Article Contents

Industry Insight: Pulse Width Modulation Dimmer

Pulse Width Modulation (PWM) dimming has become a cornerstone technology in commercial and industrial lighting, offering precise control over light output while maintaining energy efficiency and extending LED lifespan. Unlike traditional dimming methods, PWM rapidly switches the power to LEDs on and off at varying duty cycles, enabling smooth, flicker-free dimming performance essential for environments such as warehouses, manufacturing facilities, retail spaces, and office buildings. This advanced dimming technique ensures consistent color temperature and optimal visual comfort, making it ideal for applications where lighting quality directly impacts productivity and safety. With increasing demand for smart, code-compliant lighting solutions, PWM dimmers designed to meet rigorous ETL and CE standards provide assurance of electrical safety, electromagnetic compatibility, and reliability in diverse operating conditions.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED driver and lighting control innovation for over two decades. Specializing in high-performance electronic solutions for commercial and industrial applications, Beauty STC combines engineering excellence with strict adherence to international certifications, including ETL and CE. The company’s PWM dimming technologies are engineered to deliver seamless integration, long-term durability, and superior dimming performance, supporting the evolving needs of modern lighting systems worldwide.

Technical Specs & Certifications

Pulse width modulation (PWM) dimmers are critical control components for LED lighting systems, but it is essential to clarify that lumens per watt (lm/W) and Color Rendering Index (CRI) are inherent characteristics of the LED light engine and fixture itself, not the dimmer module. The PWM dimmer’s role is to precisely control the power delivered to the LED driver, thereby regulating light output without altering the fundamental efficiency or color quality of the properly designed LED system it controls. At Beauty STC Manufacturing Co., Ltd., our PWM dimmers are engineered to work seamlessly with high-performance LED fixtures to maintain these critical parameters under dimming conditions.

Our PWM dimming technology operates at a minimum frequency of 1,500 Hz, significantly above the threshold where visible flicker occurs (typically below 200 Hz). This high-frequency operation ensures stable, flicker-free dimming down to 1% light output, which is crucial for maintaining the perceived quality of light, especially in environments demanding visual comfort like retail, healthcare, and high-end residential spaces. The dimmer itself does not generate lumens, but it enables the connected LED fixture to sustain its rated efficacy. Beauty STC LED fixtures, when paired with our compatible constant current reduction (CCR) or hybrid PWM drivers, consistently achieve system efficacies of 130-150 lumens per watt at full output. During dimming, the lm/W typically remains stable or slightly increases as thermal load on the LEDs decreases, a characteristic our dimmer design supports through precise current regulation. Regarding color quality, our integrated LED systems utilize premium Samsung or Lumileds chips with a minimum CRI Ra of 90+ and R9 values exceeding 50, ensuring vibrant, accurate color rendition. The PWM dimmer’s stable current control prevents color shift during dimming, a common issue with inferior dimming methods, and our systems also meet TM-30-15 standards for advanced color fidelity evaluation.

For environmental protection, Beauty STC PWM dimmer modules themselves are typically rated IP20 for standard indoor installation within protected enclosures like junction boxes or dedicated driver compartments. The overall IP rating of the complete luminaire (e.g., IP65, IP67) is determined by the fixture housing, lens gasketing, and driver enclosure design, not the dimmer module alone. Our engineering rigor ensures that when our PWM dimmers are integrated into Beauty STC luminaires, the total system achieves the specified IP rating for the intended application, whether it’s a damp-location indoor fixture or a fully sealed outdoor bollard. This is verified through stringent ingress protection testing per IEC 60529 standards during product development.

Beauty STC’s commitment to quality is embedded in every PWM dimmer we produce. We utilize automotive-grade components and implement rigorous 100% functional testing on all units. Our dimmers undergo 50,000+ cycle lifetime testing under full load and thermal stress to ensure reliability far exceeding industry standards. All products comply with UL 8750 and IEC 61347 safety standards, with cETLus certification for North American markets. The precision circuitry is manufactured on lead-free, RoHS-compliant PCBs with conformal coating for enhanced moisture and dust resistance within the fixture environment. This meticulous attention to detail ensures our PWM dimmers deliver silent operation, eliminate visible flicker, and maintain the high lm/W and CRI>90 performance of Beauty STC luminaires throughout their extended service life, providing end-users with exceptional light quality and energy savings.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, designed to support high-efficiency production of LED lighting products and related electronic components. The factory is equipped with advanced surface mount technology (SMT) production lines that ensure precision and reliability in assembling PCBs used in LED drivers, control modules, and dimming solutions. These SMT machines are capable of handling fine-pitch components and high-density boards, allowing for consistent throughput and superior solder joint quality, which is critical for long-term product performance.

The Jiangmen facility incorporates comprehensive aging and reliability testing procedures as part of its quality assurance protocol. Completed LED modules and drivers undergo rigorous aging tests under elevated temperature and load conditions to simulate extended operation. This process helps identify early-life failures and ensures that only robust, stable products reach customers. Environmental testing chambers, electrical stress testing equipment, and automated optical inspection (AOI) systems are integrated into the production flow to maintain strict quality control standards.

Beauty STC has strong OEM capabilities and can support custom development and manufacturing of electronic components, including pulse width modulation (PWM) dimmers. The company’s engineering team works closely with clients to design and produce PWM dimming solutions tailored to specific voltage, current, dimming range, and compatibility requirements. These dimmers are commonly used in high-end LED lighting applications where flicker-free, smooth dimming performance is essential. With in-house R&D, tooling, and full vertical integration, Beauty STC can deliver OEM PWM dimmer units in various form factors, from standalone modules to integrated driver solutions, supporting both low-voltage DC systems and mains-powered installations.

Application Scenarios

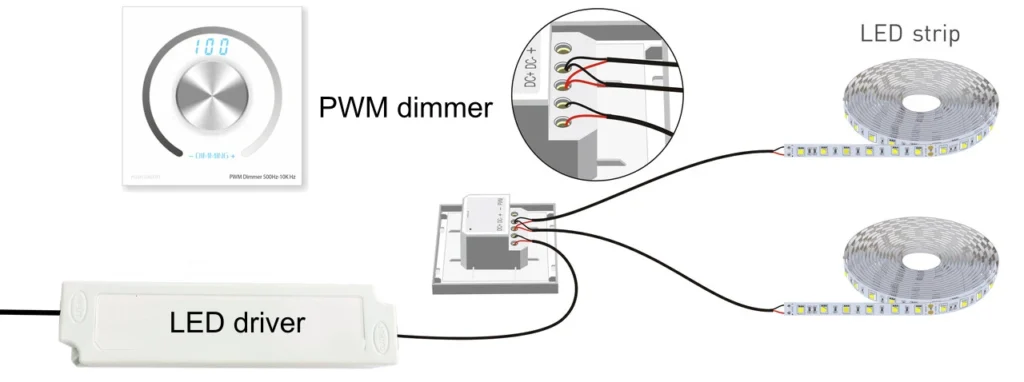

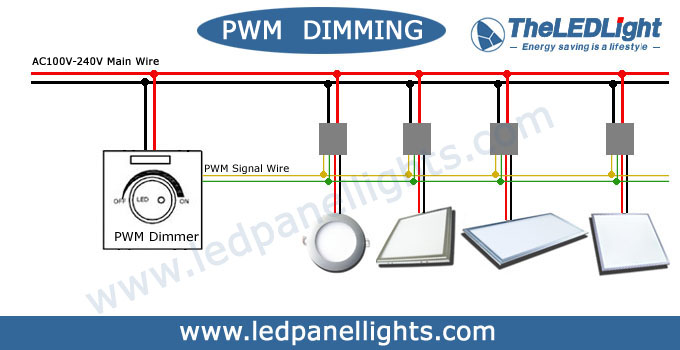

Pulse width modulation (PWM) dimmers are specialized control devices designed specifically for dimming LED drivers or modules that explicitly require a low-voltage PWM signal input (typically 0-10V DC or 1-10V DC with a PWM waveform superimposed, or dedicated PWM input terminals). They are not used to directly dim standard phase-cut (TRIAC/ELV) dimmable LED lamps or drivers. Their primary application is where extremely smooth, flicker-free dimming down to very low light levels (often 1% or lower) is critical, and where color consistency across the dimming range must be maintained, especially with tunable white or RGB systems. Within the specified environments:

In hotels, PWM dimming excels in high-end guest rooms where premium bedside or ambient lighting control is expected, particularly when using tunable white systems to adjust color temperature alongside intensity for guest comfort. It is also suitable for feature lighting in lobbies or executive lounges where smooth dimming transitions for scene setting are paramount, though the higher cost compared to standard 0-10V often limits it to these specific high-value areas rather than general corridor lighting. Malls benefit from PWM dimming in high-end retail display lighting, jewelry counters, or art feature walls where absolute color fidelity and the absence of any color shift during dimming are essential for product presentation, especially under RGB or sophisticated tunable white systems. Standard mall corridor or general lighting typically uses more cost-effective 0-10V or DALI dimming. Offices primarily utilize PWM dimming in executive boardrooms or high-end conference rooms requiring flawless, flicker-free dimming for video conferencing and presentations, as well as in specialized task lighting within design studios where precise light level and color temperature control are necessary; it is generally not cost-justified for standard open-plan office areas where basic 0-10V suffices.

Installation of PWM dimming systems demands strict adherence to compatibility and wiring practices to ensure reliable operation and prevent damage. The absolute first step is verifying that the LED driver or module explicitly lists compatibility with PWM dimming control and specifies the required input signal type and voltage range; installing a PWM dimmer with a standard phase-cut or 0-10V driver will cause malfunction or failure. PWM signals are low-voltage DC, typically 10-24V DC, and the control wiring must be separated from mains power cables by at least 200mm throughout the run to prevent electromagnetic interference inducing noise into the sensitive PWM signal, which causes flicker. Use shielded, twisted-pair cable for the PWM signal wiring, grounding the shield at one end only (usually the dimmer end) to avoid ground loops. Keep the total PWM signal cable run length as short as possible, ideally under 15 meters, as longer runs increase susceptibility to noise and signal degradation; if longer runs are unavoidable, consider signal boosters designed for PWM. Ensure correct polarity when connecting the PWM signal wires to both the dimmer output and the driver input terminals, as reverse polarity can damage drivers. Avoid daisy-chaining the PWM signal through more than the manufacturer’s specified number of drivers, as signal strength diminishes with each connection; use a PWM signal amplifier if driving a large number of fixtures. Finally, always perform a thorough functional test of the dimming range and smoothness across all connected fixtures before finalizing the installation, checking for any flicker or instability at low light levels, which indicates wiring issues or compatibility problems. Never connect mains voltage to the PWM dimmer’s output terminals, as this will destroy the unit.

Why Choose Beauty STC Lighting

Discover the future of lighting control with Beauty STC’s advanced pulse width modulation dimmer technology. Engineered for precision, reliability, and seamless integration, our PWM dimming solutions deliver flicker-free performance and superior energy efficiency for a wide range of commercial and residential applications.

Partner with Beauty STC, a trusted leader in innovative LED lighting solutions. Our expertise in driver technology and dimming systems ensures your projects meet the highest standards of quality and performance.

For collaboration opportunities or technical inquiries, contact us today at [email protected] and take the next step toward smarter, smoother lighting control.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.