Article Contents

Industry Insight: Orange Led Tape

The strategic application of specialized color temperature in commercial and industrial lighting continues to evolve beyond standard white spectrums, with orange LED tape emerging as a critical solution for specific functional and safety-driven environments. Unlike decorative residential uses, orange illumination in warehouses, manufacturing floors, transportation hubs, and emergency egress systems serves vital purposes such as enhancing visibility in low-light fog conditions, delineating hazardous zones, or providing non-disruptive nighttime guidance that preserves night vision. This niche demand requires lighting solutions engineered for rigorous duty cycles, environmental resilience, and strict adherence to electrical safety standards, where certifications like ETL (verifying compliance with North American safety norms) and CE (confirming alignment with European health, safety, and environmental requirements) are non-negotiable prerequisites for specification and installation. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to mastering such precision lighting challenges. As a leader in high-performance LED tape solutions, we combine deep industry expertise with rigorous quality control to deliver orange LED tape products that meet exacting commercial and industrial demands, ensuring reliability, regulatory compliance, and optimal functionality where standard lighting falls short. Our commitment lies in transforming specialized color requirements into engineered realities for the built environment.

Technical Specs & Certifications

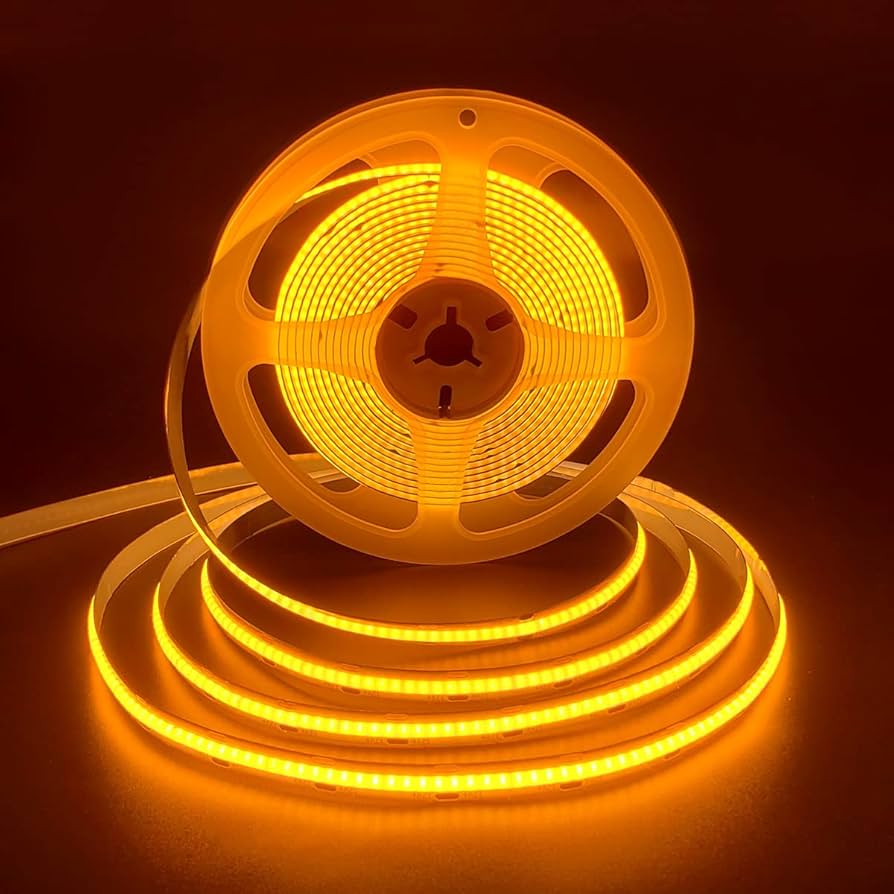

The orange LED tape offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in both residential and commercial lighting applications. Designed with precision, this LED tape delivers consistent warm orange illumination with excellent color rendering and energy efficiency.

In terms of efficiency, the orange LED tape achieves a luminous efficacy of approximately 90 to 110 lumens per watt, depending on the specific configuration and density of LEDs per meter. This high lumens-per-watt ratio ensures optimal energy consumption while maintaining bright, vibrant light output suitable for accent, cove, or decorative lighting.

A key feature of Beauty STC’s orange LED tape is its high Color Rendering Index (CRI), consistently exceeding 90. This superior CRI ensures that colors appear natural and true under the light, making it ideal for environments where visual accuracy and ambiance are critical, such as retail displays, hospitality spaces, and high-end architectural interiors.

Regarding environmental protection, the orange LED tape is available in multiple IP rating configurations to suit diverse installation conditions. Standard options include IP20 for dry indoor environments, IP65 for resistance against dust and low-pressure water jets—suitable for kitchens, bathrooms, or outdoor signage—and IP67 for full dust tightness and temporary water submersion, making it appropriate for demanding outdoor or industrial applications.

Beauty (STC) Manufacturing Co., Ltd. upholds stringent quality control throughout the production process, using premium-grade SMD LEDs, robust flexible PCBs, and high-purity phosphor coatings to ensure long lifespan, stable color consistency, and minimal lumen depreciation over time. All LED tapes are subjected to rigorous testing for thermal performance, electrical safety, and environmental durability, meeting international standards including RoHS and REACH compliance. This commitment to quality positions Beauty STC as a trusted provider of high-performance LED lighting solutions in the global market.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, vertically integrated manufacturing facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta electronics manufacturing hub. This factory serves as a core production center for our LED lighting products, featuring advanced automation and stringent quality control processes throughout the manufacturing flow. The facility is designed to handle high-volume production while maintaining flexibility for specialized OEM requirements, adhering to international standards for safety and environmental management.

The surface mount technology (SMT) production line within the Jiangmen factory utilizes state-of-the-art automated assembly equipment. We deploy high-speed, multi-head SMT pick-and-place machines from leading manufacturers such as Yamaha and Panasonic. These machines are capable of handling ultra-fine pitch components down to 0201 package sizes and managing complex double-sided PCB assemblies essential for high-density LED tape production. The line incorporates automated solder paste printing with precision stencils, nitrogen-reflow soldering profiles optimized for thermal-sensitive LED components, and comprehensive automated optical inspection (AOI) systems. These AOI systems perform 100% real-time checks on component placement, solder joint quality, and polarity immediately after reflow, ensuring minimal defects before the boards proceed to subsequent stages like conformal coating or connector attachment.

Robust aging and reliability testing is a critical, non-negotiable phase for all LED tape products manufactured at our Jiangmen site. Every production batch undergoes mandatory extended burn-in testing. Tapes are subjected to continuous operation at elevated temperatures, typically 85°C, for periods ranging from 24 to 72 hours depending on the specific product specification and customer requirements. This process, conducted in dedicated environmental chambers, effectively identifies early-life failures and infant mortality issues related to component weaknesses or assembly flaws. Concurrently, we perform rigorous photometric and electrical parameter validation before and after aging to measure lumen maintenance, chromaticity shift, and driver stability. Additionally, accelerated life testing under high-temperature/high-humidity conditions (85°C/85% RH) is routinely conducted on sample batches to predict long-term reliability and validate our product lifespan claims.

Beauty STC possesses significant OEM capability specifically tailored for customized LED tape solutions, including what is commonly referred to as ‘orange LED tape’ in the market. This term typically denotes LED tapes emitting a very warm white light, often in the 2200K to 2700K color temperature range, sometimes with a slight amber or reddish hue preferred for specific hospitality, residential, or decorative applications. Our Jiangmen factory excels in providing end-to-end OEM services for such specialized products. We work closely with clients to define exact spectral requirements, whether it’s achieving a specific CCT within the warm spectrum, optimizing for high CRI (Ra >90) for color fidelity, or fine-tuning the spectral power distribution to enhance the perceived ‘orange’ warmth. We offer customization across multiple parameters including LED chip selection and binning, phosphor formulation, PCB design (flexible or rigid), voltage options (12V, 24V, constant current), waterproofing levels (IP20 to IP68), and cutting increments. The process encompasses collaborative design, prototyping, rigorous validation against the client’s unique specifications, and seamless transition to volume production with dedicated line setup and traceability, all supported by our in-house engineering and quality assurance teams at the Jiangmen facility.

Application Scenarios

Orange LED tape is a versatile lighting solution that adds warmth, vibrancy, and visual interest to interior spaces. Its warm, energetic hue makes it particularly suitable for environments where ambiance and aesthetic appeal are important. Below are recommended applications in hotels, malls, and offices, followed by key installation tips.

In hotels, orange LED tape works exceptionally well in lobbies, hallways, and feature walls to create a welcoming and luxurious atmosphere. It can be installed under reception desks, along stair treads for safety and style, or within cove lighting in guest corridors to evoke a sense of comfort. In lounge areas or bars, accent lighting with orange LEDs enhances the mood and supports brand identity through dynamic color schemes.

Malls benefit from orange LED tape in signage backlighting, display windows, and architectural coves to draw attention to retail spaces and promotions. The color orange is known to stimulate appetite and excitement, making it ideal for food courts, entertainment zones, or youth-oriented stores. Wrapping columns or outlining architectural features with orange tape can create visual landmarks within large spaces, aiding navigation while adding aesthetic flair.

In office environments, orange LED tape should be used selectively to energize common areas such as break rooms, reception zones, or collaborative workspaces. It can help reduce the sterility of corporate interiors and foster creativity. However, it is generally not recommended for focused work areas, as the vibrant tone may be distracting. Instead, use it to highlight design elements like partition edges, shelving units, or ceiling perimeters for a modern, dynamic look.

When installing orange LED tape, start by ensuring the surface is clean, dry, and free of dust or grease to promote strong adhesion. Use a high-quality double-sided tape or mounting clips for surfaces where the adhesive may not bond well. Always plan the layout in advance, measuring the run length and determining power supply placement to avoid voltage drop—especially for longer runs. For optimal performance, use a constant voltage power supply matched to the tape’s specifications and consider using a controller if dimming or color-changing functionality is desired.

Cut the tape only at designated cut points to maintain circuit integrity. Solder or use proper connectors when joining sections to prevent loose connections. In high-traffic or exposed areas, protect the tape with an aluminum channel or diffuser to shield it from physical damage and reduce glare. Finally, ensure all electrical connections are properly insulated and comply with local safety codes, and consider professional installation for complex or large-scale applications.

Why Choose Beauty STC Lighting

For professionals seeking high-performance orange LED tape solutions that deliver exceptional color consistency and reliability, Beauty STC Manufacturing Co., Ltd. provides the engineering expertise and manufacturing precision you require. Our specialized orange LED tape is engineered with strict spectral control to ensure vibrant, true-to-spec illumination critical for retail displays, hospitality ambiance, and architectural accent lighting where standard LEDs fall short. We address common industry challenges like color shift over time and thermal degradation through proprietary phosphor formulations and robust thermal management designs within our flexible tape architecture.

As your dedicated lighting engineering partner, Beauty STC offers fully customizable solutions including tailored lumen output, CRI optimization, and IP-rated variants for demanding environments. Our in-house R&D team collaborates directly with clients to refine optical performance and mechanical integration, ensuring your orange lighting application meets both aesthetic and functional specifications without compromise. We maintain rigorous quality control from substrate selection to final reel testing, providing documentation for photometric performance and material compliance to support your project validation.

Partner with Beauty STC to transform your orange LED tape requirements into a technically superior, production-ready solution. Contact our engineering management team directly at [email protected] to discuss your project specifications, request samples, or initiate a collaborative design review. We are prepared to provide the technical consultation and scalable manufacturing support needed for your next-generation lighting application.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.