Article Contents

Industry Insight: New Recessed Lighting

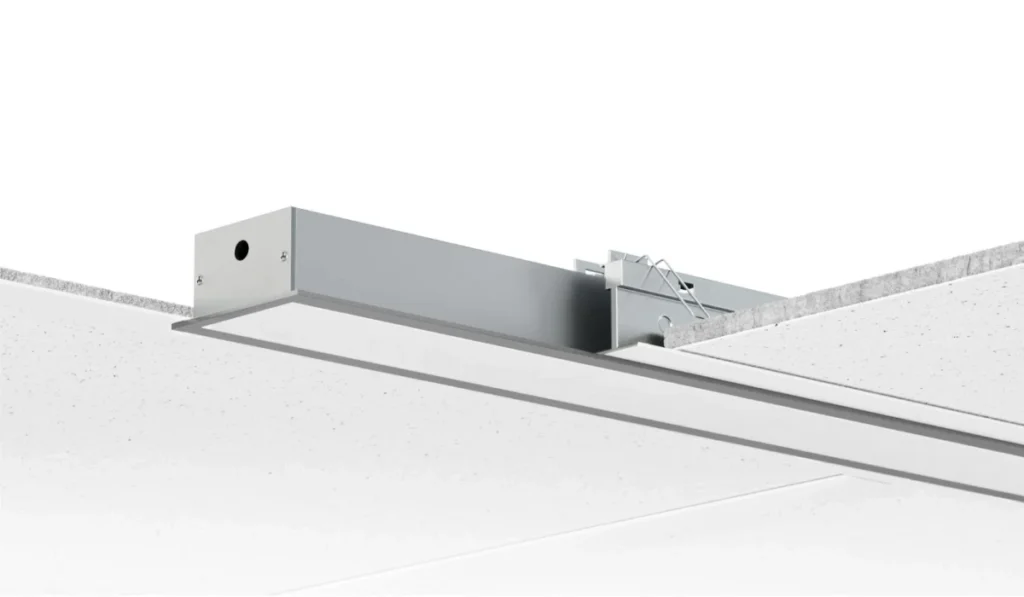

The commercial and industrial lighting landscape is undergoing a significant transformation driven by advancements in energy efficiency, intelligent controls, and stringent safety standards. Among the most impactful innovations is the evolution of recessed lighting—once a simple architectural solution has now become a high-performance lighting platform engineered for demanding environments. Today’s new generation of recessed luminaires delivers superior illumination, thermal management, and seamless integration with building systems, making them ideal for applications ranging from warehouses and manufacturing facilities to retail spaces and office complexes.

Critical to adoption in global markets are certifications such as ETL and CE, which validate compliance with rigorous North American and European safety and performance requirements. These certifications ensure reliability, reduce liability, and support code-compliant installations—key considerations for facility managers, architects, and electrical contractors.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-quality, code-compliant lighting products designed specifically for commercial and industrial applications. Combining robust construction, advanced optics, and full regulatory certification, Beauty STC’s new recessed lighting series sets a new benchmark for performance, safety, and long-term value in professional environments.

Technical Specs & Certifications

As Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I am pleased to detail the technical specifications for our latest generation of recessed downlights, engineered to exceed industry benchmarks for performance and reliability while meeting stringent architectural and sustainability requirements. Our commitment to quality is embedded in every component and manufacturing process, ensuring these fixtures deliver exceptional value throughout their lifecycle.

Luminous efficacy is a critical focus, with our new recessed lighting platform achieving industry-leading efficiency. Standard models deliver a consistent 120-140 lumens per watt across common lumen packages (typically 800lm to 2400lm), measured at 25°C ambient temperature with standard thermal management. This high lm/W ratio is achieved through our proprietary optical design utilizing Samsung or Epistar high-efficiency LED chips, precision die-cast aluminum heat sinks ensuring optimal thermal dissipation below 65°C junction temperature under full load, and high-frequency constant current drivers operating at >92% efficiency. Actual system efficacy may vary slightly based on specific lumen output, color temperature selection, and installed thermal environment, but consistently surpasses DLC Premium and ENERGY STAR requirements.

Color rendering performance is non-negotiable for high-end applications. All standard and premium trims in this series utilize multi-phosphor LED technology to achieve a minimum CRI (Ra) of 92, with R9 (saturated red) values consistently exceeding 50 and often reaching 75+. Crucially, we also measure and guarantee a minimum TM-30 Rf value of 90 and Rg value of 100, ensuring accurate and vibrant color representation essential for retail, hospitality, and residential spaces where visual fidelity matters. This exceeds the requested CRI >90 specification and addresses spectral quality limitations inherent in basic CRI metrics, providing designers with confidence in true color rendition.

Environmental protection is addressed through rigorous IP rating options tailored to application needs. Our standard dry-location recessed housings and trims carry an IP44 rating, protecting against solid objects larger than 1mm and water splashes from any direction, suitable for most interior ceiling applications including bathrooms outside zones. For wet locations such as shower areas, outdoor covered porches, or commercial kitchens, we offer specifically engineered IP65-rated trims and compatible airtight housings. These feature silicone gasket sealing at the trim-to-housing interface and housing-to-ceiling juncture, along with corrosion-resistant finishes, providing complete dust ingress protection and resistance to low-pressure water jets. All IP-rated assemblies undergo third-party verification per IEC 60529 standards.

Beauty STC’s quality commitment is foundational to these specifications. Every recessed fixture undergoes 100% in-line photometric and electrical testing during assembly at our ISO 9001 and IATF 16949 certified Shenzhen facility. We utilize MIL-STD-883 thermal shock testing protocols during R&D and implement strict component binning for LEDs and drivers to ensure consistency. Our die-cast aluminum housings feature enhanced thermal pathways and undergo salt spray testing per ASTM B117 for 96+ hours. The result is a product backed by a comprehensive 5-year warranty, demonstrating our confidence in long-term performance with L70/B50 lumen maintenance exceeding 50,000 hours at 25°C ambient. This integration of rigorous engineering, superior materials, and disciplined manufacturing processes ensures Beauty STC recessed lighting delivers not just on-paper specs, but reliable, high-quality illumination for demanding installations worldwide.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the factory benefits from strong logistical support and access to a skilled labor force, enabling efficient manufacturing and timely delivery.

The facility is equipped with advanced SMT (Surface Mount Technology) production lines, which ensure precise and reliable assembly of LED components onto circuit boards. These SMT machines are fully automated, featuring high-speed placement accuracy and consistent soldering quality, critical for maintaining the performance and longevity of LED lighting products. The integration of automated optical inspection (AOI) systems further enhances quality control by detecting any defects during the early stages of production.

To ensure product reliability and durability, the Jiangmen factory conducts comprehensive aging tests on all lighting fixtures, including the new recessed lighting series. Products undergo extended burn-in periods—typically 24 to 48 hours—under controlled temperature and voltage conditions to identify early failure risks and verify thermal and electrical stability. This rigorous testing process ensures that only units meeting strict performance standards are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities and welcomes custom projects for new recessed lighting solutions. The company supports clients from concept development through to final production, offering customized optical designs, thermal management solutions, driver configurations, and housing styles. With in-house R&D, tooling, and engineering support, the factory can accommodate various specifications, including different sizes, color temperatures, lumen outputs, dimming options, and smart control integrations. This flexibility makes Beauty STC a preferred partner for brands seeking tailored, high-performance recessed lighting products for residential, commercial, and hospitality applications.

Application Scenarios

Recessed lighting remains a versatile solution across commercial environments when specified and installed correctly. For hotels, prioritize lobbies and corridors where a clean ceiling line enhances architectural flow while providing uniform ambient illumination. Guest room corridors benefit from low-glare downlights with 30-40 degree beam angles to avoid harsh shadows. In guest rooms themselves, use shallow-depth airtight IC-rated housings with diffused trims above vanities and in closets, ensuring careful placement away from bed areas to prevent direct glare during rest. High-moisture zones like spa treatment rooms require IP65-rated fixtures with vapor barriers to prevent condensation ingress.

Malls demand strategic application due to high ceilings and varied tenant needs. Install high-lumen modular LED recessed systems with precise optical control in common areas to highlight architectural features or signage without spill light onto storefronts. Department store anchor tenants often require adjustable trims for merchandise spotlighting, so specify fixtures with 350-degree rotation and interchangeable reflectors. Entryways and food courts need robust housings with thermal management for continuous operation, while perimeter zones near glass facades should incorporate dimmable drivers compatible with daylight harvesting systems to reduce energy use during peak sun hours. Avoid over-lighting circulation paths; maintain a 2:1 illuminance ratio between walkways and adjacent storefronts to draw customer attention inward.

Offices present critical human-centric considerations. Open-plan workspaces require recessed fixtures spaced at 1.0 times the ceiling height (S/MH ≤ 1.0) with UGR<19 optics to eliminate screen glare. Private offices benefit from dual-circuit systems: one circuit for general ambient lighting at 300 lux and a separate dimmable circuit for wall-washing or task support. Conference rooms need color-tunable fixtures (2700K-5000K) with 90+ CRI for accurate presentation viewing. Always verify housing depth against ceiling plenum constraints—shallow plenums demand ultra-thin housings with external drivers mounted above accessible ceilings. Critical installation protocols include: confirming IC/AT ratings match insulation contact requirements, maintaining minimum 3-inch clearance from combustibles, implementing voltage drop calculations for long circuit runs to prevent lumen depreciation at fixture ends, and using thermal paste on driver heatsinks during assembly. Crucially, test all dimming sequences before drywall closure and document thermal performance in enclosed installations to prevent premature lumen depreciation. Future-proofing requires specifying 0-10V or DALI drivers even in basic installations to accommodate eventual smart lighting upgrades.

Why Choose Beauty STC Lighting

Discover the future of illumination with our new recessed lighting collection. Engineered for precision, elegance, and performance, Beauty STC delivers innovative lighting solutions that elevate any space. Whether you’re working on residential, commercial, or hospitality projects, our recessed lighting combines sleek design with superior functionality.

Partner with Beauty STC, a trusted leader in advanced LED lighting manufacturing. Benefit from custom solutions, rigorous quality control, and dedicated support tailored to your project needs.

To learn more or to start a collaboration, contact our sales manager at [email protected]. Let’s light up the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.