Article Contents

Industry Insight: Plug In Strip Light

Plug-in strip lighting has rapidly evolved from a niche solution to a strategic asset within commercial and industrial lighting portfolios, driven by the urgent need for flexible, cost-effective, and rapidly deployable illumination. In environments ranging from warehouse aisles and retail backrooms to manufacturing assembly lines and office under-cabinet task areas, the demand for adaptable lighting that avoids complex rewiring is paramount. These systems offer significant advantages: simplified installation slashes labor costs and project timelines, modular designs allow for precise light placement tailored to specific workflows, and easy reconfiguration supports dynamic space utilization common in modern facilities. Crucially, for commercial and industrial adoption, rigorous safety and performance certifications are non-negotiable. Products must reliably meet stringent regional standards, with ETL listing being essential for North American markets to assure compliance with safety requirements like UL 1598, and CE marking mandatory for access to European markets, demonstrating adherence to critical health, safety, and environmental directives.

At Beauty STC Manufacturing Co., Ltd., established in 1998, we have dedicated over 25 years to engineering and manufacturing high-performance LED lighting solutions specifically designed for the demanding realities of commercial and industrial applications. Our deep understanding of the sector’s unique challenges – from the need for robust durability in harsh environments to the critical importance of energy efficiency and long-term reliability – informs every product we develop. We recognize that plug-in strip lighting in these settings is not merely about convenience; it’s about delivering consistent, high-quality illumination that enhances worker safety, improves operational visibility, and contributes directly to productivity and cost savings. This commitment is embedded in our rigorous internal testing protocols that consistently exceed baseline certification requirements, ensuring our plug-in strip lights deliver the performance and safety our commercial and industrial clients require, backed by the stability and expertise of a manufacturer with a proven quarter-century track record.

Technical Specs & Certifications

The plug-in strip light offered by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high performance and reliability for both commercial and industrial lighting applications. A key technical specification is its luminous efficacy, which typically ranges from 130 to 150 lumens per watt, depending on the configuration and length. This high efficiency ensures significant energy savings over traditional lighting systems while maintaining excellent light output.

Color Rendering Index (CRI) is a critical factor in accurate color representation, and Beauty STC’s plug-in strip lights are designed with CRI values exceeding 90. This ensures vibrant, true-to-life color rendering, making them ideal for environments where visual clarity and color accuracy are essential—such as retail displays, workshops, and inspection areas.

In terms of environmental protection, these strip lights are available in multiple IP (Ingress Protection) ratings to suit various installation conditions. Standard models are rated at IP20, suitable for dry indoor environments. For more demanding applications, IP65-rated versions are offered, providing complete dust protection and resistance to low-pressure water jets. This makes them appropriate for use in damp or washdown areas such as food processing zones, garages, or outdoor canopies with cover.

Beauty (STC) Manufacturing Co., Ltd. upholds stringent quality control standards throughout the production process. Their plug-in strip lights are constructed with high-quality aluminum housings for efficient heat dissipation, long-life LED chips, and robust polycarbonate diffusers. Each unit undergoes rigorous testing for electrical safety, thermal performance, and photometric consistency, ensuring reliability and longevity. With a focus on durability and performance, Beauty STC’s lighting solutions are trusted for their consistent quality and adherence to international standards.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for LED lighting products, established to meet stringent global quality standards while supporting high-volume output. Located within a modern industrial park, the factory spans over 20,000 square meters and operates under ISO 9001 quality management systems. The facility is purpose-built for LED lighting production, featuring climate-controlled assembly areas, dedicated R&D labs, and comprehensive testing zones to ensure product reliability from component sourcing through final shipment.

Our Surface Mount Technology (SMT) production line utilizes state-of-the-art Yamaha YS series machines, including the YS12F and YSM20 models, which deliver exceptional placement accuracy down to ±25μm. These machines handle components as small as 0201 metric packages and support multi-layer PCB assemblies up to 500mm x 500mm, critical for high-density LED strip manufacturing. The line operates with automated optical inspection (AOI) systems performing real-time solder paste and component placement verification, achieving a first-pass yield rate exceeding 99.2%. For plug-in strip light production, this precision ensures consistent solder joints on flexible PCBs and accurate positioning of miniature LEDs and passive components, directly impacting lumen maintenance and thermal performance.

Aging and reliability testing represent a cornerstone of our quality assurance protocol. Completed strip light assemblies undergo mandatory 24-hour burn-in testing at 1.5 times the rated operating voltage in temperature-controlled chambers maintained at 55°C ±2°C. Each batch is monitored via automated data logging systems tracking voltage, current, and thermal profiles, with infrared thermal imaging used to identify hotspots exceeding 85°C. We maintain multiple aging chambers with a combined capacity of 500 units per batch, allowing simultaneous testing of multiple product variants. Post-aging, every strip undergoes photometric validation using integrating spheres to confirm lumen output, CCT stability, and CRI compliance against initial specifications before packaging.

Regarding OEM capabilities for plug-in strip lights, our Jiangmen factory provides fully customizable solutions from initial design through to fulfillment. We support client-specific requirements including custom lengths, color temperatures, CRI values (up to 97), and driver integrations with universal input voltage ranges (100-277V AC). Our engineering team collaborates with clients to develop proprietary connector systems, specialized diffusers, or unique mounting solutions while ensuring compliance with UL, CE, and IEC safety standards. The facility handles both turnkey manufacturing using our certified components and client-supplied material programs, with flexible minimum order quantities starting at 500 meters per configuration. All OEM projects benefit from our vertical integration, including in-house PCB fabrication for custom strip layouts and driver assembly under one roof, enabling rapid prototyping and scalable production runs from 1,000 to 500,000 units monthly.

Application Scenarios

Plug-in strip lights are versatile and energy-efficient lighting solutions ideal for a variety of commercial and hospitality environments. In hotels, they are commonly used in back-of-house areas such as laundry rooms, storage closets, and utility corridors where easy installation and reliable illumination are essential. They also work well under kitchen cabinets in hotel staff kitchens or service pantries. In malls, plug-in strip lights are frequently installed in maintenance rooms, security stations, and display preparation areas. Their plug-and-play design makes them suitable for temporary lighting setups during renovations or seasonal displays. Offices benefit from plug-in strip lights in server rooms, filing areas, under desks for task lighting, and within supply closets. They are also a practical choice for illuminating narrow hallways or interior staircases where permanent wiring is impractical.

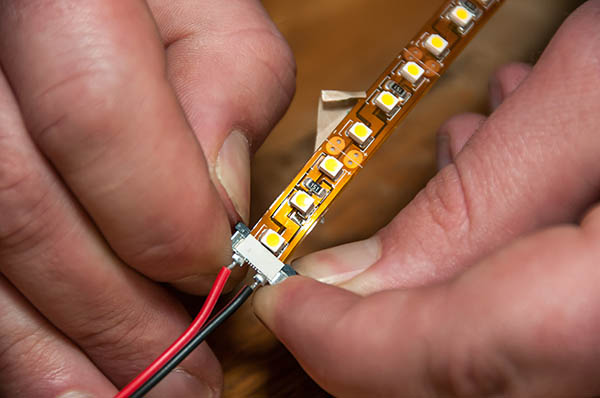

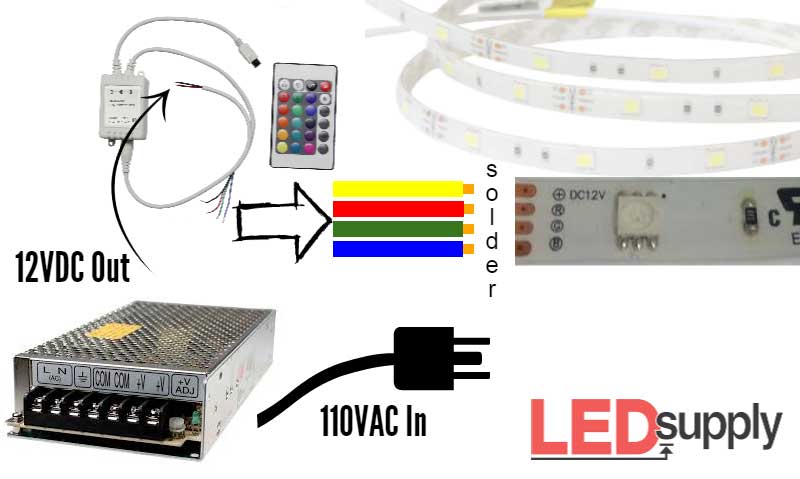

When installing plug-in strip lights, ensure the power source is easily accessible and located on a dedicated circuit to avoid overloading. Always verify that the voltage of the strip light matches the local electrical supply. For optimal performance and safety, use a grounded outlet and consider installing a surge protector, especially in environments with sensitive electronic equipment. Mount the strip light using the provided clips or adhesive backing on a clean, dry, and stable surface—avoid placing them in high-moisture areas unless they are specifically rated for damp or wet locations. Maintain proper spacing between multiple strips to prevent overheating, and avoid covering the fixture with insulation or fabric. For longer runs, check the manufacturer’s recommendations on maximum length per circuit and use extension leads or connectors designed for strip lighting. Finally, test the installation before finalizing the mounting position and routinely inspect for loose connections or signs of wear, particularly in high-traffic or high-use facilities.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium plug-in strip light solutions engineered for superior performance and seamless integration. As a global leader with over 20 years of specialized LED manufacturing expertise, we deliver rigorously tested products meeting international safety and efficiency standards including UL, CE, and RoHS. Our plug-in strip lights feature advanced thermal management, flicker-free operation, and versatile dimming compatibility ensuring reliability across retail, hospitality, and commercial environments. Partner with Beauty STC to access customizable configurations, dedicated engineering support, and scalable production capacity serving major brands worldwide. Streamline your supply chain with our turnkey solutions designed for rapid deployment and long-term durability. Contact our lighting solutions manager directly at [email protected] to discuss tailored specifications, volume pricing, and technical integration support for your next project. Let Beauty STC illuminate your success with engineering excellence you can trust.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.