Article Contents

Industry Insight: Power Source For Led Strip Lights

In the rapidly evolving landscape of commercial and industrial lighting, LED strip lights have emerged as a preferred solution for their energy efficiency, design flexibility, and long-term cost savings. At the heart of every reliable LED lighting system lies a critical component—the power source. Selecting the right power supply ensures optimal performance, longevity, and safety, especially in demanding environments such as warehouses, manufacturing facilities, retail spaces, and large-scale architectural installations. As energy codes tighten and sustainability becomes a priority, compliance with international safety and performance standards like ETL and CE is no longer optional but a fundamental requirement for market access and operational reliability.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of power solutions for LED lighting systems for over two decades. With a strong engineering foundation and a commitment to innovation, Beauty STC specializes in designing and manufacturing high-performance, code-compliant power sources tailored for commercial and industrial LED strip lighting applications. Our products meet rigorous ETL and CE certification standards, ensuring safety, durability, and seamless integration into diverse lighting infrastructures. As a trusted partner across North America, Europe, and beyond, Beauty STC continues to drive advancements in intelligent, efficient, and scalable power solutions that empower the future of professional lighting.

Technical Specs & Certifications

Power sources for LED strip lights, commonly referred to as LED drivers, are critical components that directly influence the performance, efficiency, and longevity of the lighting system. While lumens per watt (lm/W) and Color Rendering Index (CRI) are primarily characteristics of the LED chips and phosphor formulation on the strip itself, the driver plays an indispensable role in enabling and maintaining these specifications by delivering stable, clean, and appropriately regulated power. At Beauty (STC) Manufacturing Co., Ltd., our drivers are engineered to maximize the potential of high-performance LED strips, particularly those demanding CRI >90 and specific IP protection levels.

Lumens per watt is a measure of luminous efficacy, indicating how efficiently the LED strip converts electrical power into visible light. The driver significantly impacts this metric through its efficiency rating, typically expressed as a percentage. Beauty STC drivers achieve industry-leading efficiency levels of 90-95%, minimizing energy loss as heat within the power conversion process. This high efficiency ensures that the maximum possible input power is delivered to the LEDs as usable DC current, directly supporting the strip’s inherent lm/W capability. Poor quality drivers with lower efficiency (e.g., 80-85%) waste significant energy as heat, reducing the overall system efficacy and potentially causing thermal stress on the LEDs, which can degrade lumen output over time. Our drivers incorporate advanced switching topologies and high-grade components to maintain stable output voltage and current under varying line conditions, preventing efficiency droop and ensuring the LED strip operates consistently at its rated lm/W performance throughout its lifespan.

Achieving and sustaining a CRI >90 requires not only premium LED chips with sophisticated multi-phosphor blends but also exceptionally stable and clean DC power from the driver. Voltage fluctuations, excessive ripple current, or harmonic distortion introduced by a substandard driver can cause subtle color shifts, reduced color fidelity, and flicker, undermining the high CRI specification. Beauty STC drivers are meticulously designed with low ripple current (<5%, often <3%) and robust filtering to provide a smooth, regulated DC output. This minimizes any potential for color temperature variation or visible flicker, especially critical in applications like retail, museums, and high-end residential where accurate color representation is paramount. The stability ensures that the LEDs operate precisely within their optimal drive current range, preserving the intended spectral power distribution necessary for CRI >90 performance over tens of thousands of hours.

IP (Ingress Protection) ratings define the level of protection the driver housing provides against solid objects and moisture. This is distinct from the IP rating of the LED strip itself, though both are crucial for the complete system’s environmental resilience. Beauty STC offers a comprehensive range of drivers with IP ratings tailored to application demands. For indoor dry locations, IP20 drivers are standard. For damp locations like bathrooms or covered outdoor areas, IP65 or IP67 drivers are essential, featuring sealed enclosures that prevent dust ingress and withstand low-pressure water jets or temporary immersion. Our IP67 drivers, commonly used with outdoor-rated LED strips, undergo rigorous testing to ensure complete dust tightness and resistance to temporary submersion up to 1 meter for 30 minutes. For harsh environments requiring constant submersion, specialized IP68 drivers are available. All Beauty STC IP-rated drivers utilize high-quality silicone potting compounds and robust polycarbonate or metal housings, ensuring long-term reliability even under extreme temperature cycling and humidity exposure.

Beauty STC’s commitment to quality is embedded throughout our driver manufacturing process. We adhere strictly to international safety standards (UL, CE, TUV, SAA) and performance specifications (IEC 61347-2-13). Our quality control involves 100% automated testing for critical parameters like output voltage, current, efficiency, and ripple, coupled with rigorous batch sampling for accelerated life testing (ALT) and thermal stress validation. We utilize only Tier-1 components from trusted suppliers, including high-temperature electrolytic capacitors and premium MOSFETs, ensuring operational stability from -40°C to +70°C ambient temperatures. This meticulous approach, combined with our ISO 9001 certified production facilities, guarantees drivers that not only meet but consistently exceed specifications for efficiency, longevity (typically rated for 50,000+ hours at 40°C ambient), and reliability. This focus on uncompromising quality ensures that Beauty STC drivers form a dependable foundation for high-performance LED strip lighting systems demanding superior efficacy, exceptional color accuracy, and robust environmental protection.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is designed to support high-efficiency, precision manufacturing of LED lighting components, with a strong focus on product reliability and scalability for both domestic and international markets.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, which are essential for the precise assembly of compact and high-performance electronic components used in LED power sources. These SMT machines ensure accurate placement of resistors, capacitors, ICs, and other surface-mount devices onto printed circuit boards (PCBs), enabling high-density circuit integration with consistent quality and minimal defect rates. The automated SMT process is supported by automated optical inspection (AOI) systems to verify solder joint quality and component alignment, ensuring robust performance of the final product.

A critical part of the production process at the Jiangmen factory is the comprehensive aging and reliability testing conducted on all power sources for LED strip lights. Each unit undergoes extended burn-in tests under controlled thermal and electrical loads to identify early-life failures and verify long-term stability. These aging tests typically run for 4 to 8 hours or longer under elevated temperatures and full load conditions, simulating real-world operating environments. Additional quality assurance procedures include insulation resistance testing, high-voltage testing, and functional performance verification to ensure compliance with international safety and efficiency standards.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, making it well-suited to serve partners seeking customized power solutions for LED strip lighting systems. The company can develop and produce power sources tailored to specific voltage, current, dimming functionality (including PWM, 0-10V, DALI), waterproof ratings (e.g., IP67 for outdoor use), and form factors. With in-house R&D, tooling, and molding support, Beauty STC offers full turnkey OEM services—from initial design and prototyping to mass production and logistics. This flexibility allows clients to brand and integrate the power supplies seamlessly into their lighting systems while benefiting from the factory’s stringent quality control and cost-efficient manufacturing processes.

Overall, the Jiangmen factory represents a vertically integrated, quality-driven production environment that combines automation, rigorous testing, and OEM customization to deliver reliable and high-performance power sources for LED strip lights.

Application Scenarios

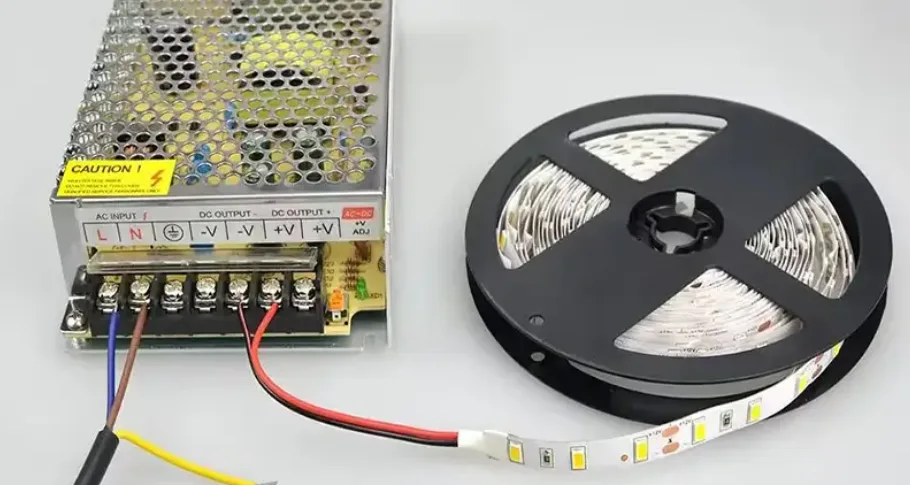

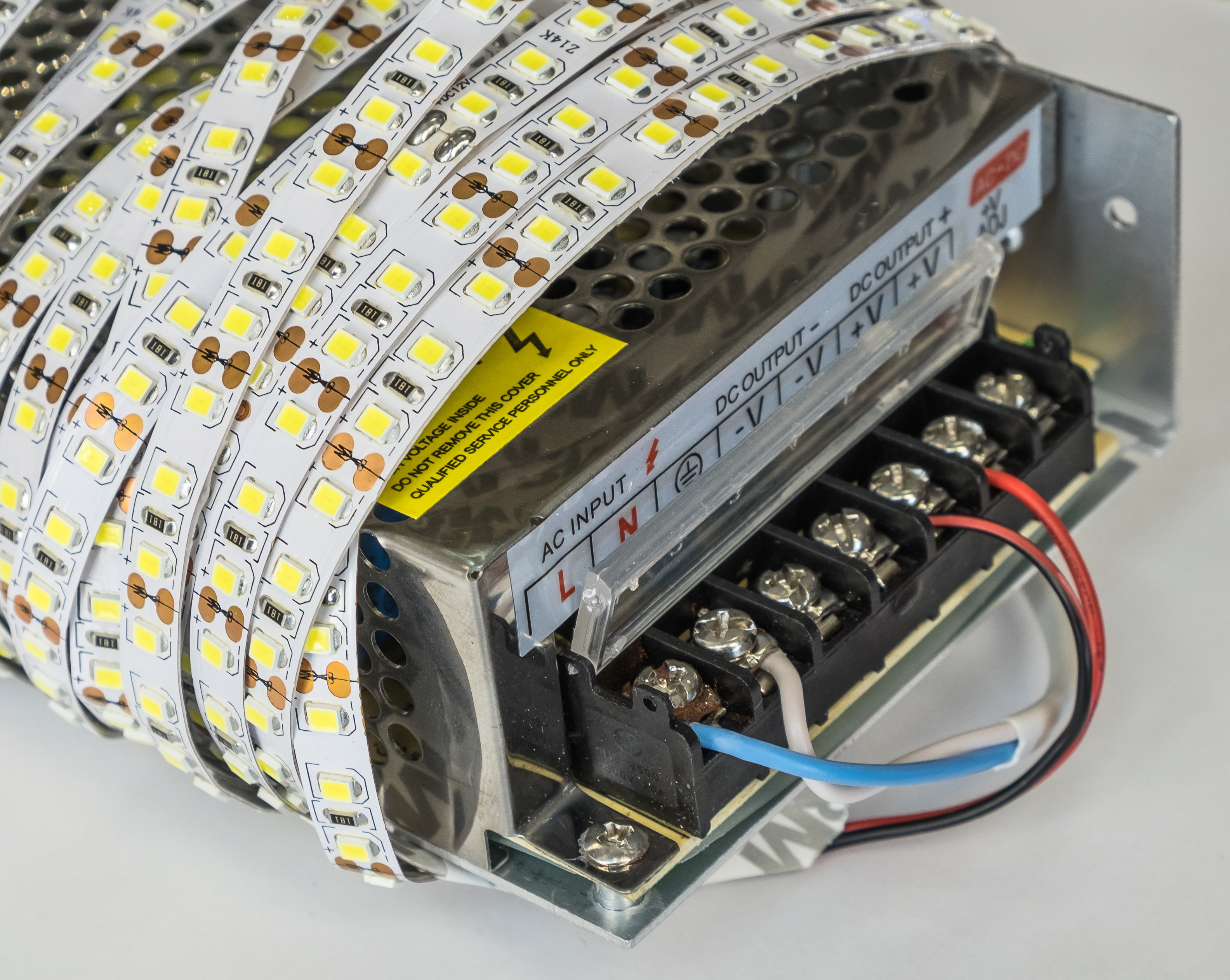

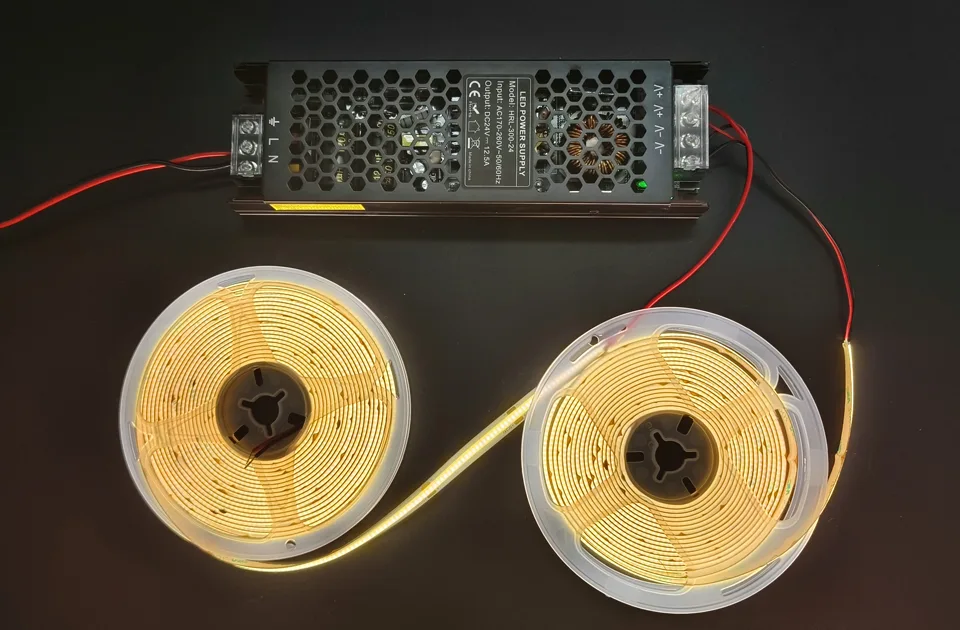

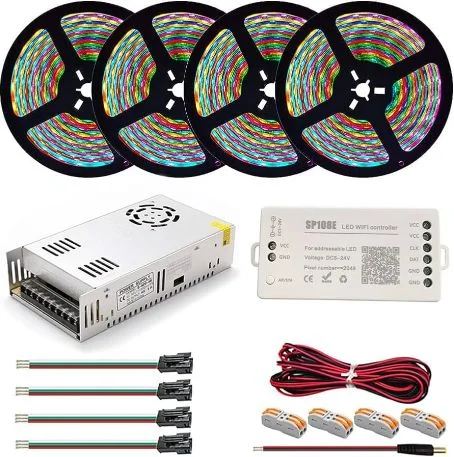

The term “power source for LED strip lights” specifically refers to the LED driver, which converts standard line voltage AC power (e.g., 120V/230V AC) to the low-voltage DC power (typically 12V or 24V DC) required by LED strips. Selecting and installing the correct driver is critical for performance, safety, and longevity in commercial applications. Below are key deployment locations within hotels, malls, and offices, followed by essential installation guidance.

In hotels, LED drivers power strips in guest room cove lighting for ambient mood lighting, under-cabinet lighting in minibars or desks, and toe-kick lighting in bathrooms for safety. They are also essential for back-of-house areas like linen closets and staff corridors where energy-efficient task lighting is needed. Lobby feature walls, reception counters, and elevator lobbies frequently use hidden cove lighting powered by drivers to create welcoming atmospheres. Special attention is required for wet locations like pool areas or spa steam rooms, where IP67-rated drivers in external enclosures are mandatory to meet safety standards like UL 8750.

Malls utilize drivers extensively for architectural cove lighting in high-ceiling atriums and walkways to highlight structural features. Retail storefronts and display windows rely on drivers to illuminate product signage and accent lighting, often requiring high-CRI drivers for accurate color rendering. Escalator undersides, handrail lighting, and directional path markers in corridors also depend on properly sized drivers. Given the scale, malls often need multiple high-wattage drivers (e.g., 200W–400W) with robust thermal management, installed in accessible electrical closets to support long strip runs exceeding 10 meters where voltage drop must be mitigated.

Offices deploy drivers for under-cabinet task lighting in workstations, providing glare-free illumination for desks without overhead lighting. Conference room accent lighting along walls or ceilings uses dimmable drivers compatible with building management systems. Reception areas and executive suites incorporate cove lighting for a premium aesthetic, while server rooms and IT closets use low-heat drivers for aisle lighting. Critical here is selecting drivers with 0–10V or DALI dimming for integration with occupancy sensors and daylight harvesting systems to meet energy codes like ASHRAE 90.1.

Installation must begin with precise driver sizing: calculate total strip wattage plus 20% headroom to avoid overload. For example, a 5-meter 24V strip at 14.4W/m requires (5 × 14.4) = 72W; select a 100W driver (72W × 1.2 = 86.4W). Always verify input voltage compatibility with local supply (e.g., 220–240V AC in Asia/Europe). Mount drivers in well-ventilated areas away from insulation or flammable materials; enclosed metal enclosures with ventilation slots are ideal for plenum spaces. Avoid daisy-chaining multiple drivers to one circuit—each should have a dedicated fused branch circuit with proper wire gauge (e.g., 18 AWG for 12V runs under 3m). For long strip runs exceeding 5 meters at 12V, inject power at both ends using a single driver with parallel wiring to prevent voltage drop. Ensure all connections use soldered or screw-terminal joints—not clips—and seal outdoor or humid-area drivers with IP65+ rated enclosures. Finally, label each driver with circuit details and maximum load for maintenance compliance. Never exceed 80% of the driver’s rated capacity to ensure thermal stability and longevity. Always test the system before final concealment of strips or channels.

Why Choose Beauty STC Lighting

Looking for a reliable power source for your LED strip lights? Partner with Beauty STC, a trusted manufacturer of high-quality LED lighting solutions. Our advanced power supplies ensure optimal performance, durability, and energy efficiency for all your lighting projects. As a leader in the industry, we offer customized solutions tailored to your specific needs.

To learn more or discuss your requirements, contact us today at [email protected]. Let Beauty STC power your next LED innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.