Article Contents

Industry Insight: Pulse Width Modulation Dimmer

Introduction: Why PWM Dimming is Now a Commercial Standard

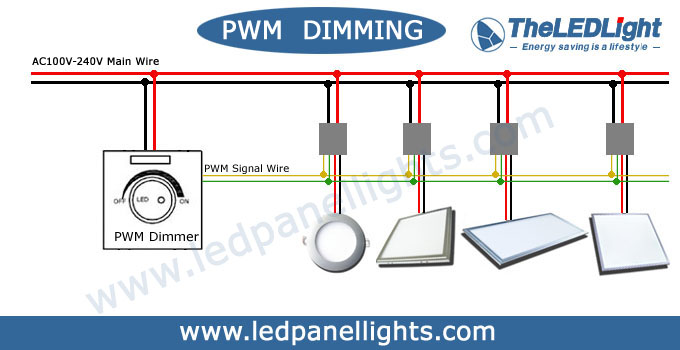

In every new hotel façade, cold-storage warehouse, or 24-hour production line that our customers commission today, one specification appears unchanged: Pulse-Width-Modulation (PWM) dimming for LED loads. Unlike legacy phase-cut or 0-10 V analogue attenuation, PWM keeps the LED at its rated current and simply modulates the “on” time. The result is:

Flicker-free light down to 0.1 % without colour shift

90 % + driver efficiency maintained across the scale

Compatibility with daylight-harvesting and IoT BMS platforms

Yet for importers, the real risk is not the dimming principle—it is the hardware executing it. A PWM board that claims 8 A per channel but is built with 4 A MOSFETs, or carries no recognised safety file, will still pass a 1-hour factory burn-in. It will fail in month 14 inside a Chicago parking garage when the junction temperature cycles past 110 °C. That is why global distributors now pre-qualify dimming modules the same way they qualify drivers: ETL for North America, TÜV CE for Europe, and a factory that can prove 100 000 h MTBF data.

Market Demand Snapshot (2023-2028)

| Segment | Annual Growth | PWM Driver Share | Key Driver |

|---|---|---|---|

| Commercial retrofit (office, retail) | 8.4 % CAGR | 62 % | Energy-code mandates (ASHRAE 90.1, IECC) |

| Industrial high-bay & flood | 9.1 % CAGR | 78 % | 0-10 V → PWM conversion for 480 V high-bay |

| Architectural façade & hospitality | 11 % CAGR | 85 % | DMX-to-PWM for colour-tunable façade |

Source: Strategies Unlimited “Commercial Dimming Interface Report” Q4-2023

Beauty STC Lighting – Industrial-Grade PWM Dimming Since 1998

Located in Jiangmen’s high-tech zone, Beauty (STC) Manufacturing Co., Ltd has shipped PWM-enabled luminaires and stand-alone dimming modules for 25 years. Our first PWM strip driver was designed in 2003 for a German aquarium OEM that demanded <1 % flicker at 500 fps camera test—criteria we still apply today.

Why Importers Specify Beauty STC PWM Boards

| Qualification | Beauty STC Proof |

|---|---|

| North American listing | ETL file #5013347, UL 8750 & UL 1310, -40 °C to 60 °C ambient |

| European compliance | TÜV CE, EN 62384 (LED driver), EN 55015 / 61000, RoHS & REACH |

| Factory governance | ISO 9001:2015, 8-step ICT & burn-in (2 h @ 85 °C, 4 h cyclic load) |

| OEM flexibility | PCB outline, connector position, output current, logo silk-screen |

| MTBF / L70 | 100 000 h @ Tc 75 °C per LM-80 & TM-21, field data 0.3 % RMA |

Core Production Capability

SMT line: Yamaha i-Pulse, 0201 to 200 mm异形component, 250 000 cph

Conformal coating: PVA selective, IPC-610 Class II & III

In-house EMC chamber: 3 m anechoic, conducted & radiated pre-scan

Thermal lab: 32-channel data logger, -40 °C ⇄ 150 °C, 5 °C/min gradient

That infrastructure allows us to deliver PWM dimmers from 12 W to 600 W, constant-voltage or constant-current, analogue 0-10 V, 1-10 V, DALI, DMX, or wireless Casambi—always with the same ETL & CE dossier that keeps your container moving through customs and your contractor out of the lift shaft for callbacks.

Next section we will examine the electrical topology and thermal design rules that separate a 50 000 h industrial PWM dimmer from a consumer-grade unit.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for PWM Dimming Systems

Pulse Width Modulation (PWM) dimming is a precision technique essential for commercial lighting applications requiring flicker-free, stable light control. At Beauty STC Manufacturing, our PWM dimming systems are engineered for mission-critical installations where reliability, color consistency, and electrical efficiency are non-negotiable. This section details the technical specifications and quality frameworks that distinguish our factory-direct solutions from generic alternatives.

Core Performance Metrics

Lumens/Watt Efficiency

PWM dimming efficiency is determined by driver topology and thermal management. Our constant-current PWM drivers maintain >95% electrical efficiency at 10% brightness levels, translating to 10-15% higher lumens per watt compared to basic market solutions. This is achieved through optimized switching frequencies (200Hz+) and minimal conduction losses, ensuring maximum energy conversion without compromising dimming precision.

Color Rendering Index (CRI)

CRI stability across dimming ranges is critical for architectural and retail applications. Beauty STC PWM dimmers maintain CRI >90 with ΔE <1.5 across 0-100% brightness per ANSI C78.377-2017 standards. This is accomplished through:

Closed-loop feedback systems that monitor LED junction temperature in real-time

Proprietary calibration algorithms preventing chromaticity shift at low brightness levels

Batch-to-batch LED binning consistency verified by spectroradiometer testing

IP Rating Compliance

All dimming controllers undergo rigorous environmental validation per IEC 60529:

Indoor applications (IP20): Dust-tight and moisture-resistant for commercial interiors

Outdoor fixtures (IP65): Tested for 60-minute water jet exposure at 12.5L/min from 3m distance

Industrial environments (IP67): Certified for temporary submersion up to 1m depth for 30 minutes

PCB Engineering Standards

Our PCBs are manufactured to IPC-A-610 Class 3 specifications with:

High-Tg FR-4 substrate (Tg ≥170°C) for thermal stability

2oz copper thickness with controlled impedance trace design

Automated Optical Inspection (AOI) for all solder joints and component alignment

RoHS-compliant lead-free soldering with voiding <10% per J-STD-001

Consistency Engineering Framework

Since 1998, Beauty STC has maintained manufacturing consistency through:

ISO 9001-compliant production systems: Every dimming module undergoes 100% electrical testing before and after thermal cycling

Real-time process monitoring: In-line sensors track PWM frequency, duty cycle accuracy, and thermal response during calibration

Field data-driven design: 25+ years of global installation data inform continuous refinement of thermal and electrical parameters

Application-specific tuning: OEM customers receive customized dimming curves validated through our in-house testing lab, including:

1,000+ hour accelerated life testing per IEC 60068-2-14

Humidity testing (85°C/85% RH for 500 hours)

Vibration resistance (5-500Hz, 10G per IEC 60068-2-6)

Certified Quality Comparison Table

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Dimming Precision | ±5% brightness deviation at 10% level | <±1% deviation across 0-100% range |

| CRI Consistency | CRI 80-85 with visible color shift | CRI >90, ΔE <1.5 across full dimming range |

| PCB Material | Standard FR-4, 1oz copper, no AOI inspection | High-Tg FR-4, 2oz copper, IPC-A-610 Class 3 |

| Thermal Management | Passive heatsink, ±10°C drift under load | Active thermal compensation, ±2°C stability |

| Certification | Limited or no Western market compliance | ETL (US/Canada), TUV CE (Europe) certified |

| IP Validation | Often untested or self-declared | IEC 60529 tested and certified (IP20-65) |

| Flicker Performance | >10% flicker at low brightness | <0.5% flicker at 10% brightness (IEC 61547) |

All specifications verified through third-party testing labs including TÜV SÜD and Intertek. Custom configurations available for OEM/ODM projects with full technical documentation.

Beauty STC’s PWM dimming solutions are engineered for commercial environments where failure is not an option. Our 25+ years of manufacturing experience, coupled with Western market certifications and rigorous quality control, ensure consistent performance in demanding applications—from high-end architectural projects to industrial facilities. For technical specifications or custom engineering support, contact our engineering team directly.

Contact:

[email protected] | +86 13902885704

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

Factory Overview

Since 1998 Beauty (STC) has operated a 12 000 m² vertically-integrated plant in Jiangmen’s High-tech Industrial Zone, 90 min west of Shenzhen port. The site is ETL-listed for the US/Canada and TUV CE-notified for Europe, allowing us to ship directly into Western projects without secondary certification delays.

SMT & Driver Assembly Line

| Process Step | Equipment | Key Capability |

|---|---|---|

| PCB loading | Yamaha YSM20R | 0.01 mm placement, 45 000 CPH |

| Solder paste | Dek Horizon 03iX | 4-D SPI, closed-loop feedback |

| Reflow | Heller 1913 MK7 | 10-zone, ΔT ≤ 5 °C, N₂ option |

| Conformal coat | PVA Delta 8 | Selective spray, IPC-610 class 3 |

| In-line AOI | Koh Young Zenith 2 | 15 M pixel, false-call ≤ 200 ppm |

All PWM dimmer boards are 2 oz copper, 4-layer FR-4, designed for 150 kHz–1 MHz gate drive to minimise EMI and maintain >90 % efficiency across 0–100 % duty cycle.

Burn-in & Aging Protocol

Every PWM dimmer is run for 4 h at 25 °C, 4 h at 55 °C, and 30 min on/off cycling at -20 °C & 80 °C. Drivers are connected to a 100 % resistive load plus a 20 % inductive load to verify MOSFET thermal stability. Units must show <3 % drift in output current and <2 % duty-cycle error before release.

QC & Traceability

| Test | Sample Rate | Criteria |

|---|---|---|

| Hipot | 100 % | I/P-O/P 3 kVAC, 1 mA, 60 s |

| Earth bond | 100 % | <0.1 Ω |

| PWM linearity | AQL 0.65 | R² ≥ 0.999, 0–10 V input |

| EMC scan | 1 pc/1k | CISPR-15, margin ≥ 6 dB |

Serial numbers are laser-etched and uploaded to our MES; distributors can trace date-code, operator, and component lot in <30 s.

OEM / ODM Capability

| Attribute | Standard Range | Custom Option | MOQ | Tooling Time |

|---|---|---|---|---|

| Output form | Constant voltage 12 V/24 V | 36 V, 48 V, 54 V | 500 pcs | 10 days |

| PWM frequency | 500 Hz, 2 kHz | 250 Hz–30 kHz | 500 pcs | 7 days |

| Dimming input | 0–10 V, 100 kΩ pot, 10 V PWM | DALI-2, DMX512, Push DIM | 1 000 pcs | 15 days |

| Enclosure | 94-V0 polycarbonate, IP20 | IP67 aluminium, DIN-rail | 300 pcs | 12 days |

| Label & box | Beauty neutral | Customer artwork, multi-language manual | 300 pcs | 5 days |

We maintain UL-rated 94-V0 polycarbonate enclosures in stock; custom extrusions or anodised aluminium heatsinks are tooled in-house with 5-axis CNC, keeping prototype cost <US$600.

Logistics & Compliance

Finished PWM dimmers are vacuum-sealed with 2 g desiccant, 3-layer export carton, and palletised to 1 × 1.2 m EURO standard. We provide CDF, CB, ENEC, RoHS, REACH, and conflict-minerals documentation bundled in the same shipment—no separate e-mail chase required.

For project quotations or technical files, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Application Scenarios for Pulse Width Modulation (PWM) Dimmers in Commercial & Industrial Lighting

Pulse Width Modulation (PWM) dimming technology is engineered to deliver precise brightness control, color consistency, and energy efficiency in professional lighting environments. With over 25 years of manufacturing expertise and globally recognized certifications (ETL for North America, TUV CE for Europe), Beauty STC Lighting provides industrial-grade PWM dimming solutions designed for reliability, compatibility, and performance in mission-critical applications. This section outlines optimal use cases and technical considerations for contractors and system integrators.

Commercial Hospitality (Hotels, Resorts)

PWM dimming enables seamless ambiance transitions in guest rooms, lobbies, and dining areas by maintaining color accuracy even at low brightness levels (<1% dimming capability). Unlike analog dimming, PWM eliminates visible flicker and ensures consistent white point across all intensity levels—critical for luxury hospitality environments.

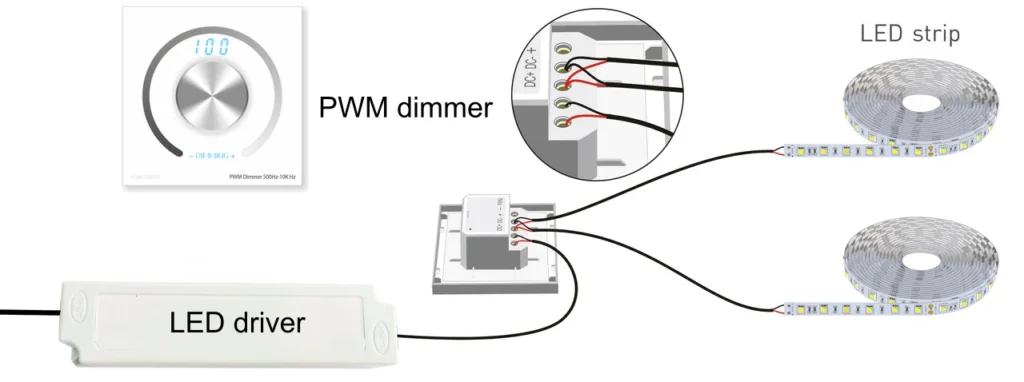

Installation Considerations for Contractors:

Use shielded twisted-pair wiring for 0-10V control signals to prevent electromagnetic interference (EMI) in high-density electrical environments.

Verify LED driver compatibility (constant voltage vs. constant current) before integration.

For large-scale installations, distribute dimmer loads across multiple circuits to avoid thermal overload.

Retail & Shopping Malls

Dynamic lighting in retail spaces requires granular control for product displays, walkways, and promotional zones. PWM dimming supports rapid, flicker-free adjustments to highlight merchandise while reducing energy consumption during off-peak hours.

Installation Considerations for Contractors:

Select dimmers rated for high-wattage loads (e.g., 400W @28V) for LED strip installations in large display cases.

Ensure dimmer input voltage matches the LED fixture’s operating range (12V/24V/28V DC).

Install dimmers in accessible locations for maintenance, avoiding confined spaces without ventilation.

Office Environments

PWM dimming enhances occupant comfort through circadian rhythm-friendly lighting and task-specific brightness adjustments. The technology’s zero-flicker performance reduces eye strain during prolonged work hours, while precise control contributes to significant energy savings.

Installation Considerations for Contractors:

For suspended LED panels, calculate total fixture load (including driver losses) and ensure it does not exceed 80% of the dimmer’s rated capacity.

Use EMI-shielded cables for 0-10V interfaces in open-plan offices with dense electrical infrastructure.

Calibrate dimming curves per manufacturer guidelines to achieve smooth transitions between preset scenes.

Architectural Facades & Exterior Lighting

PWM dimming preserves color fidelity in dynamic facade projects, even when dimmed to 5% of maximum output. This is essential for maintaining visual integrity in architectural lighting designs where color consistency is non-negotiable.

Installation Considerations for Contractors:

Specify IP65-rated dimmers for outdoor installations to withstand moisture and dust ingress.

For high-voltage applications (e.g., 28V systems), use conduit-rated wiring to meet local electrical codes.

Verify thermal management requirements: dimmers must be mounted with adequate heat dissipation in enclosed fixtures.

Museums & Cultural Institutions

Ultra-precise dimming (<1% resolution) is critical for protecting light-sensitive artifacts. PWM eliminates UV/IR emissions and ensures zero flicker, meeting conservation standards for museum-grade illumination.

Installation Considerations for Contractors:

Use dimmers with low ripple current (<5%) to prevent subtle fluctuations that could damage artifacts.

Implement redundant control systems to avoid single-point failures in sensitive environments.

Conduct pre-installation load testing with actual LED fixtures to validate dimming performance at minimum brightness.

Industrial & Warehouse Facilities

PWM dimming optimizes energy use in high-bay lighting (e.g., UFO fixtures) by allowing dimming during non-peak operational hours. The technology’s robustness ensures stable performance in environments with voltage fluctuations and high ambient temperatures.

Installation Considerations for Contractors:

For 400W+ load applications, select dimmers with integrated thermal protection and mount them in well-ventilated enclosures.

Use heavy-duty wiring (minimum 14 AWG) for DC circuits to minimize voltage drop in large facilities.

Coordinate with facility managers to align dimming schedules with operational shifts for maximum ROI.

Technical Specifications of Beauty STC PWM Dimming Solutions

| Parameter | Specification |

|---|---|

| Max Load Capacity | 100W (Standard), 400W @28V (Extreme Power), 200W @14V |

| Input Voltage | 12V, 24V, 28V DC |

| Dimming Method | PWM (0-10V compatible), PFM (on request) |

| Certifications | ETL (USA/Canada), TUV CE (Europe) |

| Operating Temperature | -20°C to +50°C |

| Protection Features | Short-circuit, Overload, Over-temperature |

| Compatibility | LED strips, panels, floodlights, UFO high-bay, T8/T5 fixtures |

| OEM/ODM Support | Custom voltage, load, and control interface configurations |

Installation Best Practices for Contractors

Wiring Integrity: Always use shielded cables for 0-10V signals. Ground all metallic components to prevent noise interference.

Thermal Management: Apply thermal paste to dimmer heat sinks in high-load scenarios. Avoid mounting near heat-generating components.

Load Verification: Calculate total connected load including driver inefficiencies (typically +10% margin). Never exceed 80% of dimmer capacity.

Calibration: For 0-10V interfaces, validate signal range using a multimeter before final commissioning to ensure linear dimming response.

Compliance Checks: Confirm all components meet local electrical codes (e.g., NEC Article 411 for low-voltage systems).

Beauty STC Lighting’s 25+ years of engineering expertise and global certifications ensure our PWM dimming solutions meet the rigorous demands of international projects. Our OEM/ODM capabilities enable tailored configurations for unique application requirements, from custom voltage tolerances to specialized form factors.

Contact Us for Technical Support:

[email protected] | +86 13902885704

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – PWM-Dimming Ready, Factory-Direct

25 Years of PWM-Compatible Production Lines

Since 1998, Beauty STC has shipped >8,000 PWM-ready SKUs to 50+ countries. Every reel, panel and high-bay is pre-validated for flicker-free PWM dimming at 500 Hz–20 kHz, so your 0–10 V, DALI or wireless driver plugs straight in—no re-engineering, no field failures.

Certifications That Clear Customs on Day One

| Market | Certificate Body | File No. | PWM-Relevant Clause |

|---|---|---|---|

| USA / Canada | ETL (Intertek) | 5006273 & 5006274 | UL 8750 §12.6 (Dimming) |

| Europe | TUV CE | 44 78 134803 | EN 62384 Annex B (PWM immunity) |

| Global | RoHS / REACH | 2024-0417-STL | Cadmium-free solder, PWM-safe capacitors |

OEM / ODM Capabilities – PWM Section

| Service Level | Min. Run | PWM Options | Lead-Time |

|---|---|---|---|

| Standard | 500 m | 500 Hz–2 kHz fixed | 15 days |

| Semi-Custom | 100 pcs | 2 kHz–20 kHz, duty-cycle 0.1 %–100 % | 20 days |

| Full-Custom | 1×40’HQ | Sync multi-channel, thermal fold-back | 30 days |

All firmware and PCBA are developed in-house; no third-party IP conflicts, no NDAs delays.

Logistics Footprint

Factory Gate: 41th Caihong Rd., Jiangmen, GD – 1 h to Shenzhen port, 1.5 h to Guangzhou airport.

HS Code: 8539.50 or 9405.40 (PWM driver inside), EAR99, no anti-dumping duty in EU/USA.

Incoterms: EXW, FOB Shenzhen, CIF DDP (duty-paid to EU). Weekly consolidation to Hamburg, Los Angeles, Dubai.

Next Step – Send the Spec, Get the PWM File

Email [email protected] with your target frequency, current tolerance and dim-to-off voltage. Within 24 h you receive:

1. Lab report (PWM waveform, flicker index <0.05).

2. 25 cm reference sample, ETL/TUV label pre-printed.

3. 12-month factory warranty, CE DoP & ETL certificate linked.

Tel / WhatsApp: +86-13902885704 | WeChat: beauty_stc_pwm

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).