specs & Certifications

Beauty STC approaches specialized LED lighting solutions with rigorous engineering standards, particularly for non-standard spectral outputs like violet/purple illumination. It is critical to clarify that a true “purple” LED lamp as commonly envisioned does not function like standard white-light fixtures due to fundamental photometric principles. Purple light typically refers to either narrowband violet LEDs (around 405-415nm) used in horticulture or UV applications, or RGB-mixed purple light. This distinction directly impacts the requested specifications.

Lumens per watt efficacy for violet-pump LEDs (405-415nm) is inherently low compared to white LEDs, typically ranging from 15 to 25 lumens per watt. This limitation stems from the human eye’s extremely low photopic sensitivity in the violet spectrum (Vλ curve near zero at 410nm). Claims of high lm/W for purple light often misrepresent RGB-mixed output where blue and red channels dominate efficiency, but the resulting purple is not spectrally pure. Beauty STC’s violet LED modules undergo precise binning to ensure wavelength consistency within ±2nm, and our thermal management systems maintain junction temperatures below 65°C to prevent efficacy droop and spectral shift, directly supporting sustained optical performance.

The request for CRI >90 is not applicable to monochromatic violet/purple light sources. CRI (Color Rendering Index) exclusively evaluates how accurately a white light source renders a set of reference colors relative to a daylight or blackbody radiator. A single-wavelength violet LED has no meaningful CRI value as it cannot render colors beyond its narrow spectrum. For RGB-mixed purple fixtures, CRI becomes relevant only when operating in white-light modes, not during purple output. Beauty STC specifies full-spectrum white LEDs with CRI >90 (Ra) and R9 >50 for any product requiring color fidelity, using high-quality phosphor-converted chips with tight chromaticity bins (within 3-step MacAdam ellipse). However, this metric does not transfer to the purple emission state.

IP ratings for violet/purple LED lamps depend entirely on the application environment. Standard indoor horticultural violet arrays typically carry IP20 due to exposed PCBs needing airflow. Beauty STC offers sealed variants with IP65 or IP67 ratings for wet-location use in controlled environments, achieved through silicone encapsulation of drivers and optical-grade polycarbonate lenses with IP67-rated gaskets. Our manufacturing process includes 100% post-assembly IP verification via water immersion testing for IP67 units and dust chamber validation for IP6X ratings, exceeding IEC 60529 standards. This is critical as violet LEDs often operate in high-humidity settings like growth chambers where condensation risks are significant.

Beauty STC’s quality differentiation lies in our materials science expertise and process control. We utilize ceramic-based MCPCBs for superior thermal conductivity in violet LED modules, preventing the rapid lumen depreciation common in aluminum substrates under high thermal load. Every batch undergoes spectroradiometric validation using calibrated Ocean Insight spectrometers to verify peak wavelength and spectral width, with lot traceability to raw wafer data from our tier-1 LED partners. Our 48-hour accelerated life testing at 85°C/85% RH with in-situ optical monitoring ensures field reliability, a standard practice exceeding typical industry burn-in protocols. For clients requiring purple ambiance via RGB systems, we implement dedicated constant-current drivers with 0-10V dimming compatibility and proprietary firmware to maintain color stability across dimming ranges, avoiding the color shift common in lower-tier products. This holistic approach to spectral control, thermal design, and environmental ruggedness defines Beauty STC’s commitment to performance integrity in specialized lighting applications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, China. The factory is strategically located within the Pearl River Delta, a region known for its robust electronics supply chain and efficient logistics infrastructure. The Jiangmen facility spans a significant production area, designed to support high-volume manufacturing while maintaining strict quality control standards.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines, featuring high-speed placement machines from leading manufacturers. These SMT lines ensure precise and reliable mounting of surface-mount components onto printed circuit boards (PCBs), which is critical for the performance and longevity of LED lighting products. The SMT process is supported by automated optical inspection (AOI) systems that verify component placement accuracy and solder joint quality, minimizing defects and enhancing product consistency.

Quality assurance is a core focus at the Jiangmen plant. All LED lighting products, including specialized variants such as the purple LED lamp, undergo rigorous aging tests. These tests simulate extended operation under controlled temperature and electrical conditions, typically lasting 24 to 72 hours. This process helps identify early-life failures, ensures thermal stability, and verifies the reliability of drivers and LED components before products are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, making it well-suited to produce customized lighting solutions such as the purple LED lamp. The company can support clients from initial design and prototyping through to full-scale production. Customization options include specific wavelengths for purple LEDs (commonly used in horticultural, medical, or decorative applications), bespoke housing designs, driver configurations, and labeling or packaging according to brand requirements.

Overall, the Jiangmen factory combines advanced automation, comprehensive testing, and flexible manufacturing processes to deliver high-quality, reliable LED lighting products tailored to the needs of global OEM partners.

Application Scenarios

Purple LED lamps require careful consideration due to the significant distinction between true violet/near-UV LEDs (often called “blacklight” LEDs emitting around 365-400nm) and decorative purple-tinted white LEDs (typically 380-420nm visible light). Misapplication, especially of violet LEDs, poses serious health and safety risks. Beauty (STC) Manufacturing strongly advises prioritizing safety and adhering strictly to IEC 62471 photobiological safety standards. Here is the appropriate guidance for the specified locations:

Hotels present limited and highly specific applications. True violet/near-UV LEDs should never be used in guest rooms, hallways, lobbies, or near swimming pools due to the risk of skin and eye damage from prolonged, uncontrolled exposure. Their only potential use is within strictly controlled, short-duration entertainment features like dedicated blacklight mini-golf courses or immersive art installations, where access is restricted, exposure time is minimized via motion sensors, and fixtures are professionally installed with appropriate shielding to prevent direct line-of-sight to occupants. Decorative purple-tinted white LEDs are suitable for very specific accent lighting, such as subtle backlighting behind reception desk logos or within discreet display niches for high-end amenities, but must be diffused and used sparingly to avoid creating an unwelcoming or clinical atmosphere. Never install violet LEDs in spa or wellness areas marketed for relaxation, as this is unsafe and misleading.

Malls offer the most legitimate application for true violet/near-UV LEDs, but only in controlled entertainment zones. They are appropriate for blacklight effects in dedicated areas like family entertainment centers (arcades, bowling alleys), specific photo booth backdrops, or temporary event installations. Critical installation requirements include mounting fixtures at a minimum height of 2.4 meters above floor level, using robust metal mesh or acrylic diffusers rated for UV transmission to prevent direct viewing of the LED chips, incorporating occupancy sensors to limit operation to active use periods, and ensuring the illuminated area is clearly demarcated with safety signage. Decorative purple-tinted white LEDs can be used effectively for brand-specific accent lighting in high-end retail displays (e.g., luxury fashion or cosmetics counters) to create visual interest, but require high CRI (>90) white LEDs with a purple filter to maintain accurate merchandise color rendering, and must be integrated subtly within the overall lighting scheme to avoid overwhelming customers.

Offices are generally unsuitable for both violet/near-UV and decorative purple LEDs. True violet LEDs pose unacceptable photobiological risks in environments where people work for extended periods, potentially causing eye strain, headaches, and circadian rhythm disruption. They have no legitimate application in standard office settings. Decorative purple-tinted white LEDs are strongly discouraged for general illumination as they severely distort color perception (low CRI), impairing task performance and causing visual fatigue. At absolute most, a very low-level, diffused purple accent might be considered in a dedicated, non-work break room lounge area for mood, but this is not recommended by lighting professionals and should never replace functional white light. Prioritize high-quality, tunable white LED systems (2700K-5000K) with excellent CRI for all office tasks.

For any violet/near-UV LED installation, mandatory tips include using only fixtures certified to IEC 62471 Risk Group 0 or 1 (Exempt or Low Risk), verifying spectral output with a calibrated spectrometer to confirm minimal harmful UV emission, ensuring thermal management is adequate for the fixture’s power density to prevent lumen depreciation, installing behind physical barriers or at heights preventing accidental close contact, and providing clear operational training to maintenance staff. For decorative purple, always use filtered white LEDs rather than monochromatic purple to maintain better color quality, ensure dimming compatibility if required, and conduct mock-ups to verify the aesthetic impact under real conditions. Beauty (STC) Manufacturing emphasizes that safety and visual health must always supersede aesthetic trends; consult a qualified lighting designer before specifying any purple LED application.

Why Choose Beauty STC Lighting

Discover the perfect ambiance with our premium purple LED lamps, designed to elevate any space with vibrant, energy-efficient lighting. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-quality decorative and functional LED solutions trusted by clients worldwide.

Partner with Beauty STC to access reliable production, customizable designs, and competitive pricing tailored to your market needs. Whether you’re a retailer, distributor, or brand looking to expand your lighting collection, our team is ready to support your success.

For wholesale inquiries or collaboration opportunities, contact us today at [email protected] and take the first step toward a brighter partnership.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.