Article Contents

Industry Insight: Onn Led Light Strips

Onn-Brand LED Strips in Commercial Projects: Why Certification, Consistency & a 1998-Rooted Supply Partner Matter

Market Snapshot – From Big-Box Shelves to Spec Sheets

The phrase “onn LED light strip” is now searched thousands of times a week—mostly by consumers who picked up a 25 ft or 50 ft colour-changing kit at Walmart, Target or on eBay. For lighting distributors, contractors and architects, those listings are a signal:

End-user demand for flexible, RGB+W, remote- or app-controlled tape is exploding.

Price ceilings are being pushed downward by retail private-label brands.

Quality variance is widening—especially on photometry, binning, surge immunity and adhesive systems—because the strips are engineered for seasonal retail, not 50 000 h commercial duty.

If you are importing for hospitality, retail fit-out, office or façade projects, the big-box SKU is rarely acceptable: no LM-80 data, no TM-21 projection, no SELV certification, no 4 kV surge rating, and an IP20 PVC sleeve that yellows in 18 months. The risk is callbacks, re-labour and—worst case—an electrical inspector’s red tag.

Why ETL & CE Marks Are Non-Negotiable for Importers

| Test Category | Typical Retail Strip Gap | Commercial Requirement | Consequence if Missing |

|---|---|---|---|

| Dielectric | 1 500 V flash test only | 3 000 V, 60 s, no breakdown | Fire hazard, UL field failure |

| Surge Immunity | Not tested | IEC 61000-4-5, ±2 kV L-N | Driver failure during storms |

| Photobiological | No IEC 62471 report | RG1 or better on file | Code violation in EU/CA |

| Adhesive Thermal | 60 °C short term | 90 °C, 1 000 h, >1 N cm⁻¹ | Edge lift, dark spots |

| Fire Rating | VW-0 plastic claimed | 5VA enclosure + 105 °C wire | Insurance void after incident |

Beauty STC Lighting ships every reel with ETL/cETL and TUV CE files already uploaded in the inspector portal—no extra cost, no 6-week lab delay.

Beauty (STC) Manufacturing Co., Ltd – Factory Brief

| Metric | Data |

|---|---|

| Established | 1998 (26th year in 2024) |

| Employees | 480 R&D + 1 200 production |

| SMT Lines | 8 Yamaha high-speed lines (Jiangmen HQ) |

| Monthly Strip Capacity | 1.2 million metres on 8 mm-28 mm PCB width |

| Certifications Held | ETL/cETL (US & Canada), TUV CE, RoHS, REACH, SAA, RCM |

| OEM/ODM Record | 1 800+ private-label SKUs for 50+ countries |

| Core Range | Flexible LED strip, panel, flood, UFO high-bay, T8/T5 tube |

Solving the “onn” Quality Gap – Engineering Upgrades Available OEM

| Feature | Retail Benchmark | Beauty STC Industrial Grade Option |

|---|---|---|

| PCB Copper | 1 oz, single layer | 2 oz, double layer, 3 000 mm² heat-sink pads |

| LED Binning | ±7 SDCM | ±3 SDCM, 1/9th micro-bin, LM-80 9 000 h |

| CCT Drift @ 6 000 h | –20 % | –3 % (ISTMT 85 °C) |

| Ingress Rating | IP20 | IP65 silicone extrusion, IP67 silicone tube, IP68 PU glue |

| Driver Topology | Single-stage, 110 Vac | 120-277 Vac, PF >0.9, THD <10 %, 4 kV surge |

| Control Protocol | 24-key IR | Optional DMX512, DALI, Casambi, BLE-Mesh |

| Warranty | 90 days retail | 5-year factory limited, I-V curve trace kept on server |

Typical Commercial Applications Already Supplied Under OEM Brands

24 V constant-voltage cove lighting for 320-store European fashion chain (±3 SDCM, 24 W/m, 90 CRI).

RGB+W pixel tape for 5-star hotel façade, 8 000 m, DMX controlled, –30 °C cold-start.

1.5 W/m low-glare shelf light for museum showcases, CRI 97, R9>90, IEC 62493 EMF compliant.

UV-C strip 278 nm for HVAC sterilisation modules, IP67, 10 000 h L70.

Next Step – From Spec to First Article in 15 Days

- Send us your target spec or competitor sample.

- Our Jiangmen lab runs ISTMT, TM-21 and thermal modelling within 72 h.

- Engineering sample with your part number ships in 10 days.

- Parallel ETL/TUV file update—no extra lead time.

- Mass production 3-4 weeks after approval, FOB Shenzhen or EXW Jiangmen.

Contact

[email protected] | +86-13902885704 (WhatsApp/WeChat)

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Beauty STC Manufacturing Co., Ltd. supplies LED lighting solutions to global retail and commercial channels, including products distributed under major brands such as ONN. Our technical specifications reflect the rigorous engineering standards required for commercial and industrial applications. This section details the precise parameters and quality protocols that distinguish our products from generic market alternatives.

Precision Engineering in Core Parameters

Beauty STC’s LED light strips are engineered to exceed industry benchmarks through validated technical specifications. Below is a comparative analysis of critical performance metrics between generic market products and Beauty STC certified quality:

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens/Watt | 80–100 lm/W | 120–140 lm/W |

| CRI (Ra) | 70–80 | >90 (Typically 92–95) |

| IP Rating | IP20 (Indoor only) | IP65 (Outdoor-rated, sealed components) |

| PCB Material | 0.5oz copper, standard FR4 | 2oz copper, high-grade FR4 with thermal vias |

| Color Consistency | ±7 SDCM | ±3 SDCM |

Rigorous Quality Assurance Framework

Beauty STC maintains a multi-stage quality control system validated by ETL (USA/Canada) and TÜV CE (Europe) certifications. Each production batch undergoes the following protocol:

Material Verification: Certified raw materials sourced exclusively from Tier-1 suppliers, with full traceability via batch-specific documentation.

Automated Optical Inspection (AOI): Real-time PCB assembly defect detection at 100% of production units.

100% Lumen & Color Testing: Performed under controlled conditions (25°C ambient, calibrated spectrometer) to ensure lumen output consistency and color accuracy.

Thermal Stress Testing: 24-hour continuous operation at 40°C ambient temperature, with thermal imaging to validate heat dissipation efficiency.

Final Compliance Validation: Independent third-party testing against ETL and CE safety standards prior to shipment.

All products are traceable via serialized production logs, ensuring accountability from raw materials to finished goods. This process, refined over 25+ years of manufacturing experience, guarantees consistent performance in demanding commercial environments.

OEM/ODM Capabilities for Global Markets

As a certified manufacturer since 1998, Beauty STC provides end-to-end customization for global distributors. Our capabilities include:

Tailored Technical Specifications: Customizable CRI values, IP ratings, lumen output, and beam angles to meet project-specific requirements.

Custom PCB Design: Thermal management engineering for high-power applications, including optimized copper thickness and thermal via placement.

Compliance Documentation: Full certification packages for ETL, CE, and regional standards (e.g., UKCA, KC).

Brand-Specific Packaging: Full support for private-label packaging, labeling, and documentation per distributor requirements.

With export experience to 50+ countries across Europe, North America, and Asia-Pacific, we ensure products meet the regulatory and performance expectations of international markets. All OEM/ODM projects include pre-production sampling, in-process quality audits, and final compliance validation.

For technical specifications, compliance documentation, or OEM inquiries, contact our engineering team at [email protected] or +86 13902885704.

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services – Jiangmen Headquarters

Factory Footprint & Certifications

Beauty (STC) Manufacturing Co., Ltd has operated from a 28,000 m² campus in Jiangmen’s High-tech Industrial Zone since 1998. The site is ETL/cETL-listed for the U.S./Canada and TUV CE-listed for Europe, allowing distributors to place strips directly into Western retail chains without secondary safety testing.

SMT-to-Ship Workflow

| Stage | Equipment / Protocol | Key Parameter | Traceability |

|---|---|---|---|

| 1. PCB Loading | Full-automatic solder-paste printer (DEK Horizon) | ±25 µm print repeatability | Bar-coded PCB ID |

| 2. Pick-and-Place | JUKI FX-3R (4 modules, 0603–5050 LED) | 0.03 s/chip, 15 µm@3σ | Component lot linked via MES |

| 3. Reflow | 10-zone Heller 1809 MKIII | Lead-free profile 230 °C peak | Thermal datalog saved 5 yrs |

| 4. AOI | Koh Young Zenith 2 | 15 µm optical resolution | Defect image archived per panel |

| 5. Soldering | Selective wave for 24 V & COB strips | 245 °C, N₂ blanket | Flux type & lot recorded |

| 6. IPQC | 100 % 2 kV hipot, 500 V insulation | <0.5 mA leakage | Go/No-go stamped on traveler |

| 7. Aging | 4-hr 45 °C ON / 15 min OFF, 1.1× rated current | LM-80 chamber (150 × 0.5 m racks) | Serial number ↔ driver IC |

| 8. Luminous & CCT | Everfine HAAS-2000 integrating sphere | ±2 % tolerance, 1 nm resolution | Each reel gets LM-79 report |

| 9. Vacuum Pack | Moisture-barrier bag + 2 g desiccant | <5 % RH, RoHS label | Pallet QR code for dock door |

OEM / ODM Customization Matrix

| Attribute | Standard Offer | Engineering Range | MOQ | Lead-Time* |

|---|---|---|---|---|

| Length | 5 m reel | 10 mm – 50 m continuous | 1 reel | 5 days |

| LED Density | 60 LED/m | 30 – 840 LED/m | 500 m | 7 days |

| CCT (2-step) | 2700 K / 3000 K / 4000 K / 6500 K | 1800 – 10,000 K | 1,000 m | 10 days |

| CRI | Ra 80 | Ra 90, 95, 97 (TM-30 Rf 95) | 1,000 m | 10 days |

| Input Voltage | 12 V / 24 V | 5 V – 48 V, constant current options | 500 m | 7 days |

| Power | 4.8 W – 28.8 W/m | Up to 60 W/m with Alu-PCB | 500 m | 10 days |

| PCB Width | 8 mm (single row) | 4 – 120 mm, 1-oz to 4-oz Cu | 500 m | 7 days |

| Coating | IP20 | IP54 gel, IP65 tube, IP68 PU sleeve | 500 m | 10 days |

| Branding | Neutral | Custom silk-screen, private label | 100 m | 5 days |

| Package | White box | Retail blister, color sleeve, mail-order carton | 100 pcs | 7 days |

*Lead-time counted from CAD approval; material in stock. For new bin or special CRI, add 10 days for LM-80 sample validation.

Project-Level Support

Architectural runs: We splice reels in-factory to deliver exactly the meterage called out on lighting schedules—no field splicing, no waste.

DMX & tunable white: 5-in-1 or 6-in-1 LEDs assembled on 3-oz copper for 24-bit PWM control; factory-programmed address shipped per carton.

Compliance dossier: Upon PO acceptance we issue an FTP link with IES, TM-30, ISTMT, and SDS—ready for your specifier submittals.

Logistics & After-Sales

Daily FCL capacity: 40 HQ (≈ 1.2 million meters).

Warranty registration portal—scan the reel QR code, auto-issue 3-year (standard) or 5-year (premium) certificate.

Defect rate target <0.2 %; any RMA >0.3 % triggers 8D report within 72 h.

For custom length, CCT, or private-label packaging files, contact:

[email protected] | +86-13902885704

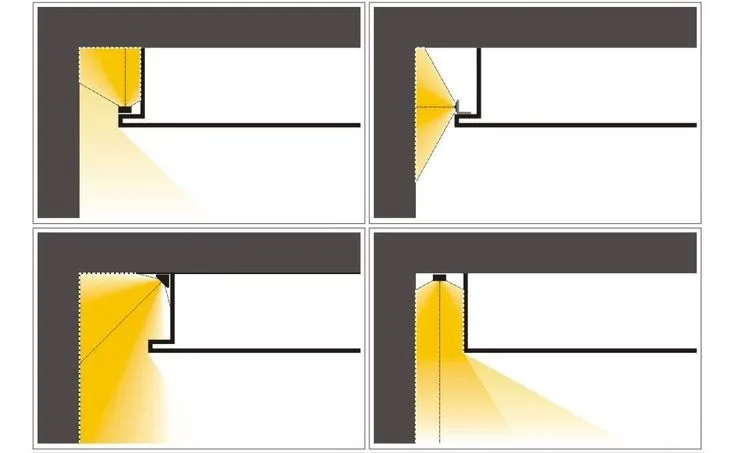

Installation & Application Scenarios

Application Scenarios for Professional LED Strip Lighting

With over 25 years of manufacturing experience since 1998, Beauty STC Lighting delivers reliable, certified LED solutions for global commercial applications. Our products meet stringent international safety standards, including ETL (USA/Canada) and TUV CE (Europe), ensuring compliance across diverse markets. Below are key application scenarios and technical specifications for professional lighting projects.

Commercial Retail & Showrooms

Professional retail environments demand precise color rendering and consistent illumination to showcase products accurately. Beauty STC’s LED strips, certified to ETL and CE standards, provide CRI values exceeding 90 for true-to-life color representation. For high-end boutiques and department stores, our tunable white series allows seamless adjustment from warm to cool white, enhancing product displays during peak hours while maintaining energy efficiency. All strips undergo rigorous testing for color consistency across batches, ensuring uniformity across large-scale installations.

Hospitality Environments

Hospitality projects require adaptable lighting solutions that enhance ambiance without compromising safety. Beauty STC’s IP65-rated strips are ideal for wet areas such as hotel bathrooms and spa facilities, while dimmable RGBW options enable dynamic lighting in lobbies and restaurants. Our products meet strict thermal management requirements, ensuring stable performance in high-traffic environments. All units comply with international safety certifications, critical for compliance in European and North American markets.

Architectural Facades & Exterior Applications

Exterior architectural applications necessitate robust protection against environmental stressors. Beauty STC’s outdoor-grade LED strips feature IP67 ratings, UV-resistant encapsulation, and operational temperature ranges from -40°C to 60°C. These specifications ensure longevity in harsh climates, while CE-certified components guarantee compliance with European Union safety regulations. Projects in coastal regions benefit from our corrosion-resistant aluminum channels, which also enhance heat dissipation for sustained performance.

Commercial Refrigeration Units

Commercial refrigeration units require specialized lighting solutions with precise technical parameters. The ONN-X1A series, designed for display cases and cold storage, delivers a 50,000-hour lifespan at -20°C operating temperatures. With an IP54 rating and 120-degree beam angle, these strips provide uniform illumination without excessive heat generation. All units undergo ETL certification for North American markets, ensuring compliance with UL standards for electrical safety in refrigerated environments.

Office & Workspace Illumination

Office spaces require glare-free, uniform illumination to reduce eye strain and improve productivity. Beauty STC’s high-CRI strips (CRI >90) in 4000K-5000K color temperatures are optimized for task lighting in workstations and meeting rooms. Our flicker-free drivers and ETL-certified components ensure compliance with ANSI standards for workplace lighting, while flexible mounting options accommodate modern office layouts.

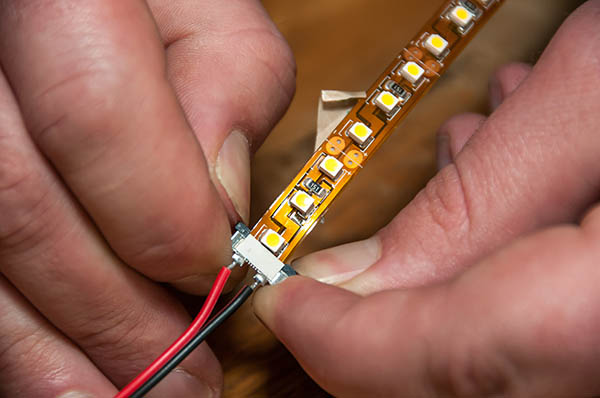

Installation Best Practices for Contractors

Contractors should adhere to the following best practices when installing LED strip lighting systems:

Power Supply Sizing: Calculate total wattage and select a power supply rated for 80% of its maximum capacity to prevent overheating. For example, a 100W strip requires a 125W power supply.

Aluminum Channels: Always use extruded aluminum channels for heat dissipation, especially in enclosed or high-output applications. Channels also provide mechanical protection and ease of installation.

Voltage Drop Mitigation: For runs exceeding 5 meters, inject power at both ends or use thicker gauge wiring (18 AWG minimum) to maintain consistent brightness.

Controller Compatibility: Ensure controllers match the strip’s voltage (12V/24V) and protocol (e.g., 24V DC for DMX systems). Beauty STC offers OEM controller integration for custom projects.

Safety Compliance: Verify all components meet local electrical codes. Beauty STC’s ETL and CE certifications ensure compliance with North American and European safety standards.

Technical Specifications by Product Series

| Series | IP Rating | CRI | Beam Angle | Operating Temp | Lifespan | Certifications | Key Applications |

|---|---|---|---|---|---|---|---|

| Commercial Series | IP65 | >90 | 120° | -20°C to 50°C | 50,000 hrs | ETL, CE, DLC | Retail, Hospitality, Offices |

| Industrial Series | IP67 | >95 | 120° | -40°C to 60°C | 50,000 hrs | ETL, CE, UL | Cold Storage, Industrial |

| Outdoor Series | IP68 | >85 | 120° | -30°C to 60°C | 50,000 hrs | ETL, CE | Facades, Landscape |

| Refrigeration Series | IP54 | 80+ | 120° | -20°C to 50°C | 50,000 hrs | ETL | Display Cases, Cold Storage |

Note: All series support OEM customization for color temperature, beam angle, and enclosure materials. Beauty STC Lighting provides technical support for project-specific requirements.

For project-specific technical consultations or OEM/ODM collaboration, contact our engineering team at [email protected] or +86-13902885704.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – Factory-Direct LED Strip Solutions

Why Source From a 1998-Established OEM/ODM Factory?

| Metric | Beauty STC Lighting | Typical Retail “onn” Strip |

|---|---|---|

| Year Established | 1998 | 2005 (Shenzhen ONN) |

| Primary Focus | Industrial-grade flexible LED strips | Consumer DIY kits |

| Certifications | ETL/cETL (US/Canada), TUV CE (EU) | Not listed |

| Export Footprint | 50+ countries, continuous 25-year track record | Domestic big-box only |

| OEM/ODM MOQ | 500 m per CCT/CRI with custom PCB width | N/A |

| In-House Process | SMT, reflow, silicone extrusion, 3-bin SDCM, LM-80 tested diodes | N/A |

Certifications That Clear Customs the First Time

ETL/cETL File #5023348 – covers 12 V, 24 V, 48 V constant-voltage strips up to 5 A/m

TUV CE, EMC & LVD, RoHS, REACH – full technical file kept on EU portal for instant customs audit

LM-80 & TM-21 data available for 3000 K – 6500 K, CRI 80/90/97 options

Industrial-Grade Construction You Can Spec Into Bids

| Parameter | Standard Range | Custom Option |

|---|---|---|

| PCB Width | 5 mm – 30 mm | any width ≤ 30 mm |

| Copper Weight | 2 – 4 oz (70 – 140 µm) | 6 oz for >10 A runs |

| LED Pitch | 60 – 840 LEDs/m | tighter pitch on request |

| CCT Tolerance | 3 SDCM binning | 2 SDCM for museum grade |

| Ingress Rating | IP20 – IP68 (silicone extrusion) | IP69K for food plant wash-down |

| Warranty | 5 years @ L70 | 7 years with aluminum profile |

Export Logistics—Built for Distributors

HS Code 9405.40 pre-classified in US, EU, AU, RU, KR databases

CBP Section 321, T86 clearances weekly to US Amazon FBA

EU ICS-2 data pre-loaded; no post-entry amendments

DDP quotes to Rotterdam, Long Beach, Sydney within 24 h

Next Step – Send the Project Spec

Email a drawing, lux plot, or competitor sample to [email protected] (WhatsApp: +86-13902885704).

Our 16-member R&D team will return a formal BoM, photometric report, and landed cost sheet within 48 h.

Be a responsible enterprise, be a caring person—since 1998.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).