Article Contents

Industry Insight: Plug In Strip Light

The Evolving Demand for Quality Plug-in Strip Lights in Commercial & Industrial Applications

Why Certification Matters for Global Importers

Commercial and industrial lighting projects demand solutions that meet rigorous safety, performance, and regulatory standards. For distributors and project managers sourcing globally, uncertified products pose significant risks: customs delays, liability exposure, and project non-compliance. Certifications like ETL (USA/Canada) and TUV CE (Europe) are non-negotiable prerequisites for market access. These marks validate compliance with North American and European safety standards, ensuring products withstand electrical, thermal, and mechanical stressors in real-world applications. Importers must prioritize suppliers with verifiable certifications to mitigate supply chain disruptions and uphold project integrity—especially in high-stakes environments like retail spaces, warehouses, and public infrastructure.

Beauty STC Lighting: Engineering Excellence Since 1998

As a factory-direct manufacturer with 25+ years of experience (established 1998), Beauty STC Lighting delivers plug-in strip light solutions engineered for global commercial and industrial applications. Our Jiangmen, Guangdong facility operates under ISO 9001-aligned quality systems, with every product subjected to rigorous in-house testing before certification. We specialize in OEM/ODM services tailored to project-specific requirements—from custom voltage configurations (110V/220V) to specialized dimming protocols and IP-rated enclosures—while maintaining full compliance with ETL and TUV CE standards.

Technical Specifications: Plug-in Strip Light Series

| Feature | Specification |

|---|---|

| Voltage Input | 110V AC / 220V AC (Dual Voltage, No External Driver Required) |

| Certifications | ETL Listed (UL 1598), CE/TUV EN 60598-1, RoHS Compliant |

| CRI (Ra) | ≥90 (Standard), ≥95 (Premium Option for Color-Critical Applications) |

| IP Rating | IP20 (Indoor), IP65 (Wet/Damp Locations), IP67 (Outdoor Submersion-Resistant) |

| Dimming Compatibility | TRIAC, 0-10V, DALI (Optional) |

| Color Temperature | 2700K–6500K (Customizable Per Project Requirements) |

| Length Options | 1m–50m (Cuttable Every 50mm) |

| Warranty | 5 Years Limited (Covering Performance & Material Defects) |

Our commitment to technical precision and regulatory adherence ensures seamless integration into diverse applications—from retail display cases and office workspaces to industrial garages and outdoor signage. With a proven track record supplying 50+ countries, Beauty STC Lighting provides distributors with a single-source solution for certified, scalable lighting projects.

For technical specifications, OEM collaboration, and certification documentation, contact our engineering team directly:

[email protected] | +86 13902885704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Beauty (STC) Manufacturing Co., Ltd – Factory-Direct, ETL & CE Certified since 1998

1. Performance Benchmarks for Plug-in Strip Light

| Parameter | Industry Target | Beauty STC Certified Range | Notes |

|---|---|---|---|

| Luminous Efficacy | ≥120 lm/W | 140–160 lm/W @ 24 VDC | 2835 mid-power LEDs, 3-step MacAdam binning |

| CRI | ≥80 | Ra ≥90 (typ. 92–94) | R9 >50, suitable for museums & retail |

| L70 Lifetime | 35 000 h | 54 000 h (TM-21) | 700 mA, 40 °C ambient |

| Flicker (IEEE 1789) | <20 % | <3 % (SVM <0.4) | TRIAC & 0–10 V options |

| Ingress Protection | IP20 | IP20 / IP54 / IP67 / IP68 | Silicone-extrusion or nano-coating |

| PCB Copper Weight | 1 oz | 2 oz (70 µm) + ED | Drop-in voltage <3 % per 5 m |

| Operating Temp. | –20 °C to +45 °C | –30 °C to +60 °C | 105 °C capacitor, 3-year min. |

| Certifications | Self-declared | ETL/cETL, TUV-CE, RoHS, REACH | CB scheme file available for OEM |

2. Consistency & Process Control

Bin-on-Reel: LEDs binned by flux, Vf and chromaticity; sealed immediately after SMT.

AOI + Functional Burn-in: 100 % AOI, 2 h 45 °C burn-in at 100 % load.

Integrating-sphere sampling: every 30 min per production lot; data logged for 10-year traceability.

Solder Alloy: SAC305 under nitrogen reflow; void rate <10 % (X-ray).

Adhesive Tape: 3M 9495LE or VHB 5952, 180° peel ≥20 N/25 mm on Al-profile.

Pull-test on 24 AWG plug leads: 30 N, 60 s, zero breakage.

3. Quality Comparison Table – Generic Market vs Beauty STC

| Feature | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| LED Source | Unknown bin, 1-step price buy | Nichia/Seoul 3-step MacAdam, LM-80 report |

| PCB | 1 oz Cu, 0.5 mm FR-4, 10 mm pitch | 2 oz Cu, 1.0 mm FR-4, 8 mm pitch, white solder mask |

| Efficacy Drop @5 m | –25 % | –8 % (24 V feed both ends) |

| IP Rating Test | Batch sample, 1 min | 100 % pressurised water jet, 30 min |

| Safety Driver | Basic isolated, no surge | 2 kV surge, –40 °C cold start, ENEC capacitor |

| Certification Marks | Printed self-declaration | Laser-etched ETL & CE file numbers on PCB |

| OEM Custom CCT | MOQ 5 000 m | MOQ 1 000 m, 24 h chromaticity report |

| Warranty | 1 year limited | 5 year full, backed by 25-year factory history |

4. Available Plug-in Form Factors (24 V)

P1-5M-PP: 5 m reel + 1.5 m 18 AWG fused plug, open lead, IP20.

P1-5M-IP67: Same as above, silicone sleeve, M16 waterproof connector.

P1-CCT-TUNE: 2700–6500 K dual-white, CRI 93, 120 LEDs/m, RF remote.

P1-RGBW-4IN1: 60 LEDs/m, 24 V, 16 W/m, DMX512 decoder inside plug box.

All variants carry ETL/cETL file #5012868 & TUV CE report #R50483411.

For OEM/ODM colour boxes, custom cable length or CCT, e-mail: [email protected] or call +86-13902885704.

Factory Tour: Manufacturing Excellence

Precision Manufacturing & Customizable OEM Capabilities

Advanced Production Infrastructure

Beauty STC Lighting’s 25+ years of operational excellence, established in 1998, is anchored in our modern Jiangmen High-tech Industrial Zone facility. The production line integrates industrial-grade automation with precision engineering:

Fully automated SMT assembly with high-speed pick-and-place machines and reflow soldering ovens

Automated Optical Inspection (AOI) systems for real-time component verification

Dedicated encapsulation and cutting stations for flexible strip production

Climate-controlled aging chambers for thermal stability testing

This infrastructure ensures consistent quality and scalability for orders of any volume, from small-batch prototypes to large-scale commercial shipments.

Rigorous Quality Assurance Protocols

All products undergo a multi-stage quality control process aligned with international safety and performance standards. Our protocols include:

| Test Type | Procedure | Compliance Standard |

|---|---|---|

| Electrical Safety | Dielectric strength, insulation resistance | ETL, TUV CE |

| Thermal Cycling | 48-hour continuous operation at max load | IEC 62471 |

| Lumen Maintenance | LM-80 testing for 6,000+ hours | LM-80 |

| IP Rating | Water ingress testing per IP code | IEC 60529 |

Every production batch is traceable through our ERP system, with documentation verifying compliance with ETL and TUV CE certifications for North American and European markets.

Tailored OEM/ODM Solutions

With 25+ years of experience serving global clients, we provide end-to-end customization for architectural, commercial, and industrial projects. Our OEM/ODM capabilities include:

| Parameter | Customization Options |

|---|---|

| Length | 1m to 50m (10cm increments) |

| CCT | 2700K–6500K (adjustable in 100K steps) |

| IP Rating | IP20 (indoor), IP65 (waterproof), IP67 (submersible) |

| Packaging | Retail-ready boxes, bulk reels, custom OEM branding |

| Certifications | ETL, TUV CE, RoHS compliant (project-specific) |

All custom solutions undergo the same rigorous testing protocols as our standard products, ensuring reliability and compliance for global distribution. Contact us to discuss project-specific requirements and receive a technical specification sheet.

Contact: [email protected] | +86 13902885704

Address: 41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Installation & Application Scenarios

Application Scenarios & Installation Guidelines for Plug-In Strip Light

(Industrial-grade, ETL/TUV CE certified, factory-direct from Beauty (STC) – est. 1998, OEM/ODM ready)

Where to Deploy Plug-In Strip Light

| Segment | Typical Mounting Height | Required IP | Lumen Target (lm/m) | Key Certification Check |

|---|---|---|---|---|

| Hotel corridors & guest-room coves | 2.2–3.5 m | IP20 | 600–900 | ETL cETL for North-America |

| Shopping-mall display niches | 1.8–3 m | IP44 | 900–1200 | TUV CE, RoHS |

| Office under-shelf / above-desk task | 0.4–0.8 m | IP20 | 400–700 | UGR<19, flicker-free |

| Facade soffit & canopy perimeter | 3–6 m | IP65 | 1200–1600 | 600 V outdoor rating |

| Pop-up retail & exhibition booths | 2–3 m | IP33 | 700–1000 | Plug-and-play 120-240 V |

Contractor Field Notes

1. Pre-Installation Checklist

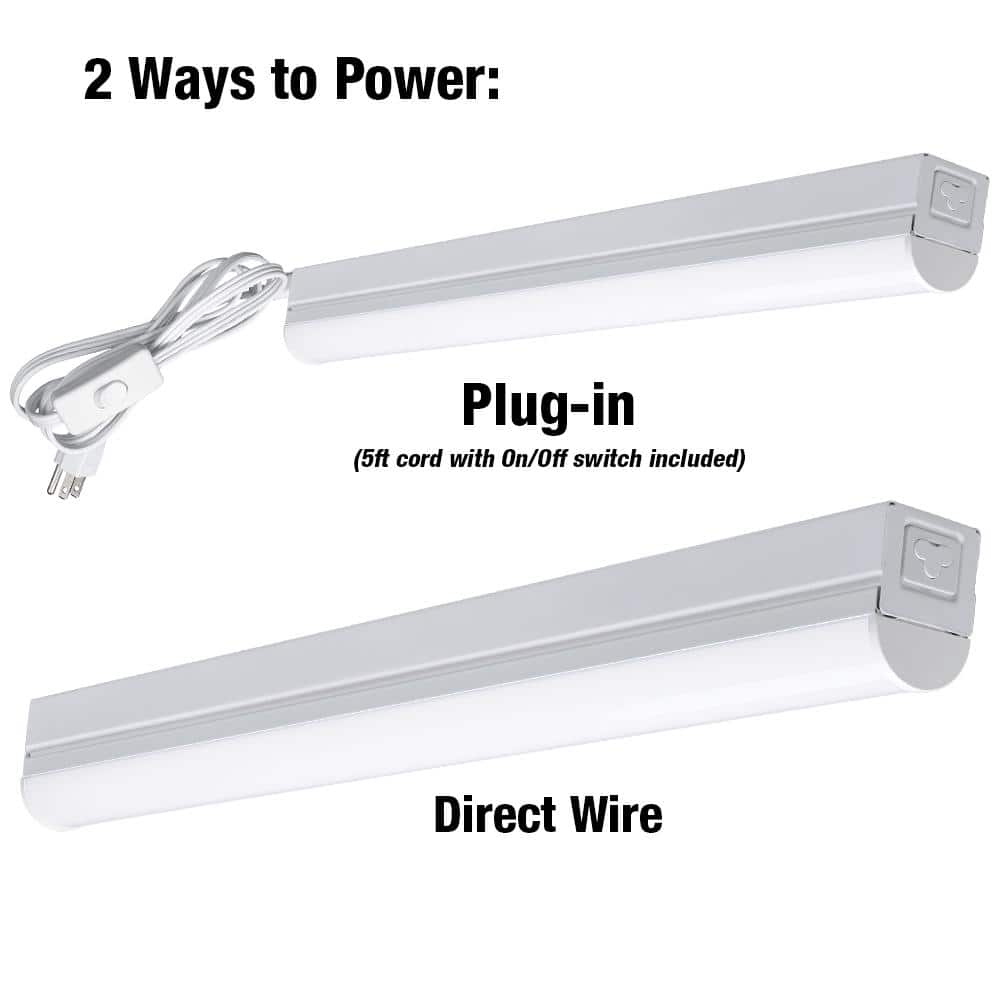

Verify local voltage: 120 V (N-America) or 220-240 V (EU/Asia); our PCB-integrated rectifier auto-senses 110-277 V, 50/60 Hz.

Confirm total load ≤ 80 % of branch breaker; each 5 m reel draws 45 W @ 120 V (0.38 A).

Use only factory-supplied polarized plug or WAGO 2273 series for hard-wire conversion—maintains ETL continuity.

2. Mounting & Thermal

Aluminum channel mandatory for >600 lm/m to keep junction ≤70 °C; 3M VHB tape is auxiliary, not primary.

Minimum 10 mm gap from heat-sensitive surfaces (wood, EPS); maintain 50 mm clearance from fluorescent ballasts to avoid EMI.

3. IP65 Outdoor Runs

End-cap silicone (Dow Corning 7091) cure 30 min before energizing.

Threaded cable gland M16 × 1.5 for through-wall feed; torque 1.2 Nm—prevents capillary ingress that voids CE IP rating.

4. Dimming & Controls

TRIAC forward-phase dimming compatible down to 10 % without shimmer (tested with Lutron MACL-153M).

0-10 V or DALI available on OEM basis—add 2-pair 22 AWG in trunk; share class-2 separation per UL 8750.

5. Code Compliance Snapshot

| Market | Standard | Document We Provide |

|---|---|---|

| USA/Canada | UL 2108 + CSA C22.2 No. 250.4 | ETL certificate & DGUV report |

| Europe | EN 60598-2-21, EN 62031 | TUV CE DoC, RoHS 10 substances |

| Australia | SAA RCM | CB test report, LoA |

Quick Specification Reference (Factory-Direct Reel)

| Parameter | Value |

|---|---|

| Input | 120-277 V AC, 50/60 Hz (integrated bridge) |

| Power | 9 W/m, 45 W/5 m reel |

| Lumen efficacy | 110 lm/W @ 4000 K, CRI 90 |

| Binning | 3 SDCM, MacAdam ellipse |

| IP grade | IP20 (indoor) / IP65 (outdoor sleeve) |

| Cut segment | 50 mm (every 6 LEDs) |

| Lifetime | L70 >54 000 h @ 45 °C Tc |

| Warranty | 5 years (conditions apply) |

OEM/ODM Support

PCB width 8-20 mm, copper ≥2 oz, single or double-side SMT.

Custom CCT 2400-6500 K, CRI 80-97, bin-code traceability for each reel.

Private-label packaging, barcode & QR trace system—ready for distributor ERP upload.

For project submittals or sample reels, email [email protected] or WhatsApp +86-13902885704.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Your Trusted Source for Certified LED Solutions

Global Compliance & Quality Assurance

Beauty STC Lighting meets the stringent requirements of international markets through certified products and rigorous quality control. Our manufacturing processes adhere to global standards, ensuring reliability and safety for end-users.

| Key Metric | Detail |

|---|---|

| Certifications | ETL (USA/Canada), TÜV CE (Europe) |

| Years in Operation | 25+ (since 1998) |

| Export Markets | 50+ countries across Europe, Americas, Asia, Australia, Russia, Japan, Korea |

| Manufacturing Capabilities | Full OEM/ODM services with in-house production |

25+ Years of Manufacturing Expertise

Established in 1998, Beauty STC Lighting has consistently delivered high-performance LED solutions through decades of industry experience. Our commitment to quality is embedded in every stage of production, from component selection to final testing. This long-standing expertise ensures that our products meet the evolving demands of commercial and industrial applications.

OEM/ODM Capabilities

We provide tailored solutions for diverse project requirements. Our engineering team collaborates with clients to develop customized LED strip lights, including specifications for voltage (120V/220V), color temperature (2700K–6500K), CRI >90, waterproofing (IP20–IP67), and dimming compatibility (TRIAC, 0-10V). All products are manufactured to exact technical specifications while maintaining compliance with international safety standards.

Contact Us for Your Project

For inquiries regarding specifications, certifications, or custom solutions, contact our export team directly:

Email: [email protected]

Phone: +86 13902885704

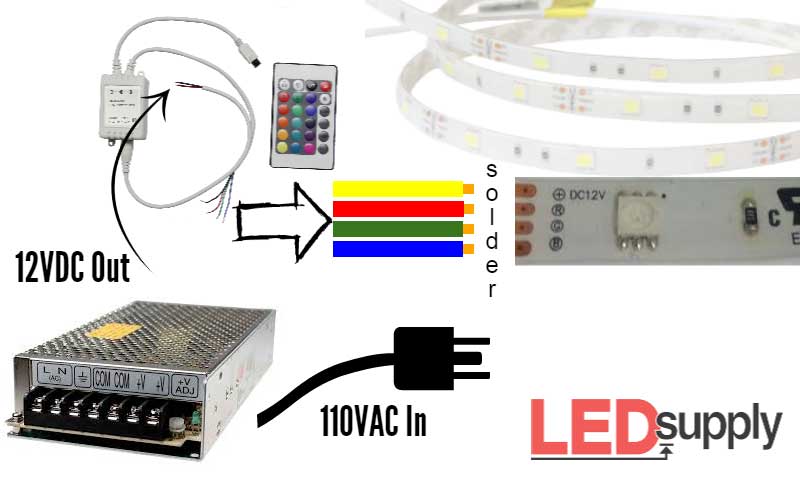

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).