Article Contents

Industry Insight: Neon Or Led

The commercial and industrial lighting landscape has undergone a profound transformation, moving decisively beyond the limitations of traditional neon solutions towards the superior efficiency, durability, and versatility of modern LED technology. While neon signage retains nostalgic appeal in specific decorative contexts, its inherent fragility, high energy consumption, significant maintenance demands, and operational hazards make it increasingly impractical and costly for demanding commercial environments like warehouses, manufacturing facilities, retail spaces, and outdoor industrial sites. Today’s facility managers and lighting specifiers prioritize solutions that deliver maximum uptime, minimal operational expenditure, and robust safety compliance – requirements where high-performance LED systems are now the undisputed standard. Critical to adoption in these professional settings are rigorous safety certifications; products must demonstrably meet ETL standards for the North American market and CE marking for Europe, ensuring electrical safety, electromagnetic compatibility, and adherence to regional regulatory frameworks. These certifications are not optional extras but fundamental prerequisites for procurement, providing essential assurance against fire risks, equipment failure, and liability exposure in mission-critical operations. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this industry evolution. For over 25 years, we have dedicated ourselves to engineering and manufacturing high-reliability LED lighting solutions specifically designed to meet the exacting demands of commercial and industrial applications, combining deep technical expertise with a commitment to certified quality and performance that facility operators depend on.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. specializes in high-performance LED lighting solutions that serve as modern, energy-efficient alternatives to traditional neon lighting. Our LED neon flex and linear LED systems are engineered for superior optical quality, durability, and efficiency, making them ideal for architectural, commercial, and decorative applications.

In terms of luminous efficacy, Beauty STC’s LED neon products deliver an industry-competitive range of 90 to 110 lumens per watt, depending on color temperature and density configuration. This high lumens-per-watt ratio ensures significant energy savings over conventional neon and lower-grade LED strips, while maintaining consistent light output over extended operating periods. Our advanced SMD LED chips—such as 2835, 3528, and 5050—are optimized for maximum efficiency and thermal management, contributing to long-term performance and reduced power consumption.

Color accuracy is a hallmark of Beauty STC’s lighting systems. All premium LED neon products are available with a Color Rendering Index (CRI) greater than 90, ensuring exceptional color fidelity and natural light rendition. This high CRI performance is especially critical in retail, hospitality, and display environments where accurate color representation enhances visual appeal. Optional R9 values above 50 further improve the rendering of saturated reds, contributing to a fuller, more balanced spectrum.

Durability and environmental resilience are built into every product. Beauty STC’s LED neon solutions are offered with IP65, IP67, and IP68 ingress protection ratings. IP65-rated strips are dust-tight and protected against low-pressure water jets, making them suitable for outdoor signage and semi-exposed areas. IP67 provides protection against temporary immersion in water up to 1 meter for 30 minutes, ideal for landscape lighting or damp indoor environments. For fully submerged or harsh outdoor installations, IP68-rated LED neon—capable of continuous submersion beyond 1 meter—ensures reliable operation in demanding conditions.

Built with high-quality silicone encapsulation, robust copper PCBs, and rigorously tested electrical components, Beauty STC’s LED neon products exceed industry standards for flexibility, longevity, and safety. Each batch undergoes strict quality control, including aging tests, color consistency checks, and waterproof verification, ensuring uniform performance across large-scale installations.

With engineering precision, consistent photometric performance, and a commitment to sustainable design, Beauty (STC) Manufacturing Co., Ltd. delivers LED neon solutions that combine aesthetic brilliance with technical excellence.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, serves as our primary production hub for advanced LED lighting solutions, including specialized neon alternatives and standard LED products. The factory is a modern, ISO 9001-certified operation designed for high-volume, precision manufacturing with stringent quality control throughout the production chain.

Our SMT production lines are centered around multiple high-speed Fuji NXT III platforms, capable of placing components as small as 005020 metric package sizes with exceptional accuracy. These machines feature dual-lane configurations for concurrent processing, significantly boosting throughput while maintaining tight tolerances. Automated optical inspection (AOI) systems are integrated immediately after each SMT line to validate component placement, solder paste volume, and potential defects before boards proceed to reflow ovens. The entire SMT process is supported by automated material handling and real-time production monitoring software, ensuring traceability and minimizing human error.

Rigorous aging and reliability testing form a critical part of our quality assurance protocol at the Jiangmen site. Dedicated aging chambers subject finished LED strips, neon flex products, and complete luminaires to continuous operation under controlled thermal stress conditions, typically running 72-hour cycles at elevated temperatures (e.g., 65°C ambient) to accelerate early-life failures. Parametric measurements, including luminous flux maintenance, forward voltage drift, and color consistency, are recorded at regular intervals during these tests. Statistical process control methodologies guide our sampling plans, ensuring representative batches undergo this stress testing to validate long-term performance claims before shipment. Environmental testing capabilities also include thermal cycling and humidity exposure for products destined for demanding applications.

Beauty STC possesses extensive OEM capabilities specifically tailored for both flexible neon LED alternatives and conventional LED strip products. We support full customization from initial concept through to volume production, including bespoke silicone extrusion profiles for neon flex with precise light diffusion characteristics, custom PCB layouts for unique form factors or densities, and tailored driver integration. Our engineering team works closely with clients to match specific color points (including Pantone matching for silicone jackets), achieve required IP ratings (up to IP68), and develop proprietary mounting solutions or connectors. The Jiangmen factory houses dedicated tooling resources for rapid prototyping of extrusion dies and custom housings, alongside flexible production cells that can quickly reconfigure for low-volume, high-mix OEM runs or transition seamlessly into high-volume manufacturing for established clients. This end-to-end capability ensures clients receive fully branded, specification-compliant products meeting exact performance and aesthetic requirements.

Application Scenarios

Neon and LED lighting are both excellent choices for architectural and decorative illumination, each offering unique advantages depending on the application. While traditional neon has a classic glowing appeal, modern LED alternatives—especially LED neon flex—provide greater energy efficiency, durability, and design flexibility. Here’s where and how to use them effectively in hotels, malls, and offices, along with essential installation tips.

In hotels, neon and LED lighting are ideal for creating ambiance and enhancing guest experience. Use them in lobbies to highlight logos, feature walls, or artistic installations that reflect the brand’s identity. LED neon signs work well behind reception desks or in lounge areas to add a warm, inviting glow. In guest corridors, subtle LED cove lighting or illuminated signage improves wayfinding while maintaining a premium aesthetic. Guest rooms can benefit from soft LED neon lighting under beds, headboards, or in bathrooms for mood lighting. When installing in hotels, ensure lighting is dimmable and color temperature is warm (2700K–3000K) to maintain comfort.

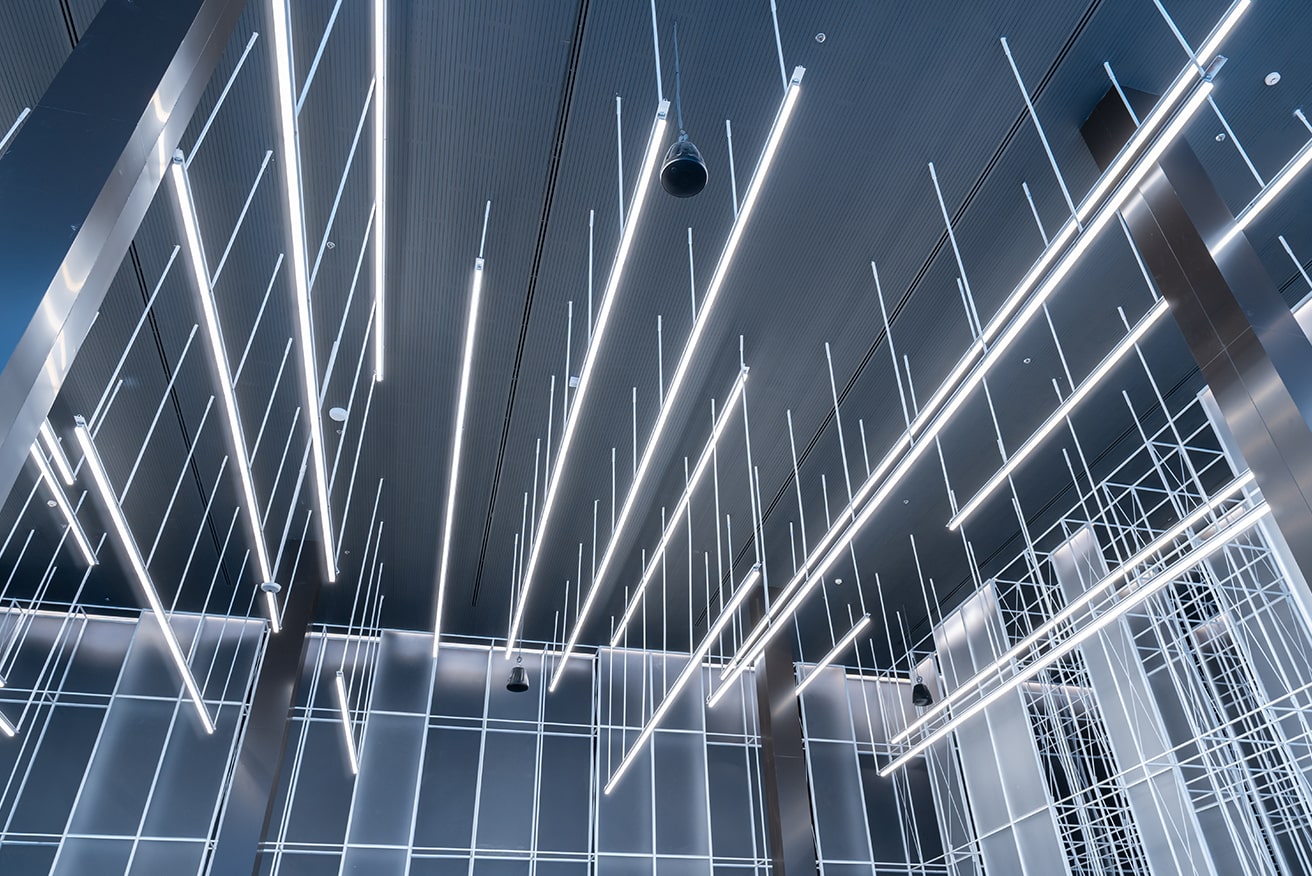

Malls benefit greatly from the visual impact of neon and LED lighting, especially in high-traffic zones. Use illuminated signage for brand logos, directional indicators, or promotional displays in food courts and atriums. LED neon is excellent for creative ceiling installations, art features, or highlighting architectural curves and edges. Since malls operate long hours, energy-efficient LEDs are preferred to reduce power consumption and maintenance costs. Installations should be bright enough to attract attention but not cause glare. Mounting should be secure and accessible for maintenance, and lighting should complement the mall’s overall lighting scheme—often a mix of cool and neutral white temperatures (3500K–4000K) for vibrancy.

In offices, neon and LED lighting serve both functional and branding purposes. While traditional neon is less common in corporate spaces due to its fragility, LED neon flex offers a sleek, modern look suitable for reception areas, conference rooms, or employee breakout zones. Use illuminated company logos or motivational quotes to reinforce brand culture. In open-plan offices, LED strip lighting can define zones or add visual interest to partitions and ceilings. Installations should prioritize subtlety and professionalism—opt for neutral white or soft white tones. Avoid overly bright or colored lighting that may distract or strain the eyes.

For installation, always begin with a detailed lighting plan that aligns with the space’s design and electrical layout. Ensure all fixtures are compatible with existing power systems and use low-voltage LED options where safety is a concern. Mount neon or LED strips using aluminum channels to protect the lights, improve heat dissipation, and achieve a clean, uniform glow. Secure connections with waterproof connectors if used in humid areas. In commercial spaces, adhere to local electrical codes and consider hiring a licensed electrician for final connections. For ceiling or overhead installations, use sturdy mounting brackets and ensure easy access for future servicing. Finally, test the lighting before finalizing the installation to confirm brightness, color consistency, and control functionality—especially if integrating with smart systems or dimmers.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty (STC) Manufacturing Co., Ltd., I see daily how our advanced LED solutions outperform traditional neon across every critical metric. Our proprietary flex LED technology delivers the authentic, vibrant glow clients expect from neon signage but with superior energy efficiency, dramatically longer lifespans, and zero risk of glass breakage or hazardous gas exposure. We engineer each custom profile for seamless integration into existing neon infrastructure, ensuring immediate operational cost savings while maintaining the aesthetic appeal that drives brand recognition.

Partnering with Beauty STC means accessing engineering expertise that transforms lighting challenges into competitive advantages. Our team collaborates directly with your designers and installers to optimize thermal management, color consistency, and structural durability—addressing the real-world failures common in inferior LED alternatives. Whether you require intricate channel letters for retail storefronts or large-scale architectural installations, we provide rigorously tested solutions that perform reliably in extreme temperatures and high-moisture environments where neon consistently falters.

Contact our engineering management team today at [email protected] to discuss your specific project requirements. We will provide tailored technical specifications, photometric data, and a clear implementation roadmap demonstrating how Beauty STC’s LED systems deliver immediate ROI through reduced energy consumption and near-zero maintenance costs. Let us help you future-proof your lighting investments with technology built to last.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.