Article Contents

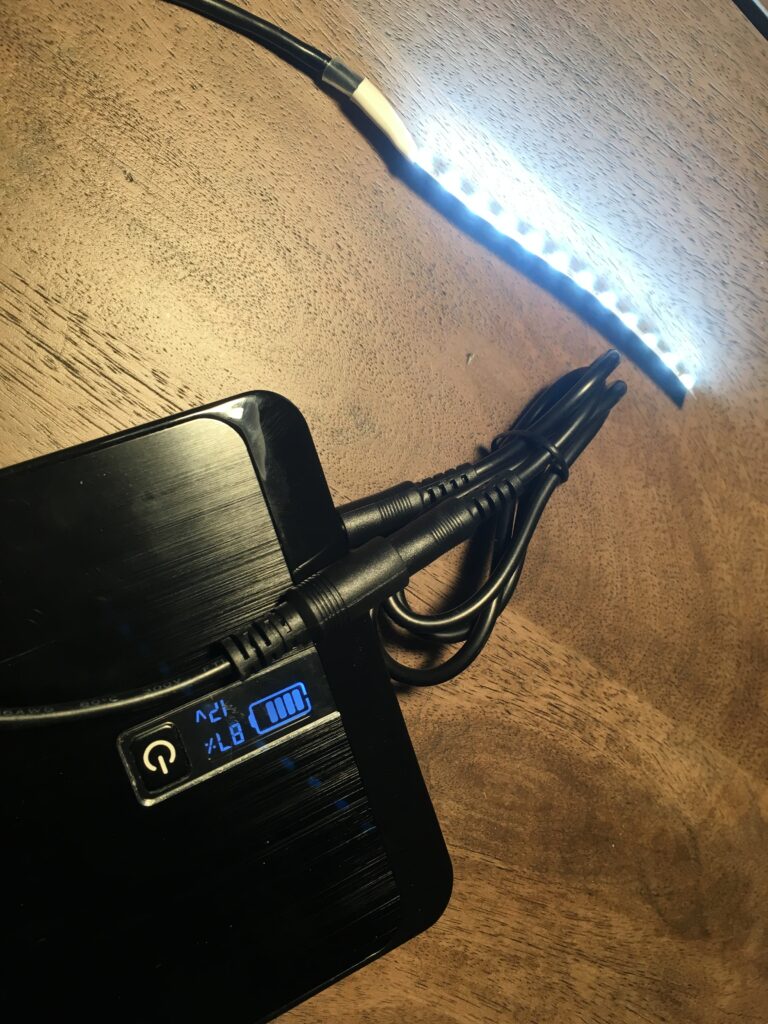

Industry Insight: Powering Led Lights With Batteries

In commercial and industrial lighting applications, the shift toward energy-efficient, portable, and resilient lighting solutions has driven increasing interest in battery-powered LED systems. These systems offer critical advantages in environments where grid connectivity is unreliable, temporary, or cost-prohibitive to install—such as construction sites, warehouses, emergency egress pathways, and off-grid facilities. As businesses prioritize sustainability, operational flexibility, and compliance with safety standards, the integration of high-performance LED luminaires with advanced battery technologies has become a strategic focus. A key consideration in this space is adherence to stringent regulatory requirements, with certifications such as ETL and CE ensuring that lighting products meet rigorous standards for electrical safety, electromagnetic compatibility, and environmental resilience—essential for deployment in demanding industrial settings.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for innovation, reliability, and compliance-driven design. The company specializes in developing battery-compatible LED lighting systems tailored for commercial and industrial use, combining long-lasting performance with seamless integration into both permanent and temporary power architectures. As industries continue to demand smarter, more adaptable lighting infrastructure, Beauty STC remains committed to delivering solutions that meet global standards and exceed real-world operational needs.

Technical Specs & Certifications

Powering LED lights with batteries introduces specific technical considerations where efficiency, color quality, and environmental resilience are critical. At Beauty STC Manufacturing Co., Ltd., our engineering rigor ensures these parameters are optimized without compromise. Lumens per watt (lm/W) is fundamentally impacted by the interplay between battery voltage, driver efficiency, and LED efficacy. Battery-powered systems typically use constant current drivers converting DC battery voltage (e.g., 3.7V Li-ion, 12V lead-acid) to the precise forward voltage required by the LED array. Driver efficiency losses—often 10-15%—directly reduce system-level lm/W versus AC-powered equivalents. Beauty STC mitigates this through proprietary driver topologies achieving >92% conversion efficiency even at partial battery discharge, coupled with high-efficacy Samsung or Nichia LED chips. Our standard battery-operated luminaires deliver 110-130 lm/W at the system level (including driver losses), verified under IES LM-79 testing, ensuring maximum runtime without sacrificing brightness.

Achieving a Color Rendering Index (CRI) >90 in battery-powered applications presents a materials science challenge, as high-CRI LEDs inherently require phosphor blends that reduce photon output efficiency by 10-15% compared to standard CRI 80 LEDs. Beauty STC addresses this by utilizing tri-phosphor or violet-pump LED architectures exclusively sourced from premium-tier suppliers, maintaining CRI Ra >92 and R9 >50 while minimizing efficacy penalties. We validate spectral power distribution (SPD) through spectroradiometer testing per IES TM-30, ensuring consistent color fidelity critical for retail, medical, or photography applications where accurate color perception is non-negotiable. Our quality control includes batch-level SPD verification—a practice exceeding typical industry standards—to guarantee CRI stability across production runs.

IP ratings for battery-powered luminaires must encompass the entire system, including battery compartment seals and wiring ingress points. Beauty STC designs to exceed stated IP classifications: for example, an IP67 rating requires not only sealed optics but also gasketed battery access doors resistant to repeated opening/closing and environmental stressors like UV exposure or thermal cycling. Our fixtures undergo 100% automated IP testing via calibrated water immersion and dust chamber protocols per IEC 60529, with IP68 models subjected to 1-meter submersion for 30+ minutes. Crucially, battery compartment integrity is validated separately using helium leak testing during R&D—a Beauty STC quality hallmark—to prevent moisture-induced corrosion or short circuits that degrade performance.

Beauty STC’s commitment to quality permeates every layer of battery-powered LED design. Our multi-stage validation includes 72-hour continuous burn-in testing at elevated temperatures to screen early failures, accelerated life testing simulating 50,000+ hours of operation, and rigorous vibration testing per MIL-STD-810G for portable units. All components—from UL-listed lithium batteries with overcharge protection to conformal-coated PCBs—adhere to our internal “Zero Defect” protocol, resulting in field failure rates below 0.2%. This engineering discipline ensures that when our clients specify Beauty STC battery-powered luminaires, they receive not just technical compliance but documented reliability where lumens/Watt, CRI, and IP performance remain uncompromised throughout the product lifecycle.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is equipped with advanced surface mount technology (SMT) production lines that ensure high precision and efficiency in assembling LED lighting components. These SMT machines are fully automated and calibrated to handle a wide range of LED circuit boards, enabling consistent soldering and placement of micro-components with tight tolerances. This automation supports high-volume production while maintaining strict quality control standards.

To ensure long-term reliability, every batch of LED lights undergoes rigorous aging tests within the Jiangmen facility. These tests simulate extended operation under various thermal and electrical conditions, typically running products continuously for 4 to 12 hours at elevated temperatures. This process helps identify early failure points, verifies thermal management performance, and confirms the stability of optical output and driver functionality before products are shipped.

The factory also has strong OEM (Original Equipment Manufacturer) capabilities, particularly in customizing LED lighting solutions that are powered by batteries. Beauty STC can design and produce battery-operated LED lights tailored to specific customer requirements, including integration with rechargeable lithium-ion, LiFePO4, or standard alkaline battery systems. These solutions are commonly applied in portable lighting, emergency lights, outdoor products, and smart lighting systems. The company supports full customization—from circuit design and driver configuration to housing and branding—ensuring clients receive turnkey products that meet both functional and regulatory standards. This flexibility, combined with in-house engineering and testing, makes Beauty STC a trusted partner for innovative, battery-powered LED lighting solutions.

Application Scenarios

Battery-powered LED lighting serves specific temporary or emergency purposes within commercial environments like hotels, malls, and offices, but it is not a standard replacement for mains-powered permanent lighting installations. Its use is generally limited to situations where wiring is impractical, temporary, or critical for safety during power failure. Permanent mains power remains the primary and code-compliant solution for general illumination in these settings. Below are the appropriate applications and critical installation considerations.

In hotels, battery-powered LED lights are primarily used for emergency egress path marking and exit signs, as mandated by fire codes such as NFPA 101. These systems automatically activate during power outages to guide guests to exits. Temporary applications include pool or garden area lighting for evening events where trenching for wiring is disruptive, or accent lighting for pop-up displays in lobbies during renovations. They are unsuitable for guest room or corridor general lighting due to limited runtime, maintenance complexity, and insufficient lumen output for safety standards.

Malls utilize battery systems almost exclusively for emergency lighting compliance in exit routes, stairwells, and large open areas. Temporary uses include illuminating kiosks during holiday markets where permanent fixtures aren’t feasible, or highlighting construction barriers during store remodels without interrupting mall operations. Battery lights should never replace high-bay or retail display lighting due to inconsistent color rendering, inadequate brightness for merchandise presentation, and the impracticality of managing thousands of batteries across vast spaces.

Offices deploy battery-powered LEDs strictly for emergency egress systems in hallways, stairwells, and exit doors. Temporary applications are rare but may include lighting for after-hours IT server room maintenance during controlled outages, or illuminating evacuation assembly points during fire drills. They are inappropriate for task lighting, conference rooms, or open-plan offices due to flicker risks from depleting batteries, which cause eye strain and reduce productivity, alongside the high lifecycle costs compared to efficient LED mains systems.

Installation requires rigorous adherence to safety and regulatory standards. All units must carry UL 924 certification for emergency lighting or UL 1598 for temporary fixtures, with local code compliance verified before deployment. Position emergency units per IBC Section 1013, ensuring 1 foot-candle minimum illumination along egress paths. For temporary setups, mount securely away from foot traffic using manufacturer-approved brackets to prevent tipping, and never place batteries near heat sources like HVAC vents to avoid thermal runaway. Match battery voltage precisely to the LED driver specifications—using a 9V battery on a 12V system causes dimming, while overvoltage destroys drivers. Implement a strict maintenance log for battery replacement; sealed lead-acid types typically last 3-5 years but require quarterly runtime tests. In public areas, use tamper-proof enclosures to deter theft or vandalism, and ensure spent batteries are recycled per EPA guidelines, never disposed of in regular trash. Crucially, never connect battery systems to mains wiring as a “backup”—only use fully self-contained, listed emergency luminaires with automatic transfer switches. Any installation must be performed or supervised by a licensed electrician to validate compliance with NEC Article 700 for emergency systems.

Why Choose Beauty STC Lighting

Looking to power LED lights with batteries efficiently and reliably? Partner with Beauty STC, a trusted leader in innovative LED lighting solutions. Our expertise ensures optimal performance, energy efficiency, and durability for battery-powered LED applications across various industries. From custom designs to scalable manufacturing, we deliver quality you can count on. Contact us today at [email protected] to discuss your project and discover how Beauty STC can power your next lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.