Article Contents

Industry Insight: Neon Vs Led

The commercial and industrial lighting landscape continues to evolve rapidly, with the transition from traditional neon to modern LED technology representing one of the most significant and impactful shifts. Where traditional neon signage and linear lighting once dominated storefronts, warehouses, and factories, facility managers and lighting specifiers now face a critical evaluation of operational efficiency, safety, and long-term value. Neon, while possessing a certain nostalgic aesthetic, presents well-documented challenges for demanding commercial environments: high energy consumption, significant maintenance requirements due to fragile glass tubes and high-voltage transformers, sensitivity to vibration and weather, and the environmental concerns associated with mercury content. In stark contrast, LED solutions deliver superior energy efficiency, drastically reduced maintenance costs through exceptional longevity and durability, enhanced safety with low-voltage operation, and greater design flexibility. Crucially, for any commercial or industrial installation, adherence to stringent safety and performance standards is non-negotiable. Reputable LED products must carry recognized certifications such as ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements), ensuring reliability and mitigating liability risks for building owners and operators. At Beauty STC Manufacturing Co. Ltd., established in 1998, we have dedicated over 25 years to engineering and manufacturing high-performance, certified LED lighting solutions specifically designed to meet the rigorous demands of the commercial and industrial sectors, providing the reliability, efficiency, and safety these critical applications require. The choice is no longer merely between aesthetics; it is a strategic decision centered on operational excellence and total cost of ownership, where modern LED technology has firmly established itself as the present and future standard.

Technical Specs & Certifications

When comparing neon lighting to LED lighting from a technical standpoint, several key performance metrics highlight the advantages of modern LED solutions, particularly in efficiency, color quality, and durability. Beauty (STC) Manufacturing Co., Ltd. specializes in high-performance LED lighting systems designed to outperform traditional lighting technologies such as neon across these critical parameters.

Lumens per Watt (Efficacy):

LED lighting typically delivers between 80 to 130 lumens per watt, depending on the configuration and application. High-efficiency LED strips and linear fixtures, such as those engineered by Beauty STC, often exceed 110 lm/W while maintaining consistent light output over time. In contrast, traditional neon lighting is significantly less efficient, producing only about 10 to 20 lumens per watt. This stark difference means LED systems consume far less energy to achieve equivalent or superior brightness, resulting in lower operational costs and reduced environmental impact.

Color Rendering Index (CRI):

Achieving a CRI greater than 90 is essential for applications where accurate color representation is critical, such as retail displays, architectural accent lighting, and high-end interiors. Beauty STC’s premium LED products are engineered with high-CRI LEDs, typically rated at CRI >90 and often reaching CRI >95, using carefully selected phosphor blends and binning processes to ensure uniform color quality. Traditional neon lighting, while capable of vibrant colors, does not render a full spectrum of light and cannot be accurately measured using the standard CRI scale due to its narrow emission lines. As such, it falls short in applications demanding true color fidelity.

Ingress Protection (IP) Ratings:

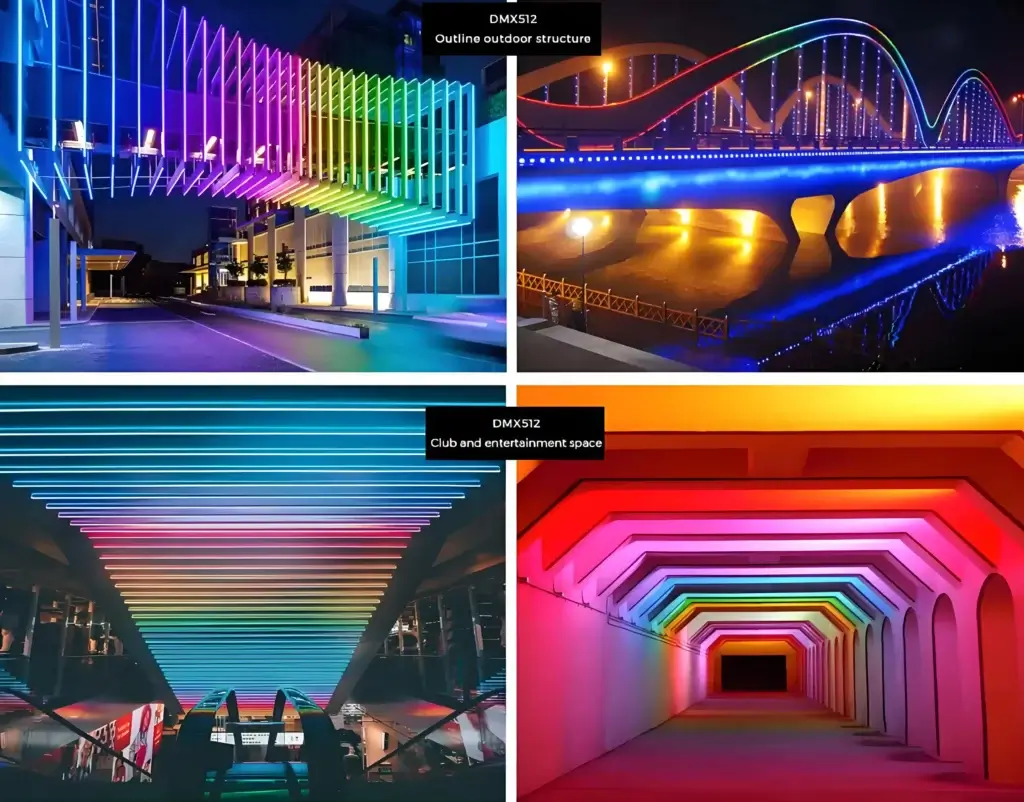

Durability and environmental resistance are where LED solutions from Beauty STC truly excel. Our LED neon flex and linear lighting systems are routinely manufactured with IP65, IP67, and even IP68 ratings, offering complete protection against dust and resistance to water immersion. This makes them ideal for both indoor and outdoor applications, including signage, cove lighting, and façade illumination. Traditional neon, constructed from fragile glass tubes filled with gas, is highly susceptible to breakage and typically lacks standardized IP ratings. Even when housed in protective enclosures, it rarely achieves the same level of environmental resilience as modern sealed LED systems.

Beauty STC’s Commitment to Quality:

At Beauty (STC) Manufacturing Co., Ltd., we prioritize long-term reliability and performance. Our LED lighting solutions are built using high-grade components, including robust silicone jackets, stable constant-current drivers, and thermally efficient PCBs. Each product undergoes rigorous testing for lumen maintenance (LM79, LM80), color consistency, and environmental endurance. By combining superior lumens per watt, exceptional color rendering, and industry-leading IP protection, Beauty STC’s LED systems offer a technically advanced, energy-efficient, and durable alternative to conventional neon lighting.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED lighting production. Strategically located within the Pearl River Delta manufacturing hub, the Jiangmen factory leverages regional supply chain advantages while adhering to stringent international quality standards expected of a leading OEM/ODM supplier. The facility is designed for high-volume, precision manufacturing with a strong emphasis on process control and product reliability.

The core of the surface mount technology assembly within the Jiangmen plant centers around multiple high-speed, high-precision SMT lines. These typically feature state-of-the-art machines from leading manufacturers such as Yamaha or Fuji, configured for dual-lane operation to maximize throughput. Each line integrates fully automated pick-and-place systems capable of handling the smallest 0201 metric components alongside larger LED packages and driver ICs with micron-level accuracy. The process is supported by advanced solder paste printers with laser alignment, multi-zone reflow ovens with precise thermal profiling, and mandatory automated optical inspection stations after both paste printing and component placement. This comprehensive SMT infrastructure ensures consistent solder joint quality and component alignment critical for the thermal management and longevity of LED lighting products.

Rigorous aging and reliability testing form a non-negotiable part of the production flow at the Jiangmen facility. Completed LED light engines and fixtures undergo extended burn-in procedures within dedicated environmental chambers. These aging tests typically subject products to elevated temperatures, often exceeding 65°C ambient, while operating at or above nominal voltage for periods ranging from 48 to 168 hours. This process effectively identifies early-life failures related to component weaknesses, solder joint integrity, or thermal design flaws before products reach customers. Continuous electrical parameter monitoring during aging, including forward voltage and luminous flux measurement, ensures only units meeting strict performance decay thresholds are cleared for final assembly and shipment. This commitment to accelerated life testing directly translates to the high reliability and extended warranty periods Beauty STC offers on its products.

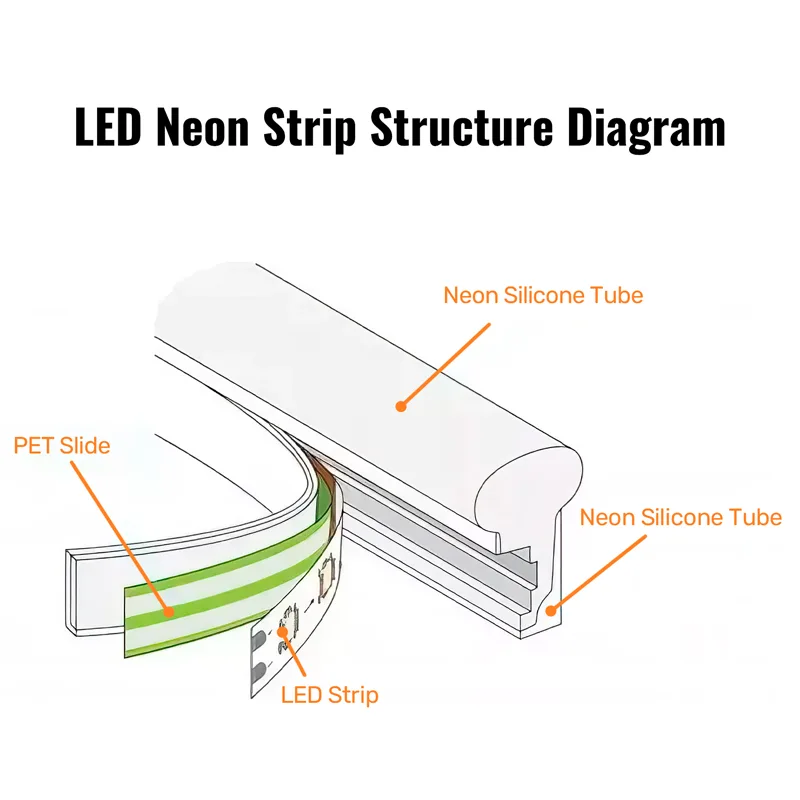

Regarding OEM capabilities specifically for ‘neon vs LED’ solutions, Beauty STC possesses extensive expertise in both technologies but has strategically focused its core OEM/ODM manufacturing on modern flexible LED neon alternatives. While the company historically had the capability to produce traditional glass neon signage involving gas-filled tubes and high-voltage transformers, the overwhelming market shift towards safer, more efficient, and versatile LED-based solutions has directed significant resources into this area. The Jiangmen factory excels at producing custom LED neon flex products under OEM agreements, offering clients complete design-for-manufacturability support, various color temperatures and densities, multiple silicone jacket options, and integrated low-voltage power solutions. Beauty STC’s OEM strength lies in providing turnkey LED neon manufacturing that outperforms traditional neon in energy efficiency, durability, installation simplicity, and safety, while meeting specific client branding and performance requirements. Traditional neon manufacturing is no longer a standard offering due to inherent limitations in cost, fragility, energy consumption, and environmental considerations compared to advanced LED alternatives. The company’s OEM focus is firmly on delivering the superior value proposition of modern LED technology for decorative and signage applications.

Application Scenarios

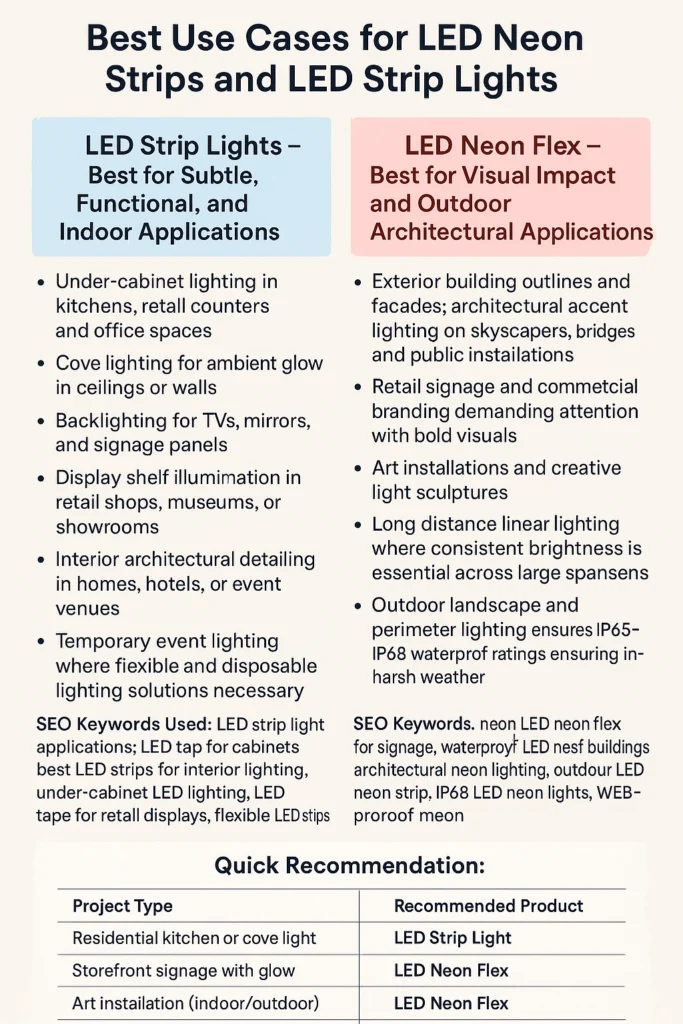

When deciding between neon and LED lighting for commercial environments such as hotels, malls, and offices, it’s important to understand the strengths and applications of each technology. While traditional neon lighting has iconic visual appeal, modern LED alternatives—especially LED neon flex—offer greater versatility, energy efficiency, and durability. Here’s where each is best suited and some key installation tips.

In hotels, ambiance is crucial. Traditional neon can provide a vintage, artistic flair in lounges, bars, or boutique hotel signage, enhancing a retro or luxurious aesthetic. However, LED neon flex is increasingly preferred for its safety, lower maintenance, and ability to mimic the soft glow of real neon without the fragility. LED neon is ideal for outlining architectural features, creating backlit headboards, or accentuating reception desks. It’s also excellent for custom branding elements in lobbies or corridors due to its flexibility in design and color options.

Malls benefit from high-impact visual displays to attract foot traffic. LED lighting dominates here due to its brightness, energy efficiency, and long lifespan. LED neon signs are commonly used for storefront branding, promotional signage, and dynamic wayfinding solutions. They perform well in both indoor and outdoor environments, with resistance to weather and temperature fluctuations. While authentic neon can be used for high-end fashion or lifestyle brand installations, the operational costs and maintenance make LED a more practical choice for large-scale or temporary displays.

In office environments, functionality and energy efficiency are top priorities. Traditional neon has limited application here due to its fragility and higher power consumption. LED lighting, including LED neon flex, is ideal for corporate branding, reception area highlights, or modern design accents in collaborative spaces. Its low heat output and minimal maintenance make it safe and cost-effective for continuous use. Additionally, tunable white or color-changing LEDs can support circadian lighting strategies, improving occupant well-being.

For installation, whether using traditional neon or LED neon, proper planning is essential. Always begin with a detailed layout and voltage drop calculation, especially for longer LED neon runs. Use mounting channels or clips to ensure even spacing and secure attachment, particularly on curved surfaces. For outdoor or high-moisture areas, ensure all components are rated for the environment—typically IP65 or higher. When installing traditional neon, work with certified professionals due to high-voltage transformers and glass handling risks. For LED neon, avoid sharp bends below the manufacturer’s specified radius to prevent damage to internal LEDs. Finally, conceal wiring and power supplies neatly to maintain a clean, professional appearance across all settings.

Why Choose Beauty STC Lighting

Transitioning from traditional neon to modern LED solutions represents a critical evolution for lighting professionals prioritizing performance and sustainability. At Beauty STC, our engineering team confirms that LED technology consistently outperforms neon across every measurable metric including lifespan, energy efficiency, and operational safety. Neon tubes typically fail within 5,000 to 15,000 hours while our rigorously tested LED flex systems deliver 50,000+ hours of maintenance-free operation, eliminating costly replacements and service calls.

The thermal management and driver efficiency engineered into our LED neon alternatives reduce energy consumption by up to 70% compared to neon equivalents, directly lowering your clients’ operational expenses. Unlike fragile glass neon requiring high-voltage transformers and mercury handling protocols, Beauty STC’s flexible LED solutions operate at safe low voltages with superior impact resistance, simplifying installation and compliance.

Partner with Beauty STC to access custom-engineered LED neon solutions that replicate neon’s aesthetic appeal without its limitations. Our technical team provides seamless retrofit guidance, photometric validation, and dedicated support to ensure your projects meet the highest industry standards.

Secure your competitive advantage with lighting technology built for the future. Contact our engineering partnership team directly at [email protected] to discuss specifications, volume pricing, and technical integration for your next project. Don’t gamble with outdated lighting technology when Beauty STC delivers proven reliability and ROI.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.