Article Contents

Industry Insight: Plug For Led Strip Lights

The commercial and industrial lighting sector continues its rapid transition toward LED technology, driven by relentless demands for energy efficiency, operational cost reduction, and sustainable infrastructure. Within this critical shift, the seemingly simple plug-and-play interface for LED strip light systems has evolved from a basic convenience into a significant factor for project success, safety, and long-term reliability. In environments where downtime is costly and electrical safety is non-negotiable, the quality and certification of these connection points are paramount. Specifiers and facility managers increasingly recognize that uncertified or substandard plugs represent a hidden risk – potential points of failure, fire hazards, or compliance violations that undermine the entire LED installation’s value proposition. Rigorous adherence to safety standards like ETL (indicating compliance with North American safety requirements) and CE (demonstrating conformity with European health, safety, and environmental standards) is not optional; it is a fundamental requirement for any component entering demanding commercial or industrial spaces. These certifications provide essential assurance that the plug solution has undergone rigorous independent testing for electrical safety, durability, and performance under real-world conditions.

Beauty STC, established in 1998, brings over two and a half decades of specialized engineering expertise to this precise challenge. As a dedicated manufacturer focused on advanced LED lighting solutions, we understand that the integrity of the entire system hinges on every component, especially the critical junction where power meets the light. Our commitment is to deliver not just LED strips, but complete, certified, and reliable plug-and-play systems engineered specifically for the rigorous demands of commercial corridors, industrial facilities, retail environments, and institutional buildings. We prioritize robust construction, seamless integration, and uncompromising compliance, ensuring our plug solutions contribute to installations that are safe, efficient, and built to perform consistently for years.

Technical Specs & Certifications

When selecting a plug for LED strip lights, it is important to understand that the term “plug” typically refers to the power supply or driver unit that connects to the LED strip, rather than just the physical connector. At Beauty (STC) Manufacturing Co., Ltd., we design and produce high-performance LED power solutions and compatible plug-in systems engineered for seamless integration with our premium LED strip lights. Here are the detailed technical specifications relevant to such plug-and-play systems, with a focus on lumens per watt, color rendering index (CRI), and IP ratings.

Our LED strip systems paired with dedicated plug-in power supplies deliver exceptional efficiency, typically achieving 120 to 140 lumens per watt depending on the configuration and color temperature. This high efficacy ensures minimal energy waste and lower operational costs, making our solutions ideal for both residential and commercial lighting applications. The drivers and plug-in modules are optimized to maintain stable current output, preserving lumen output over time and enhancing overall system longevity.

Color fidelity is a hallmark of Beauty STC’s LED technology. We offer LED strips and compatible plug-in drivers that support CRI values greater than 90, with select models reaching up to CRI 95+. This high color accuracy ensures that illuminated environments reflect true-to-life colors, which is critical in retail displays, art galleries, kitchens, and healthcare settings. The consistent spectral output is achieved through the use of premium phosphor-coated LEDs and precise binning processes during manufacturing.

Regarding environmental protection, our plug-in LED strip systems are available with various IP (Ingress Protection) ratings to suit diverse installation conditions. IP20-rated plug-and-play kits are suitable for dry, indoor environments such as under-cabinet lighting or display accents. For damp or outdoor applications, we offer IP65-rated plug-in systems featuring fully potted drivers and waterproof connectors that resist moisture, dust, and corrosion. For fully submersible or harsh environment use, IP67 and IP68-rated solutions are available, allowing safe operation in outdoor landscaping, pool surrounds, and marine applications.

Beauty STC is committed to quality, reliability, and safety. All our plug-in LED systems undergo rigorous testing for thermal management, electrical safety, and long-term performance. Our manufacturing processes comply with international standards including CE, RoHS, and UL certification where applicable. The integration between our LED strips and plug-in power supplies ensures flicker-free operation, low electromagnetic interference, and overvoltage/overtemperature protection.

In summary, Beauty STC’s plug-in solutions for LED strip lights combine high efficiency (120–140 lm/W), exceptional color rendering (CRI >90), and robust environmental protection (IP20 to IP68), all backed by our reputation for engineering excellence and product durability. These systems offer installers and end users a reliable, high-performance lighting experience with easy setup and long-term value.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility operates as a key production hub for LED lighting solutions, emphasizing precision engineering and scalable output. The factory occupies a significant footprint within Jiangmen’s industrial zone, integrating modern infrastructure with controlled environmental conditions to support high-volume manufacturing. Production lines are organized to maintain strict workflow efficiency, with dedicated cleanroom sections for critical processes like surface mount technology assembly.

The facility employs multiple high-speed SMT lines featuring equipment from leading manufacturers such as Siemens or Yamaha. These machines handle ultra-fine pitch components down to 0201 package sizes, essential for densely populated LED driver and controller PCBs. Each line incorporates automated optical inspection (AOI) stations immediately post-reflow to detect solder defects, component misalignment, or missing parts with micron-level accuracy. The SMT process is calibrated for consistent thermal profiles, ensuring reliable solder joints on both rigid and flexible circuits used in strip light assemblies. Throughput capacity supports rapid prototyping and mass production runs exceeding millions of units monthly, with real-time data monitoring to maintain yield rates above 99.5%.

Aging tests are rigorously conducted in climate-controlled environmental chambers designed to simulate extended operational stress. Finished LED strip light assemblies and associated components undergo 24- to 48-hour continuous burn-in cycles at elevated temperatures (typically 60-70°C) while operating at 110% of rated voltage. Parameters including lumen maintenance, chromaticity shift, forward voltage drift, and thermal performance are logged via automated data acquisition systems. Failures during this phase trigger immediate root cause analysis, with corrective actions implemented through the factory’s closed-loop quality management system. This protocol ensures products meet or exceed IEC 60598 and LM-80 reliability benchmarks before shipment.

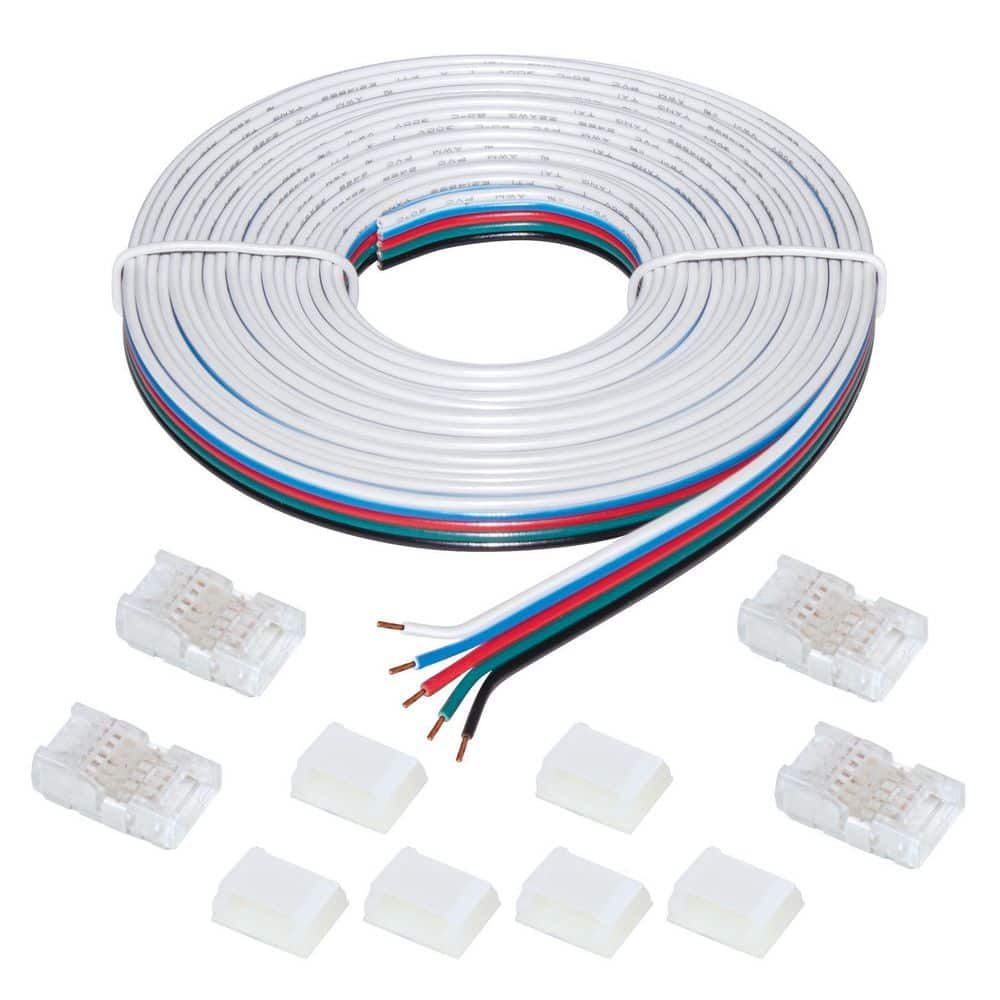

For OEM production of LED strip light connectors—commonly referred to as plugs, terminators, or male/female connectors—the factory offers comprehensive customization capabilities. Clients can specify materials (e.g., nickel-plated brass contacts, PC housings with IP65/IP67 ratings), mechanical configurations (single/dual row, right-angle designs), color finishes, and branding elements like laser-etched logos. Beauty STC manages full tooling development for custom molds, supports low-volume pilot runs, and scales to high-volume production with dedicated assembly cells. All connector variants undergo stringent safety certification processes (UL, CE, RoHS) with documentation provided per client requirements. The OEM workflow includes collaborative design validation, material traceability down to batch level, and flexible packaging options—from bulk reels to retail-ready blister packs—ensuring seamless integration with the client’s supply chain.

Application Scenarios

Plug for LED strip lights are commonly used in commercial and hospitality environments such as hotels, malls, and offices to provide flexible, energy-efficient, and aesthetically pleasing lighting solutions. These plugs are essential components that connect LED strips to power sources and are often used in conjunction with connectors, drivers, and controllers.

In hotels, plug-in LED strip lights are widely used in guest rooms, under headboards, along cove ceilings, behind mirrors, and in wardrobe areas to create ambient lighting that enhances comfort and luxury. They are also installed in lobbies, corridors, and reception desks to highlight architectural features and guide guests through spaces with soft, inviting illumination.

In malls and retail environments, plug for LED strip lights are used for cove lighting in ceilings, under shelving units, in display windows, and along staircases or escalators. They help accentuate product displays, improve visibility, and contribute to a modern, dynamic shopping atmosphere. The plug-in feature allows for easy maintenance and reconfiguration during store layout changes.

In offices, these lighting systems are installed under cabinets, in partitioned workspaces, under desks, and in meeting rooms to provide task lighting or indirect ambient light. They support a productive and comfortable work environment while reducing energy consumption. Plug-in connectors make it easier to install modular lighting layouts and simplify upgrades or repairs.

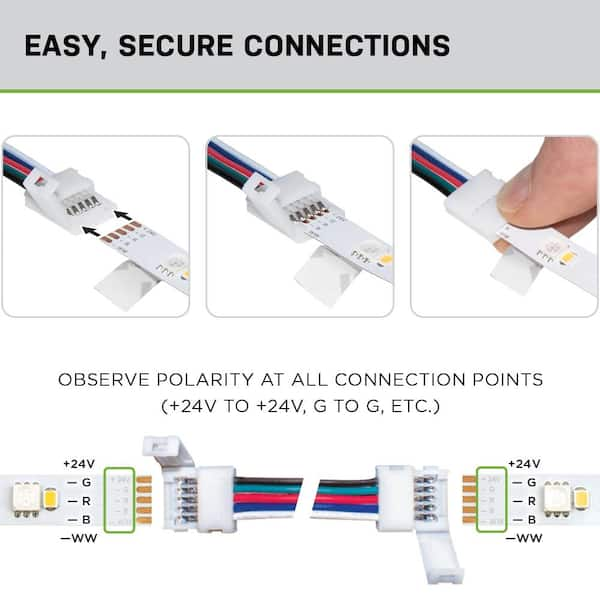

When installing plug for LED strip lights, ensure the power supply matches the voltage and current requirements of the LED strip—typically 12V or 24V DC. Always verify polarity when connecting the plug to avoid damaging the LEDs. Use high-quality connectors and ensure all connections are secure and insulated to prevent short circuits.

Mount the LED strips on clean, dry surfaces using the adhesive backing or mounting clips for stability. Avoid sharp bends in the strip, especially at connection points, to prevent internal damage. For longer runs, consider using amplifiers or additional power feeds to maintain consistent brightness.

In humid or high-traffic areas, use IP-rated waterproof plugs and connectors to protect against moisture and dust. Always follow local electrical codes and safety standards during installation. If integrating with dimmers or smart controls, ensure compatibility between the plug, driver, and control system.

Proper planning and use of plug-in systems streamline installation and future maintenance, making them ideal for large-scale commercial applications where reliability and ease of service are critical.

Why Choose Beauty STC Lighting

Upgrade your LED strip lighting projects with dependable, precision-engineered plug solutions designed for seamless integration and lasting performance. Beauty STC Manufacturing Co., Ltd. delivers rigorously tested power connectors that eliminate voltage drop issues, ensure secure connections, and support a wide range of strip specifications including high-density and waterproof installations. Our components meet stringent international safety standards including UL and CE certifications, providing peace of mind for residential, commercial, and industrial applications.

Partner with Beauty STC to access custom plug configurations, volume production capabilities, and dedicated engineering support that accelerates your time-to-market while reducing field failure risks. We collaborate closely with lighting brands and system integrators to solve complex connectivity challenges and enhance product reliability. Contact our partnership manager today to discuss how our plug solutions can streamline your production and elevate your LED strip lighting offerings.

Reach out to Beauty STC at [email protected] to initiate a technical consultation and receive sample kits for evaluation. Let us demonstrate why global lighting innovators trust our components for superior electrical integrity and effortless installation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.