Article Contents

Industry Insight: Programmable Led Tape

Programmable LED tape has rapidly evolved from a niche architectural accent to an indispensable tool for commercial and industrial lighting design, fundamentally reshaping how spaces are illuminated, experienced, and managed. Its unique combination of flexibility, precise controllability, and energy efficiency addresses critical demands across diverse sectors, from retail environments requiring dynamic merchandising displays and adaptive ambiance to industrial facilities needing task-specific illumination, enhanced safety signaling, and seamless integration with building management systems. The ability to dynamically adjust color temperature, intensity, and even create complex lighting scenes on demand translates directly into tangible benefits: optimized occupant well-being and productivity, significant energy savings through intelligent scheduling and zoning, and unprecedented design freedom for architects and engineers tackling complex retrofit or new construction projects. However, deploying this technology reliably and safely in demanding commercial and industrial settings necessitates rigorous adherence to stringent safety and performance standards, making certifications such as ETL (indicating compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements) non-negotiable prerequisites, not optional features, for any serious professional application.

Beauty STC, established in 1998, stands at the forefront of this technological shift as a specialized manufacturer deeply rooted in the commercial and industrial LED lighting sector. With over two decades of focused engineering expertise, we understand the exacting demands of professional lighting projects where performance, reliability, and regulatory compliance are paramount. Our commitment extends beyond simply producing programmable LED tape; we engineer robust, certified solutions designed from the ground up to meet the harsh realities of industrial environments and the sophisticated expectations of commercial installations, ensuring our products deliver consistent, high-quality performance while seamlessly integrating into complex control ecosystems.

Technical Specs & Certifications

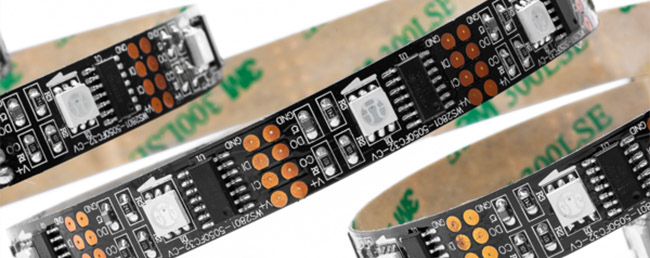

Programmable LED tape from Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance, reliability, and superior light quality, making it ideal for both residential and commercial lighting applications. Designed with advanced SMD LED technology, our programmable LED tape delivers exceptional efficiency, typically achieving luminous efficacies in the range of 100 to 130 lumens per watt, depending on color temperature and density configuration. This high lumen-to-watt ratio ensures energy savings without compromising brightness, supporting sustainable lighting solutions.

A key hallmark of Beauty STC’s programmable LED tape is its consistent Color Rendering Index (CRI) exceeding 90, with options available up to CRI 95. This ensures accurate and vibrant color representation, critical for environments where visual clarity and aesthetic fidelity are paramount—such as retail displays, art galleries, and high-end architectural interiors. The high CRI is achieved through carefully selected phosphor coatings and rigorous binning processes during manufacturing.

In terms of environmental protection, Beauty STC offers programmable LED tapes in multiple IP (Ingress Protection) ratings to suit diverse installation conditions. Our standard non-encapsulated tape carries an IP20 rating, suitable for indoor dry locations. For damp or outdoor applications, we provide fully potted versions with IP65, IP67, and even IP68 ratings. IP65 indicates protection against low-pressure water jets, IP67 ensures submersion resistance up to 1 meter for 30 minutes, and IP68 offers extended submersion protection, making these options ideal for outdoor signage, landscape lighting, and marine environments.

Beauty STC is committed to quality and consistency. Each batch of programmable LED tape undergoes stringent testing for color consistency, thermal performance, and long-term reliability. Our manufacturing processes comply with international standards, including ISO 9001 and RoHS, ensuring durable, safe, and environmentally responsible products. With tight binning tolerances, stable driver integration, and excellent heat dissipation characteristics, Beauty STC’s programmable LED tape stands out for its uniform light output, extended lifespan (typically 50,000 hours L70), and seamless compatibility with leading control systems such as DMX512, SPI, and DALI.

Engineered for precision and built to last, Beauty STC’s programmable LED tape combines high efficiency, exceptional color quality, and robust environmental protection—delivering a premium lighting solution trusted by professionals worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is located in Jiangmen, Guangdong Province, serving as our central hub for advanced LED lighting production. This modern factory integrates comprehensive in-house capabilities to ensure strict quality control and efficiency from raw materials to finished goods. The facility is designed to meet international standards, featuring climate-controlled production floors, dedicated cleanrooms for sensitive processes, and rigorous environmental management systems compliant with ISO 9001 and ISO 14001 certifications.

Our Surface Mount Technology (SMT) production lines represent a core strength of the Jiangmen factory. We operate multiple high-speed, precision SMT lines equipped with industry-leading Yamaha YS24 and Siemens SiPlace machines. These lines handle components down to 0201 package sizes, critical for the dense integration required in programmable LED tape controllers and ICs. Each line includes automated optical inspection (AOI) systems for real-time solder paste and component placement verification, ensuring exceptional first-pass yield rates exceeding 99.5%. The SMT capacity supports high-volume production with rapid changeover capabilities, enabling us to efficiently manage both large OEM orders and flexible small-batch prototyping.

Aging and reliability testing are rigorously enforced at Jiangmen, particularly for programmable LED tape products where thermal management and IC stability are paramount. We subject all programmable LED tape reels to a mandatory 72-hour aging test under controlled thermal conditions, typically at 50°C ambient temperature with full operational load. This extended burn-in process occurs in dedicated environmental chambers equipped with automated monitoring systems that track voltage, current, and thermal performance across the entire reel. Crucially, we verify not only LED output consistency but also the functionality and communication stability of integrated control ICs (such as SK9822, APA107, or WS2815) throughout the aging cycle. Units exhibiting any deviation in color, brightness, or signal integrity are automatically flagged and removed from the production flow before final packaging.

Regarding OEM capabilities for programmable LED tape, the Jiangmen factory offers extensive customization services beyond standard manufacturing. We provide full turnkey solutions including custom PCB layout design for unique form factors or high-density configurations, tailored firmware development for specific control protocols (DMX512, Art-Net, DALI, or proprietary apps), and integration of specialized ICs as required by the client. Our engineering team collaborates closely with OEM partners to develop bespoke solutions—from modifying tape widths and adhesive types to incorporating custom connectors, specialized diffusers, or unique cutting marks. We support low minimum order quantities for prototyping and scale seamlessly to high-volume production, maintaining consistent quality through our integrated SMT, aging, and final assembly processes. All OEM projects benefit from our in-house material sourcing, strict component traceability, and comprehensive testing protocols developed specifically for the demanding requirements of addressable LED systems.

Application Scenarios

Programmable LED tape is a versatile lighting solution that finds application across various commercial and hospitality environments due to its flexibility, energy efficiency, and dynamic lighting capabilities. In hotels, programmable LED tape is ideally used in guest rooms to provide ambient lighting along headboards, under beds, or in cove lighting to create a welcoming and customizable atmosphere. It is also effective in lobbies, corridors, and event spaces where dynamic color changing and brightness control can enhance the guest experience and support branding or mood-based lighting schemes.

In malls and retail environments, programmable LED tape can be used to highlight architectural features, accent display areas, or illuminate signage with vibrant, changeable colors. Its ability to be synchronized across large areas makes it ideal for creating immersive environments during seasonal promotions or special events. The dynamic lighting effects can attract attention and influence customer behavior by enhancing visual appeal.

In office spaces, programmable LED tape supports both functionality and well-being. It can be installed under shelves, in recessed ceiling coves, or behind monitors to reduce glare and eye strain, providing indirect ambient lighting. Tunable white options allow adjustment of color temperature throughout the day to align with circadian rhythms, potentially improving focus and productivity. Conference rooms and breakout areas can also benefit from customizable lighting scenes to suit different activities.

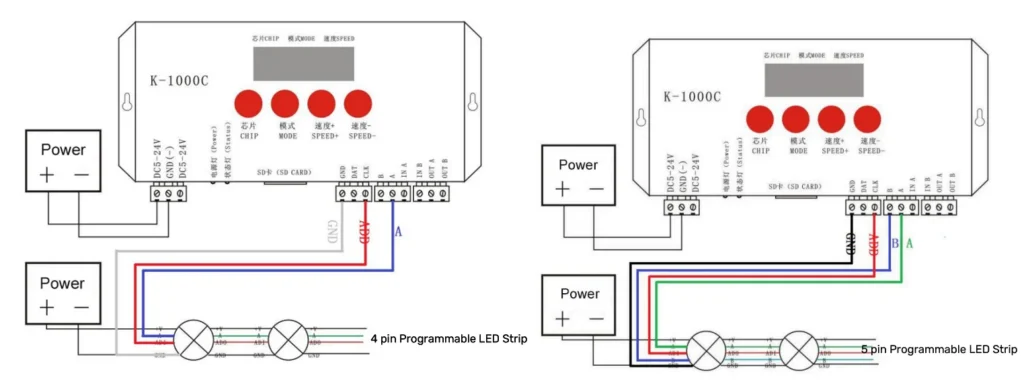

When installing programmable LED tape, proper planning is essential. Begin by calculating the required length and ensuring compatibility with the power supply and controller. Always cut the tape only at designated cut points to avoid damaging the circuitry. For optimal performance, use a constant voltage power supply matched to the tape’s voltage—typically 12V or 24V DC—and ensure the power supply can handle the total wattage of the installed length.

Surface preparation is crucial—clean and dry the mounting area thoroughly to ensure strong adhesion of the tape’s backing. For longer runs, consider feeding power from both ends or using power injection at intervals to prevent voltage drop, which can cause dimming at the far end. Use aluminum channels to protect the tape, improve heat dissipation, and provide a clean, professional finish.

Always connect the tape to a compatible controller—such as DMX, DALI, or Wi-Fi-enabled systems—according to the manufacturer’s wiring diagram. Test the system before finalizing the installation, and secure all connections with appropriate connectors or soldering, followed by insulation. Finally, follow local electrical codes and safety standards, and consider using a licensed electrician for permanent installations, especially in commercial settings.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s cutting-edge programmable LED tape, engineered for precision, versatility, and seamless integration into any architectural or decorative application. Our advanced solutions empower you to create dynamic, customizable lighting experiences while maintaining exceptional energy efficiency and reliability. Partner with Beauty STC to access industry-leading technology, dedicated engineering support, and scalable manufacturing capabilities tailored to your specific project demands. Elevate your offerings and meet evolving market expectations by collaborating with a trusted innovator in professional LED lighting. Contact our partnership team today at [email protected] to discuss how we can drive mutual growth and deliver exceptional value to your clients.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.